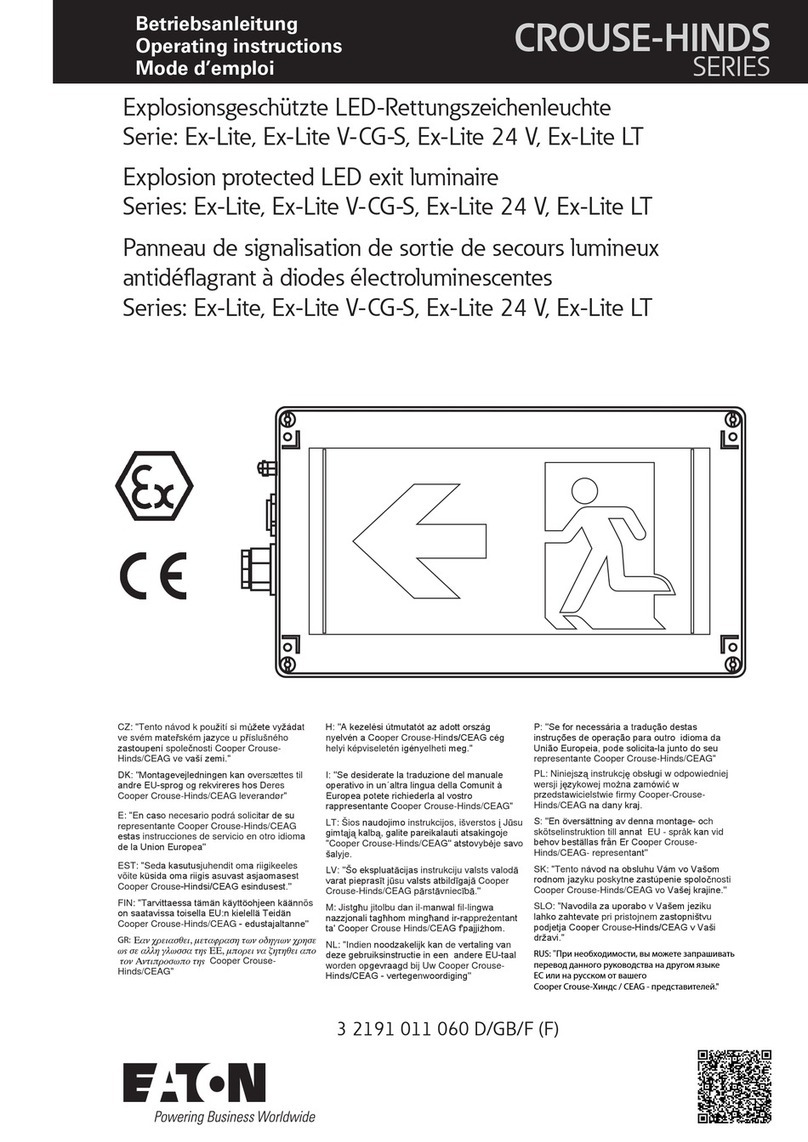

8EATON’s Crouse-Hinds Business

Achten sie auf die plane Anbringung der

Leuchte zur Sicherstellung der Schutzart,

siehe Bild 10-12! Beachten Sie beim

Befestigen des Montagezubehörs an der

Leuchte die max. Gewindetiefe der Monta-

gebohrung von 14 mm (5 Nm)!

Verwenden Sie keine zu langen Schrauben!

Montagezubehör: siehe Eaton/CEAG Katalog.

5.2 Netzanschluss

Zum Öffnen des Anschlussraumes grünen

Drehgriff in Pfeilrichtung bis zum Anschlag

drehen, dann ziehen und die Klappe abklappen

(Bild 4 und 5).

Für den Netzanschluss Leitungen mit Kupfer-

adern verwenden.

– Die Leitung durch die Ex-Kabel- und Leitungs-

einführung einführen (Bild 5).

Für Leitungen von Ø 10,0 bis 13,0 mm beide

Dichtungseinsätze, von Ø 13,5 bis 15,0 mm

nur den äußeren Dichtungseinsatz verwen-

den. Auf korrekten Sitz des verbleibenden

Dichtungseinsatzes in der Verschraubung

achten.

– Die Leitungen an den Anschlussklemmen PE,

N, L1, L, (L2, L3) gemäß Klemmenbezeich-

nung anklemmen (Schaltpläne, Seite 2). Auch

nicht benutzte Klemmen anziehen!

Ladeleitung L und Netzanschluss der

Leuchte müssen stets auf demselben Außen-

leiter des Netzes liegen!

Bei nicht benutzten Kabel- und

Leitungseinführungen ist die Schutzscheibe

zu entfernen und die Einführung durch einen

Verschlussstopfen zu verschließen. Beim

Verschließen mit einemVerschlussstopfen

stets beide Dichtungseinsätze verwenden!

Bei Metall-Kabeleinführungen sind die

Schutzkappen der nicht benutzten Ein-

führungen zu entfernen und diese durch

bescheinigte Ex-Verschlussstopfen zu

verschließen!

5.3 Installation eLLM 92 NIB

Die Montage und Installation der Mastleuchte

erfolgt in folgender Reihenfolge:

– Die drei Kreuzschlitzschrauben im Deckel des

Mastanschlussraumes lösen (Bild 2, Pos. 1).

– Anschlussraum durch Aufklappen des Deckels

öffnen (Bild 2, Pos. 2).

