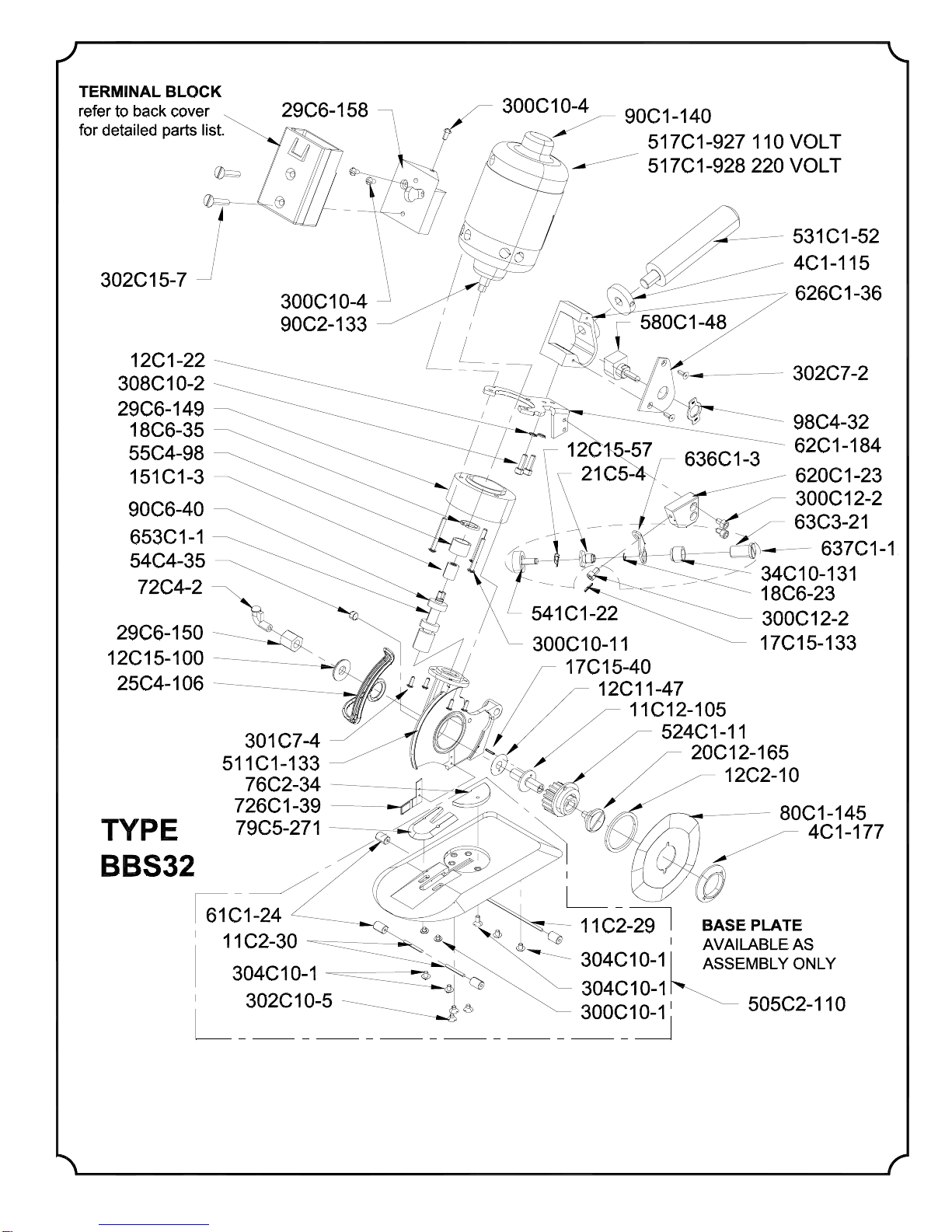

8FormC-1206

DESCRIPTION

Your new Chickadee D2 or D2H is designed for increase perfor-

mance and capacity, with a minimum of maintenance and ser-

vice when not subjected to abnormal use.

CAUTION

Read instructions carefully before starting motor. Be sure

thatvoltageandcurrent are the same as stampedonname-

plate.

TO OPERATE MACHINE

Turn machine to on position; if cutter does not perform properly

check line output and be sure the unit it plugged in properly

making full contact. Do not attempt to start this unit while it is in

material to be cut.

WARNING

Before performing any of the following procedures, make

sure that the attachment plug has been disconnected from

power source.

