3

Cleaning the spray tip

1. If the spray tip clogs while spraying shut off pump and relief paint

pressure.

2. Loosen the retaining nut, for the spray tip, and release pressure slowly

before removing completely.

3. Then remove spray tip and put it in solvent.

4. Blow obstruction out with air from front of spray tip, or let it soak

long enough to dissolve the particle.

5. If it won’t dissolve, clean it with a Ecco cleaning broach from front

of spray tip.

Always remove spray tip from gun to clean it.

Be very careful when removing spray tip or hose from gun.

The pump must be switched off and paint pressure relieved.

A plugged high pressure hose contains fluid under high

pressure. Loosen tip retaining nut or hose coupling slightly and

release slowly before removing completely.

WARNING

Trouble shooting

Introduction

Always commence troubleshooting by checking the general condition

of the spray gun. This can most easily be determined by test spraying,

which provides an opportunity for checking the spray pattern and capacity

and gasket leakage.

The following external factors can cause malfunctioning and should be

thoroughly checked:

1. The quality of the paint, i.e. its viscosity, purity. etc.

2. The paint pressure in relation to viscosity of the paint and

spray tip used.

3. The size of paint hoses.

Trouble shoouting chart (see the last page)

Types of problems

Collection of information which makes it possible to identify the error

symptoms applicable to the spray gun in the event of malfunctioning

is a matter of vital importance. Identification of symptoms makes it

possible to decide whether the spray gun itself is the direct cause of the

malfunctioning or if this may have been caused by an external factor.

