Technical data CSA08937 1330-D, 1335-CSA

1340-D, 1345-CSA

Eaton is a registered trademark.

All other trademarks are property

of their respective owners.

Eaton

EMEA Headquarters

Route de la Longeraie 7

1110 Morges, Switzerland

Eaton.eu

Cooper Csa S.r.l. - via San Bovio, 3

20090 Segrate (MI) ‐ Italy

Tel: +39 02.9595.01

Fax: +39 02.9595.0598

www.coopercsa.it

© 2020 Eaton

All Rights Reserved

Publication No. CSA08937_11

Article No. 1330-D, 1335-CSA, 1340-D,

1345-CSA

September 2020

perfect joint, and lead to considerable, proportional reduction of the holding force.

Testing

Power the electromagnet and bring it close to the keeper-plate, so that the two parts

will attract. Press the release button to separate the two parts. Clean from time to

time with a soft cloth (do not use water).

Technical Specications

Material Thermoplastic / Steel

Connection Wired terminals [1330, 1340] – Terminal Block [1335, 1345]

Power Supply 24 Vdc

Consumption 52mA (1,2W) [1330, 1335] - 100mA (2,4W) [1340, 1345]

Holding Force 50Kg - 490N [1330, 1335] - 100Kg – 981N [1340, 1345]

