10

ATV-MX160 Breakdown

Ref # Qty. Part Number Description

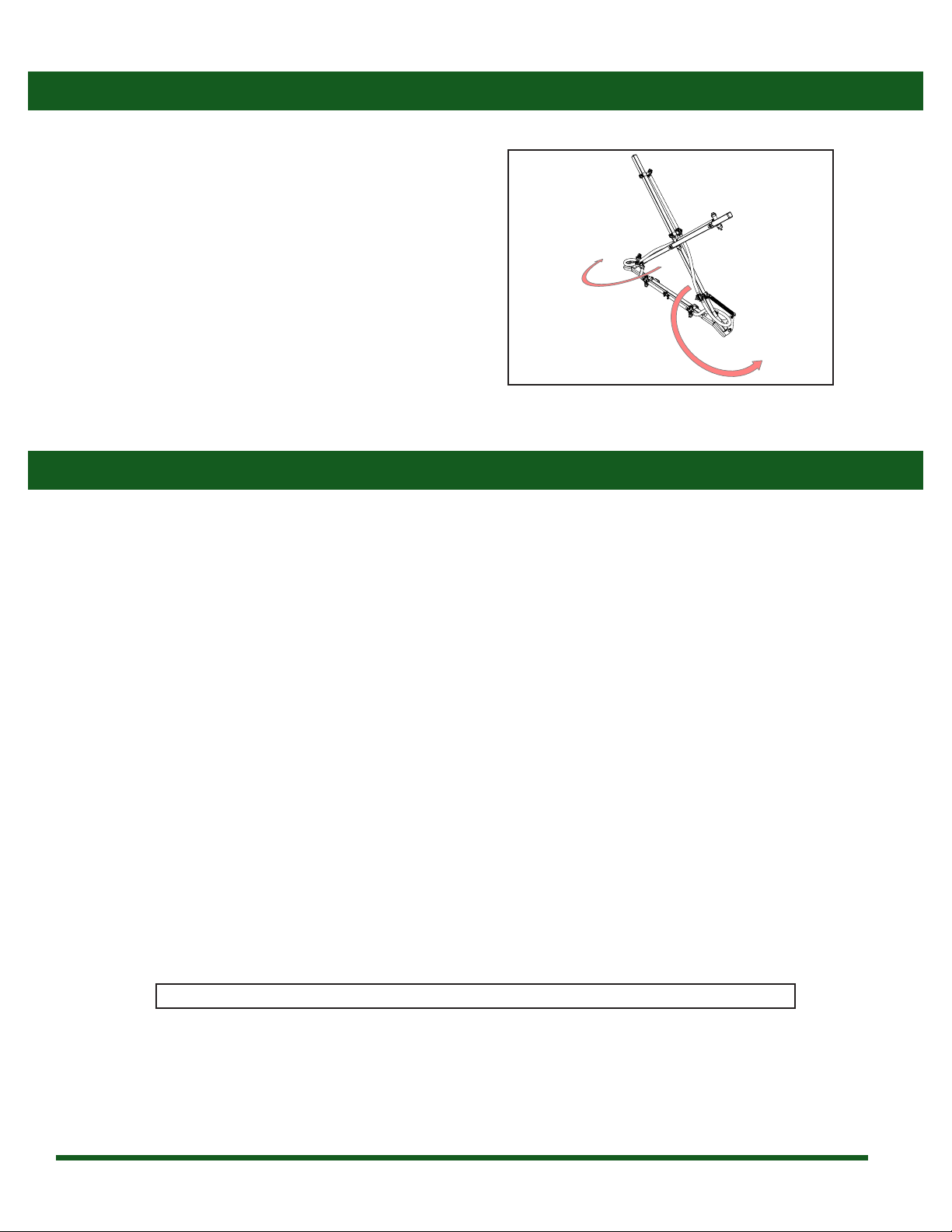

1 12’ 1208 Hose, EPDM Rubber 1/2”200 PSI

2 17 6806052 Hose Clamp, 1/2”- 19/32” SS

3 2 22251311500NYB * Body, Nozzle Elbow 1/2”QJ300

