The given data is only intended as a product

description and should not be regarded as a legal

warranty of proper ties or guarantee. In the interest

of further technical developments, we reserve the

right to make design changes.

EUROPE (EMEA):

+44 (0)1582 723633

THE AMERICAS:

+1 800 835 7075

ASIA-PACIFIC:

+65 6 645 9888

The given data is only intended as a product

description and should not be regarded as a legal

warranty of proper ties or guarantee. In the interest

of further technical developments, we reserve the

right to make design changes.

EUROPE (EMEA):

+44 (0)1582 723633

THE AMERICAS:

+1 800 835 7075

ASIA-PACIFIC:

+65 6 645 9888

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

www.mtl-inst.com

© 2016 Eaton

All Rights Reserved

Publication No. INS MTL GIR6000 Rev 2 141116

November 2016

Eaton Electric Limited,

Great Marlings, Butterfield, Luton

Beds, LU2 8DL, UK.

Tel: + 44 (0)1582 723633 Fax: + 44 (0)1582 422283

www.mtl-inst.com

© 2016 Eaton

All Rights Reserved

Publication No. INS MTL GIR6000 Rev 2 141116

November 2016

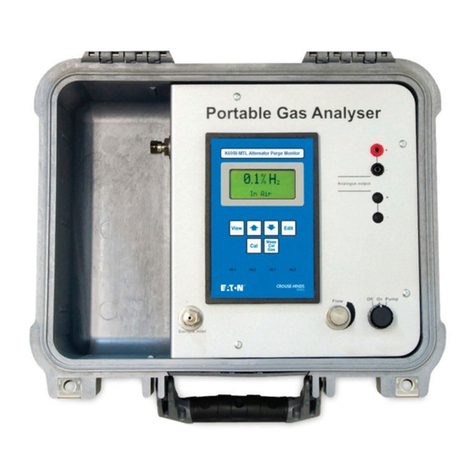

MTL GIR6000 replacement modules

November 2016

MTL GIR6000 replacement modules

November 2016

2 2

NOTE

Before ANY module is inserted into a position on the inner

door, ALWAYS check the O-ring seals for any sign of damage;

replace any that appear to show signs of damage or wear. It

is also good practice to do a quick visual inspection on the

pins of the module’s multi-way connector to check for any

bent or distorted pins.

Remove any packaging from the new module and, before

inserting it into the door panel, take care to align it with the

guides on each side of the opening. When the guides are

engaged, insert the module gently into the door until the

connectors are encountered then press firmly to engage both

gas and electrical connectors.

Tighten the two bolts with the fingers and then use a

screwdriver to tighten the bolts to a recommended torque of 1.5

Nm – i.e. sufficient to prevent them being unscrewed by hand.

Leak Testing

It is now necessary, following any module replacement, to

perform a Module Leak Test. All leak-testing procedures are

described in the MTL GIR6000 Instruction Manual (Section 7.4.

Leak-testing)

ATEX Safety Instructions for

MTL GIR6000 sensor, pump & filter modules

The replacement modules form part of the certification of the

MTL GIR6000 and are not separately certified. Refer to the

certificate and instructions of the MTL GIR6000 for full details.

The following information is in accordance with the Essential

Health and Safety Requirements (Annex II) of the EU

Directive 94/9/EC [the ATEX Directive - safety of apparatus]

and is provided for those locations where such requirements

are applicable.

General

a) This module must only be installed, operated and maintained

by competent personnel. Such personnel shall have

undergone training, which included instruction on the various

types of protection and installation practices, the relevant

rules and regulations, and on the general principles of area

classification. Appropriate refresher training shall be given on

a regular basis. [See clause 4.2 of EN 60079-17].

b) The module is designed for operation in a MTL GIR6000 gas

analyser which is mounted in a Zone 2 hazardous area.

c) This equipment has been designed to meet the requirements

of EN 60079-0 and EN 60079-15.

Installation

a) The installation must comply with the appropriate European,

national and local regulations, which may include reference

to the IEC code of practice IEC 60079-14. In addition,

particular industries or end users may have specific

requirements relating to the safety of their installations and

these requirements should also be met. For the majority of

installations the Directive 1999/92/EC [the ATEX Directive -

safety of installations] is also applicable.

b) The module is designed for operation in a Zone 2 hazardous

area.

c) The removable modules must not be inserted or removed

unless the MTL GIR6000 has been de-energised and isolated

from the sample gas supply.

