fwr

>

— \

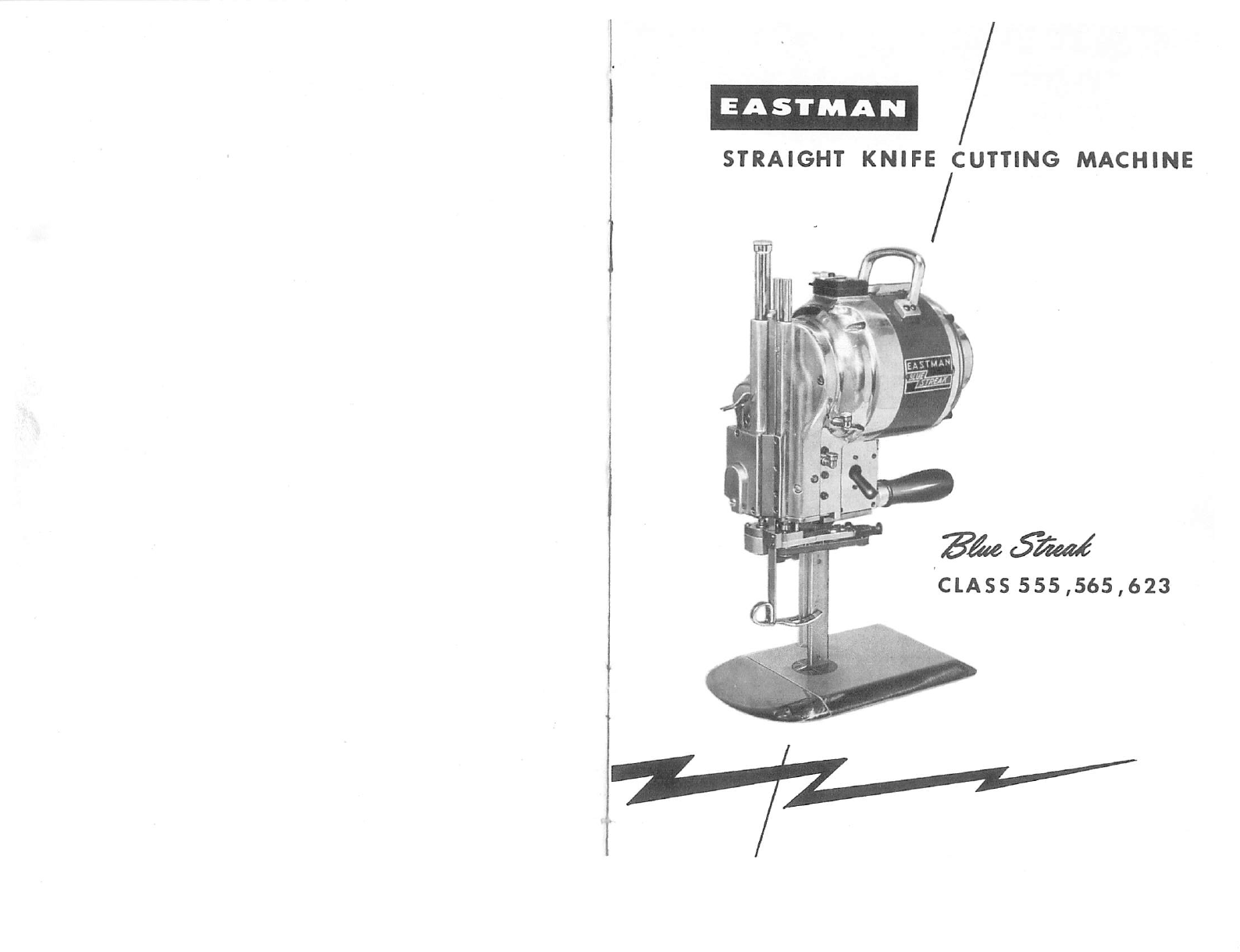

TO

CHANGE

SHARPENER

BELTS

Push

brackets

Sinward to

release

tensionand remove worn

belts.

Place

new belt over front pulley T, then between

sharpener

shoe U and knife

and then over

rear

pulley O. Sharpener belts

are

available in 4 grits:

Rough,

Coarse, Medium and Fine. When changing from one

grit

sharp

ener

belt to another, sharpener shoes U should be adjusted to maintain

a

uniform

cutting

edge.

