ECKELMANN UA 412 S User manual

Operating instruction

Case Controller UA 412 S / UA 413 S

Case Controller UA 412 S / UA 413 S - Version V1.16

Version V1.16

KGL Operating Manual – UA 412 S 2019-01-14 /2 122

Eckelmann AG

Business Unit Refrigeration and Building Automation

Berliner Straße 161

65205 Wiesbaden, Germany

Tel.: +49 611 7103-700

Fax: +49 611 7103-133

E-Mail: [email protected]

Internet: www.eckelmann.de

Board of Management:

Dipl.-Ing. Peter Frankenbach, Spokesman,

Dipl.-Wirtsch.-Ing. Philipp Eckelmann, Dr.-Ing. Marco Münchhof, Dr.-Ing. Frank Uhlemann

Chairman of the Supervisory Board: Hubertus G. Krossa

Deputy Chairman of the Supervisory Board: Dr.-Ing. Gerd Eckelmann

Registration court / registration number

District court Wiesbaden, HRB 12636

Before commissioning and use, please check that this is the latest version of the document. With the

publication of a new version of the documentation, all previous versions lose their validity.

Errors and technical modifications are expressly reserved.

The current operating manual and information such as data sheets, more detailed documentation and FAQs

are available for you on-line in E°EDP (Eckelmann ° Electronic Documentation Platform) at

www.eckelmann.de/elds

You reach all relevant documents for this component directly using the QR code:

Information on safety and connection instructions are described in detail in chapter ”Industrial safety notes”.

All rights to any use whatever, utilisation, further development, forwarding and creation of copies remain with

the Eckelmann AG company.

In particular, neither the contract partners of Eckelmann AG nor other users have the right to distribute or

market the IT programs/program parts or modified or edited versions without express written permission. To

some extent, names of products/goods or designations are protected for the respective manufacturer

(registered trademarks etc.); in any case, no guarantee is assumed for their free availability/permission to use

them. The information provided in the description is given independently of any existing patent protection or

other third-party rights.

KGL Operating Manual – UA 412 S 2019-01-14 /3 122

Table of Contents

1 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Explanation of 'Safety Instructions and Hazard Warnings' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Explanation of 'General Note' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Warning Signs and Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Exclusion of liability for non-observance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Requirements for the personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Five safety rules according to BGV A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Electrostatic sensitive components and control components (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 ESD - guidelines for handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 System design UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Applications UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 Controller types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Function UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Starting characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.1 First start- reset controller to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.2 Restart - restart of the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Selection of the sensor type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Necessary and optional sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Description of the controller function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Safety chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.1 Compressor enable according to supply air and return air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5.2 Compressor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.2.1 Controller type SPIR410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.2.2 Controller type SPIR290 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5.3 Compressor end temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.4 Continuous run monitoring of the regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.5 Minimum running and standstill times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5.6 Emergency operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6.1 General notes for defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6.2 Master-slave mode for the synchronisation of the defrost termination . . . . . . . . . . . . . . . . . . . . . 31

5.6.2.1 Master-slave mode for the synchronisation of multiple controllers . . . . . . . . . . . . . . . . . . . . . 31

KGL Operating Manual – UA 412 S 2019-01-14 /4 122

5.6.2.1 Master-slave mode for the synchronisation of multiple controllers . . . . . . . . . . . . . . . . . . . . . 31

5.6.2.2 Necessary settings for the master / slave mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6.2.3 Special features and limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.7 Fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.8 Frame heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.9 Manual shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.10 Toggle setpoint (day / night operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.11 Lighting control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.12 Emergency power operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.13 BT 30 temperature display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.14 Recording of messages and alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6 UA 412 S installation and start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1.1 Case controller for DIN rail mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1.1.1 Mounting on the DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.1.1.2 Removal from the DIN rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.1.2 Handling of the spring terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.2 Basic settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.3 Setting the CAN bus address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.4 Setting of the controller type and master/slave mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.5 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.5.1 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.6 Basic configuration of the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.7 Naming the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.8 Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.9 Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.9.1 Requirements for firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.9.2 Installing firmware update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.9.2.1 Update for controller with 9-pole DIP switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.9.2.2 Update for controller with 8-pole DIP switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.9.3 Rectification of driver problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7 UA 412 S connection and terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.1 Terminal diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.2 Terminal assignment of the 230 V AC power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.3 Terminal assignment of the 230 V AC relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.4 Assignment of the 230 V AC digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.5 Assignment of the 0..10 V analogue outputs DEF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.6 Terminal assignment of the CAN bus terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.7 Terminal assignment of the 24 V DC transistor outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.7.1 Function of the relay and transistor outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.8 Assignment of the DISPLAY interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.9 Assignment of the 4..20 mA analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.10 Terminal assignment of the analogue inputs for temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . 72