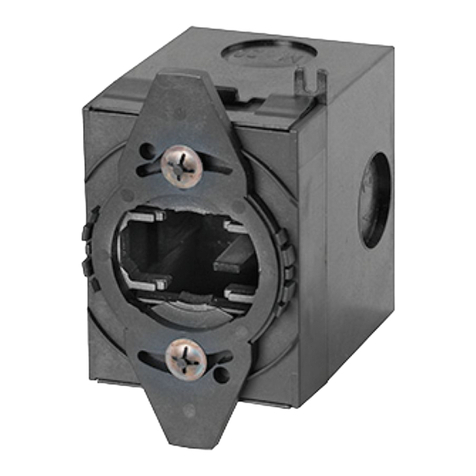

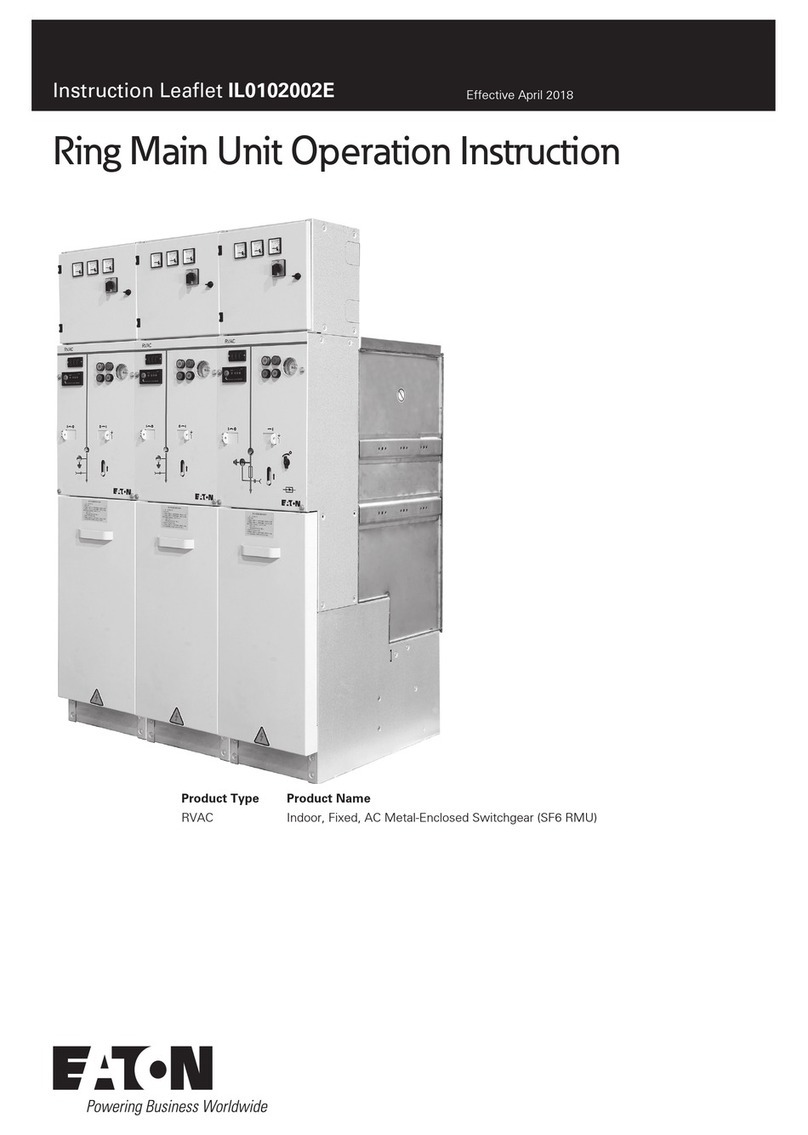

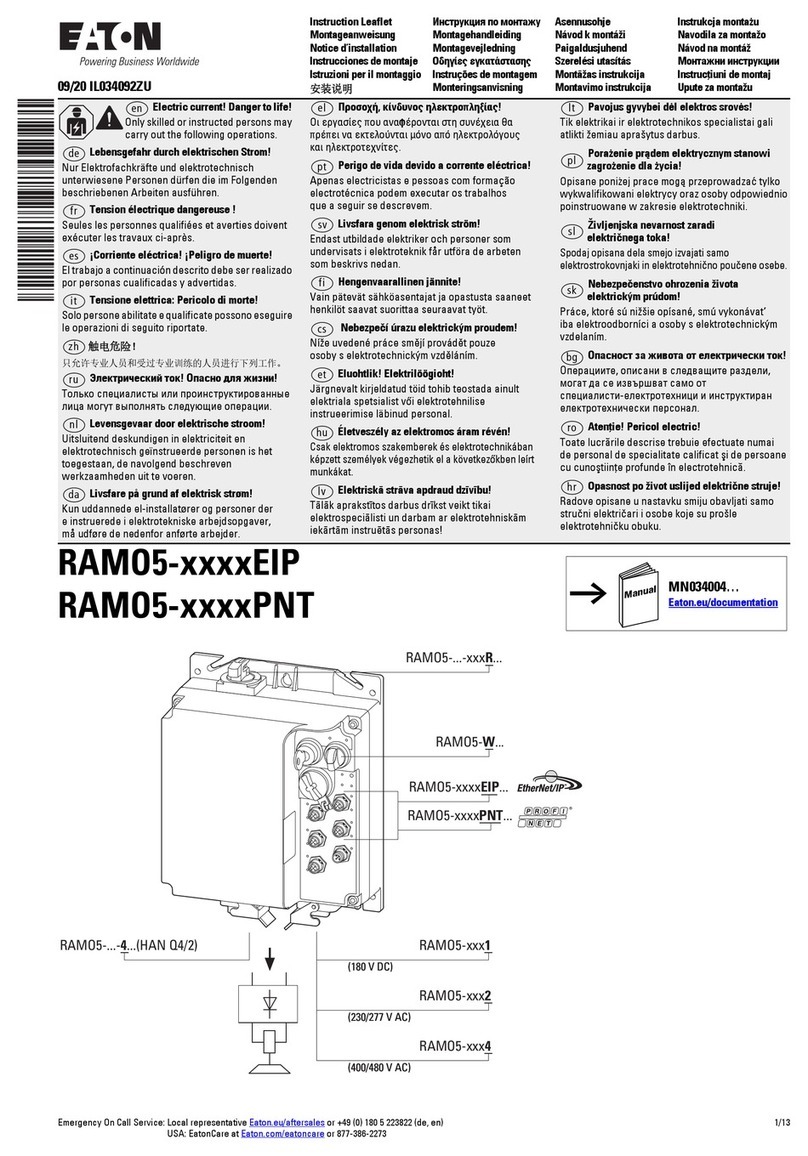

Description

The series 1330, 1335, 1340 and 1345 are used to keep the re or transit

doors open and release them automatically in the event of re. They consist

of two parts, the electromagnet and the keeper-plate. The electromagnet is

wall mounted and the keeper-plate is tted to the door.

