S Återvinning

ECCO Finishing AB jobbar för en hållbarare global miljjö,

därför vill vi att förbrukad produkt återvinns på bästa sätt.

Detta görs lämpligast genom att skicka tillbaka den förbru-

kade produkten till ECCO Finishing AB (paketet märkt med

”Återvinning”), eller om möjlighet finnas att demontera produk-

ten och källsortera delarna enligt gällande föreskrifter.

Retur adress:

ECCO Finishing AB Att. Återvinning

Afsengatan 6532 37 Skara

Sweden

D Recycling

ECCO Finishing AB bemüht sich um nachhaltigen Umgang

mit Ressourcen und Umweltschutz. Deshalb möchten wir

sicherstellen, dass Produkte und Materialien in der best-

möglichen Weise recycelt werden. Deshalb bieten wir die

Möglichkeit der Rücksendung von ‘verbrauchten’ Produkten zum

Recyceln an. Bitte demontieren Sie die Produkte soweit es

möglich ist, und sende diese in einem Paket mit der Kenn-

zeichnung ‘Recycling’ an uns zurück.

Rücksendeanschrift:

ECCO Finishing AB Att. Recycling Afsengatan 6

532 37 Skara Sweden

GB Recycling

ECCO Finishing AB is working for a more sustainable global environme-

nt, that’s why we would like to make sure that the consumed product

is recycled in the best possible way. This is best done by returning the

consumed product to ECCO Finishing AB (package marked with "re-

cycling"), or isible dismantled and recycled according to the applicable

local regulations.

Return address:

ECCO Finishing AB Att. Recycling Afsengatan 6

532 37 Skara

Sweden

FR Recyclage

Ecco Finishing AB réalise des efforts permanents pour la protection de

l’environnement, c’est pourquoi nous voulons nous assurer du meilleur

recyclage possible de nos produits. Il est préférable pour cela de retour-

ner les produits marqués « recyclable » directement à Ecco Finishing,

ou si possible de les recycler sur place dans le respect de la

régulation locale.

Adresse de retour:

