3

aLoctite No. 225. b Loctite No. 243. c Not for plastic paint nozzle. d Set of 10. eSold singly. f Set of 5. g

Including in service set.

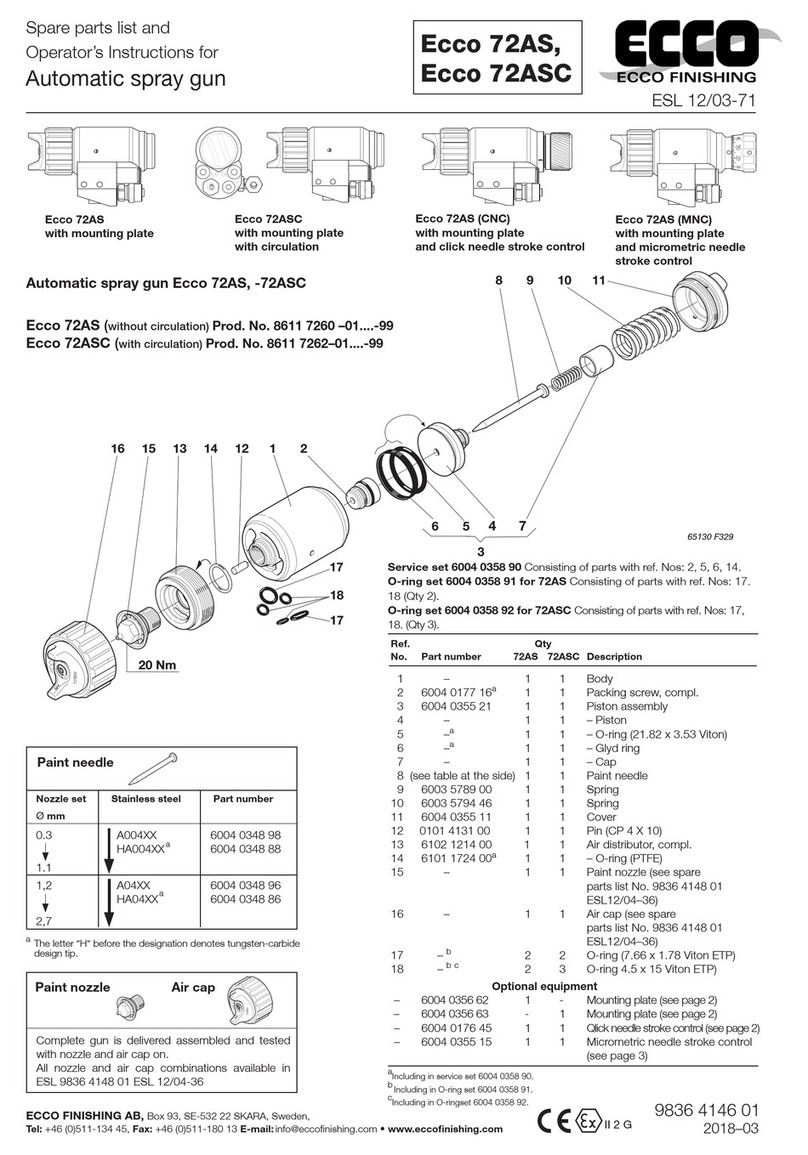

Ref. Qty

No. Part number Description

Part numbers in bold type designate consumption parts.

Service set 6003 9095 00 for Ecco 65S, -651S, -652S

Consists of parts with ref. Nos. 2, 3 (Qty 1), 7, 10, 11, 19, 20, 22, 23,

25, 27, 29 and 31.