Installation

• Use the two parts as a template, making sure the nucleus of the elec-

tromagnet and the keeper-plate surface are aligned.

• Fix the two parts having care that the keeper-plate is mounted with the

word TOP facing upwards to avoid bending that could damage or break

it at some future time.

• To make the connections, use insulating terminals (codes1330 and

1340). Codes 1335 and 1345 are fitted with terminal block.

Note: Even the tiniest impurities or dents due to accidental shock between

the nucleus of the electromagnet and the keeper-plate surface will prevent a

GB

Haltekraft und führen zu einer Verminderung der Schließkraft. Der Elektromagnet darf

nicht in seine Bestandteile zerlegt werden.

Funktionstest

Versorgen Sie den Elektromagneten mit Strom, und drücken Sie ihn leicht gegen die

auf die Tür montierte Kontaktplatte, so daß beide Teile angezogen werden. Bei den

Modellen 1330 und 1340 muß zur unmittelbaren Entsperrung der beiden Teile die

Stromzufuhr unterbrochen werden. Bei den Modellen 1335 und 1345 wird das gleiche

Ergebnis erzielt, indem die Auslösetaste gedrückt wird Um die vorschriftsmäßige

Funktion zu gewährleisten, sollten Sie beide Einheiten in regelmäßigen Abständen mit

einem weichen Tuch (ohne Wasser) abwischen.

Technische Daten

Baumaterial Thermoplast / Stahl

Anschluss Kabel [1330, 1340] – Klemmen [1335, 1345]

Stromversorgung 24 Vdc

Stromaufnahme 52mA (1,2W) [1330, 1335] - 100mA (2,4W) [1340, 1345]

Schliesskraft 50Kg - 490N [1330, 1335] - 100Kg – 981N [1340, 1345]

Beschreibung

Die Elektromagneten der Baureihen 1330, 1335, 1340 und 1345 werden

eingesetzt, um Brandschutztüren und Durchgänge offen zu halten und

im Falle eines Brandes automatisch zu schließen. Sie bestehen aus zwei

Hauptbestandteilen, und zwar aus dem Elektromagneten selbst und einer

zugehörigen Kontaktplatte. Der Elektromagnet wird an der Wand montiert,

während die Kontaktplatte direkt auf der Brandschutztüre installiert wird.

Installation

• Benutzen Sie die beiden Grundplatten als Schablone; achten Sie darauf,

dass der Kern des Elektromagneten und der Plattenteller in einer Achse

montiert werden.

• Achten Sie bei der Befestigung der beiden Bestanteile darauf, daß die

Kontaktplatte mit nach oben gerichteter Schrift “TOP” installiert wird,

so daß eine Verdrehung bzw. Beschädigung der Kontaktplatte auch nach

längerem Einsatz ausgeschlossen wird.

• Benutzen Sie zum Anschluss isolierte Klemmen (Modelle 1330 und

1340). Die Modelle 1335 und 1345 haben eine eigene Klemmleiste zum

elektrischen Anschuß.

Zu beachten: Fremdkörper, Schmutz und Unreinheiten beeinträchtigen die

D

seja perfeita e portanto dar lugar uma redução significativa da força de fixação. Não

deve desmontar o electroiman.

Teste

Alimente o electroiman e exerça uma pequena pressão e alinhe-o com a contrachapa.