– Verriegelungsbügel des Kabel- und Leitungs-

einführungsstutzens bis zum Anschlag

hochziehen und Abdeckplatte abnehmen

(Bild 2, Pos. 3).

– Kabel- und Leitungseinführungsstutzen aus

den Führungsnuten im Anschlussraum

entnehmen.

– Mastrohr oder das Rohr des Wandarmes von

jeweils Ø 42 mm (Bild 2, Pos. 4) bis zum

Anschlag in die Öffnung der Mastleuchte

einführen (Bild 2, Pos. 4a).

5. Installation eLLK 92..NIB;

eLLS 08..NIB

Die für das Errichten und Betreiben

von explosionsgeschützten elektrischen

Betriebsmitteln geltenden Sicherheitsvor-

schriften gemäß des Gerätesicherheitsgeset-

zes sowie die allgemein anerkannten Regeln

der Technik sind einzuhalten! Transport und

Lagerung der Leuchte ist

nur in Originalverpackung und der ange-

gebenen Lage gestattet!

Aufgrund der Selbstentladung der

Batterie ist nach spätestens 6 Monaten auch

bei nicht angeschlossenen Leuchten die

Batterie mindestens 14 Stunden nachzula-

den.

Achtung! Zeigt der Lichtaustritt nach oben

sind zusätzliche Schutzmaßnahmen gegen

dauerhafte Wasseransammlungen im

Bereich derWannendichtung zu treffen.

Hinweis

Bei Montage der Leuchte mit Neigung um

die Längsachse (z.B.: Geländer-Montage),

wird empfohlen, die Abdeckung des Zentral-

verschlusses gegen die Version mit der

Ident-Nr. 22216904000 zu tauschen.

In diesem Falle sollte die Schutzwanne mit den

Haltescharnieren oben am Gehäuse befestigt

sein.

Kondensatbildung kann auf Grund der hohen

Schutzart nicht vollständig ausgeschlossen

werden. Daher empfehlen wir für den Einsatz

im Außenbereich mit hoher Luftfeuchtigkeit und

hohen Außentemperaturen den Einsatz eines

Entlüftungsstutzen.

(z.B. M20 Bestellnr GHG9601954R0014 oder

M25 Bestellnr. GHG9601954R0002)

5.1 Öffnen und Schließen der Leuchte

– Den Zentralverschluss mit Steckschlüssel

(Schlüsselweite SW 13) um 90° bis zur

Raststellung drehen und Schutzwanne

abklappen (Bild 3).

Bei Verwendung von ungeeignetem

Werkzeug ist ein kraftschlüssiges Drehen

des Zentralverschlusses nicht gewährleistet.

Dieser wird dadurch beschädigt.

–

Schutzwanne ein- und ausbauen (Bild 6 und 7).

– Die Schutzwanne ist wahlweise beidseitig

scharnierbar.

– Schutzwanne zum Verschließen der Leuchte

fest an das Leuchtengehäuse andrücken und

den Zentralverschluss um 90° drehen.

– Leuchte ausrichten und die vormontierten

Spezialschrauben M6 anziehen (Drehmoment

3,0 Nm, Bild 2, Pos. 5).

– Leitung durch das Rohr einführen und auf die

entsprechende Länge abisolieren.

– Leitung durch die Ex-Kabel- und Leitungs-

einführung (KLE) einführen und mit der

Druckschraube der KLE die Leitung anziehen).

– KomplettenTräger (mit eingeführter Leitung)

in die Führungsnuten der Mastleuchte

einsetzen (Bild 2, Pos. 6).

– Träger mit Verriegelungsbügel verschließen

(Bild 2, Pos. 3).

– Leitung in die Zugentlastung legen und

anziehen (Bild 2, Pos. 7).

– Leitung entsprechend der Klemmenbezeich-

nung anschließen.

– Bei Verwendung von mehr- oder feindrähtigen

Anschlussleitungen sind die Aderenden

entsprechend den geltenden nationalen und

internationalen Vorschriften zu behandeln

(z.B. Verwenden von Aderendhülsen).

5.4 Einsetzen der Lampe

Nur solche Lampen verwenden, die für

diese Leuchte zugelassen sind, siehe

Technische Daten und Typenschild!

T12-Lampen (Ø 38 mm) werden von der

EOL-Schaltung als fehlerhaft erkannt und

abgeschaltet!

Einstiftsockellampe (Fa6)

Lampe erst auf der einen Seite in die Fassung

stecken. Danach die gegenüberliegende

Fassung etwas nach außen ziehen und die

Lampe einstecken (Bild 8.1 und 9.1).

Zweistiftsockellampe (G13)

Lampe in beide Fassungen bis zum Anschlag

einstecken (Bild 8), so dass an jeder Seite der

Lampe beide Stifte im Eingriff der Fassung

sind.

Danach die Lampe um 90° in Raststellung

drehen (Bild 9), wobei die grüne Fläche in

der Fassung sichtbar wird. Die Lampe ist nun

gegen Herausfallen gesichert.

6. Inbetriebnahme

Vor der Inbetriebnahme die korrekte

Funktion und Installation der Leuchte in

Übereinstimmung mit dieser Betriebsanlei-

tung und anderen zutreffenden Bestimmun-

gen überprüfen!

D

Explosionsgeschützte Notleuchten

Serie: eLLK 92 NIB, eLLM 92 NIB, eLLS 08 NIB