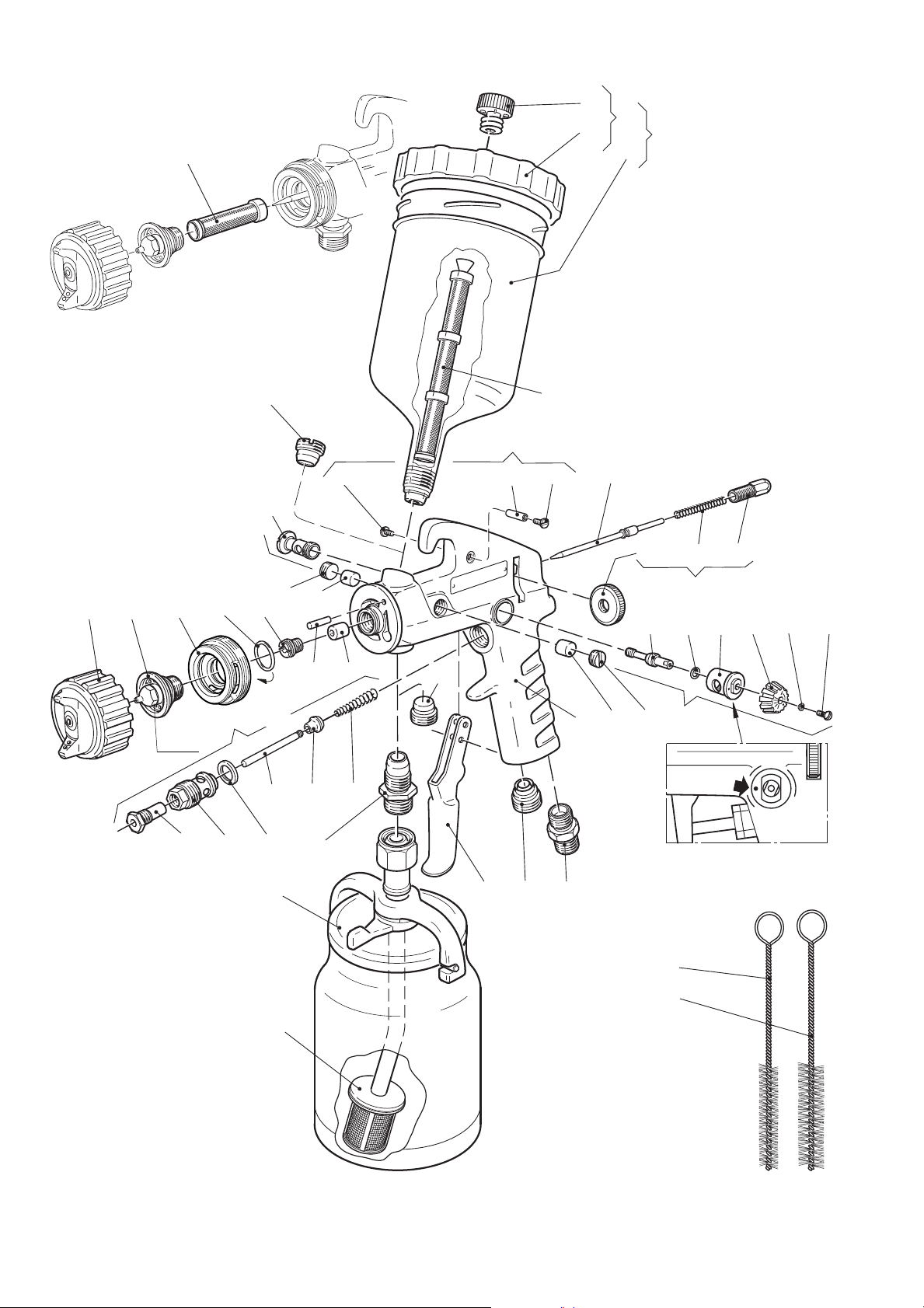

1 – 1 1 1 Gun body

2 6102 2401 00g1 1 1 Packing set

3 6000 8369 00g2 2 2 Packing screw (stainless steel)

4 6101 5100 00 1 1 1 Fan width control, compl.

5 6101 3788 00 1 1 1 – Valve screw

6 6101 3790 00 1 1 1 – Valve pin

7 6101 3796 00g1 1 1 – O-ring

8 6101 3789 00 1 1 1 – Valve housing

9 6101 3648 00 1 1 1 – Wheel

10 0333 5109 00g1 1 1 – Lock washer (V 3.2)

11 0164 5013 00g1 1 1 – Screw (MKFS 3 x 6 SS A2)

12 (see page 4) 1 1 1 Paint needle

13 6000 9191 80 1 1 1 Back head, compl.

