2

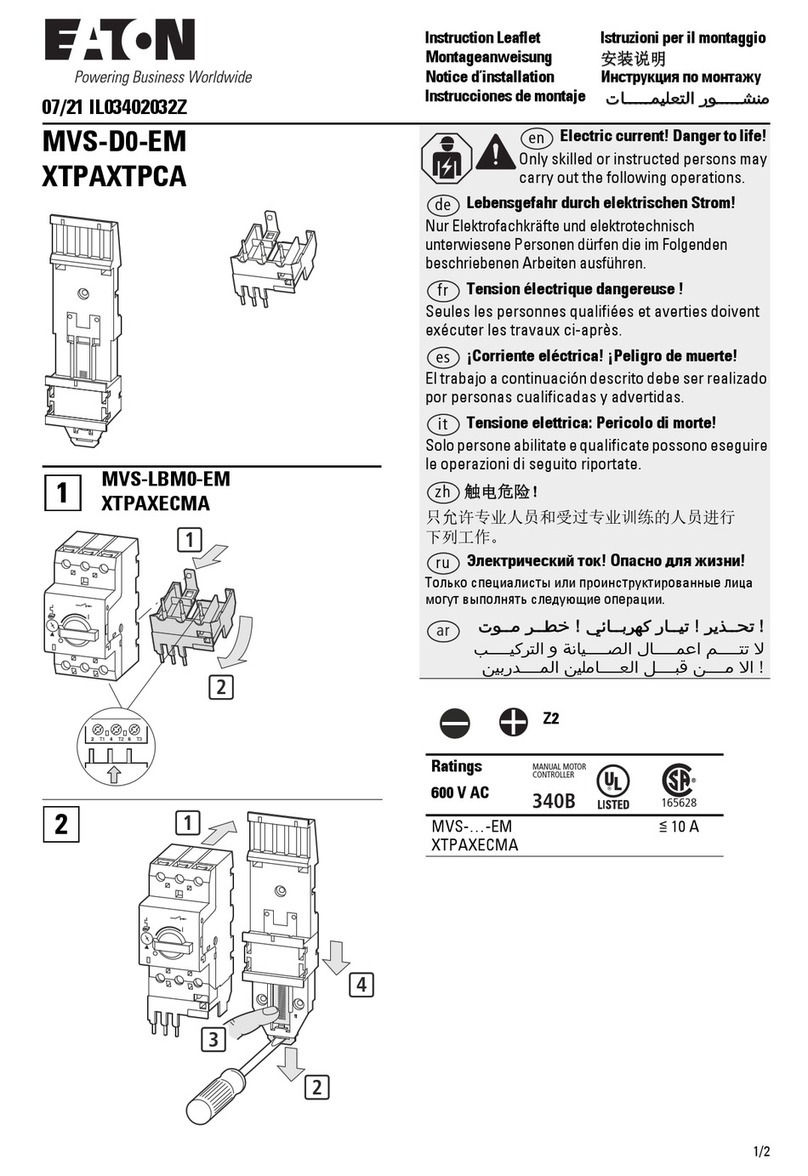

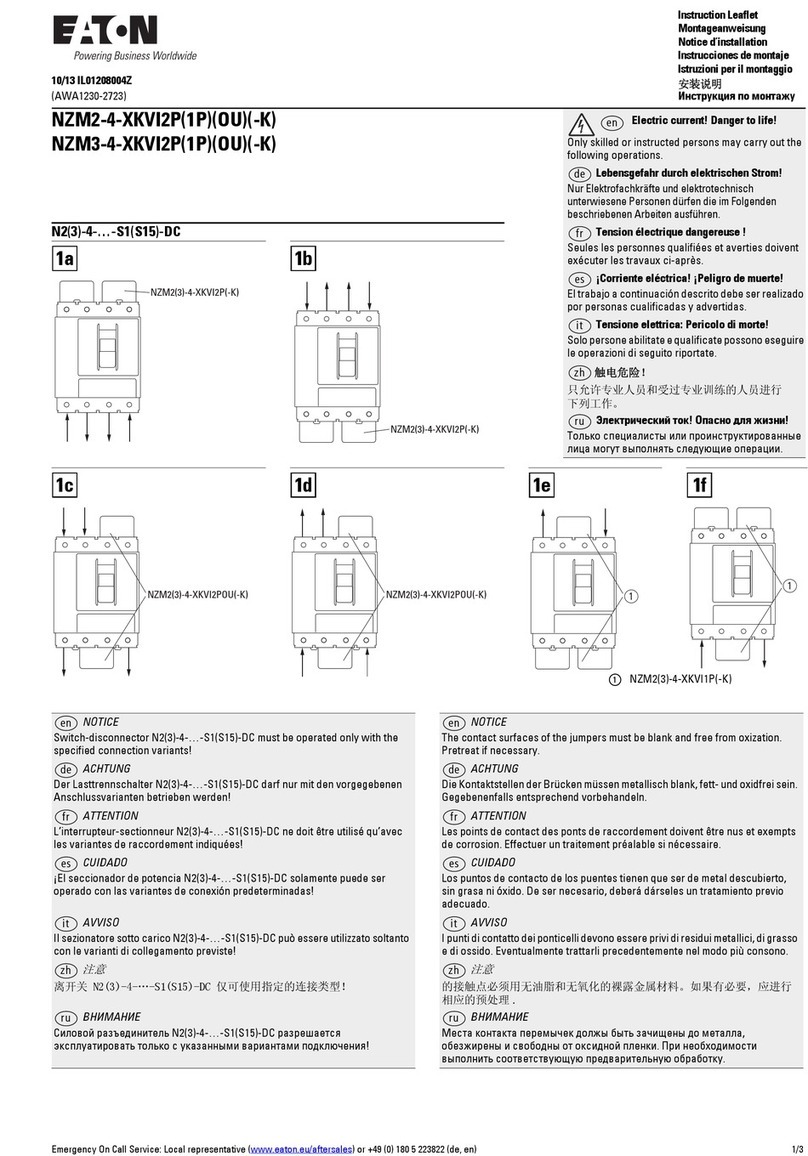

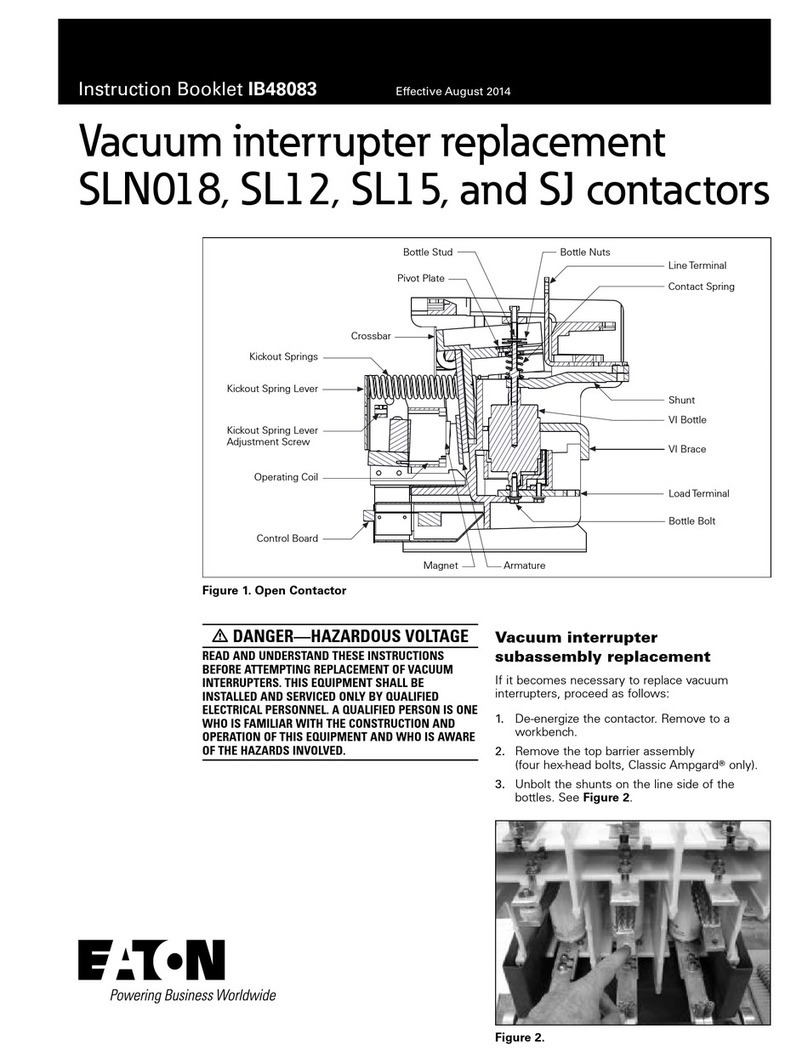

Service Pullout

Installation

91712

NOTE: The Service Pullout is shipped with the Front

Legs in their uppermost position.