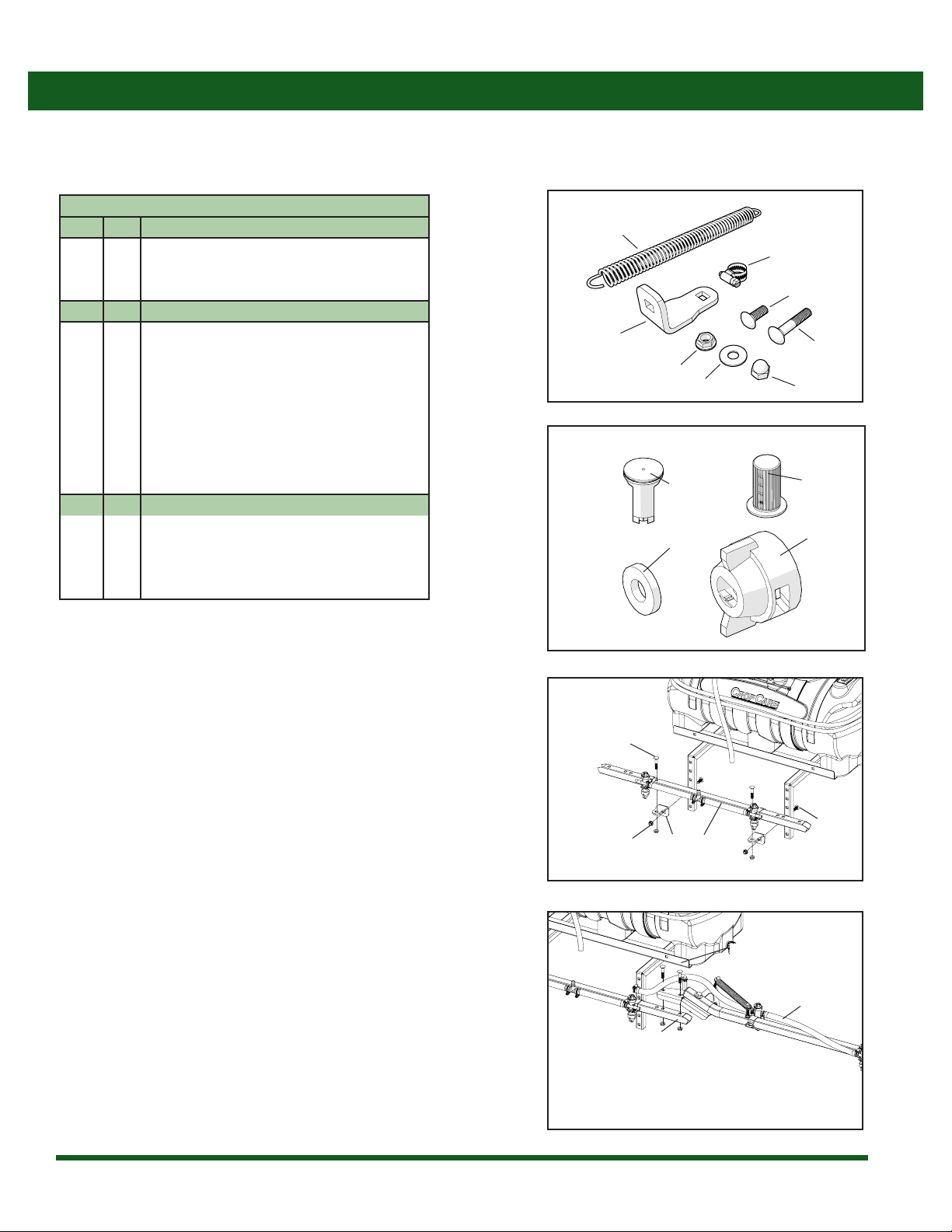

4 6 22252312500NYB * Body, Nozzle Tee 1/2” QJ300

5 8 256121NYR Cap & Gasket, Quick TeeJet Black

6 2 33*TS Spring, Extension 1” x 8” (8.5” OAL)

