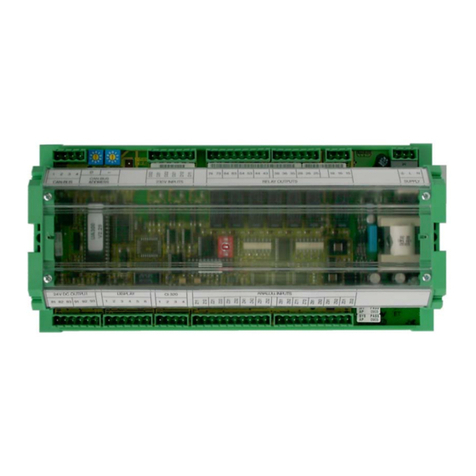

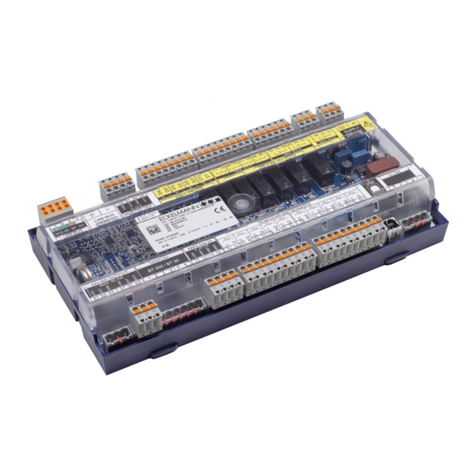

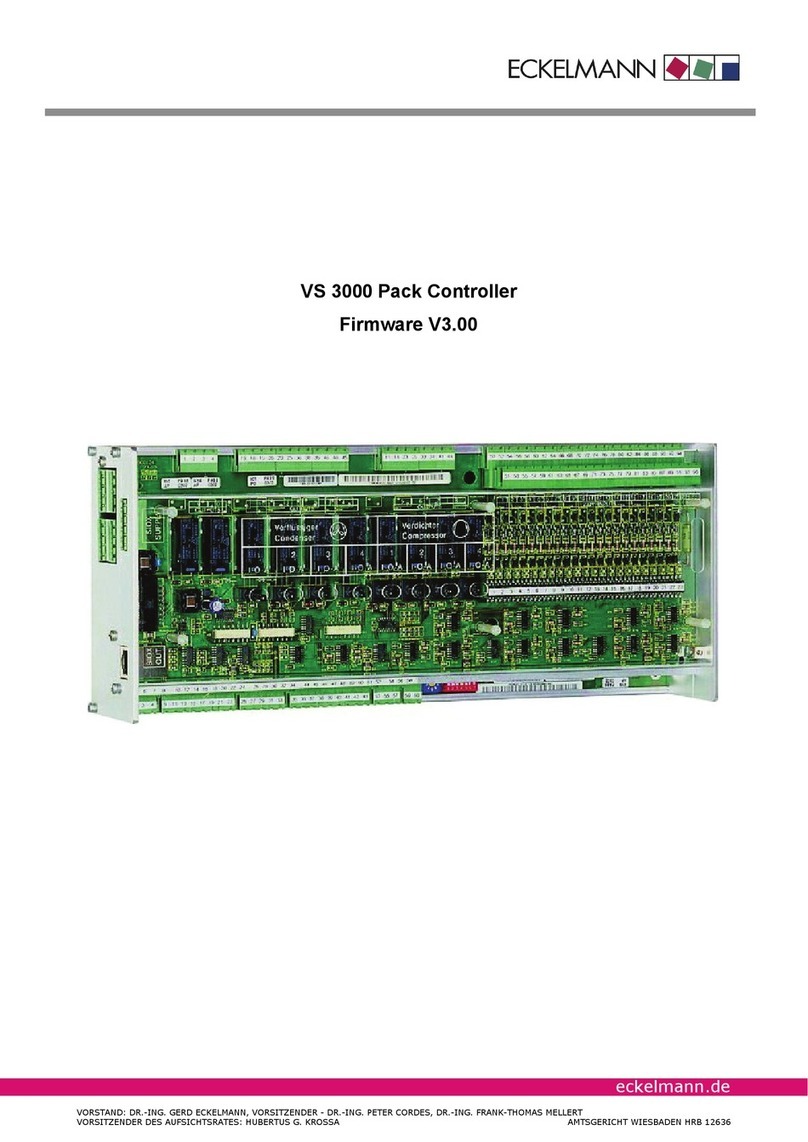

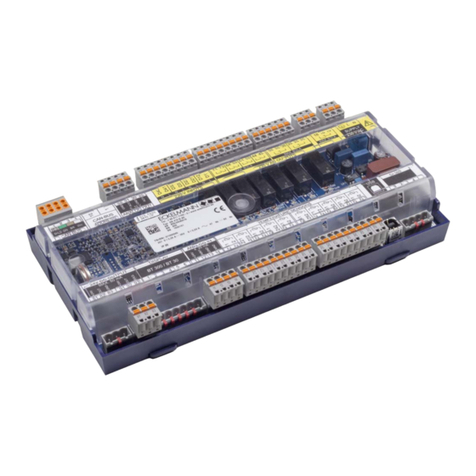

6.1.1 DIN Rail Mounting of the Temperature Data Logging Controller..............................................................28

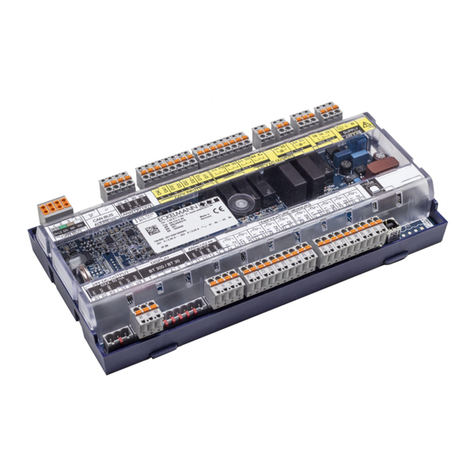

6.1.1.1 Mounting on the DIN rail...........................................................................................................................29

