REV. H

Instruction Manual

Style II

FAA Approach Fixture

8 Installation

The style 2 FAA light units are shipped complete and are ready for installation as received.

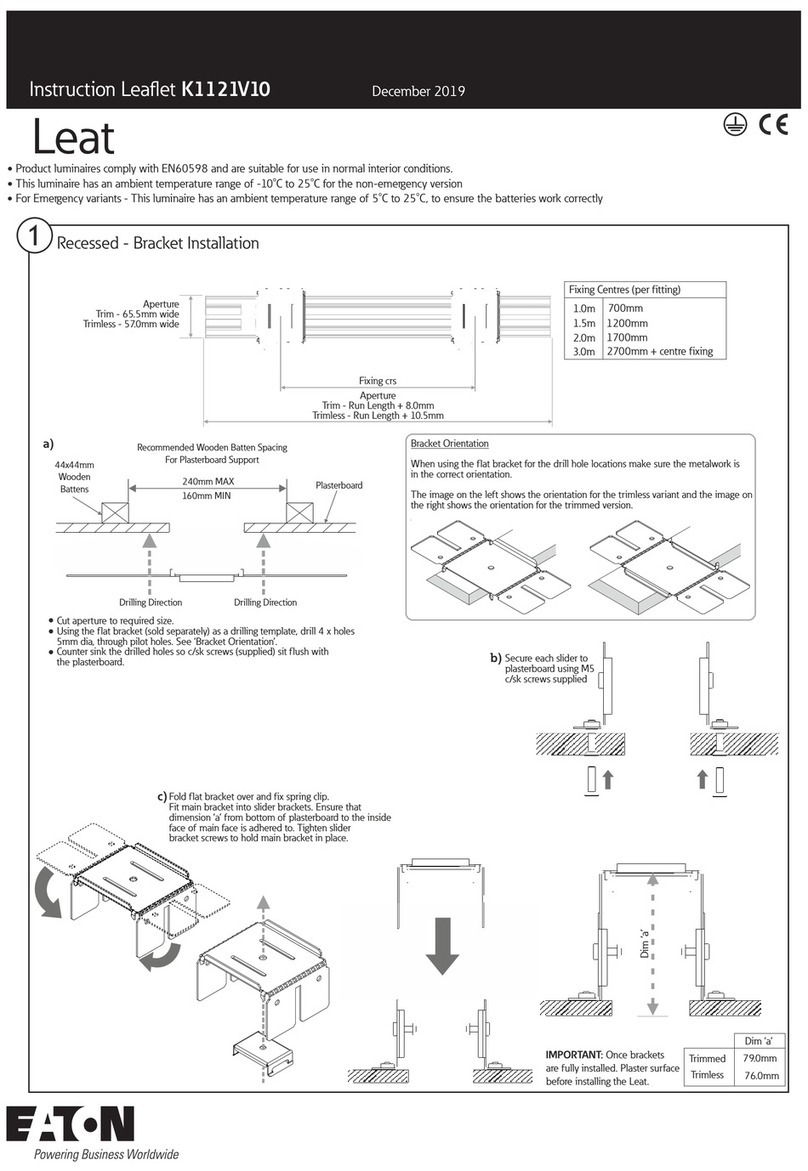

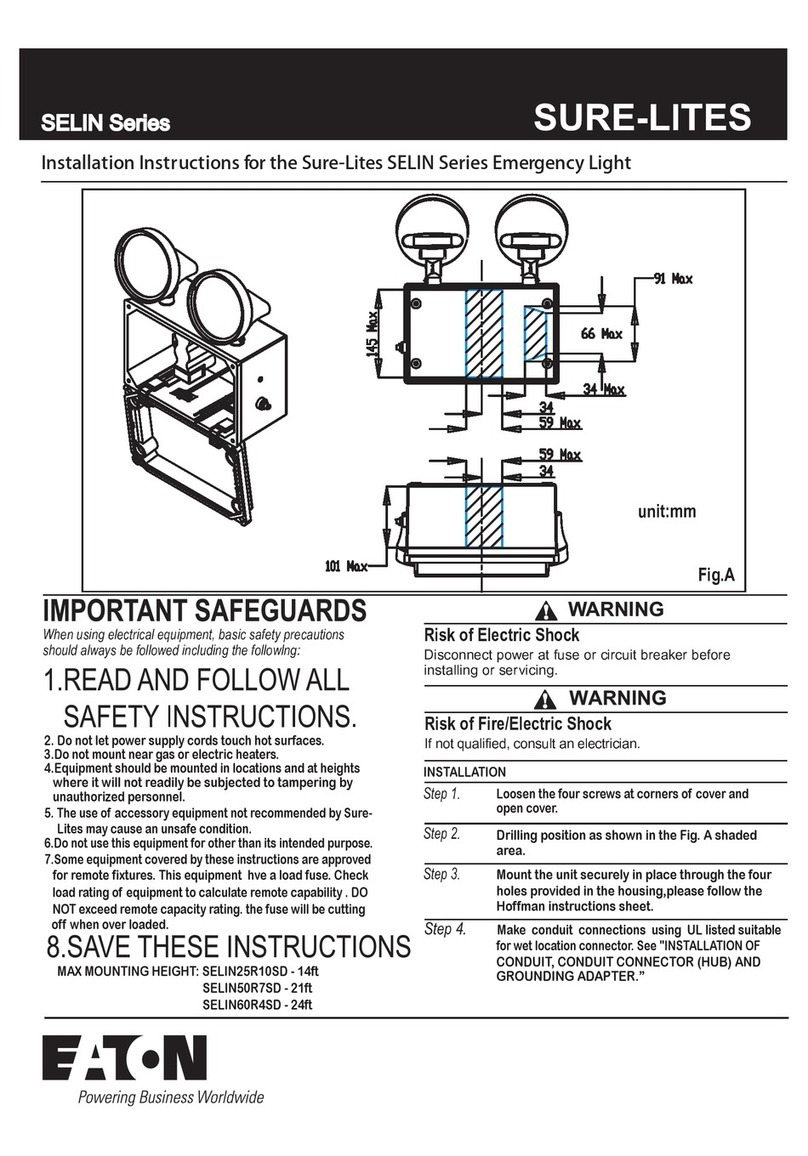

Installation of a light unit is to be done with primary POWER OFF and SECURED. At each

light location, install a steel, Size B, 24 inch deep minimum, L-868 Light Base per FAA AC

150/5340-4 (latest revision). Place the properly sized isolation transformer in the light base

and make necessary primary power connection using L-823 connectors. The light unit

requires a 6.6A secondary transformer. Verify that the mounting flange on the light base is

clean and the o-ring (optional on deep cans) is coated with Dow Corning FS 1292 grease and

is in place on the light base. Connect the plug from the light unit to the secondary of the

previously installed isolation transformer. Installation tool, Crouse-Hinds P/N 19999, will

ease in the installation and removal of the light unit. The threaded eyebolts on the lifting tool

screw into threaded holes in the light fixture. Lower the light unit straight down onto the

base. The light fixture is subject to optical misalignment or mechanical damage if not seated

properly. Secure the light fixture to the base per section 8.1. After installation, the mounting

bolts shall be periodically checked for proper torque to ensure a secure installation. See

section 9.8.4.