7 8 8079PP50 Strainer, Tip 50 Mesh Red Poly Body SS Screen

8 8 AIXR110025VP Tip, AIXR TeeJet Polymer Purple

9 4 AN38 Nut, Acorn 3/8-16

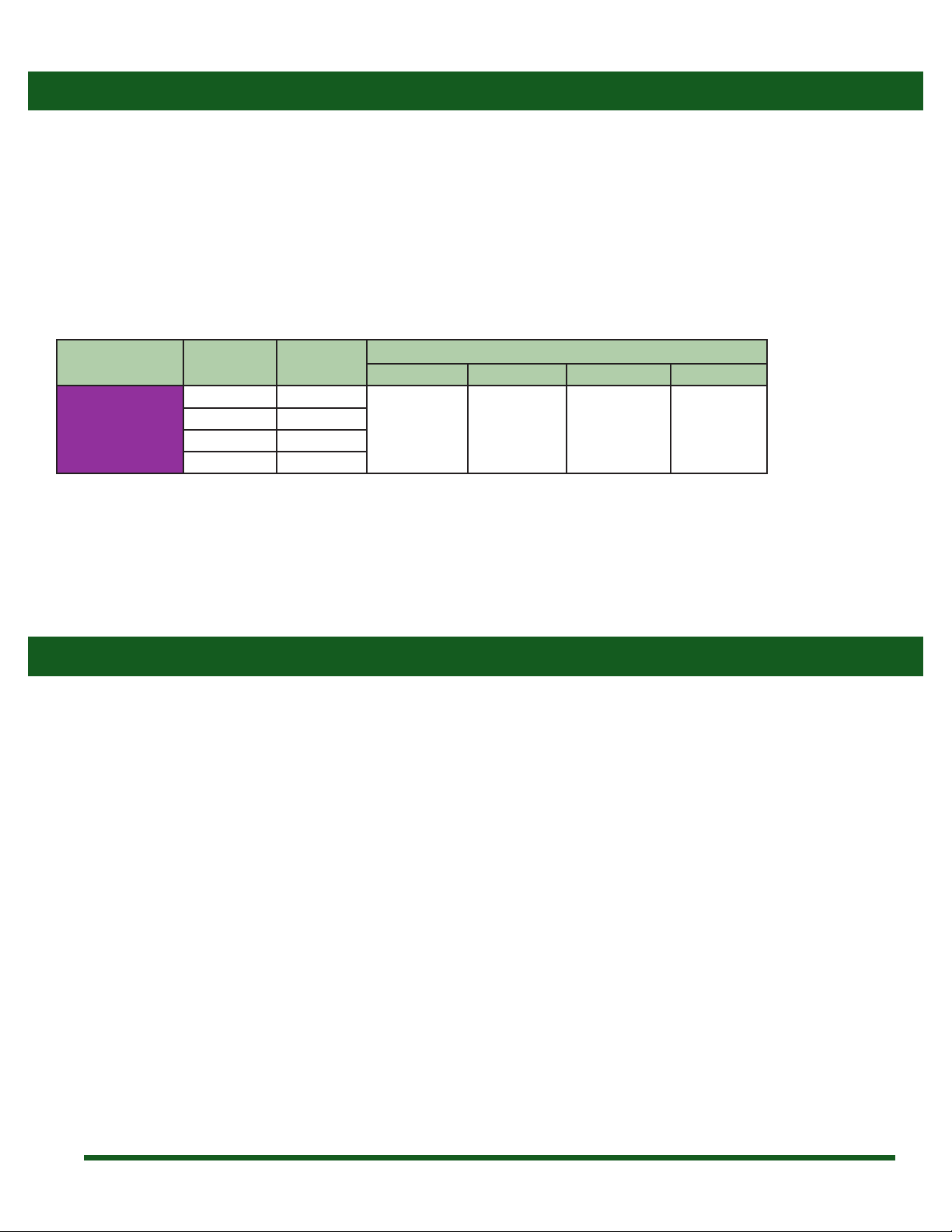

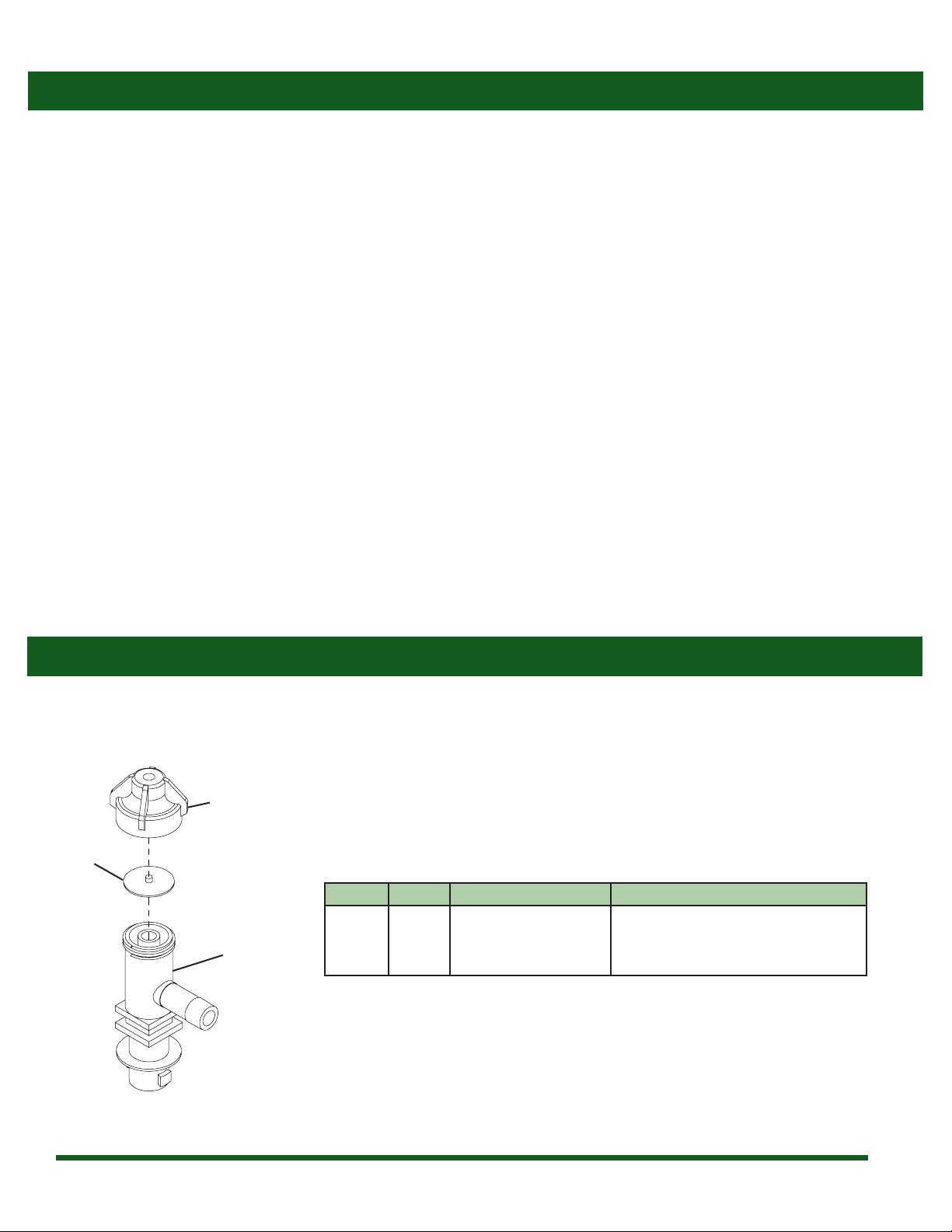

10 1 BF1220 13’ Manual Fold Boom, center tube

11 1 BF1221 13’ Manual Fold Boom, inner hinge, left

12 1 BF1222 13’ Manual Fold Boom, inner hinge, right

13 2 BF1223 13’ Manual Fold Boom, outer wing

14 2 BF1224 13’ Manual Fold Boom, mounting brackets

15 2 CB38*1G5 Bolt, Carriage 3/8-16 x 1” Gr 5

16 2 CB38*212G5 Bolt, Carriage 3/8-16 x 2-1/2” Gr 5

17 6 CB38*2G5 Bolt, Carriage 3/8-16 x 2” Gr 5

18 2 CB38*312G5 Bolt, Carriage 3/8-16 x 3-1/2” Gr 5

19 4 CC5520 Cap, Poly Square 1-1/4”x 14-20 Ga Blk

20 2 CN38*118 Nut, Coupling 3/8-16 x 1 1/8”

