DRAFT- 28 July 2014

The given data is only intended as a product

description and should not be regarded as a legal

warranty of properties or guarantee. In the interest

of further technical developments, we reserve the

right to make design changes.

2

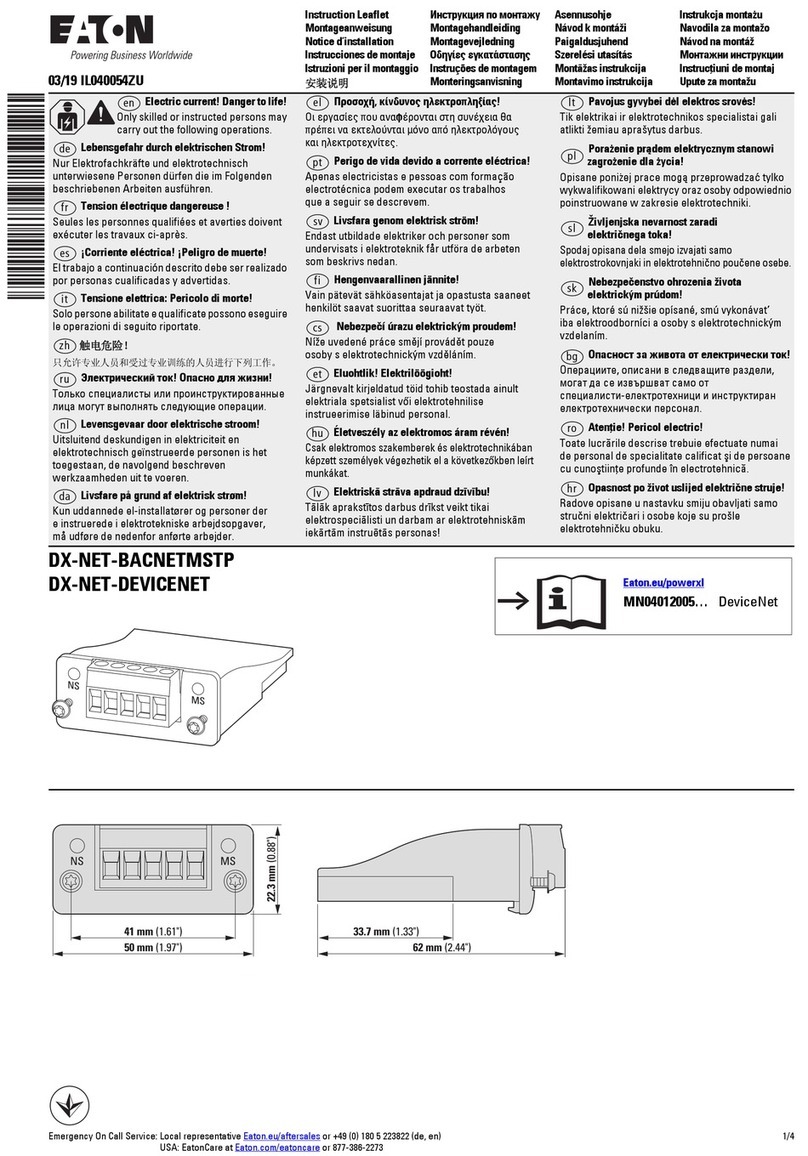

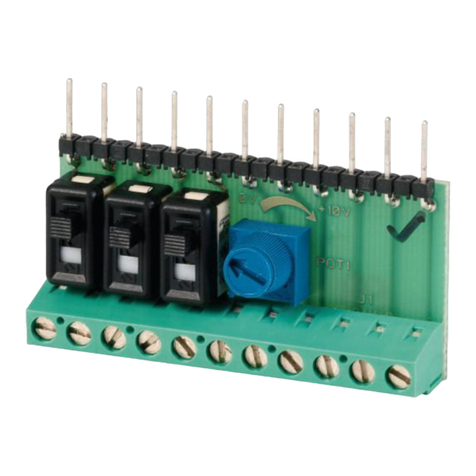

MTL fieldbus barrier module

November 2016

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

www.mtl-inst.com

© 2016 Eaton

All Rights Reserved

Publication No. INS9377 Rev 4 071116

November 2016

EUROPE (EMEA):

+44 (0)1582 723633

THE AMERICAS:

+1 800 835 7075

ASIA-PACIFIC:

+65 6 645 9888

DRAFT- 28 July 2014

The given data is only intended as a product

description and should not be regarded as a legal

warranty of properties or guarantee. In the interest

of further technical developments, we reserve the

right to make design changes.

MTL fieldbus barrier module

November 2016

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

www.mtl-inst.com

© 2016 Eaton

All Rights Reserved

Publication No. INS9377 Rev 4 071116

November 2016

EUROPE (EMEA):

+44 (0)1582 723633

THE AMERICAS:

+1 800 835 7075

ASIA-PACIFIC:

+65 6 645 9888

2

ATEX and IECEx Safety Instructions for 9377-FB-R

Fieldbus Barrier Module

The following information is in accordance with the

Essential Health and Safety Requirements (Annex II) of the

EU Directive 2014/34/EU [the ATEX Directive - safety

of apparatus] and is provided for those locations where

such requirements are applicable.