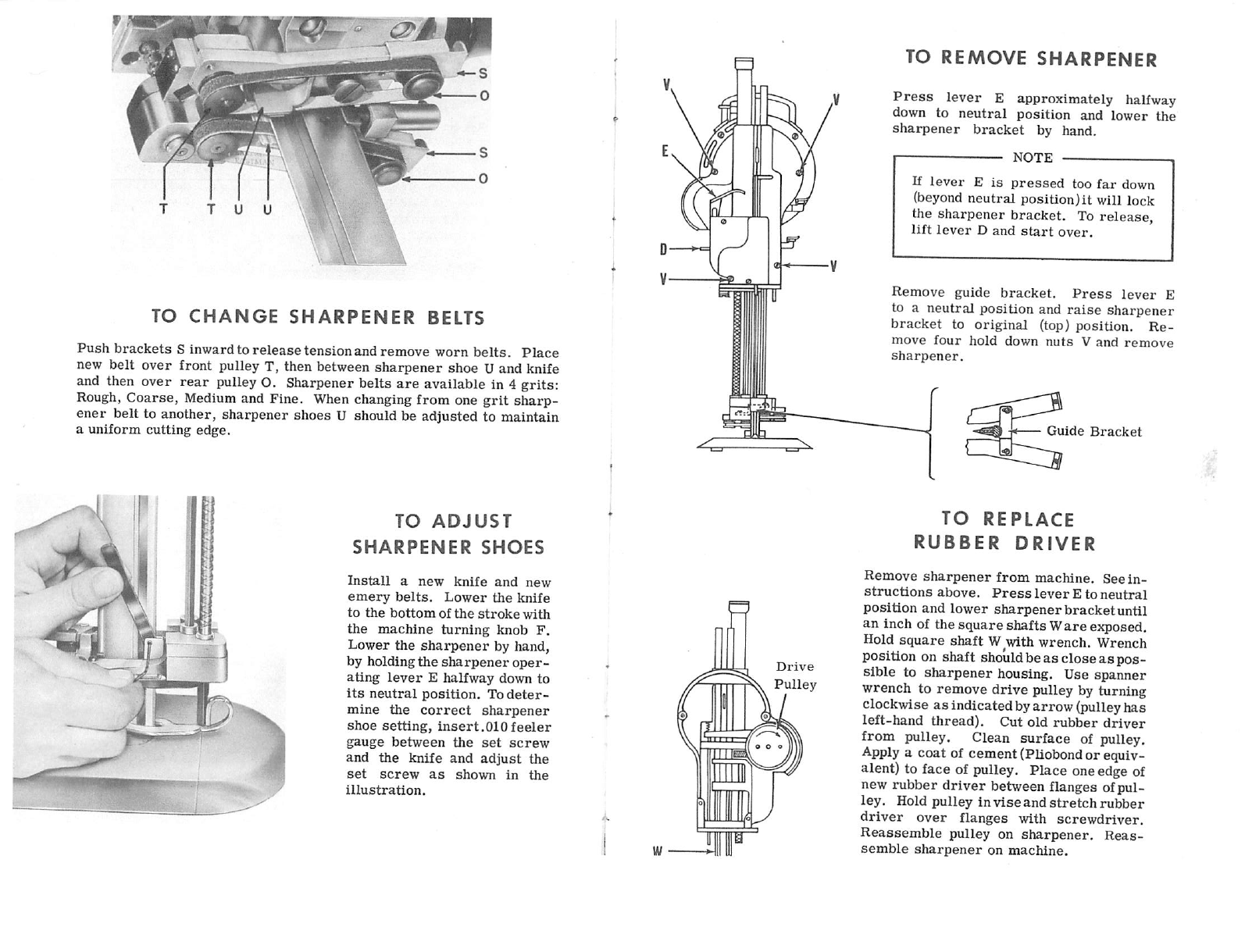

TO

ADJUST

SHARPENER

SHOES

Install

a

new

knife

and

new

emery

belts.

Lower

the

knife

to

the

bottom

of

the

stroke

with

the

machine

turning

knob

F.

Lower

the

sharpener

by hand,

by

holding

the

sharpener

oper

ating

lever

E

halfway

down

to

its

neutral

position.

To

deter

mine

the

correct

sharpener

shoe

setting,

insert

.010

feeler

gauge

between

the

set

screw

and

the

knife

and

adjust

the

set

screw

as

shown

in

the

illustration.

Drive

Pulley

TO

REMOVE

SHARPENER

Press

lever Eapproximately halfway

down to

neutral

position

and

lower

the

sharpener

bracket

by hand.

NOTE

If

lever

E

is

pressed

too

far

down

(beyond

neutral position)it will lock

the sharpener bracket. To release,

lift

lever

D

and

start

over.

Remove

guide

bracket.

Press

lever

E

to a

neutral

position

and

raise

sharpener

bracket

to

original

(top)

position.

Re

move

four

hold

down

nuts

V

and

remove

sharpener.

Guide

Bracket

TO

REPLACE

RUBBER

DRIVER

Remove

sharpener

from

machine.

See

in

structions

above.

Press

lever

E

to

neutral

position

and

lower

sharpenerbracketuntil

an inch of the squareshaftsW

are

ejqjosed.

Hold

square

shaft

Wwth

wrench.

Wrench

position on shaft should be as close

as

pos

sible to

sharpener

housing. Use spanner

wrench to remove

drive

pulley by turning

clockwise as indicated byarrow(pulleyhas

left-hand

thread).

Cut

old

rubber

driver

from pulley. Clean surface of pulley.

Apply

a coat of cement(Pliobondor equiv

alent) to face of pulley. Place oneedgeof

new rubber

driver

between flanges ofpul

ley.

Hold

pulley

in

vise

and

stretch

inibber

driver

over

flanges

with

screwdriver.

Reassemble

pulley on

sharpener.

Reas

semble

sharpener

on

machine.