21 2 D-1335 Spring, Die 1/2”Rod ID x 2” x .225x.158 Wire 840lbs/in

22 4 FB38*112G5 Bolt, Flange 3/8-16 x 1 1/2”Gr 5

23 12 FN38 Nut, Flange 3/8-16

24 2 FW12 Washer, Flat 1/2” USS

25 4 FW38 Washer, Flat 3/8”

26 2H5C12*4 Bolt, Hex 1/2-13 x 4” Gr 5

27 2NNC12 Nut, Lock Nylon 1/2-13

28 8QJ111SQ114 Clamp, Nozzle Body 1-1/4”Sq Tube Steel

29 1 T12 Tee, 1/2” Hose Barbs Nylon

30 2 CN38 Nut, Coupling 3/8-16 x 1-3/4”

31 2 H5C38*34 Bolt, Hex 3/8-16 x 3/4” Gr 5

32 2 618UV Cable Tie, 6” 18 Lb black

Breakdowns & Parts Lists

ATV-MX160 Parts List

* Nozzle body breakdown is listed on page 9

Contact the original retailer for ordering information

4

5

7

8

3

5

1

2

6

9

10

11

12

13

14

15

16

17

17

18

19

19

20

21

22

23 23

23

24

25

26

27

28

29

22

30

31

32