Operating and Maintenance Instructions

210-OMI12422_Iss3.doc ORIGINAL INSTRUCTIONS Page 3 of 9

ebm-papst UK Ltd, 2012

Chelmsford Business Park Chelmsford Essex CM2 5EZ

Telephone: +44(0)1245468555 Fax: +44(0)1245466336

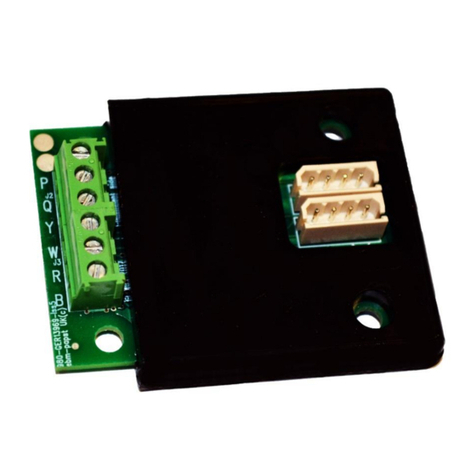

CN1083

Control Connector Two, J3

Filter Maintenance Relay, Contact A

Filter Maintenance Relay, Contact B

Select Input 3, Volt Free Contacts

0V for Low/High fan speed

ummer Bypass Relay, Normally Open Contact

Summer Bypass Relay, Common Contact

Summer Bypass Relay, Normally Closed Contact

Fan Compatibility

Fan Speed control outputs compatible with EC 0-10V or Open Collector PWM speed controlled fans, 2kHz PWM,

maximum of 12 EC Fans per 0-10V output.

Tachometer / Relay input compatible with Open Collector tachometer or Relay Alarm fans.

Mechanical Outline

Enclosure 180(L) x 94(W) x 57(H), transparent lid for LED visibility, fixing centres 165 x 79mm

PCB 157mm x 71mm, Hole centres 146 x 60mm. Height 31mm max.

LED Identification LED “Fan1” and “Fan2” Run and Alarm, indicated by PCB silk screen legend

LED “En” Run Enable and LED “B” Fast, indicated by PCB silk screen legend

LED “FILTER” – filter maintenance LED, indicated by PCB silk screen legend

Trimmer Identification Trimmer indicated by PCB silk screen legend, R1, R2, R3 and R4

IP Rating IP66 with Enclosure.

Cable Glands Not included. Enclosure supplied, has “knock-outs” to suit 16mm or 20mm glands.

Safety

•Installation must be by qualified personnel in accordance with local applicable standards.

•This equipment must be Earthed.

•Access is limited to service personnel only. Live parts accessible when cover removed.

•Residual risk of contact with fan. Maintenance personnel should take due care and attention.

•Complies with Low Voltage Directive 37/23/EEC as amended by 93/68/EEC

•Complies with EN60335-1 - Specification for safety of household and similar electrical appliances

•Connector J1 Terminals SL1 and SL2, and Summer Bypass relay contacts may be live even with the

controller supply disconnected

•EC Fans use Capacitors to store mains voltage. Contact with the mains wiring must be avoided for 5

minutes following supply disconnection.

•If the Summer Bypass relay is used to switch mains voltage then the controller 0V should be connected to

Protective Earth and the supply should incorporate a residual-current circuit breaker.

EMC Compliance

BS EN61000-6-3:2007 (emissions), BS EN61000-6-2:2005 (immunity)

Radiated Emissions BS EN55022:2006, Class B, Radiated Immunity EN61000-4-3:2002 +A1+A2

Fast Transient Bursts EN61000-4-4:2004, Conducted Immunity EN61000-4-6:2007