KGL Operating Manual – UA 412 S 2019-01-14 /5 122

7.10 Terminal assignment of the analogue inputs for temperature sensors . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.10.1 Explanation for the sensor designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.11 Assignment of the USB port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.12 Wiring of the master-slave function for defrost synchronisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8 Operation UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.1 Operation possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.2 Local operation with a BT 300 x operator interface: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.2.1 Locking of the setpoint change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.3 Remote control via the terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.3.1 Menus and operating screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.3.2 Call controller menu using remote operation, page 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3.2.1 CI 4x00 System Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3.2.2 CI 3x00 store computer / AL 300 operator terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3.3 Cancelling entry block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3.3.1 CI 4x00 System Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3.3.2 CI 3x00 store computer / AL 300 operator terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.3.4 Activating service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.3.4.1 CI 4x00 System Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.3.4.2 Store computer CI 3x00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.1 Controller type SPIR410 - Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

9.1.1 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1.2 Menu 1 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1.3 Menu 2 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.1.4 Menu 3 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1.5 Menu 4 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.6 Menu 5 Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.7 Menu 6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.2 Controller type SPIR290 - Menu tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.2.1 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.2.2 Menu 1 Actual values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.2.3 Menu 2 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9.2.4 Menu 3 Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.2.5 Menu 4 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.2.6 Menu 5 Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.2.7 Menu 6 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10 Decommissioning and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.1 Decommissioning / Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11 Alarms and messages UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11.1 Alarm signaling and monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.1.1 Alarm for overtemperature or low temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.1.2 Alarm in the absence of a defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

11.1.3 Alarm due to sensor fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.1.4 Alarm suppression of the sensor fault alarm during a defrost . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.1.5 Alarm due to hardware problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.1.6 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

KGL Operating Manual – UA 412 S 2019-01-14 /6 122

11.1.6 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

11.2 Individual allocation of priorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

11.3 Alarm paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.4 End of an alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.5 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.5.1 Transient alarms and messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

11.5.2 Message list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

12 Technical Data UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

12.1 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

12.2 Mechanical Data UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

12.3 Mechanical data of the temperature sensors L243 / 5K3A1 / Pt1000 . . . . . . . . . . . . . . . . . . . . . . . . . 121

13 Order numbers and accessories of UA 412 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13.1 Case controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

13.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

KGL Operating Manual – UA 412 S 2019-01-14 /7 122

1.

2.

3.

4.

1.

2.

1 Conventions

1.1 Explanation of 'Safety Instructions and Hazard Warnings'

Safety instructions or hazard warnings are composed of four elements:

The pictogram and the text at the side pf the page.

A short, concise description of the danger.

A description of the possible consequences.

A catalogue with measures for avoidance.

For example:

Warning about dangerous electrical voltage! Danger of electric shock! BEFORE connecting and

disconnecting, it must be checked that at the 230 V AC relay outputs!no voltage is present

1.2 Explanation of 'General Note'

A general note consists of two elements:

The pictogram and the "Info" text at the side pf the page, and

the actual note text:

For example:

Further information for the protection rating of the device is contained in the chapter Technical Data

.UA 412 S, page 119

1.3 Warning Signs and Symbols Used

Explanation of the warning signs and symbols used for the safety instructions and hazard warnings in this

documentation:

Attention symbol - general hazard warning

1. Hazard warning

The attention symbol indicates all safety instructions in this operating and service manual that result

in danger to life and limb of persons if not observed. Carefully comply with the work safety

instructions and proceed with particular caution in these cases.