General

a) This module must only be installed, operated

and maintained by competent personnel. Such

personnel shall have undergone training, which

included instruction on the various types of

protection and installation practices, the relevant

rules and regulations, and on the general principles

of area classification. Appropriate refresher training

shall be given on a regular basis. [See clause 4.2 of

EN 60079-17].

b) This module has been designed to provide

protection against all the relevant additional hazards

referred to in Annex II of the directive, such as

those in clause 1.2.7.

c) This equipment has been designed to meet the

requirements of EN 60079-0, EN 60079-1, EN

60079-7, EN 60079-11, EN 60079-18 and EN

60079-25.

Installation

a) The installation must comply with the appropriate

European, national and local regulations, which

may include reference to the IEC code of practice

IEC 60079-14. In addition, particular industries

or end users may have specific requirements

relating to the safety of their installations and these

requirements should also be met. For the majority

of installations the Directive 1999/92/EC [the ATEX

Directive - safety of installations] is also applicable.

b) This module can be mounted in a Safe area or a

Zone 2 or Zone 1 hazardous area. When mounted

in a Zone 2 or Zone 1 location the module must

be provided with an enclosure, which offers an

additional degree of protection appropriate to the

area classification.

Unless already protected by design, this module must be

protected by a suitable enclosure against:

i) mechanical and thermal stresses in excess of those

noted in the certification documentation and the

product specification

ii) aggressive substances, excessive dust, moisture

and other contaminants.

Read also the Schedule of Limitations (below) for

any additional or more specific information.

Schedule of Limitations

1) The 9377-FB-R Fieldbus Barrier must plug

into equipment that uses the mating part

of the connector covered by certificates

IECExTUN09.0014U and TUV09ATEX555354U.

2) The component must be housed in an

appropriatedly certified enclosure when used in

hazardous areas. When used in safe areas, the

enclosure must provide ingress protection of at

least IP20.

3) The component is intended to meet the

requirements for temperature class T4 when used

within its certified temperature range.

4) The air temperature inside the external enclosure

around the component must not exeed +75°C

during normal operation.

5) The component shall only be powered from

supplies conforming to IEC 61158.

Inspection and maintenance

a) Inspection and maintenance should be carried out

in accordance with European, national and local

regulations which may refer to the IEC standard

IEC 60079-17. In addition specific industries or end

users may have specific requirements which should

also be met.

Repair

This module cannot be repaired by the user and must

be replaced with an equivalent certified product.

ATEX and IECEx Safety Instructions for 9377-FB-R

Fieldbus Barrier Module

The following information is in accordance with the

Essential Health and Safety Requirements (Annex II) of the

EU Directive 2014/34/EU [the ATEX Directive - safety

of apparatus] and is provided for those locations where

such requirements are applicable.

General

a) This module must only be installed, operated

and maintained by competent personnel. Such

personnel shall have undergone training, which

included instruction on the various types of

protection and installation practices, the relevant

rules and regulations, and on the general principles

of area classification. Appropriate refresher training

shall be given on a regular basis. [See clause 4.2 of

EN 60079-17].

b) This module has been designed to provide

protection against all the relevant additional hazards

referred to in Annex II of the directive, such as

those in clause 1.2.7.

c) This equipment has been designed to meet the

requirements of EN 60079-0, EN 60079-1, EN

60079-7, EN 60079-11, EN 60079-18 and EN

60079-25.

Installation

a) The installation must comply with the appropriate

European, national and local regulations, which

may include reference to the IEC code of practice

IEC 60079-14. In addition, particular industries

or end users may have specific requirements

relating to the safety of their installations and these

requirements should also be met. For the majority

of installations the Directive 1999/92/EC [the ATEX

Directive - safety of installations] is also applicable.

b) This module can be mounted in a Safe area or a

Zone 2 or Zone 1 hazardous area. When mounted

in a Zone 2 or Zone 1 location the module must

be provided with an enclosure, which offers an

additional degree of protection appropriate to the

area classification.

Unless already protected by design, this module must be

protected by a suitable enclosure against:

i) mechanical and thermal stresses in excess of those

noted in the certification documentation and the

product specification

ii) aggressive substances, excessive dust, moisture

and other contaminants.

Read also the Schedule of Limitations (below) for

any additional or more specific information.

Schedule of Limitations

1) The 9377-FB-R Fieldbus Barrier must plug

into equipment that uses the mating part

of the connector covered by certificates

IECExTUN09.0014U and TUV09ATEX555354U.

2) The component must be housed in an

appropriatedly certified enclosure when used in

hazardous areas. When used in safe areas, the

enclosure must provide ingress protection of at

least IP20.

3) The component is intended to meet the

requirements for temperature class T4 when used

within its certified temperature range.

4) The air temperature inside the external enclosure

around the component must not exeed +75°C

during normal operation.

5) The component shall only be powered from

supplies conforming to IEC 61158.

Inspection and maintenance

a) Inspection and maintenance should be carried out

in accordance with European, national and local

regulations which may refer to the IEC standard

IEC 60079-17. In addition specific industries or end

users may have specific requirements which should

also be met.

Repair

This module cannot be repaired by the user and must

be replaced with an equivalent certified product.