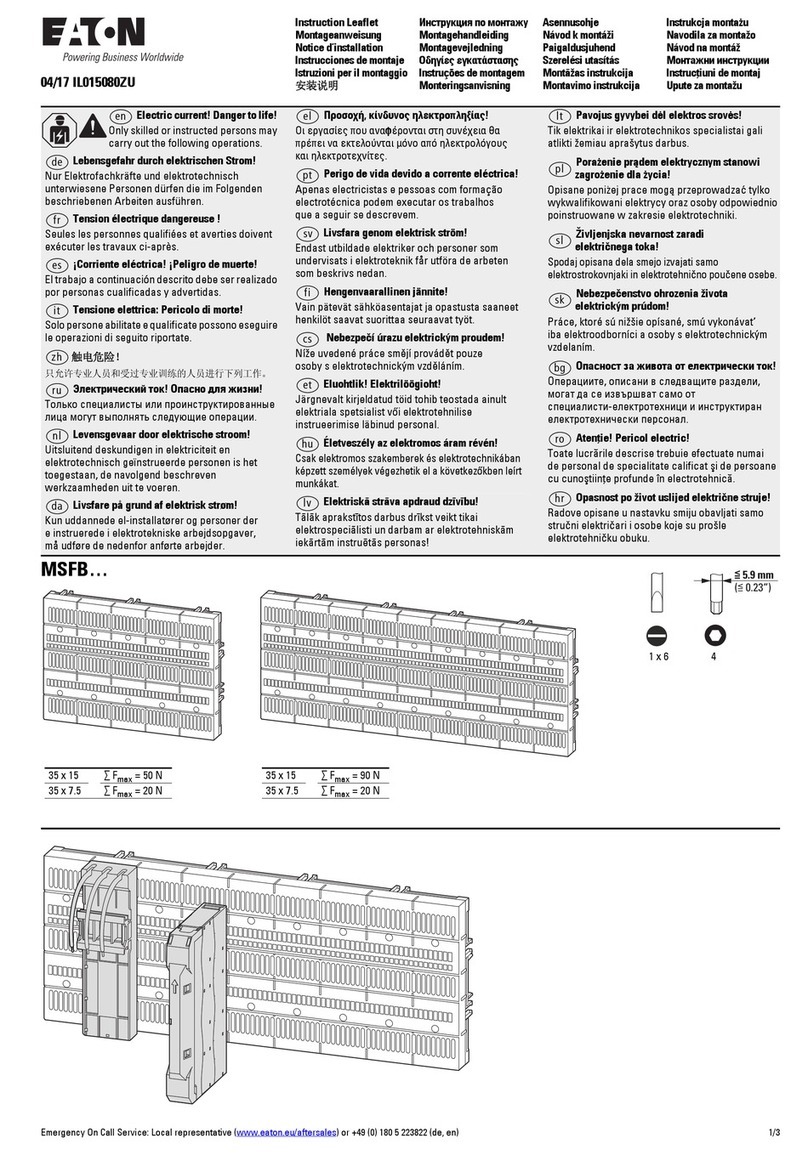

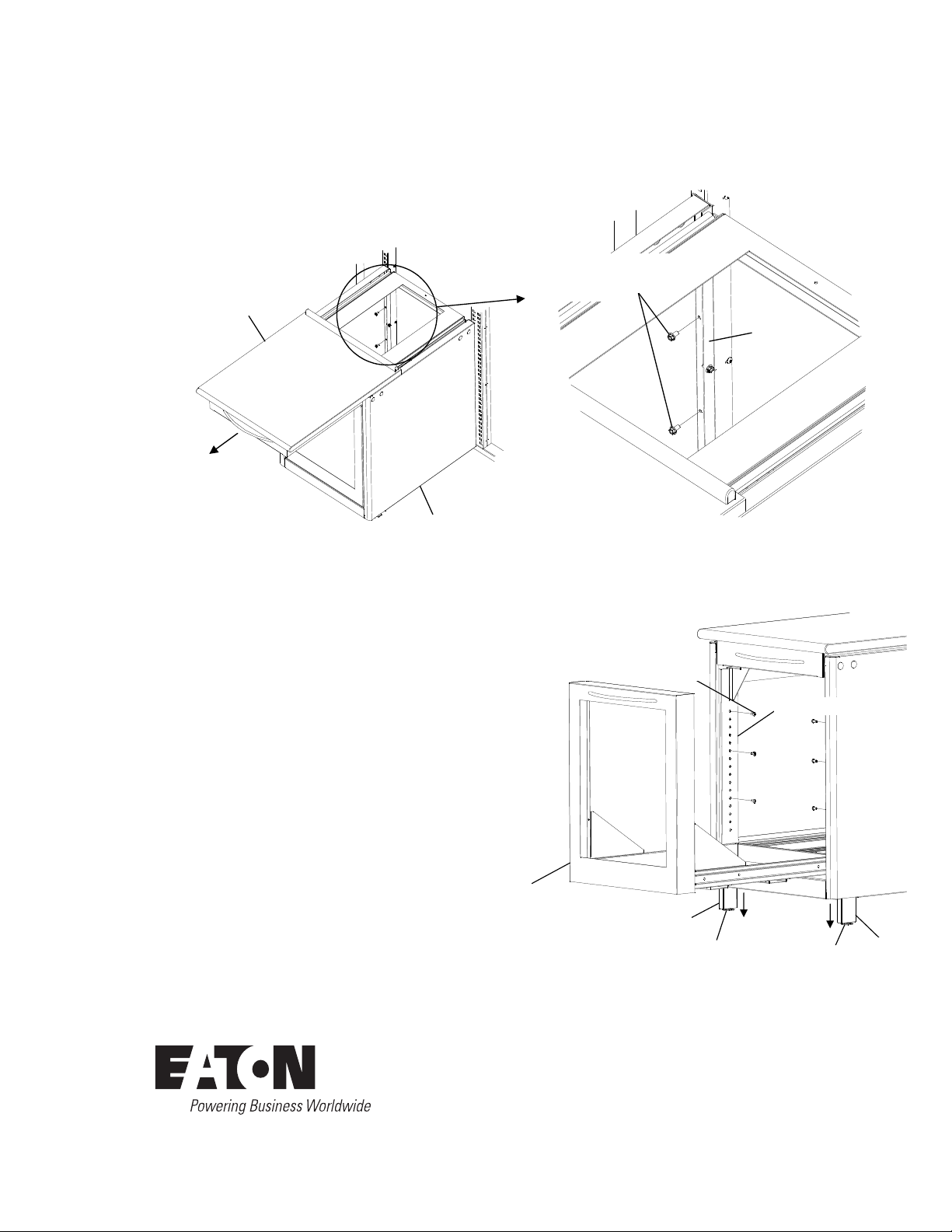

LEVELING THE SERVICE PULLOUT

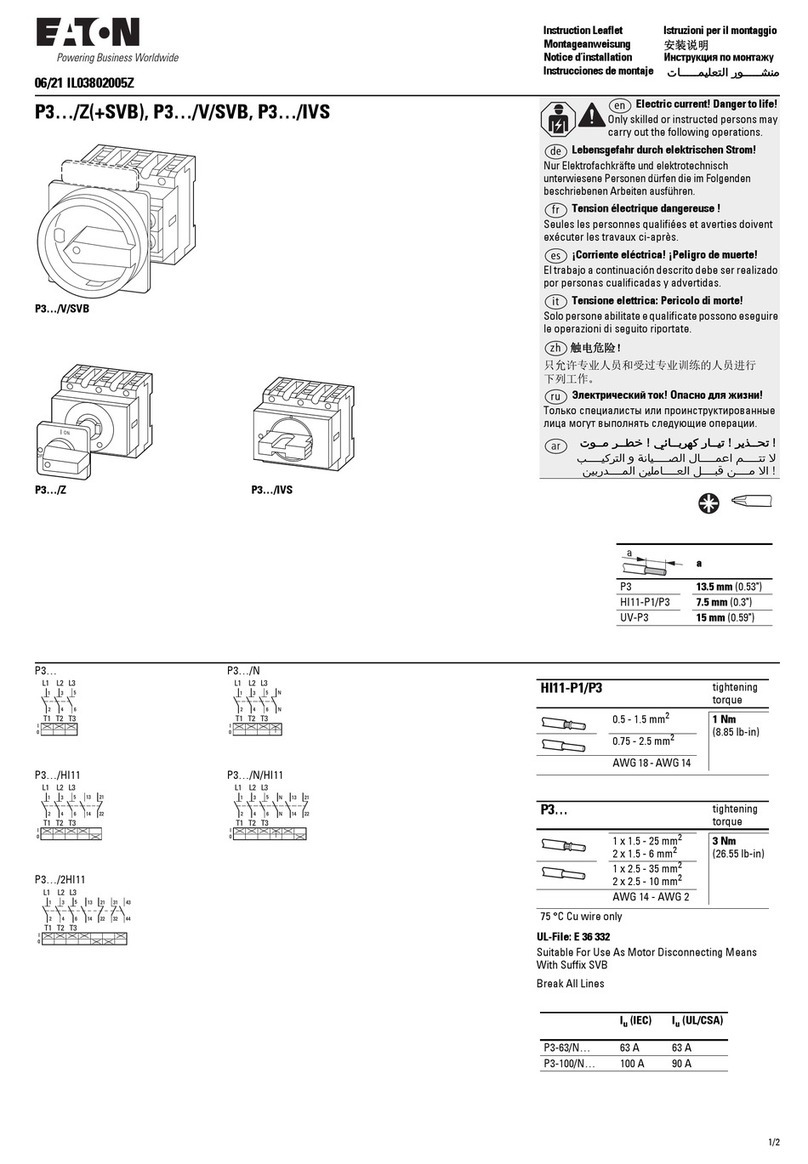

1. Pull the Drawer out. See figure 4.

2. Remove the three 1/4”-20 x 1/2” button head cap

screws that secure each Front Leg. Do not discard.

3. Drop the Front Legs down until the levelers touch the

floor. Move each leg up until the threaded holes in

the legs align with the nearest holes in the Front

Channels. Re-install the 1/4”-20 x 1/2” button head

cap screws and tighten securely.

4. Turn the levelers counter clockwise until they touch

the floor. Adjust the levelers to level the unit.