14 6000 9191 00 1 1 1 – Back head

15 6101 2582 00 1 1 1 – Spring (3.4 kg)

16 6000 7764 00 1 1 1 – Wheel

17 6101 2796 00 1 1 1 Trigger (stainless steel)

18 6101 2990 80 1 1 1 Shaft, coml.

19 6101 2990 00g1 1 1 – Shaft (stainless steel)

20 0164 5013 91g2 2 2 – Screw (MSCS A4-70 3 x 6

stainless steel)

21 6101 5730 00 1 1 1 Air valve, compl.

22 6101 2111 00g1 1 1 – Spring

23 6101 5008 00g1 1 1 – Air valve

24 6101 3631 00 1 1 1 – Valve pin

25 6001 1008 00g1 1 1 – Packlng

26 6003 2167 00 1 1 1 – Valve housing

27 6101 5716 00g1 1 1 – Bushing

28 0101 4131 00b1 1 1 Pin (CP 4h6 x 10 S )

29 6103 3112 00g1 1 1 Screw (stainless steel)

30 6102 1214 00 1 1 1 Distribution ring with O-ring

31 6101 1724 00g1 1 1 – O-ring

32 (see page 4) 1 1 1 Paint nozzle

33 (see page 4) 1 1 1 Air cap

34 6001 2619 00a1 1 1 Nipple (G 1/4)

35 6101 5560 00 – – 1 Paint cup Ecco G 5, compl.

36 6101 5561 00 – – 1 – Paint cup (G 3/8) volume 0.5 l

37 6101 5559 00 – – 1 – Cover, compl.

38 6003 9094 00 – – 1 – – Cover

39 6003 9068 00 – – 1 – – Plug (Drip guard)

40 6003 9974 00 1 1 – Plug (G 3/8)

41 6101 3742 00 – – 1 Plug (M14 x1)

42 6101 5021 00 1 1 – Nipple (G 3/8 stainless steel)

43 6101 5626 00 1 1 1 Plug (G 3/8 )

44 6003 9714 00 – 1 – Suction cup Ecco SD 15,

volume 1 l (see spare parts list

No. 9836 3175, ESL 12/04-20)

45 6000 8004 00 1 1 1 Cleaning brush (ø10 mm)

46 6000 8001 00 1 1 1 Cleaning brush (ø17 mm)

47 (see optional 3 3 – Strainer 100 mesh

equipment)

48 (see optional – – 1 Strainer 100 mesh (yellow)

equipment)