REMOVE AND REPLACE THE KNIFE

Insert a pin thru knife against bottom of machine housing and

with a large screwdriver, remove screw (300C12-3) and flange

(53C11-112). DISCARD WORN SHARPKNIFE WITH CARE and

install new blade with the Eastman facing outward.

To obtain a fine keen edge on the blade, press lightly on sharp-

ener button with a constant pressure.

LUBRICATION

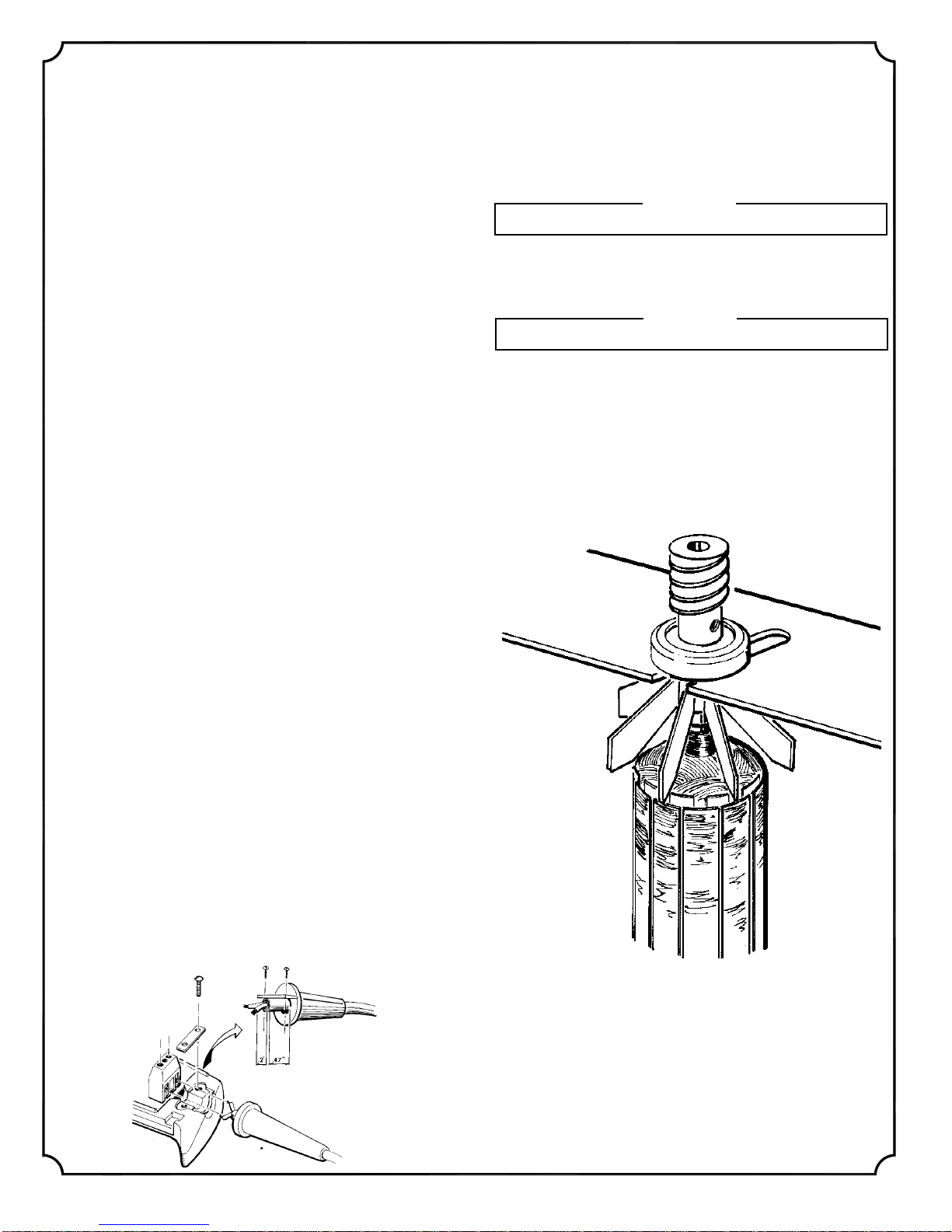

Follow this procedure yearly for intermittent use, or every six

months for continuous use. Remove knife, remove retainer plate

(79C12-276) (2 screws) with gear intact. Then remove screw

(20C13-99) emery wheel (541C1-24) and wipe away any grit de-

posits. Apply a light coat of Eastman Lubricko Grease (242C2-2)

to parts and reassemble. Then add small quantity of Eastman

Lubricko Grease to gears and shaft. Saturate wick (191C1-37)

with good quality SAE 30 non-detergent motor oil when

changing blade.

