EASTMAN HVN User manual

Other EASTMAN Industrial Equipment manuals

EASTMAN

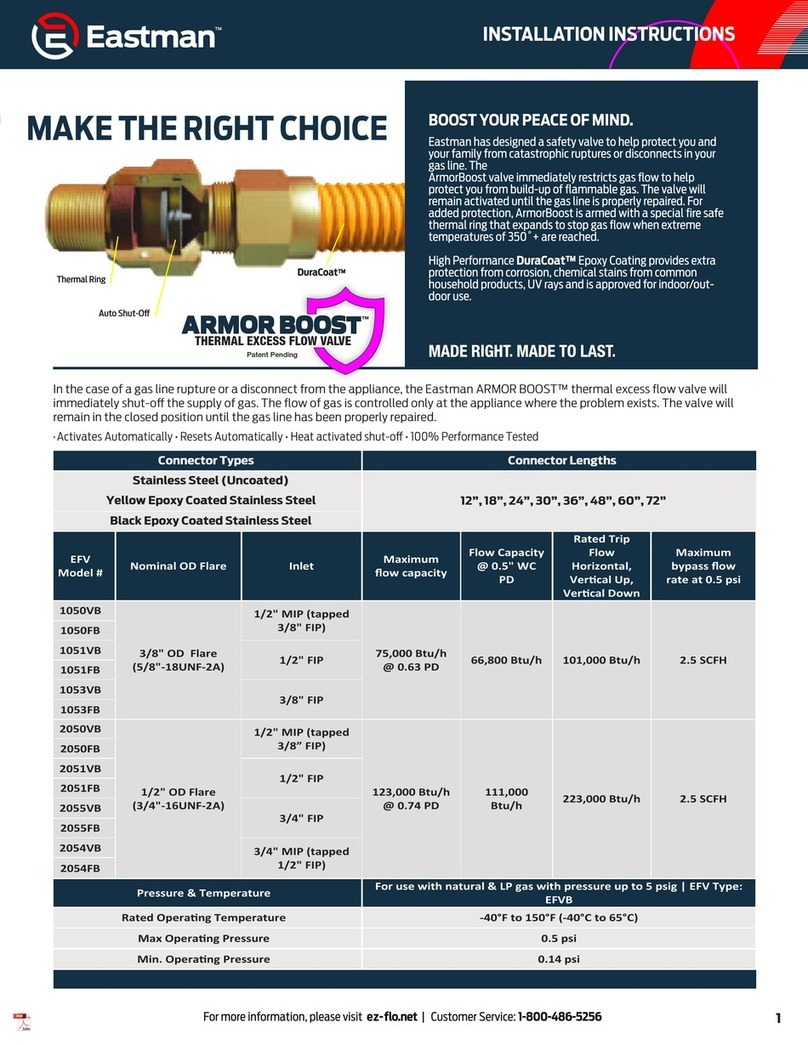

EASTMAN 1050VB User manual

EASTMAN

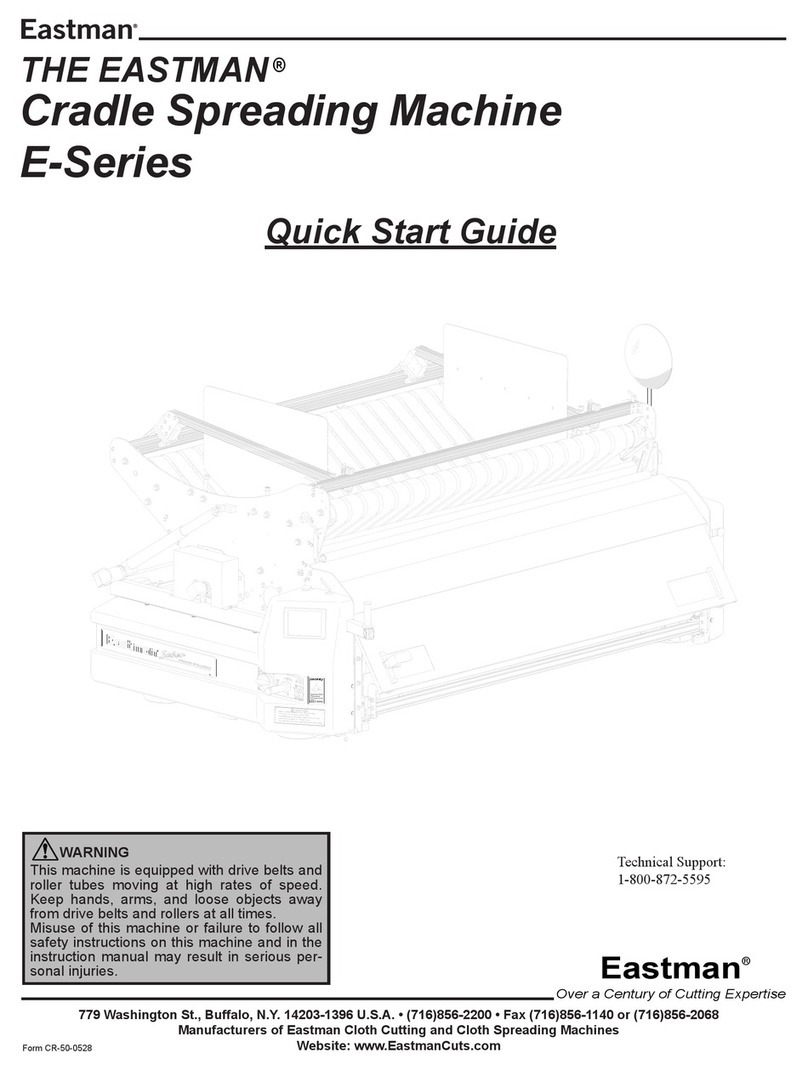

EASTMAN E Series User manual

EASTMAN

EASTMAN RS2 User manual

EASTMAN

EASTMAN Kodak X-Omatic 4 User manual

EASTMAN

EASTMAN 534 Setup guide

EASTMAN

EASTMAN Kodak X-Omat 180 LP User manual

EASTMAN

EASTMAN Blue streak II 629X User manual

EASTMAN

EASTMAN DYNAFIX DF 4800 Setup guide

EASTMAN

EASTMAN TRIGGER PLUS Knifebox User manual

EASTMAN

EASTMAN C Series Setup guide