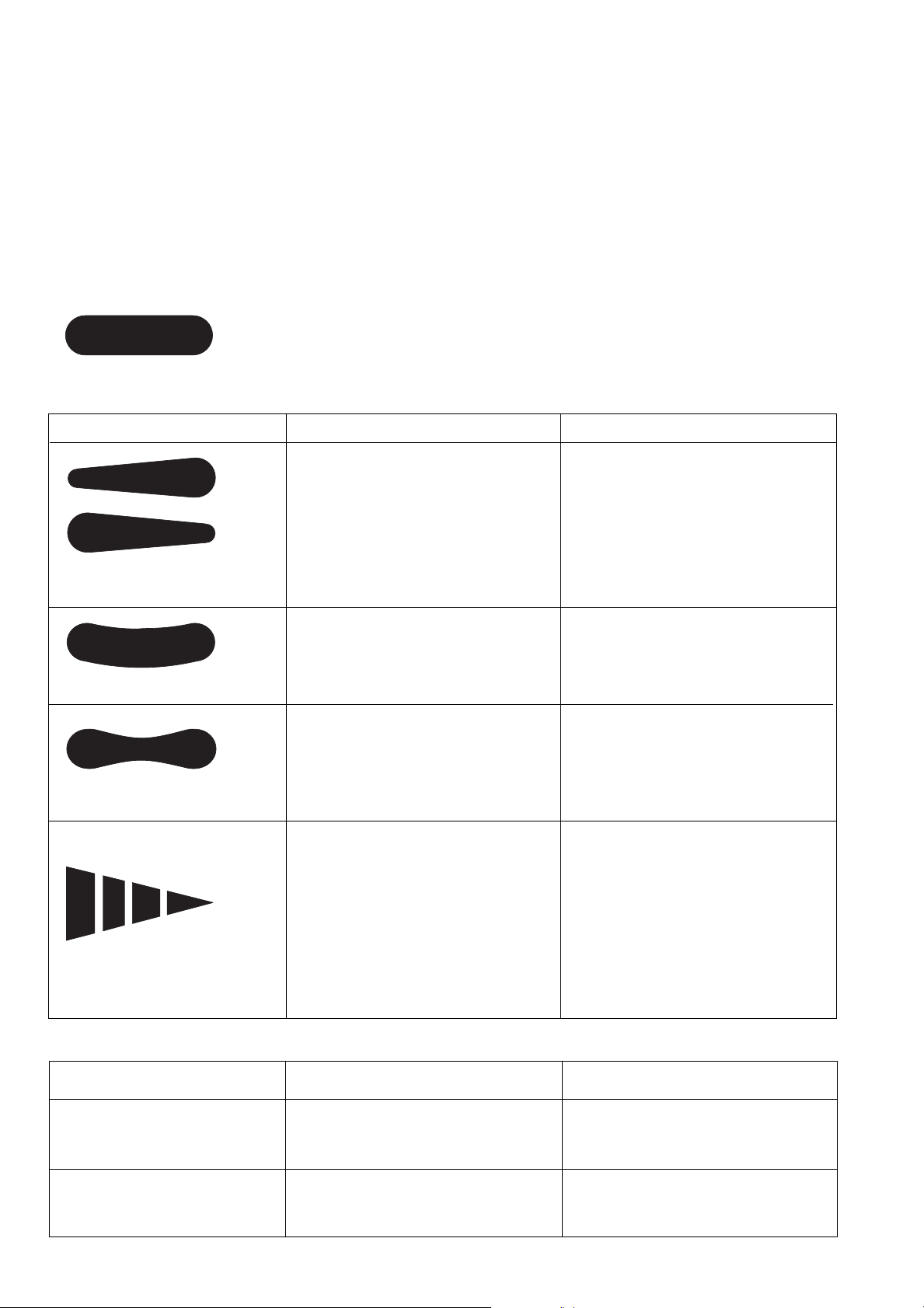

Optional Equipment

-65S -651S -652S -65S -651S -652S

Ref. Qty

No. Part number Description

– 6101 6065 00 1 1 1 Retaining ring, acetal plastic

(for air cap)

4 6101 9230 00 1 1 1 Fan width control for left

handed

4 6003 9602 00 1 1 1 Quick fan width control

15 6101 2582 65 1 1 1 Spring, soft (2.7 kg)

15 6001 2036 00 1 – – Spring, stiff (6.4 kg)

30 6102 1215 00 1 1 1 Distribution ring, compl.

(stainless steel threads)

34 6000 1877 00 1 1 1 Air inlet nipple (9/16" 20G)

34 6002 0233 00 1 1 1 Air inlet nipple (1/4" 18 NPSM)

35 6101 5560 95 – – 1 Paint cup Ecco G 1.25,

volume 0.125 l

42 6003 7393 00 1 – – Paint inlet nipple (9/16" 20G

stainless steel)

44 6003 9714 00 1 – – Suction cup Ecco SD 15,

volume 1 l

44 6003 9676 00 1 1 – Suction cup Ecco SD 15T,

volume 1 l (inside coated with

teflon)

44 6803 4867 00 1 1 – Suction cup Ecco SD 10,

volume 1 l

47 6103 3200 00c1 1 1 Strainer setd60 mesh (white)

47 6103 3201 00c1 1 1 Strainer setd 100 mesh (yellow)

47 6103 3202 00c1 1 1 Strainer setd200 mesh (black)

47 6103 1088 00c1 1 1 Strainere300 mesh (red)

48 6003 9754 05 – – 1 Strainer setf60 mesh (white)

48 6003 9752 05 – – 1 Strainer setf100 mesh (yellow)

