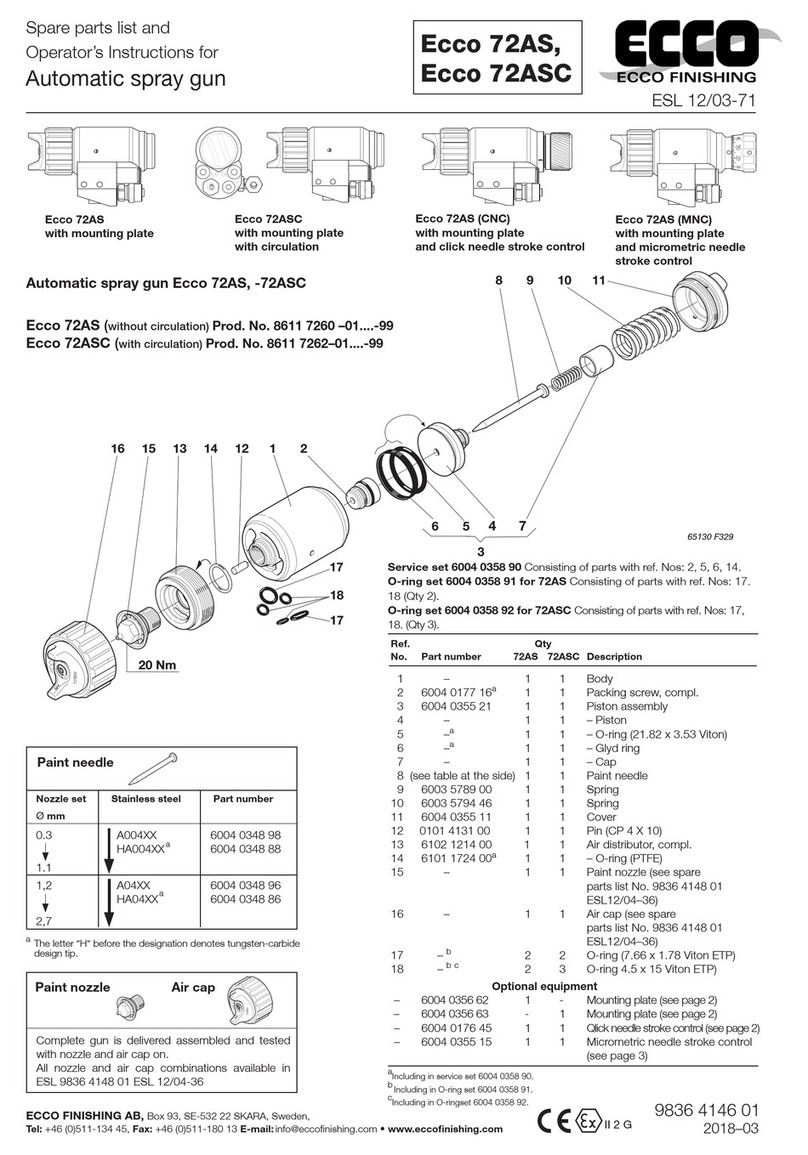

Fig. 2

Connections

For gun with mounting plate 6003 9770 20 for Robot

For gun with mounting plate 6003 9770 35 for Robot

65130 F254-1

5

Operation

•Install and operate the spray gun according to Fig.1, 2, 3 and 3.

•Blow the paint and air hoses clean before connection.

•Check that all connections are tight .

•Keep the spray gun clean and lubricate (waterfree vaseline)

moving parts at regular intervals.

•Lubricants for surface-treatment equipment must not contain

silicon.

• For short standstill periods, for instance over a night, it will

suffice to clean the air and paint nozzles on the outside. If a

two-component paint is used, however, the gun must be flushed

through immediately with solvent. This must also be done if the

gun is to remain unused for a longer period of time.

•When cleaning the air cap and the paint nozzle, use a soft

brush dipped in clean solvent. Do not place the entire gun in

solvent, as the oil on the lubricated parts would be dissolved. Blow

the air cap dry with comressed air from both sides.

•Never use iron or steel wire to clean air holes and ducts in

the nozzles.

•When assessing the reaction time of the connected spray

gun (the time from the start impulse until spraying commen-

ces) the reaction time of the control valve must be taken into

consideration.

• Rec om mend size for control valve:

– Control valve, 3-way, G 1/4. Min. flow area 28 mm2.

Mechanically, pneumatically or electrically actuated.

As the equipment works under pressure the utmost care must

be observed during the work. Bearing this in mind, never aim

the spray gun at a person or towards any part of the body. In

the event of personal injury caused by the spraying pressure,

immediate medical attention is essential. Before carrying out

any adjustment or repair, the equipment must be switched off

and the paint pressure relieved.

WARNING

How to operate

Note:

Valve orifice inside three-way solenoid valve should be minimum

ø 4 mm and also operating air hose length should be within 10 m

with the inner diameter more than ø 6 mm to avoid delayed

operation and any kind of failure.

Recommended paint viscosity differs according to paint properties

and painting conditions. 15 to 23 sec./Ford cup 4 is recommendable.

The gun is operate at low air pressure, high transfer efficiency will not

be obtained if the spray distance is to far.

Set the spray distance from the gun to the work piece as near as possible

within the range of 150-300 mm.

Paint spraying

Inhalation of paint, paint dust and solvent is not healthy. Make

sure an approved spraybooth is used. The operator must use

personal protection-breathing mask or fresh air hood.

CAUTION

Fig. 1 65130 F253-1

Connections (See Fig.1, 2, 3 and 4)

STL-HN (Fig.1 ) Operation air.

Coupling for tube ø 6/8 mm.

STL-HN (Fig.2 ) Operation air.

Coupling for tube ø 4/6 mm.

STL (Fig.3 ) Operation air.

Coupling for tube ø 4/6 mm.

F Paint. Coupling for tube ø 6/8 mm / ø 2.5/4 mm

for mounting plate 6003 9770 35

ZL Atomizing air.

Coupling for tube ø 6/8 mm.

HL Fan air.

Coupling for tube ø 6/8 mm.

RF (Fig.1) Return paint.

Coupling for tube ø 6/8 mm.

RF (Fig.2) Return paint.

Plug G 1/8.

RF (Fig.4) Return paint.

Coupling for tube ø 4/6 mm.

65130 F309-2

Connections

For gun with mounting plate 6003 9770 43 for Robot

with 13 mm guide pin

Fig. 3

Fig. 4

Connections

For gun with connection plate 6003 9770 15

for paint circulation

65130 F256

Connections

For gun with mounting plate 6003 9770 00 for Spraymate