2. Attention

The attention symbol highlights guidelines, regulations, instructions and correct working procedures

that must particularly be observed in order to prevent damage to and destruction of E*LDS

components or any malfunction (for example to prevent damage to goods).

Failure to observe the attention symbol can result in personal injury (in extreme cases serious injuries or

death) and/or damage to property!

Warning Symbol

KGL Operating Manual – UA 412 S 2019-01-14 /8 122

Warning Symbol

1. Warning about dangerous electrical voltage

This work safety s ymbol warns about hazards from dangerous electrical voltage with possible

consequences of serious injuries and death.

Failure to observe this symbol can result in personal injuries (serious personal injuries or death in

extreme cases) and/or in damage to property!

If this symbol is seen, the operating manual must be consulted to find out the type of the potential

HAZARD and the required actions for the avoidance of the HAZARD.

2. Warning about electrostatic sensitive components and control components

This symbol also indicates electrostatic sensitive components and control components.

Note symbol

The note symbol highlights usage tips and other useful information contained in this operating and

service manual.

Battery disposal symbol

Never dispose of this product using the residual waste bin.

Please inform yourself about the local regulations for the separated disposal of electrical and electronic products.

The correct disposal of your old equipment protects the environment and people against possible negative consequences. Further

information for this can be found in the chapter " ".Decommissioning and Disposal, page 112

KGL Operating Manual – UA 412 S 2019-01-14 /9 122

2 Safety Information

The safety regulations, instructions and information described in this chapter must be strictly

observed and complied with. During repairs on the entire E*LDS system, the accident prevention

regulations and general safety regulations must be strictly complied with. Important information

(safety instructions and hazard warnings) are indicated by appropriate symbols (see chapter

). Follow these instructions in order to prevent accidents and danger to life Conventions, page 7

and limb, as well as damage to the E*LDS system.

Warning about dangerous electrical voltage! Danger of electric shock! Beware of external voltage at

the digital inputs and outputs! All device connections/male connectors may only be plugged in,

unplugged and/or wired when .no voltage is present

This operating manual is part of the device. It be kept in the vicinity of the controller as well as for must

future use so that it can be consulted when required. The operating manual must be available for the

operating and maintenance personnel for the avoidance of operating errors, see chapter at any time

.Requirements for the personnel, page 10

For safety reasons, the equipment must not be used for any applications other than described in the

operating manual and only for the intended use, see chapter .Intended Use, page 11

Before using the device, check whether it is suitable for your application with regard to its limit values.

The equipment must be installed in an electrically shielded area within the switch cabinet.

Before connecting the device, it must be checked whether the power supply is suitable for the device.

When using uncoded plug connectors, it is possible to connect them so that there is a danger to life and

limb! If this cannot be ruled out, coded plug connectors must be used .

Specified environmental conditions (e.g. humidity and temperature limits) must be observed and

complied with. Otherwise, malfunctions are possible (see chapter ).Technical Data UA 412 S, page 119

Before switching on the device, check correct wiring of the connections.

The device must never be operated without its case. Before opening the case, the device must be

disconnected from the power supply.

Note the maximum load of the relay contacts (see chapter ).Technical Data UA 412 S, page 119

Contact the supplier in the case of any malfunction.

Note that all supply lines from and to the device, particularly those of the CAN bus must be shielded or

installed with sufficiently large distance from live cables. This prevents faulty measurements and

protects the device against electrical interference via the analogue inputs. Connection in parallel of RC

elements is recommended for applications with critical environment.

KGL Operating Manual – UA 412 S 2019-01-14 /10 122

1.

2.

According to experience, transmission of alarms is not yet functional during putting into service

(no telephone line laid etc.). It is strongly recommended in such cases to monitor the controller

via the CAN bus using a system centre, a store computer or an operator terminal and to

enable transmission of alarms, for example using a GSM modem via a mobile telephone

system. In standalone operation, or as an alternative to monitoring with system centre / store

computer / operator terminal, an available alarm contact on the controller must be used to

realise transmission of alarms via a telephone network.