49 6003 7886 00 – 1 – Strainer setd 80 mesh

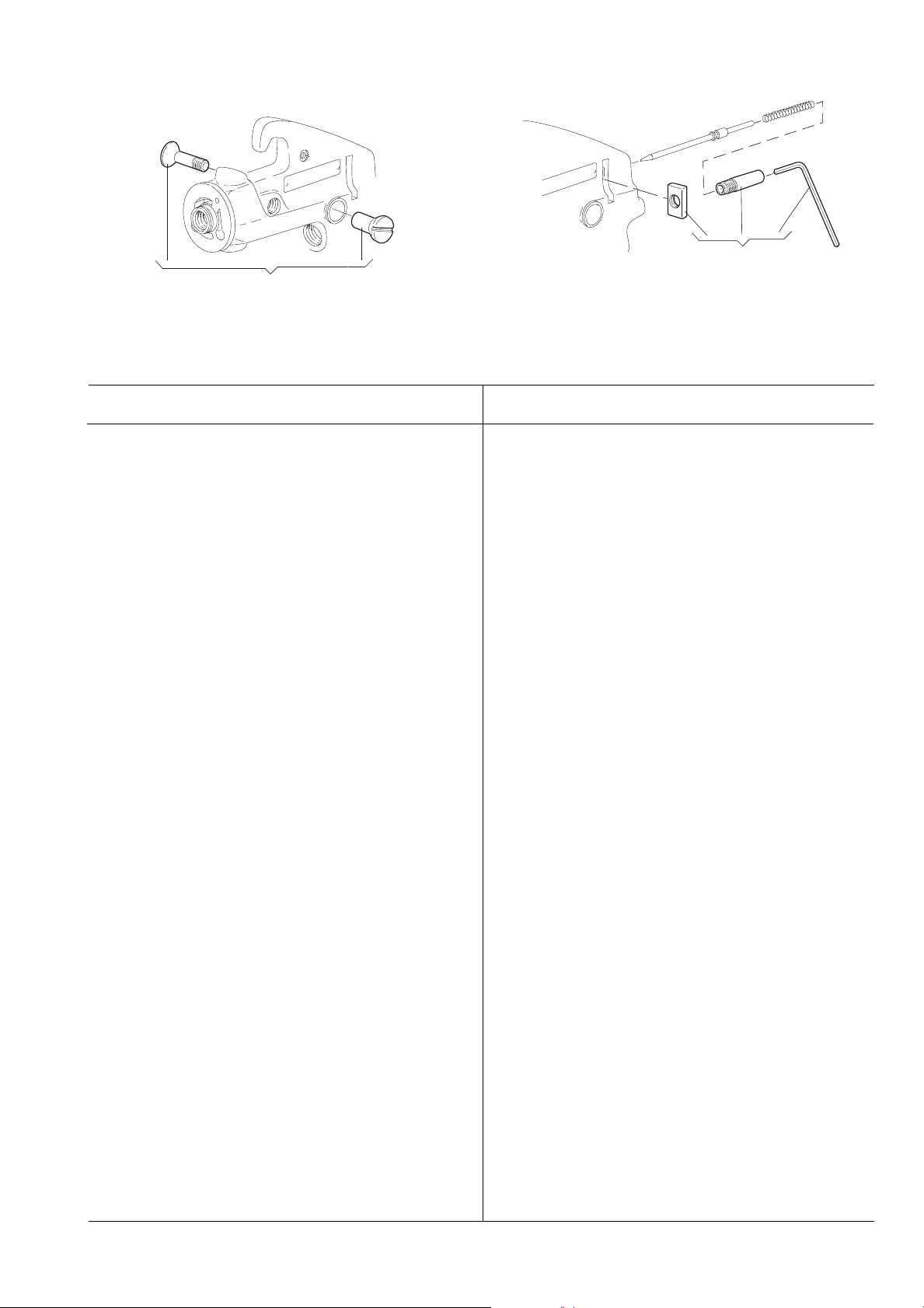

50 6101 5247 80 1 1 1 Plug set, for gun is not fitted

with fan width control