6.1.1.2 Disassembling from the DIN rail...............................................................................................................31

6.1.2 Handling of the Spring Terminals .............................................................................................................32

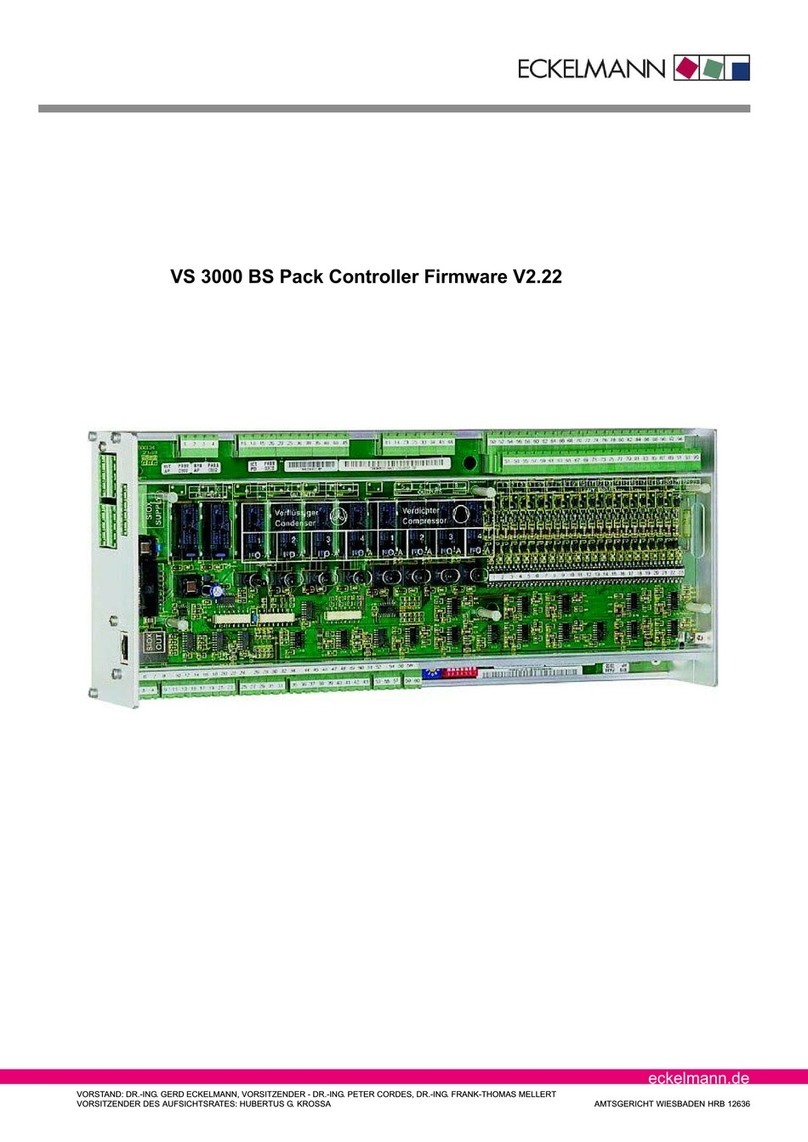

6.2 Basic Configuration ...............................................................................................................................33