DISASSEMBLY

Remove knife. Remove two (2) flat head screws (302C8-2)

and gear retaining plate (79C12-276) from housing.

Note: it is not necessary to loosen two fillister head screws

(301C3-1) from knife flange.

Remove brush caps and brushes. Completely remove three

fillister head screws (308C1-1, 308C1-4, 308C1-5) from housing

and lift off left side motor housing, leaving motor parts in right

side housing. Clean lint and dirt from motor housing and grease

from gear cavity.

PART NO. DESCRIPTION

1C13-21 ............................................................................ SLEEVE

1C13-26 .................................................................CORD SLEEVE

4C1-149 ...........................................................................HEX NUT

4C2-106 ...........................................................................HEX NUT

10C1-45 ................................................................................... FAN

12C15-14 ....................................................... WASHER, FLAT #10

12C15-89 ........................................................................ WASHER

12C15-124 ...................................... WASHER, BLADE RETAINER

14C1-23 .................................................................. HANDLE GRIP

17C15-133 ............................................................ARMATURE PIN

17C15-136 ........................................... PIN LABEL (4 REQUIRED)

18C6-71 ...........................FRONT “O” RING HALF (2 REQUIRED)

18C6-72 ............................. BACK “O” RING HALF (2 REQUIRED)

20C13-99 ....................................................... PAN HEAD SCREW

21C6-3 ....................................................SHARPENER BUSHING

25C4-169 ................................................................ KNIFE GUARD

34C8-12 .............................................................................SPRING

34C10-165 ................................................. SHARPENER SPRING

50C7-25 ......................................................... CORD CLAMP D-2H

50C7-26 ............................................................CORD CLAMP D-2

52C5-176 ................................................................BASE SWITCH

53C11-112................................................KNIFE COVER FLANGE

57C1-61 ............................................................... SWITCH LEVER

63C3-22 .................................................... SHARPENER BUTTON

68C3-6 .............................................................PRESSURE FOOT

68C3-7 ........................................... NARROW PRESSURE FOOT

79C1-151 ........................................................... PLATE, NO. 120V

79C1-152 ........................................................... PLATE, NO. 230V

79C2-61 .............................................................. CAUTION PLATE

79C2-77 .................................................................... NAME PLATE

79C12-276 ............................................ GEAR RETAINING PLATE

79C12-284 ....... GEAR RETAINING PLATE FOR NARROW FOOT

80C1-147 .................................................... ROUND KNIFE, 2 1/4"

80C1-149 .......................................................... HEX KNIFE, 2 1/4"

83C4-25 ................................................................ KNIFE FLANGE

86C7-42 ............................................ BRUSH CAP (2 REQUIRED)

87C7-43 .....................................................................KNIFE GEAR

87C7-44 ................................................................... WORM GEAR

90C6-42 ............................................................... REAR BEARING

90C6-48 ............................................................. FRONT BEARING

95C5-7 ........................................................................ ALLEN KEY

98C4-32 .................................................................ON/OFF PLATE

109C5-1 ........................................................... TIP SHEAR PLATE

190C1-2 ............................................................. ARMATURE 120V

191C1-37 ............................................................... WICKING FELT

199C1-29 ................................................................................. LUG

300C8-1 ........ SCREW, 4-40 X 3/8 ROUND HEAD (2 REQUIRED)

300C8-9 ............................... SCREW, 4-40 X 3/16 ROUND HEAD

300C12-3 ............................... SCREW, 8-32 X 3/8 ROUND HEAD

301C3-1 ....SCREW, 2-56 X 1/2 FILLISTER HEAD (2 REQUIRED)

301C8-1 ............................. SCREW, 4-40 X 1/2 FILLISTER HEAD

301C8-4 ............................. SCREW, 4-40 X 3/4 FILLISTER HEAD

301C8-5 .......................... SCREW, 4-40 X 1 1/2 FILLISTER HEAD

301C8-6 ........................... SCREW, 4-40 X 3/16 FILLISTER HEAD

301C15-6 ............................ SCREW, 10-32 X 1 FILLISTER HEAD

302C8-1 ............. SCREW, 4-40 X 3/8 FLAT HEAD (2 REQUIRED)