Figure 4

Drawer

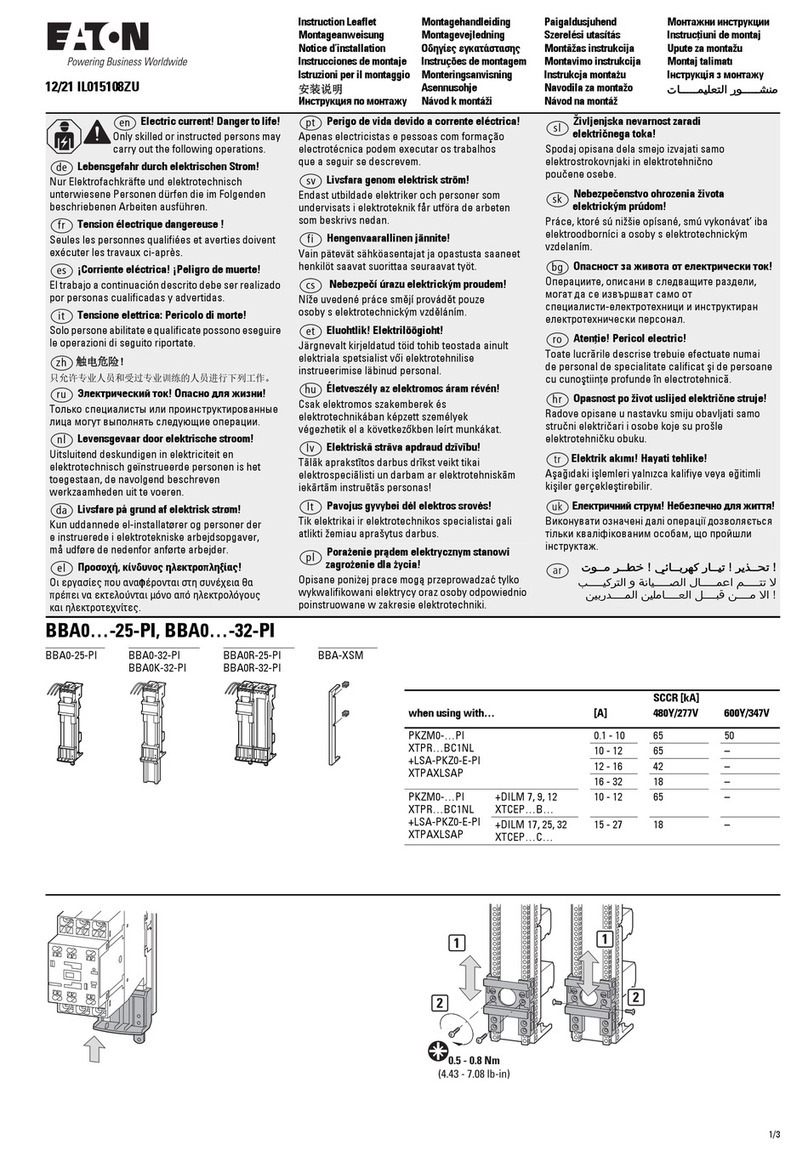

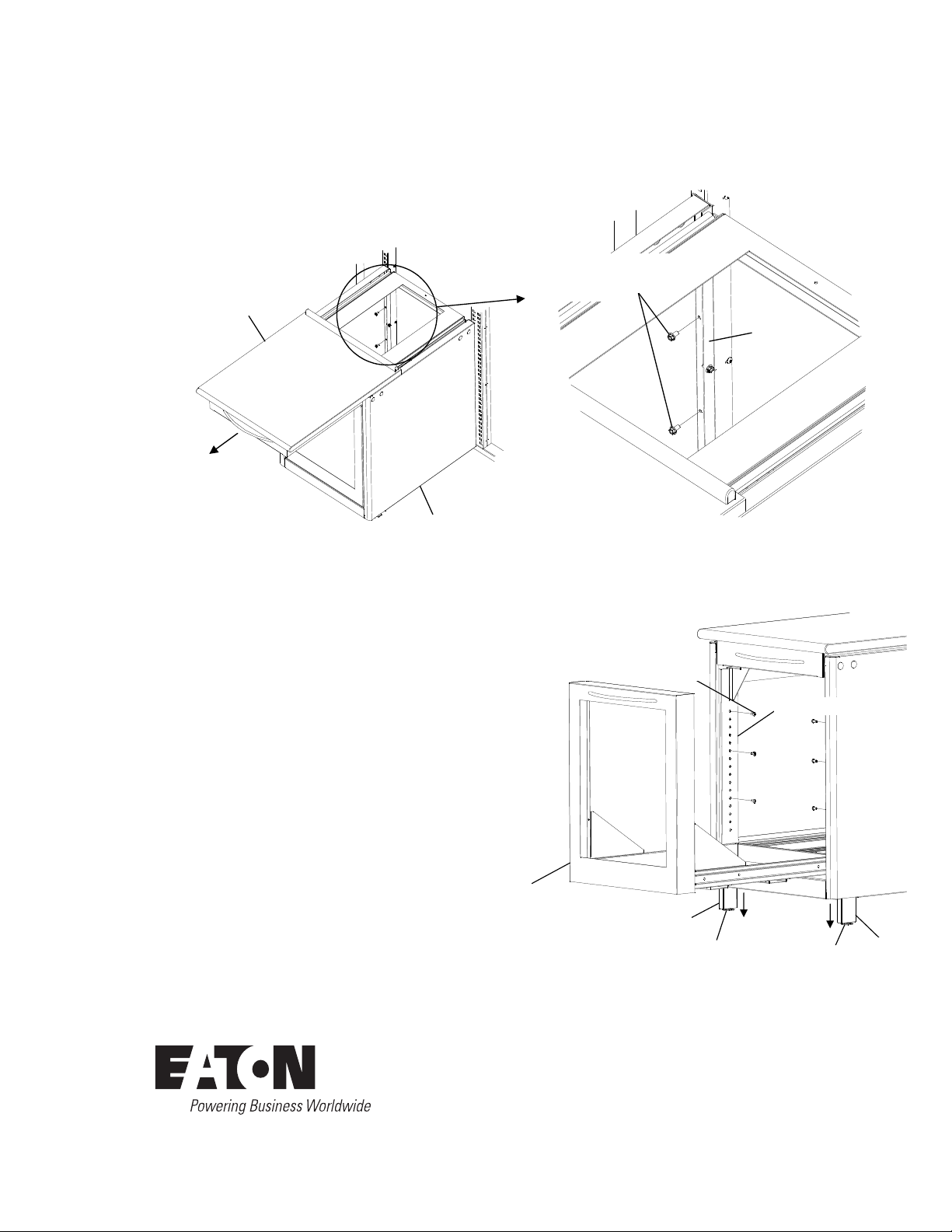

Figure 3

1/4-20 x 1/2” hex

washer head screws

Hook Plate

1. Pull the top surface of the unit out to gain access to

the inside of the unit. Locate the two holes at the rear

corners of the Service Pullout and using a 3/8” socket

wrench, thread a 1/4”-20 x 1/2” hex washer head

screw into each hole. Tighten each screw securely .

See figure 3.

SECURING THE UNIT TO THE FRAME

IMPORTANT!

Top surface

Service Pullout

Leveler

1/4”-20 x 1/2” button

head screws

Leg

Leg

Leveler

Leg Channel

2

Service Pullout

Installation

91712

NOTE: The Service Pullout is shipped with the Front

Legs in their uppermost position.

LEVELING THE SERVICE PULLOUT

1. Pull the Drawer out. See figure 4.

2. Remove the three 1/4”-20 x 1/2” button head cap

screws that secure each Front Leg. Do not discard.

3. Drop the Front Legs down until the levelers touch the

floor. Move each leg up until the threaded holes in

the legs align with the nearest holes in the Front

Channels. Re-install the 1/4”-20 x 1/2” button head

cap screws and tighten securely.

4. Turn the levelers counter clockwise until they touch

the floor. Adjust the levelers to level the unit.

Figure 4

Drawer

Figure 3

1/4-20 x 1/2” hex

washer head screws

Hook Plate

1. Pull the top surface of the unit out to gain access to

the inside of the unit. Locate the two holes at the rear

