<<Range of Application of this equipment>>

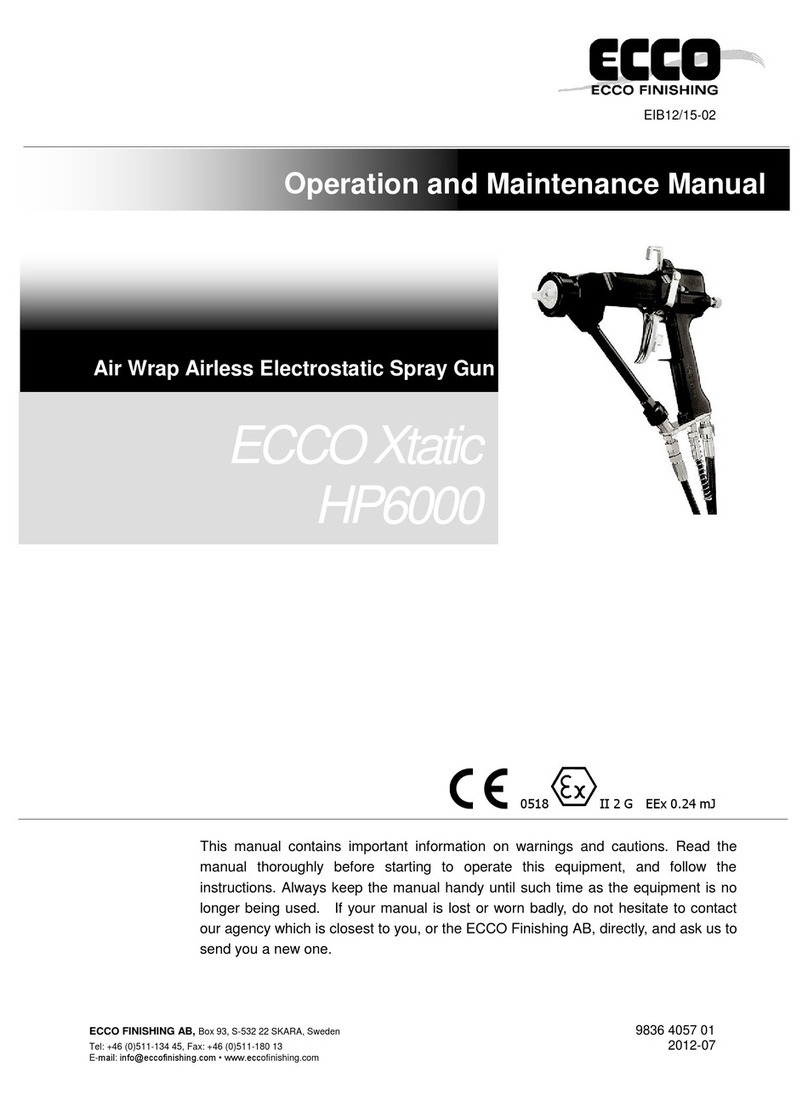

Equipment covered by this Instruction Manual are electrostatic hand spray guns, Model

LP6000W/S/M which are to be used for manual paint spraying in a spray booth equipped with a

power exhaust.

This equipment is a manually operated spray gun used to apply paint to a grounded object.

If there is any question or if these instructions are not perfectly understandable, please consult

our distributor or contact a representative of ECCO Finishing AB for clarification.

The use of this equipment for any purpose other than that for which it is intended could cause

serious consequences.

<<CAUTIONS When Using the Painting Equipment>>

1. The object to be painted should be grounded without fail. Always use a conductive hanger.

Periodical cleaning should be performed so as to maintain conductivity.

2. All conductors or thinner container in the coating booth should be grounded. The structure of

the floor should have a preventive structure for static charge of 1M ohm or less.

3. The applicable area for the working floor of the open structure-coating booth is a rectangle

shaped area with a side of 1.5m (opening width + both sides) and the other side of 2.5m

(closer side of the opening part). This entire area should have a static charge preventive

structure of 1 M ohm. The area should be clean.

4. Operators should use bare hands or ware non-conductive gloves during operation.

5. Operators should ware the anti-electrostatic protective footwear.

6. Ventilation should properly be ensured during coating.

7. Fluid pressure and air pressure should be zero, and power switch of the control panel should

be turned off before the nozzle is washed. Do not touch nozzles during high voltage is

charged.

8. Do not use the metal brush for washing nozzles.

9. Do not immerse guns and hoses in the washing solvent.

10. Hoses should be hanged from the ceiling or side walls instead of being trailed on the floor.

11. Duct fan of the coating booth should always be cleaned to maintain cleanliness.

12. Distance between the nozzle end and the object to be painted should be 150mm or more.

13. Fire extinguisher should always be provided in the vicinity of the work site for in case of fire

caused by electrostatic.

14. Operator should take a safety-operational lesson regarding the applicable coating

equipment before operation.