Inspection and maintenance

a) Inspection and maintenance should be carried out in

accordance with European, national and local regulations

which may refer to the IEC standard IEC 60079-17. In addition

specific industries or end users may have requirements which

should also be met.

b) There are potential electrostatic hazards when cleaning the

equipment. Clean only with a damp cloth

Repair

A module cannot be repaired by the user and must be replaced

with an equivalent certified product – see ‘Disposal’ on this

instruction sheet.

Disposal of modules

Any module removed from this equipment must

not be treated as general waste. By ensuring

that this product is disposed of correctly you

will be helping to prevent potentially negative

consequences for the environment and human

health, which could otherwise be caused by

incorrect waste handling of this product.

For more detailed information about take-back and equipment

recycling visit our website.

NOTE

Before ANY module is inserted into a position on the inner

door, ALWAYS check the O-ring seals for any sign of damage;

replace any that appear to show signs of damage or wear. It

is also good practice to do a quick visual inspection on the

pins of the module’s multi-way connector to check for any

bent or distorted pins.

Remove any packaging from the new module and, before

inserting it into the door panel, take care to align it with the

guides on each side of the opening. When the guides are

engaged, insert the module gently into the door until the

connectors are encountered then press firmly to engage both

gas and electrical connectors.

Tighten the two bolts with the fingers and then use a

screwdriver to tighten the bolts to a recommended torque of 1.5

Nm – i.e. sufficient to prevent them being unscrewed by hand.

Leak Testing

It is now necessary, following any module replacement, to

perform a Module Leak Test. All leak-testing procedures are

described in the MTL GIR6000 Instruction Manual (Section 7.4.

Leak-testing)

ATEX Safety Instructions for

MTL GIR6000 sensor, pump & filter modules

The replacement modules form part of the certification of the

MTL GIR6000 and are not separately certified. Refer to the

certificate and instructions of the MTL GIR6000 for full details.

The following information is in accordance with the Essential

Health and Safety Requirements (Annex II) of the EU

Directive 94/9/EC [the ATEX Directive - safety of apparatus]

and is provided for those locations where such requirements

are applicable.

General

a) This module must only be installed, operated and maintained

by competent personnel. Such personnel shall have

undergone training, which included instruction on the various

types of protection and installation practices, the relevant

rules and regulations, and on the general principles of area

classification. Appropriate refresher training shall be given on

a regular basis. [See clause 4.2 of EN 60079-17].

b) The module is designed for operation in a MTL GIR6000 gas

analyser which is mounted in a Zone 2 hazardous area.

c) This equipment has been designed to meet the requirements

of EN 60079-0 and EN 60079-15.

Installation

a) The installation must comply with the appropriate European,

national and local regulations, which may include reference

to the IEC code of practice IEC 60079-14. In addition,

particular industries or end users may have specific

requirements relating to the safety of their installations and

these requirements should also be met. For the majority of

installations the Directive 1999/92/EC [the ATEX Directive -

safety of installations] is also applicable.

b) The module is designed for operation in a Zone 2 hazardous

area.

c) The removable modules must not be inserted or removed

unless the MTL GIR6000 has been de-energised and isolated

from the sample gas supply.

Inspection and maintenance

a) Inspection and maintenance should be carried out in

accordance with European, national and local regulations

which may refer to the IEC standard IEC 60079-17. In addition

specific industries or end users may have requirements which

should also be met.

b) There are potential electrostatic hazards when cleaning the

equipment. Clean only with a damp cloth

Repair

A module cannot be repaired by the user and must be replaced

with an equivalent certified product – see ‘Disposal’ on this

instruction sheet.

Disposal of modules

Any module removed from this equipment must

not be treated as general waste. By ensuring

that this product is disposed of correctly you

will be helping to prevent potentially negative

consequences for the environment and human

health, which could otherwise be caused by

incorrect waste handling of this product.

For more detailed information about take-back and equipment

recycling visit our website.