corners of the Service Pullout and using a 3/8” socket

wrench, thread a 1/4”-20 x 1/2” hex washer head

screw into each hole. Tighten each screw securely .

See figure 3.

SECURING THE UNIT TO THE FRAME

IMPORTANT!

Top surface

Service Pullout

Leveler

1/4”-20 x 1/2” button

head screws

Leg

Leg

Leveler

Leg Channel

1∕4" - 20 x 1∕2" button

head screws

Securing the unit to the frame

1. Pull the top surface of the unit out to gain access

to the inside of the unit. Locate the two holes at

the rear corners of the Service Pullout and using

a 3∕8" socket wrench, thread a 1∕4" - 20 x 1∕2" hex

washer head screw into each hole. Tighten each

screw securely. See gure 3.

Leveling the service pullout

NOTE: The Service Pullout is shipped with the Front

Legs in their uppermost position.

1. Pull the Drawer out. See gure 4.

2. Remove the three 1∕4" - 20 x 1∕2" button head cap

screws that secure each Front Leg. Do not discard.

3. Drop the Front Legs down until the levelers touch

the oor. Move each leg up until the threaded holes

in the legs align with the nearest holes in the Front

Channels. Re-install the 1∕4" - 20 x 1∕2" button head cap

screws and tighten securely.

4. Turn the levelers counter clockwise until they touch

the oor. Adjust the levelers to level the unit.

Hook plate

Service pullout

Leg channel

Top surface

1∕4" - 20 x 1∕2" hex

washer head screws

Drawer

Leg

Leg

Leveler Leveler

Figure 3

Figure 4