Features

Support 4-channel digital isolation input, default dry contact;

Support 4-way relay output, support 3A 30VDC and 3A 250VAC;

Adopt Modbus RTU protocol for data processing;

Command reset is supported. After sending the AT+RESTORE\r\n command to the 485 serial port

within 3S after power on, the Modbus device address, RS485 serial port baud rate and check bit are

restored to factory settings;

Support pulse counting, which can be configured as rising edge counting, falling edge counting and

level counting

Hardware watchdog with high reliability;

Three indicators display the working status;

The power supply has good over-current, over-voltage, anti reverse connection and other functions;

Wide voltage input 8V-28V. 12V or 24V is recommended.

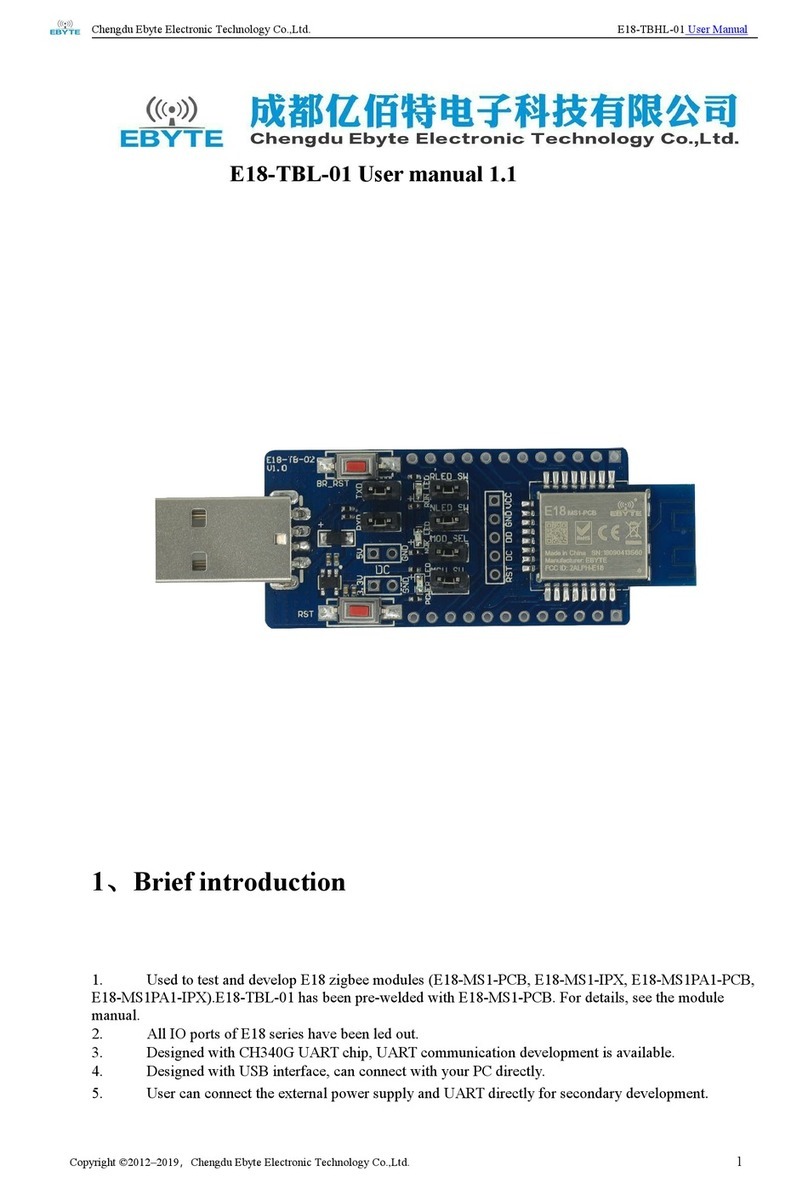

1.Quick start

This chapter is a quick introduction to E831-RTU(4040R-485) series products. It is recommended that

users systematically read this chapter and operate it according to the instructions. They will have a

systematic understanding of the module products. Users can also choose the chapter you are interested in to

read according to their needs. For specific details and instructions, please refer to the following chapters.

1.1.

Port connection

1.1.1 RS485 connection

Note: when the 485 bus high-frequency signal is transmitted, the signal wavelength is shorter than the

transmission line, and the signal will form a reflected wave at the terminal of the transmission line,

interfering with the original signal. Therefore, it is necessary to add a terminal resistor at the end of the

transmission line, so that the signal will not be reflected after reaching the end of the transmission line. The

terminal resistance should be the same as the impedance of the communication cable, with a typical value of

120 ohms. Its function is to match the bus impedance and improve the anti-interference and reliability of

data communication.

1.1.1 Switch input connection