ECCO Finishing AB Att. Recycling Afsengatan 6

532 37 Skara Sweden

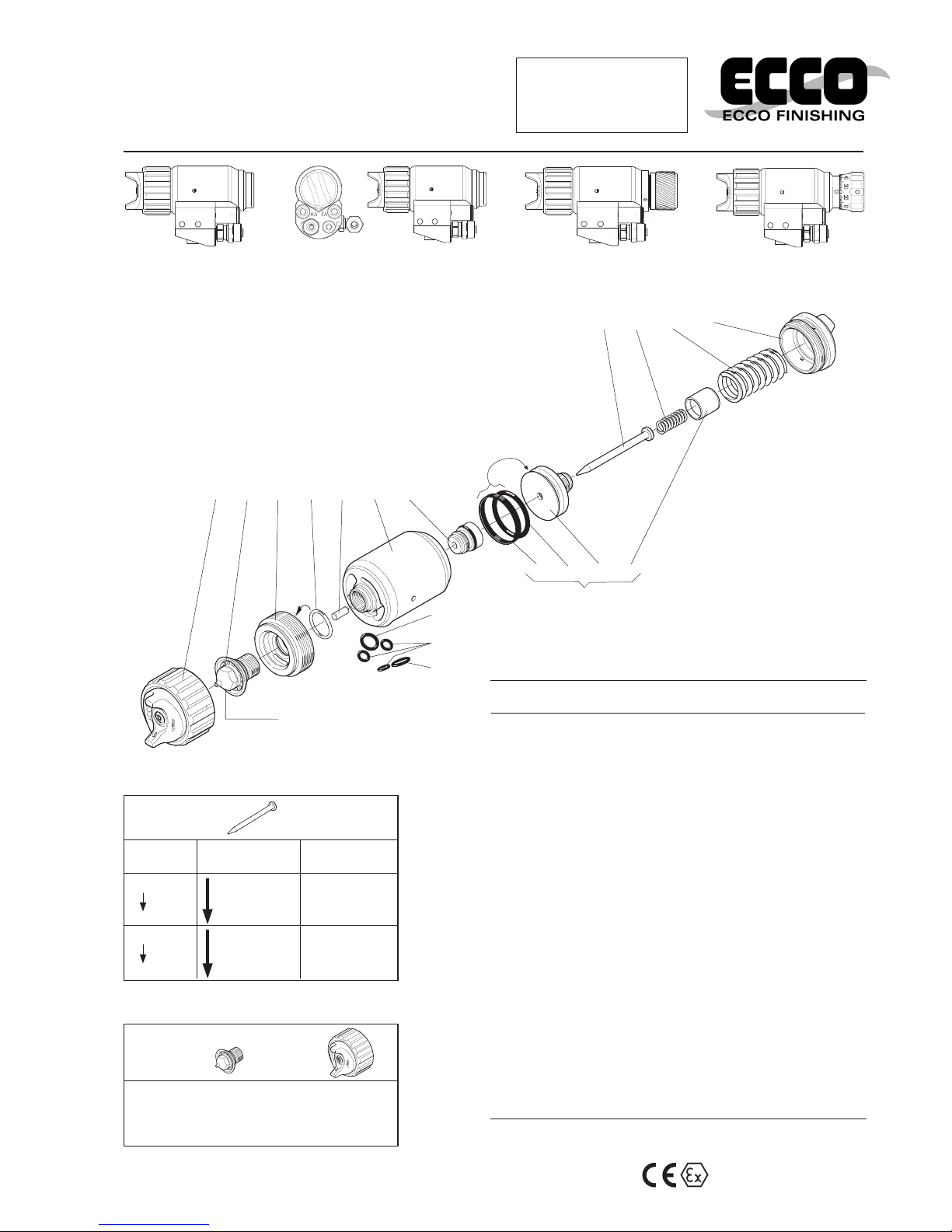

Automatic air spray gun used for spraying of wet

paint under low pressure.

Principal data

Type Max. working Max. flushing Min/.max. air

fluid pressure pressure operation pressure

Ecco bar bar bar

52AS 7 7 4/10

All parts for the gun has been tested and certified for

optimum performance and can only be replaced with

genuine spare parts to maintain the total performance.

Before starting, read through all instructions carefully.

Operators instructions

Important

Do not use halogenated hydrocarbons in coating application

equipment where aluminium or galvanized parts come

in contact with the solvent or coating material.

Halogenated hydrocarbons e.g. 1,1,1-thrichloroethane and

methylene chloride react, violently with such parts, causing

corrosion and danger for explosion.

WARNING

The high velocity flow of air and liquids through hoses and

nozzles may develop static electricity. Be sure that the

equipment, object being sprayed, spraybooth, paint and

waste container are properly grounded to prevent static

discharge or sparks.