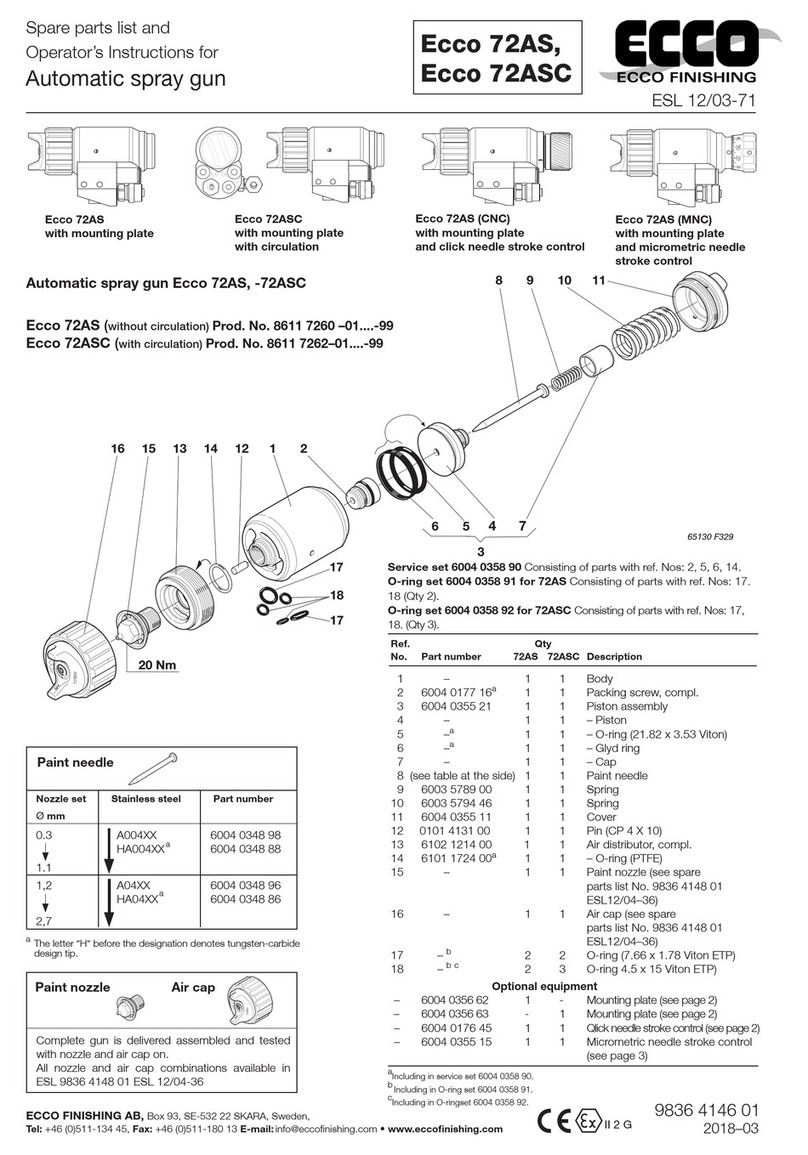

Replacement of fluid needle and fluid needle

gaskets

Removal

1. Shut off pump and relief paint pressure.

2. Undo the two screws (19).

3. Remove the servo part (14) by screwing out the back head (15).

4. Unscrew the sealing element (4).

5. Withdraw fluid needle (12) and take away the washer (5).

6. Unscrew the guide bushing (11).

7. Press the packing set out with the aid of the 5-mm pinprovided in the

tool set. Note! Take care to avoid damaging the outside diameter of

the packing screw (10) which is a sealing surface. Use the flats of the

packing screw when clamping between the jaws of a vice.

8. Clean and inspect all parts.

Assembly

All moving parts must be lubricated

1. Mount the packing set on the fluid needle (12) in the following order:

The washer (5), the guide (6), the packings (7) with the o-rings (8)

and finally the sleeve (9). Note! The packings (7) are to be fitted with

the tip of the Vee facing away from the valve cone in the fluid needle.

2. Screw the assembled sealing element (4) into the gun body.

3. Drip a little oil onto the sealing surface of the packing screw and mount

the servo part (14).

4. Secured the fluid needle with the two lock screws (19).

Replacement of fluid needle only

1. Unscrew the retaining ring (29) and remove the spray tip (28) together

with its gasket (27)

2. Uns crew the fluid nozzle (3) with its gasket (2).

3. Undo the lock screws (19) and pull the fluid needle (12) out from the

front.

4. Insert a new fluid needle and tighten the lock screws (19).

5. Fit the fluid nozzle (3) and spray tip (28). Don’t forget to refit the gaskets

(2 and 27).