302C8-2 ............. SCREW, 4-40 X 3/4 FLAT HEAD (2 REQUIRED)

305C8-4 .......SCREW, 4-40 X 1/8 BINDING HEAD (2 REQUIRED)

309C8-3 ................................ SCREW, 4-40 X 1/8 SOCKET HEAD

523C1-91 ................................. ATTACHMENT PLUG 120V MALE

523C1-92 .............................ATTACHMENT PLUG 120V FEMALE

523C1-93 ................................. ATTACHMENT PLUG 230V MALE

523C1-94 .............................ATTACHMENT PLUG 230V FEMALE

523C2-25 .................................................................... CORD 120V

523C2-41 .................................................................... CORD 230V

523C2-46 .................................................... CORD 230V EUROPE

523C2-47 .............................CORD ASSEMBLY 120V DOMESTIC

523C2-48 .............................CORD ASSEMBLY 230V DOMESTIC

541C1-24 .......................................... EMERY WHEEL ASSEMBLY

542C1-102 ..................................... ARMATURE ASSEMBLY 120V

580C1-48 ................................................................SWITCH, D-2H

580C1-103 .......................................................RED, SWITCH, D-2

580C1-221 ...................................................BLACK, SWITCH, D-2

614C1-31 .............................................................FAN & BEARING

632C1-8 ....................HOUSING, COMPLETE W/SWITCH LEVER

708C1-15 ............................... BRUSH W/SPRING (2 REQUIRED)