6.2.1 Setting CAN Bus Address ........................................................................................................................34

6.2.2 Setting the Controller Type.......................................................................................................................35

6.3 Assignment for 230 V AC Power Supply..............................................................................................36

6.3.1 Status LEDs .............................................................................................................................................37

6.4 Basic Configuration of the Controller ..................................................................................................39

6.4.1 Designation of the Controller and the Sensors.........................................................................................42

6.5 Battery Replacement..............................................................................................................................43

6.6 Firmware Update ....................................................................................................................................45

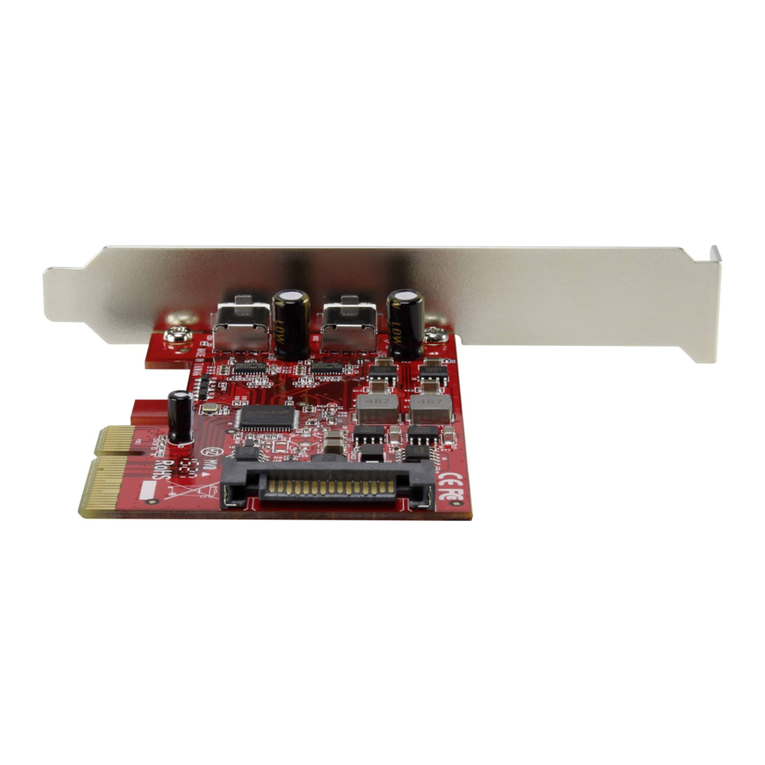

6.6.1 Requirements for Firmware Update .........................................................................................................46

6.6.2 Installing Firmware Update.......................................................................................................................48

6.6.2.1 Update for Controller with 8-Pole DIP Switch...........................................................................................48

6.6.2.2 Update for Controller with 9-Pole DIP Switch...........................................................................................53

6.6.3 Rectification of Driver Problems ...............................................................................................................56

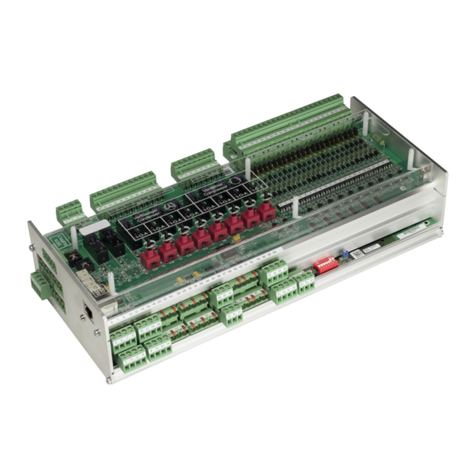

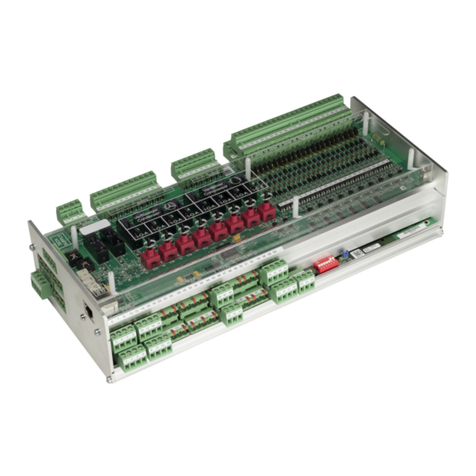

7 Connection and Terminal Assignment UA 410 L.................................................................................57