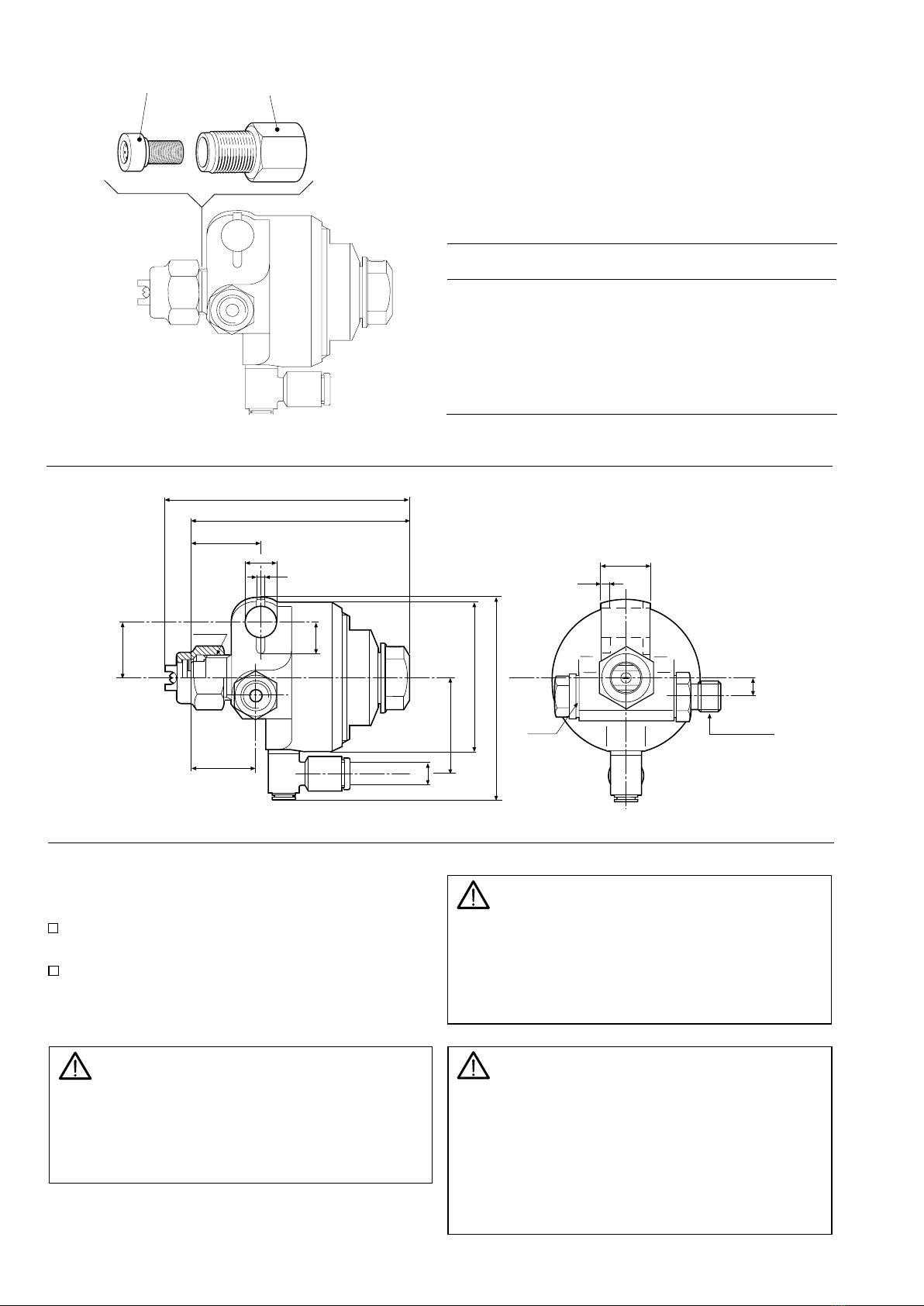

• Max. fluid pressure 360 bar.

• Fluid hose connection 1/4-18 NPSM.

• Min./Max. control air pressure 4/8 bar.

•Control air tube connection is elbow coupling for 6/8 mm nylon tubing.

• Blow the fluid and air tube clean before connecting them.

• When assessing the reaction time of the connected spray gun

(the time from the start impulse until spraying commences) the

reaction time of the control valve must be taken into consideration.

•Recommended sizes for control valve and air hoses:

– Control valve, 3-way, G1/4. Min. flow area 28 mm2.

Mechanically, pneumatically or electrically actuated.

– Air hose, nylon, dia. 6/8 mm, max. Iength 7.5 m for control air.

• To prevent the fluid hose from getting stuck on account of dried

paint, it is recommended that the connection threads be greased

with vasseline or a similar lubricant.

• Take great care to keep the spray gun clean and to lubricate all

moving parts at regular intervals.

• Lubricants for paint spraying equipment must not contain silicones.

• Check that all connections are tight.

• If the gun does not work satisfactorily it must on no account be used.

Repair or replace it immediately.

Paint spraying

Advice on high-pressure spraying

1. Consult your paint supplier for information to choose the correct

spray tip for the actual paint.

2. As rule the best spraying distance is 30-40 cm.

3. The spray passes do not need to overlap as much as in spray painting

with air atomization.

4. The capacity of high pressure spraying is very large. To avoid runs, the

spray gun should usually be moved faster than in spray painting

with air atomization.

Maintenance

The entire spray gun gun should be cleaned at the end of each working

day. The spray tip should be cleaned more frequently.

Wipe the spray gun thoroughly clean on outside and clean it internally by

flushing a suitable solvent through it.

More extensive cleaning and overhauling should be carried out at least

once a month, depending on the material being sprayed.