726C1-17 .......................................... SHEAR PLATE W/CARBIDE

731C3-1 ............ GEAR RETAINING NARROW FOOTASSEMBLY

829C1-4 ....................................................... MAGNETASSEMBLY

830C1-11 .................. (110V ONLY) CIRCUIT BOARD ASSEMBLY

830C1-11-1 ....... (110V D2H ONLY) CIRCUIT BOARD ASSEMBLY

830C1-90 ................... (220V ONLY)CIRCUIT BOARD ASSEMBLY

831C1-4-24 ............................... 24” HANDLE & TUBE ASSEMBLY

831C1-4-30 ............................... 30” HANDLE & TUBE ASSEMBLY

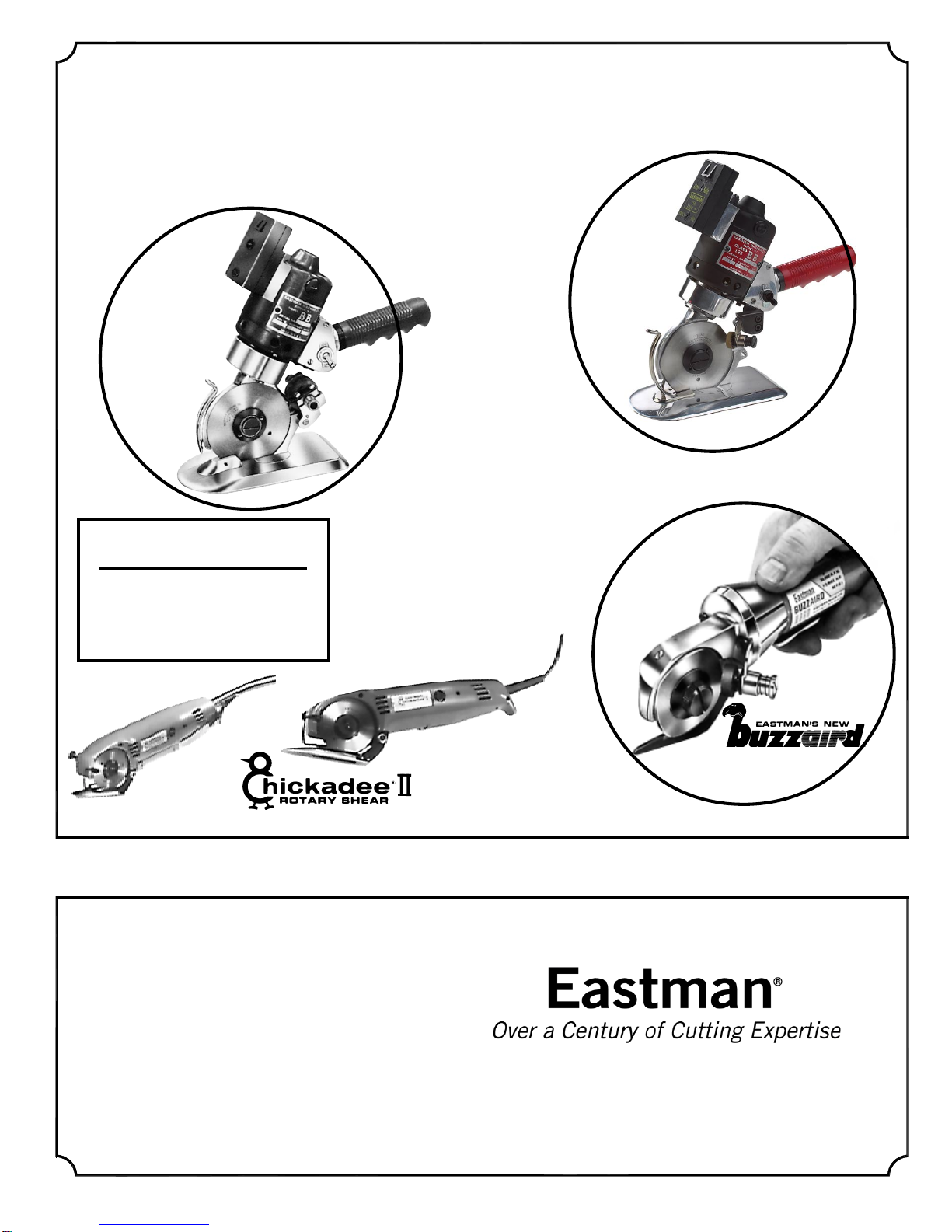

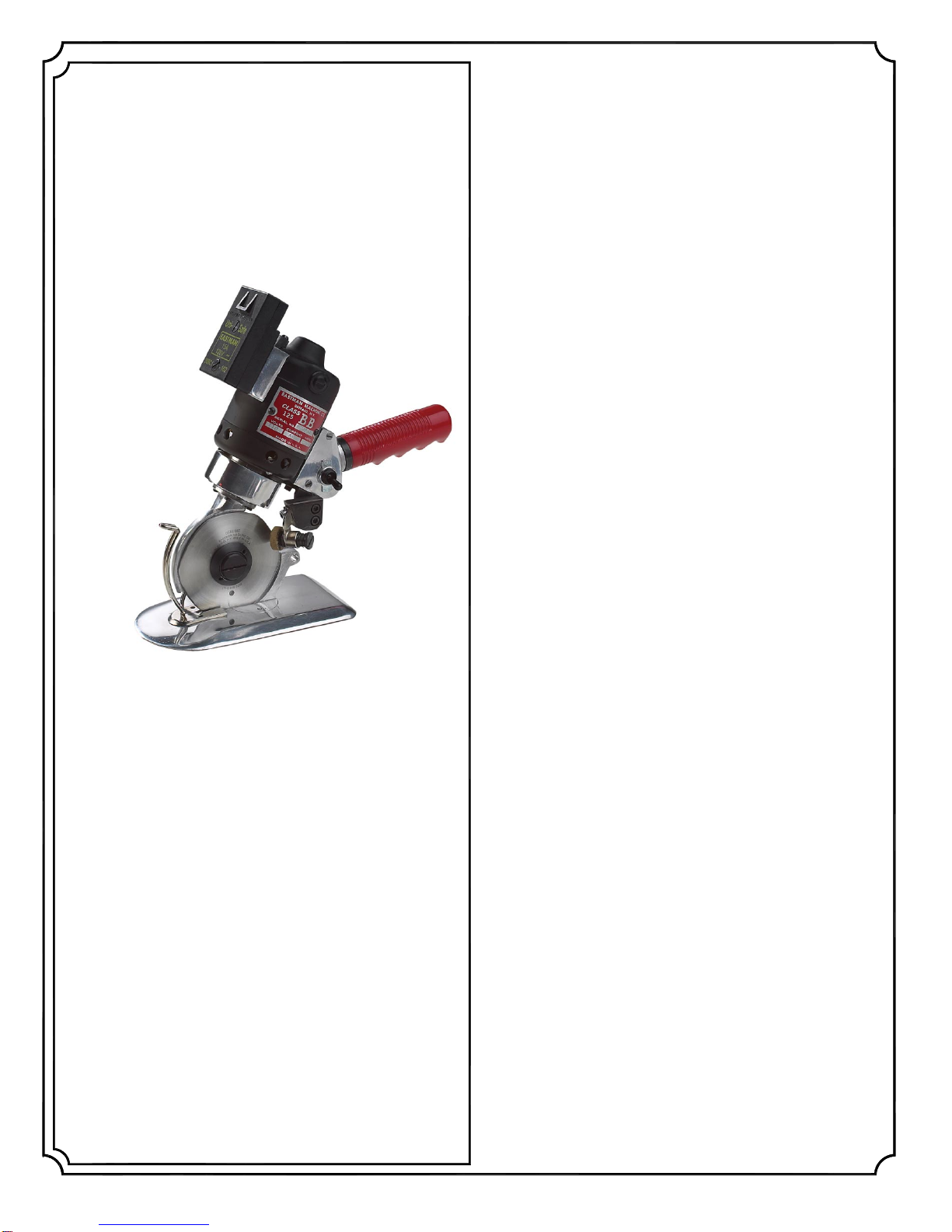

TYPE D2H

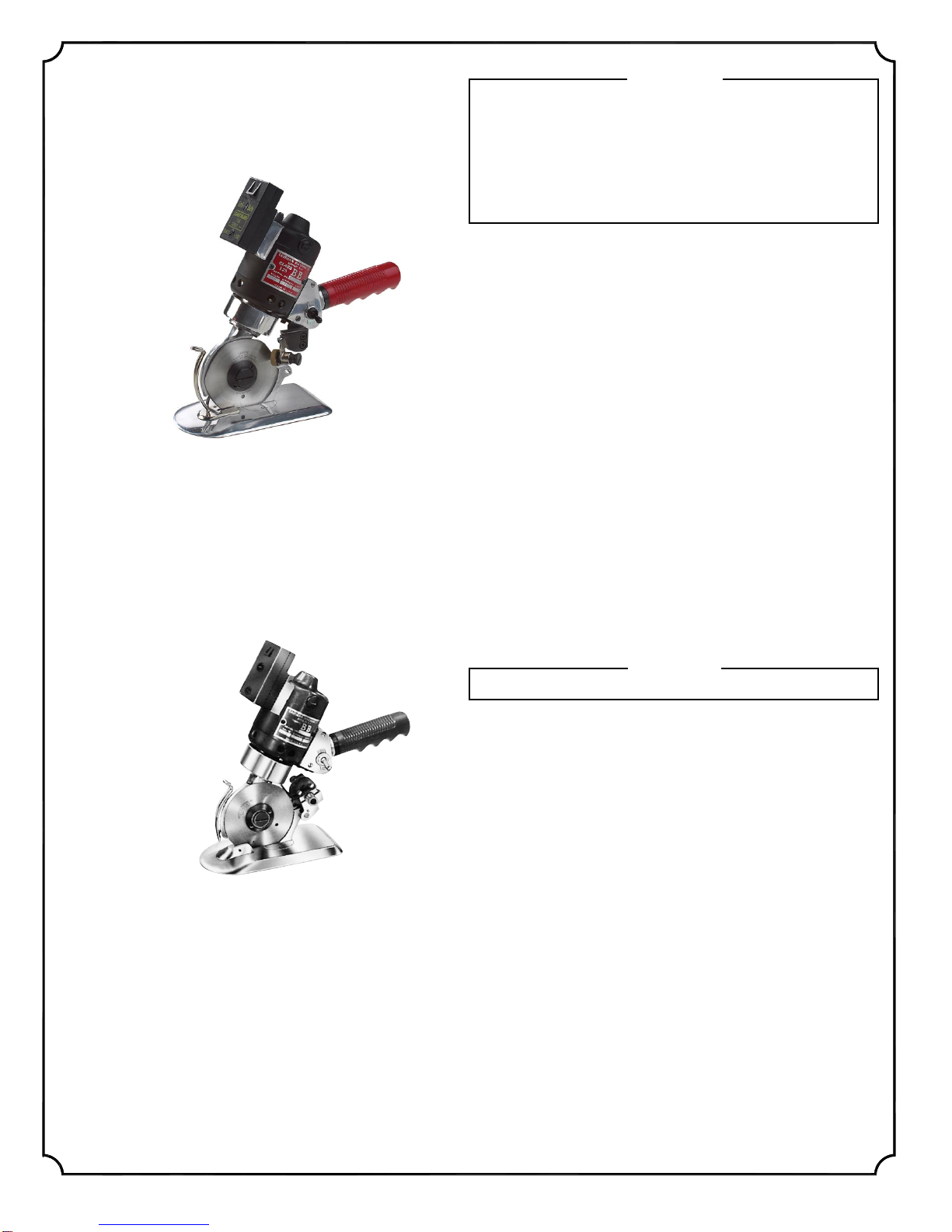

TYPE D2

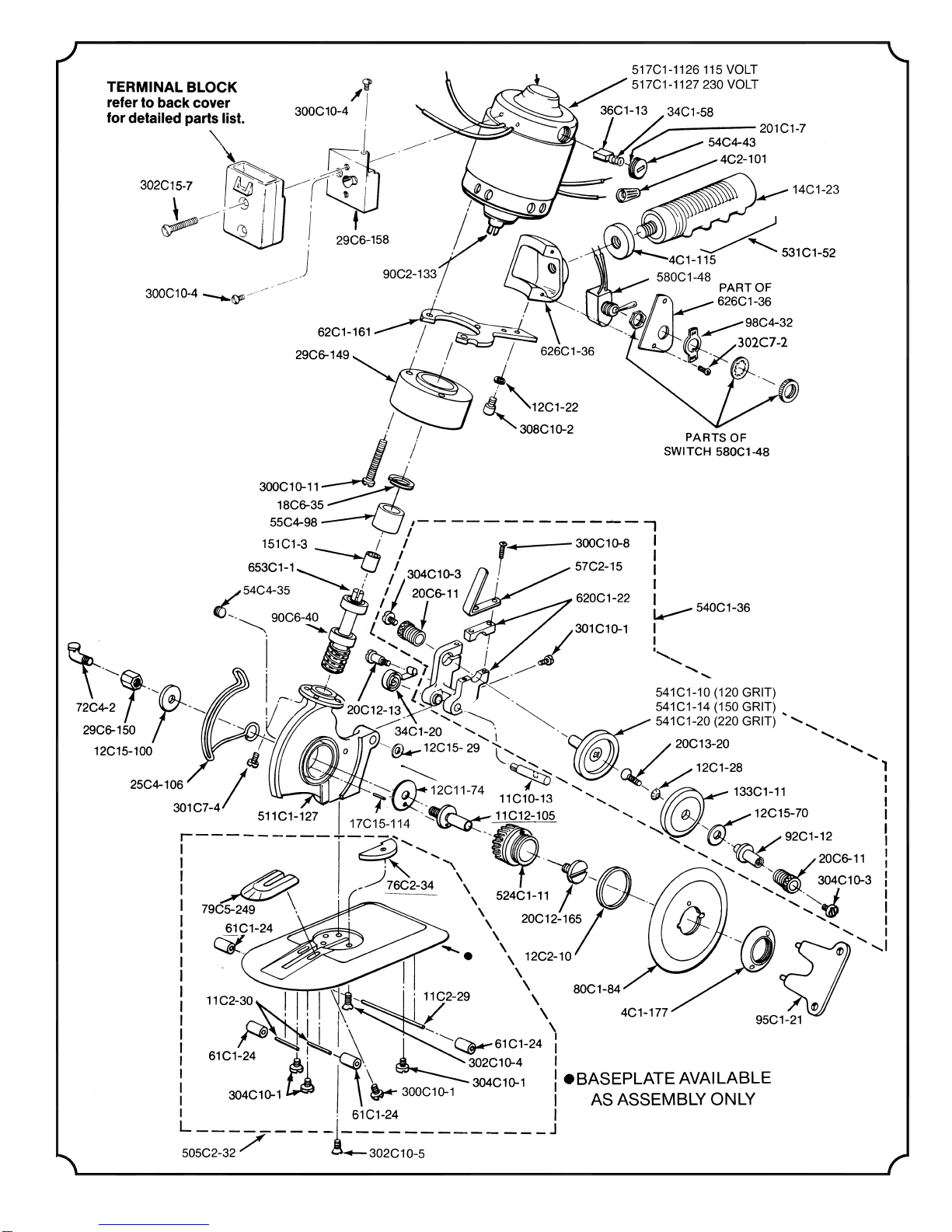

ILLUSTRATED

PARTS LIST