WARNING

Operation

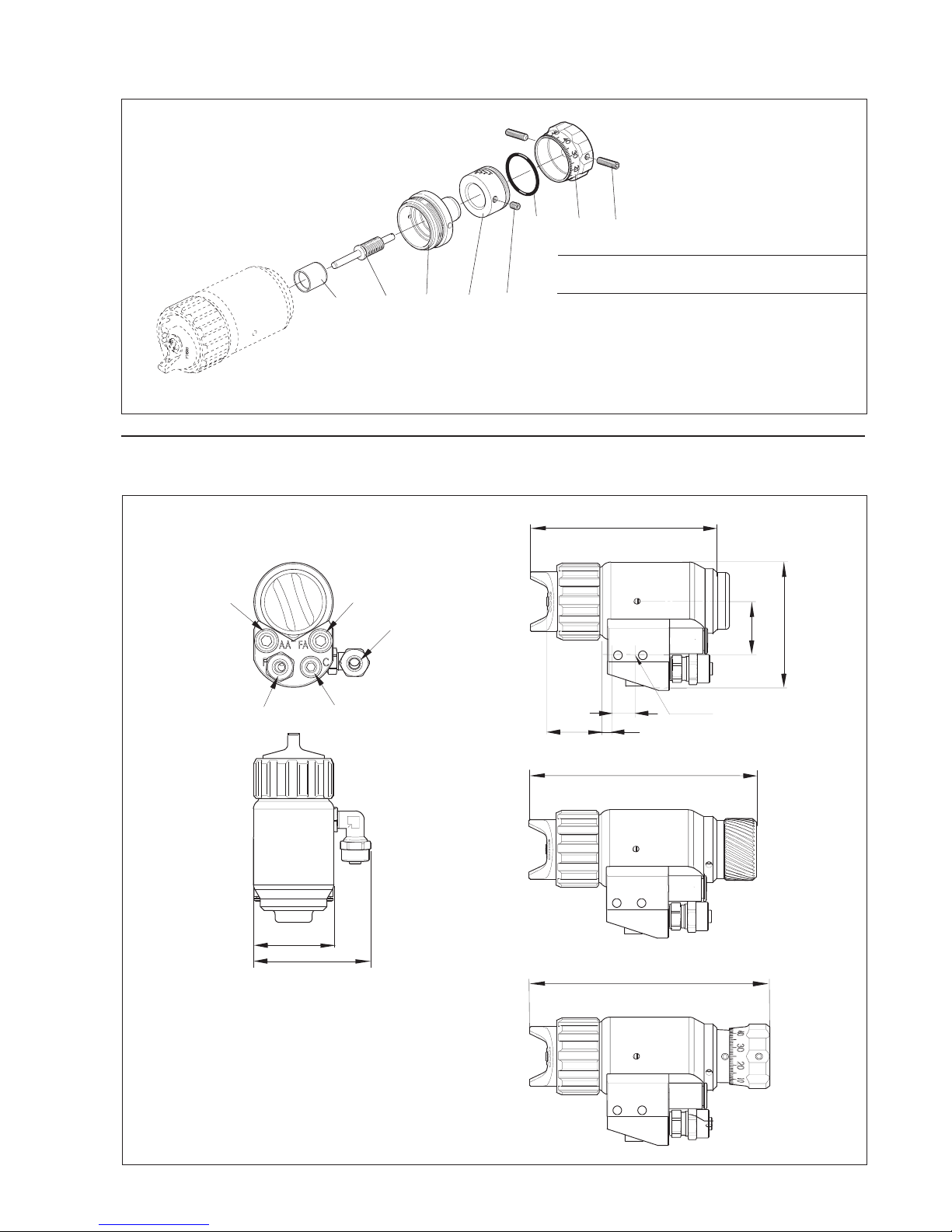

•Install and operate the spray gun according to Fig. Automatic spray

gun Ecco A72AS page 3. Blow the paint and air hoses clean before

connection.

•Check that all connections are tight .

•Keep the spray gun clean and lubricate (waterfree vaseline)

moving parts at regular intervals.

•Lubricants for surface-treatment equipment must not contain

silicon.

• For short standstill periods, for instance over a night, it will

suffice to clean the air and paint nozzles on the outside. If a

two-component paint is used, however, the gun must be flushed

through immediately with solvent. This must also be done if the

gun is to remain unused for a longer period of time.

•When cleaning the air cap and the paint nozzle use a soft

brush dipped in clean solvent. Do not place the entire gun in

solvent, as the oil on the lubricated parts would be dissolved. Blow

the air cap dry with comressed air from both sides.

•Never use iron or steel wire to clean air holes and ducts in the

nozzles.

•When assessing the reaction time of the connected spray gun

(the time from the start impulse until spraying commences) the

reaction time of the control valve must be taken into

consideration.

• Recommend size for control valve:

– Control valve, 3-way, G 1/4. Min. flow area 28 mm2.

Mechanically, pneumatically or electricallyactuated.

As the equipment works under pressure the utmost care must

be observed during the work. Bearing this in mind, never aim

the spray gun at a person or towards any part of the body. In

the event of personal injury caused by the spraying pressure,

immediate medical attention is essential. Before carrying out

any adjustment or repair, the equipment must be switched off

and the paint pressure relieved.

WARNING

Paint spraying

Inhalation of paint, paint dust and solvent is not healthy. Make

sure an approved spraybooth is used. The operator must use

personal protection-breathing mask or fresh air hood.

CAUTION

The spray gun must be earthed to prevent any electrostatic

discharge.

This can be done through the mounting or air/fluid hoses.

A resistance less than 106Ohms is recommended.

WARNING