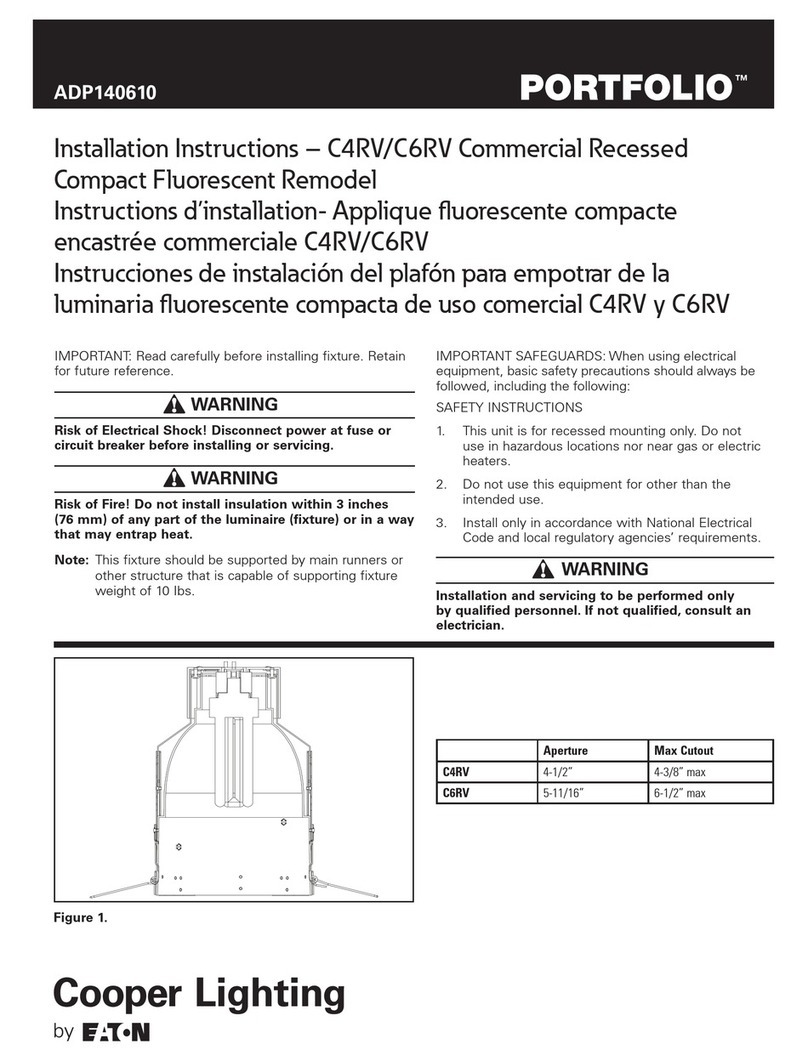

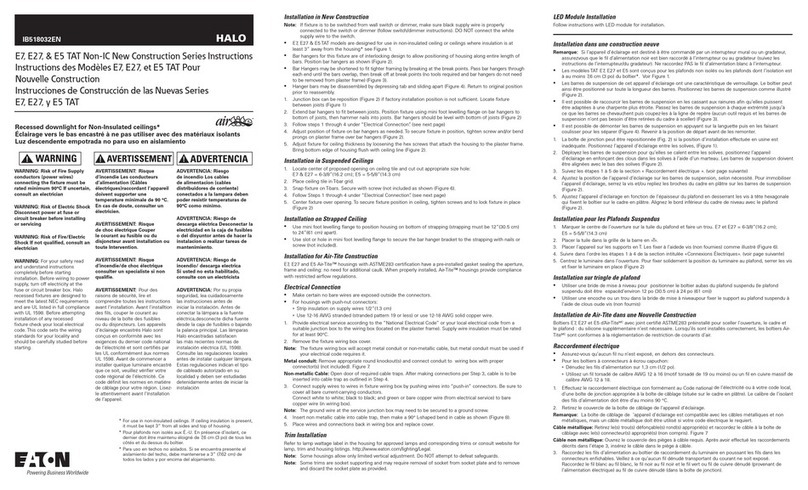

8.1 Installation Bolt Torque

•Use fully threaded, 3/8-16 bolts meeting requirements of FAA EB83A. (P/N 21716 is

recommended.)

•Use Heico-Lock or Nord-Lock stainless steellock-washers per FAA specifications*.

•Mounting base holes must be degreased, cleaned, and dried prior to bolt installation.

•Base-to-fixture mating surfaces must be degreased, cleaned, and dried prior to

installation.

•Apply marine grade anti-seize (K=.18) per manufacturer’s instructions to each bolt.

•Install the 3/8-16 bolts with lock-washers per lock-washer manufacturer’s guidelines.

•See Section 8.2 for Heico-Lock installation guidelines (2014)

•Achieve a full final torque of 28 FT-LBS (37.9 N-m) ±10% with a calibrated torque

wrench.

•Impact wrenches are notrecommended as installation tools.

•Check torque and re-torque all bolts within 2 weeks of initial installation.

•Maintain all bolts by checking and re-torqueing per FAA specifications*.

•If any lubricants or thread locking compounds are used (not recommended), torque

must be recalculated based on K factor provided by lubricant or compound

manufacturer.

•New bolts and lock-washers shall be used each time a light unit is removed from its

base.