Notará a atracção que exercem as duas partes. Nos modelos 1330 e 1340, é

necessário cortar a alimentação para conseguir que se separem imediatamente as

duas partes. Nos modelos 1335 e 1345 obtem-se o mesmo resultado ao premir o

botão de desbloqueio. Para um funcionamiento óptimo, limpe o electroiman de vez em

quando com um pano suave (não utilize àgua).

Características Técnicas

Material Aço / Termoplástico

Ligação 2 fios de ligação [1330, 1340] – Terminais [1335, 1345]

Alimentação 24 Vcc

Consumo 52mA (1,2W) [1330, 1335] - 100mA (2,4W) [1340, 1345]

Força de Fixação 50Kg - 490N [1330, 1335] - 100Kg – 981N [1340, 1345]

Descrição

Os electroimans da série 1330, 1335, 1340, 1345 utilizam-se para manter

abertas as portas de passagem ou cortafogo e libertá-las automáticamente

em caso de incêndio. São constítuidos por duas partes, o electroiman

própriamente dito e a contrachapa. O electroiman é montado na parede e a

contrachapa na porta.

Instalação

• Utilize os dois componentes para marcar os furos. Assegure-se de

que o núcleo do electroiman e a superfície da contrachapa coincidem

perfeitamente.

• Fixe as duas partes e verifique que a contrachapa fica montada com a

palavra “TOP” na parte superior para impedir que se dobre, já que se

poderia danificar ou ficar destruído após algum tempo de utilização.

• Efectue as ligações com terminais isolados (artigo 1330, 1340). Os

modelos 1335 e 1345 dispõem de lacas com terminais para a ligação

eléctrica

NOTA: A presença de impurezas ou amolgaduras acidentais, por mais peque-

nas que sejam, entre o núcleo do electroiman e a superfície da contrachapa

podem fazer com que a união destes dois equipamentos não

P

reducción proporcional y considerable de la fuerza de sujeción. No debe desmontar el

electroimán.

Prueba

Alimente el electroimán y presione ligeramente para alinearlo con la contrachapa.

Observará la atracción que se ejerce entre las dos partes. En los modelos 1330 y 1340,

es necesario cortar la alimentación para conseguir que se separen inmediatamente

las dos partes. En los modelos 1335 y 1345 se obtiene el mismo resultado pulsado el

botón de desbloqueo. Para un funcionamiento óptimo, limpie el electroimán de vez en

cuando con un trapo suave (no utilice agua).

Caracteristicas Tecnicas

Material Acero / Termoplástico

Conexión Terminación con hilos [1330, 1340] – Terminales [1335, 1345]

Alimentación 24 Vcc

Consumo 52mA (1,2W) [1330, 1335] - 100mA (2,4W) [1340, 1345]

Fuerza de retención 50Kg - 490N [1330, 1335] - 100Kg – 981N [1340, 1345]

Descripción

Los electroimanes de la serie 1330, 1335, 1340, 1345 se utilizan para

mantener abiertas las puertas de paso o cortafuegos y liberarlas automáti-

camente en caso de incendio. Se componen de dos partes, el electroimán

propiamente dicho y la contrachapa. El electroimán se monta sobre la pared y

la contrachapa en la puerta.

Instalación

• Utilice los dos componentes como plantilla. Asegúrese de que el núcleo

del electroimán y la superficie de la contrachapa comparten eje.

• Fije las dos partes y compruebe que la contrachapa queda montada con

la palabra “TOP” en la parte superior para impedir que se doble, ya que

se podría dañar o llegar a romper con el paso del tiempo.

• Realice las conexiones con terminales aislados (artículo 1330/1340).

Los modelos 1335 y 1345 disponen de placas con terminales para la

conexión eléctrica.

NOTA: Incluso la presencia de pequeñas impurezas o abolladuras acciden-

tales entre el núcleo del electroimán y la superficie de la contrachapa pueden

impedir que éstos se unan perfectamente y por lo tanto ocasionar una

E