For fire prevention reasons, a suitable device for shutting down the defrost heating in the

event of excessive temperatures (high temperature circuit breaker) must already be taken into

account during planning of the installation.

For further information about the CAN bus, see the manual “Basics and General Safety and

Connection Notes”.

Work on the electrical system may (according only be performed by authorised specialist personnel

to the definition for specialists in DIN/VDE 0105 and IEC364) and in accordance with the respective

applicable

VDE regulations, local safety regulations

Intended use

Five safety rules according to BGV A3

ESD measures

Operating instructions

2.1 Exclusion of liability for non-observance

This operating manual contains information about the putting into service, function, operation and maintenance

of the controller and the associated components.

A basic requirement for safe and trouble-free operation is .compliance with this operating manual

2.2 Requirements for the personnel

Special technical knowledge is required for planning, programming, installation, putting into service and

maintenance work. This work may only be performed by trained or specially trained personnel. The installation,

putting into service and maintenance personnel must have training which authorises interventions in the

system and the automation system. The planning and programming personnel must be familiar with the safety

concepts of automation technology. Specialist knowledge is required for work on electrical systems. Work on

electrical systems may only be carried out by qualified electricians or persons under their guidance or

supervision. In doing so, the respective applicable regulations (e.g. DIN EN 60204, EN 5017 DIN 8, BGV A3,

VDE 0100/0113) must be observed. The operating personnel must be instructed in handling the system /

machine and the controller and must be familiar with the operating instructions.

KGL Operating Manual – UA 412 S 2019-01-14 /11 122

2.3 Intended Use

This controller is exclusively provided for the intended use: The UA 412 S / UA 413 S controller is intended for

use as case controller in commercial and industrial refrigeration systems with the scope of functions and in

accordance with the environmental conditions described in this operating manual.

Note the safety instructions and the instructions for installation and putting into service, operation and

maintenance. Start the commissioning and/or the operation of the machine / system AFTERWARDS.

The safety and the function of the machine / system are only fulfilled with this intended use.

Therefore, never use the machine / system, its components, control components or parts for any other

purpose.

The system must not be put into operation until conformity with the applicable EC Directives has been

established for the entire installation.

2.4 Five safety rules according to BGV A3

The following rules .must be strictly observed

1. Disconnect: The entire system to be worked on must be disconnected from the power supply at all poles.

Warning about dangerous electrical voltage! Pay attention to possible external power supply!

connecting and disconnecting it must be checked that at the BEFORE no voltage is present

controller! All device connections / connectors may only be plugged in, unplugged and/or wired when

no voltage is present.

2. Secure against restarting: Attach information signs to the disconnected operating equipment stating:

What has been disconnected.

Reason for the disconnection.

Name of the person who made the disconnection.

Restarting must be prevented using a suitable lock (e.g. padlock).

3. Establish absence of voltage (only by authorised specialist personnel):

Check voltmeter just before use.

Establish absence of voltage on all poles at the disconnection point.

Establish absence of voltage on all poles at the place of work.

4. Ground and short-circuit: All electrical parts at the place of work must be grounded and then short-circuited.

5. Cover or shield neighbouring live parts: If there is neighbouring live equipment in the work area, this must be

covered using appropriate materials (e.g. insulation blankets / insulating plates).

2.5 Electrostatic sensitive components and control components (ESD)

Electronic components and control components (e.g. circuit boards) are sensitive to electrostatic

charges. Therefore, the guidelines for handling electrostatic sensitive components and control components

must be strictly observed, see chapter ESD - guidelines for handling, page 12 .

All electrostatic sensitive components and control components (referred to as "ESD" below) are labelled with

the warning sign shown. Electrostatic charges arise from friction of insulating materials (e.g. floor covering,

items of clothing made of synthetic fibres etc.). Even small charges can result in damage to or destruction of

components. Damage cannot always be established directly, but partially does not result in failure until after a

certain operating time.

KGL Operating Manual – UA 412 S 2019-01-14 /12 122

2.5.1 ESD - guidelines for handling

Only transport and store ESD in the protective packaging provided for this.

materials that can produce electrostatic charge such asAvoid

plastic containers and tabletops

synthetic clothing

footwear with plastic soles

transparent covers

polystyrene packaging

monitors etc.