51 6102 1203 80 1 1 1 Back head, lockable fluid

volyme control

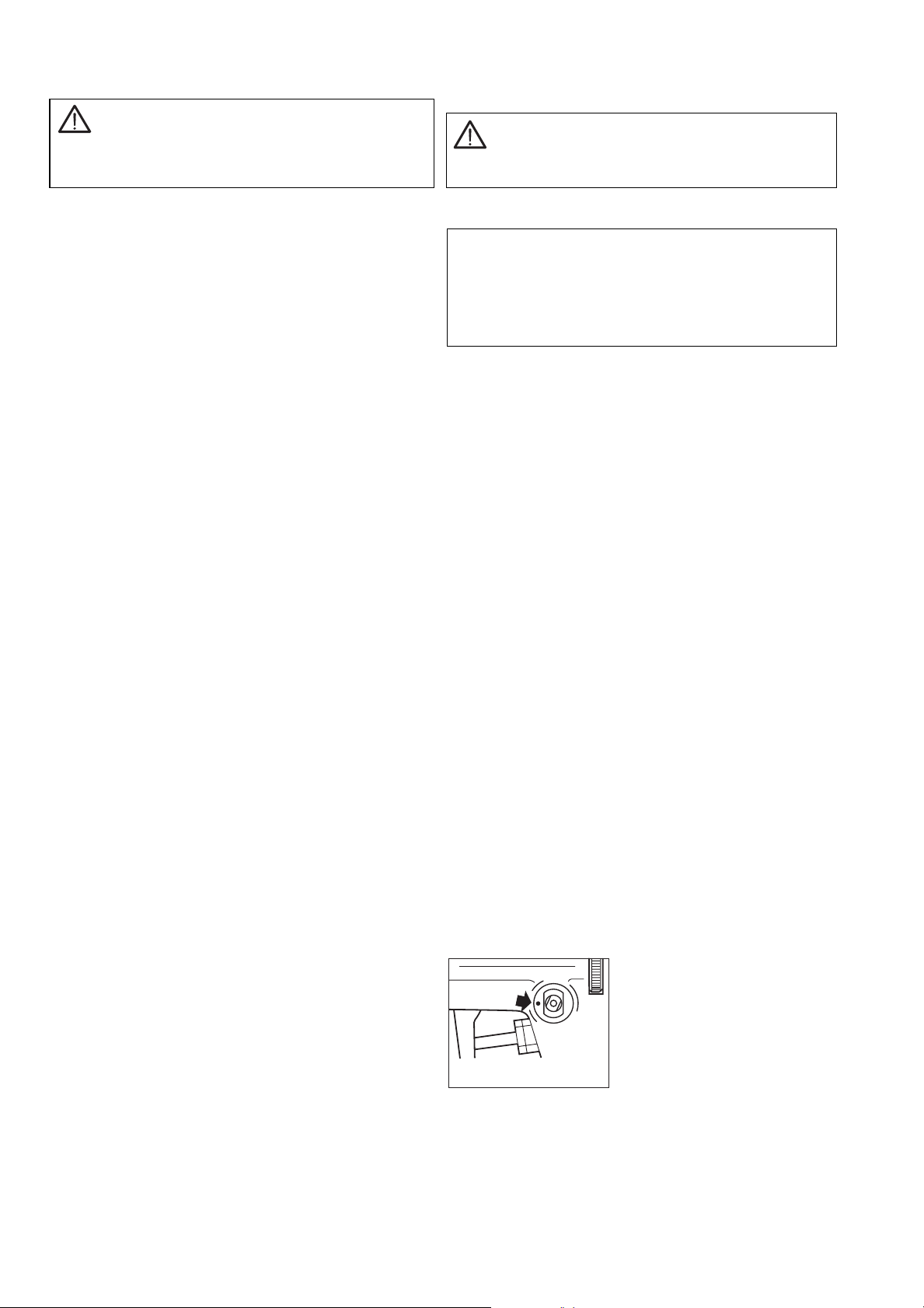

– 6003 9249 00 1 1 1 Testing air pressure gauge

(incl. connection parts, excl.

testingaircap)