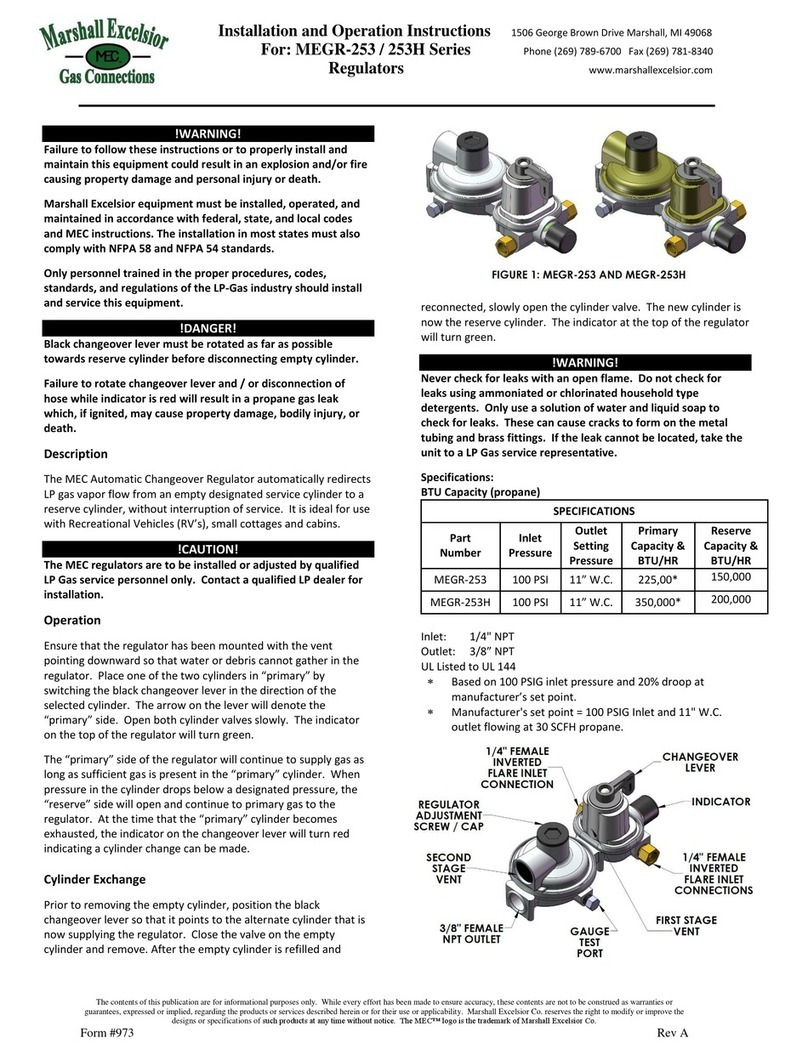

7.1 Connectors for 230 V AC .......................................................................................................................58

7.1.1 Assignment of the 230 V AC Power Supply .............................................................................................58

7.1.2 Assignment of the 230 V AC Relay Outputs.............................................................................................59

7.1.3 Assignment of the Digital Inputs 230 V AC...............................................................................................60

7.2 Connectors for Safety Extra-low Voltage.............................................................................................61

7.2.1 Assignment of the 0..10 V Analogue Outputs...........................................................................................61

7.2.2 Assignment of the CAN bus .....................................................................................................................62

7.2.3 Assignment of the 24 V DC Transistor Outputs........................................................................................63

7.2.4 Assignment of the DISPLAY Interface......................................................................................................64

7.2.5 Assignment of the 4..20 mA Analogue Inputs...........................................................................................65

7.2.6 Assignment of the Analogue Inputs of Temperature Sensors ..................................................................66

7.2.7 Assignment of the USB Interface .............................................................................................................67

7.3 Wirksinn der Relais- und Transistor-Ausgänge ..................................................................................68

8 Operation of UA 410 L............................................................................................................................69

8.1 Operation Possibilities ..........................................................................................................................69

8.2 Local Operation with a BT 300 x Operator Interface...........................................................................70

8.2.1 Lock-down of the Setpoint Change ..........................................................................................................71

8.3 Remote Control via a Terminal..............................................................................................................72

8.3.1 Menus and Operating Screens.................................................................................................................73