8Eastwood Technical Assistance: 800.343.9353 >> tech@eastwood.com

CNC PLASMA TABLE SET-UP

LOCATION

• The Eastwood Elite 4’ x 4’ CNC Plasma Table must be located in an indoor area, on a firm, clean, level surface. Having a solid, level concrete floor is ideal.

If the table is fully loaded with water and a 4’ x 4’ x 0.375” steel plate, total machine weight will be near 1725 lbs. [782kg].

• The table should be placed in an area away from flammables, with ample ventilation. A minimum of 6 feet [1.8m] of free space must be maintained around

all sides and above the CNC Table. This is to allow for adequate ventilation and to allow room for a person to access all sides for maintenance purposes.

Do not store anything in the immediate vicinity of the table.

• The temperature environment for proper operation must be between 32°F and 110°F [0°C and 43°C]. The table may not function properly in extreme

ambient temperature conditions.

• Plan the location to minimize the transfer time and effort required to load sheet metal.

• The table requires AC single phase 110-120V, 50/60HZ power from a NEMA 5-15R outlet.

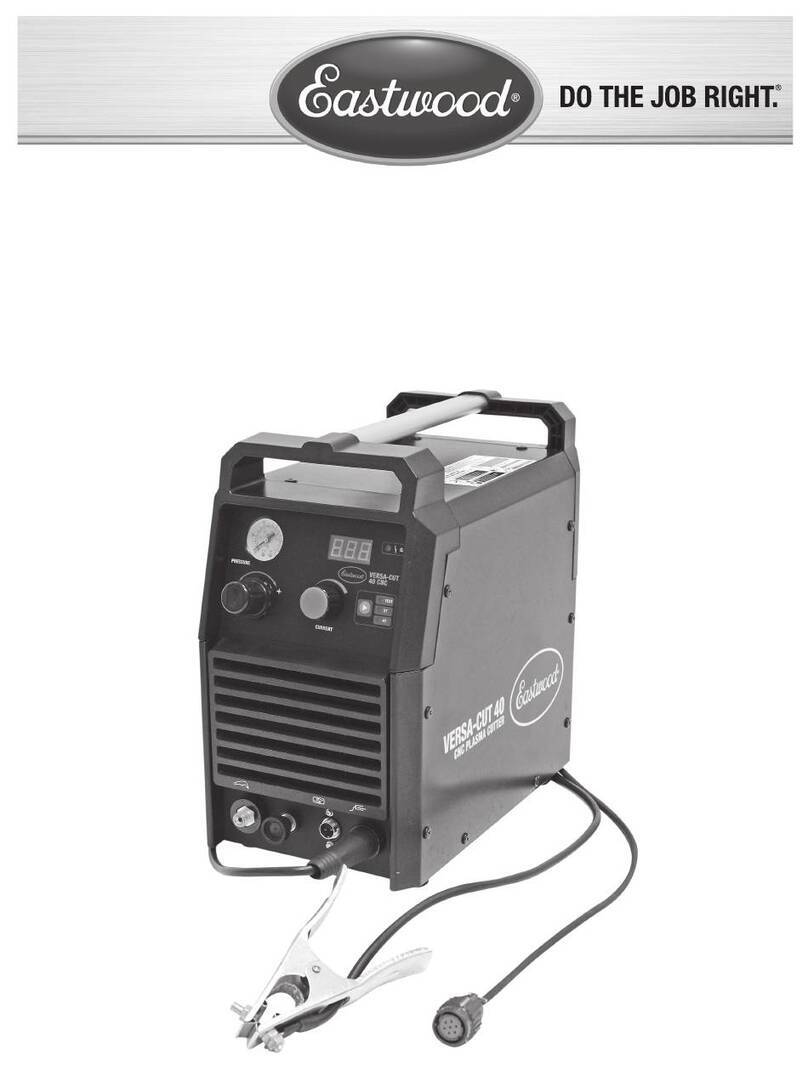

• Additionally, the included plasma cutter requires AC single phase 208-240V, 50/60HZ power from a NEMA 6-50R outlet capable of supplying 50A.

UNCRATING AND ASSEMBLY

FIRE OR EXPLOSION HAZARD!

Keep flammables a minimum of 6 feet [1.8m] from the edge of the Eastwood Elite 4’ x 4’ CNC Plasma Table.

The CNC Table generates heat, sparks, dust, and gas during operation. Sufficient space and ventilation must be provided around the

unit for user safety.

• While allowing the opposite side to remain on the pallet, carefully hoist one side of the CNC Plasma Table assembly just high enough to allow the attaching

of two Legs [a].

• Secure the two Legs with six M12x35 Screws [AA] and Washers [BB] each.

• Slowly lower the hoisting device to allow the attached Legs to rest on the pallet.

• Relocate the lifting straps as required and lift the opposite side to install the remaining two Legs [a].

PINCH AND CRUSH HAZARD!

The Eastwood Elite 4 x 4 Plasma Table is a heavy assembly 974 lbs. [442kg.] which can cause serious injuries if allowed to drop. The

use of a hoist or similar mechanical lifting equipment capable of lifting a minimum of 1000lbs (454kg.) is required. Lifting straps

rated for a minimum of 1000lbs (454kg) are required (not included). Obtaining the assistance of a capable helper during assembly

is strongly recommended.

• Remove top and side panels from crate.

• Remove Table Leg Assemblies from crate framing.

• Remove crate framing leaving the Plasma Table components resting on the shipping pallet.

• Remove the Plasma Cutter box, small parts box, and Plasma Cutter Shelf components from the Plasma Table Bed area.

• Remove the four fasteners at the base of the Control Panel Mount [D] that secure it to the Table. The Control Panel [D] can now be rotated to the

operational position and hardware reinstalled.

• Unmount the Control Panel [D] from the Control Panel Mount [D] by removing the four fasteners at the rear. The Control Panel [D] can now be remounted

in the outboard position so that it clears the sheet loading path.

• Using lifting straps rated for a minimum of 1000lbs (454kg.), secure them by looping around the welded-in Table Slat Supports.

INJURY HAZARD!

DO NOT allow any body part to be under the Plasma Table assembly while lifted.

• Carefully use the lifting device to allow removal of the pallet and lower the unit to the floor.

• Install Ball Drain Valve [FF] to the bottom side of the Table with PTFE Tape [JJ] on the threads to seal it watertight.

• Assemble Plasma Cutter Shelf with components [b], [c], and [d] utilizing M5 Screws [EE] and nuts [EE]. The Shelf can now be installed on the

underside of the Plasma Table Frame at the mount points near the Control Panel with the M12x25 Screws [CC] and nuts [DD].

PINCH AND CRUSH HAZARD!

Keep hands and feet from under the Plasma Table assembly while withdrawing the pallet.