– 6003 9249 09 1 1 1 Testing air cap 6509

– 6003 9249 11 1 1 1 Testing air cap 6511

– 6003 9249 14 1 1 1 Testing air cap 6514

– 6003 9249 18 1 1 1 Testing air cap 6518

– 6003 9249 21 1 1 1 Testing air cap 6521

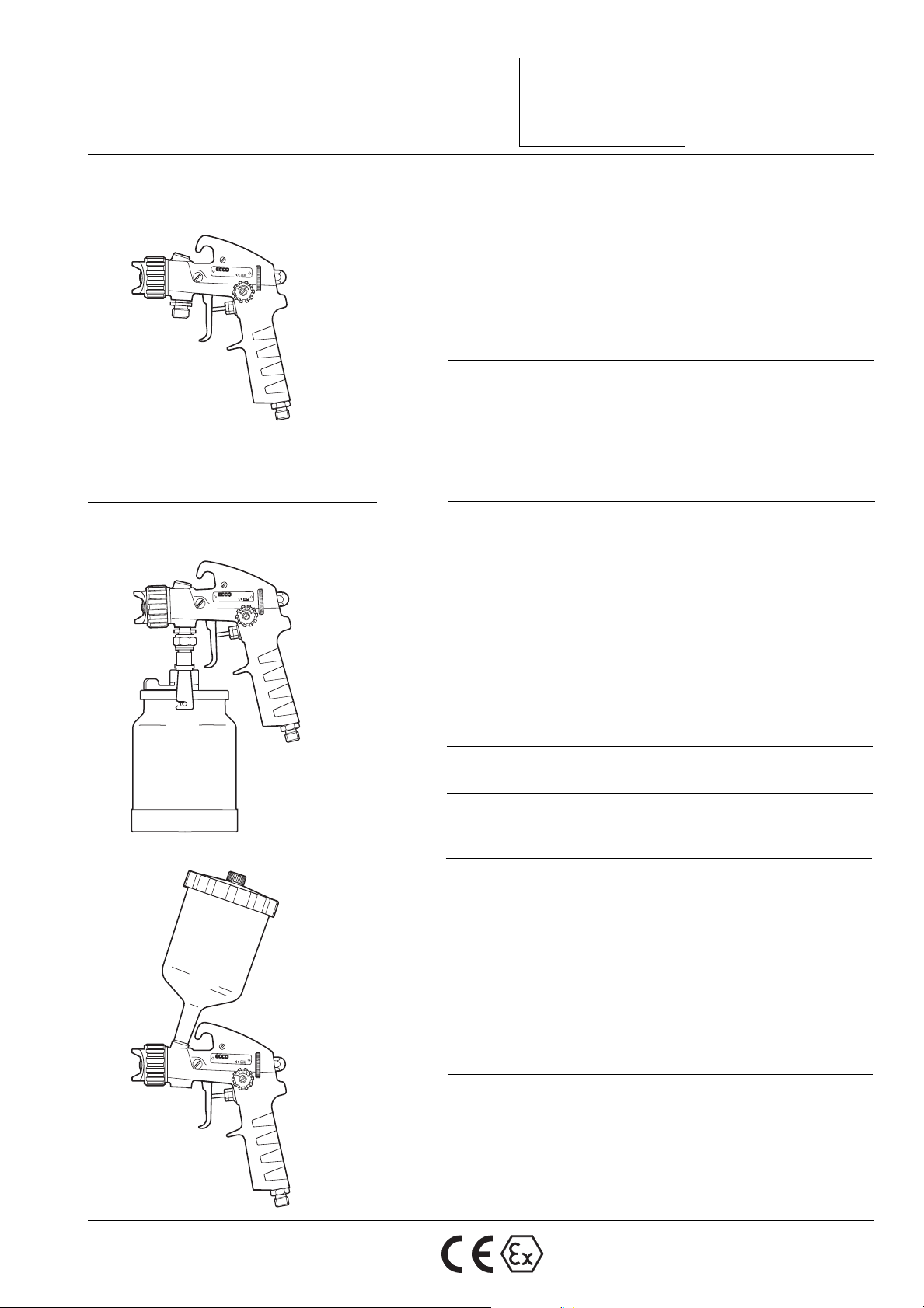

65130 F287 65130 F288

50

51