Wear

work clothing made of cotton

ESD footwear with electrically conductive soles or leather soles

Use

conductive floors

ESD work places with the tools provided for them (earthed soldering irons, earthing wrist strap and

similar)

conductive ESD bags, conductive plastic containers, IC rods or cartons with conductive foam

containers and worktops made of wood, metal, conductive plastics or paper bags.

2.6 Abbreviations used

DIN eutsches nstitut für ormung e. V.D I N

EGB lektrostatisch efährdete auelemente oder BaugruppenE G B

ESD lectro- tatic ischarge ( lectro ensitive evices)E s d E S D

VDE erband er lektrotechnik lektronik Informationstechnik e.V.V d E E

IEC nternational lectric ommitteeI E C

BGV A3 m loyers Liability ssociation regulations for health and safety in the workplaceE p A

KGL Operating Manual – UA 412 S 2019-01-14 /13 122

3 System design UA 412 S

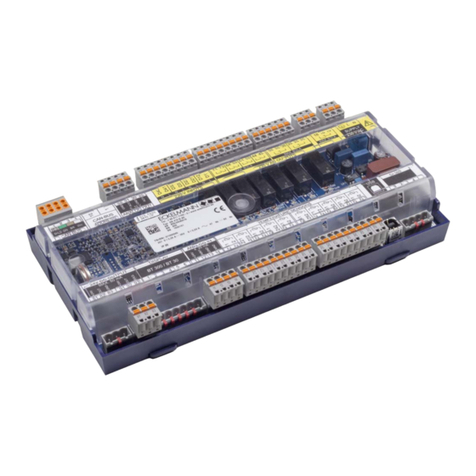

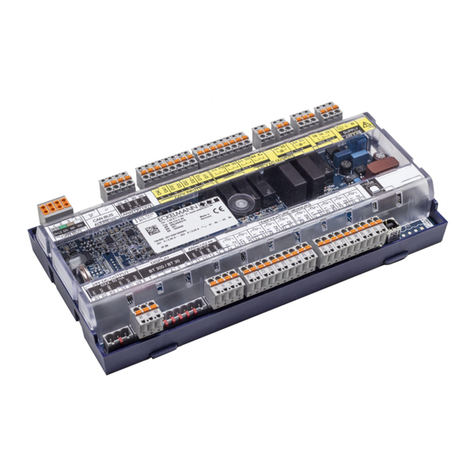

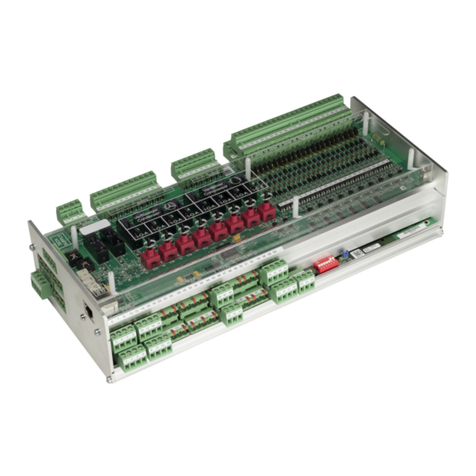

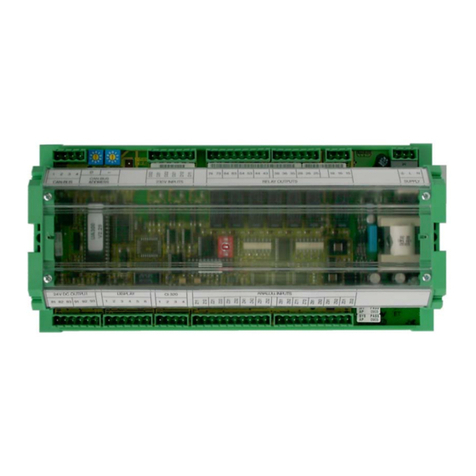

UA 412 S AC - complete design

3.1 Application

There are two controller versions with the designations UA 412 S (complete design) and UA 413 S,

see chapter . The designation Versions, page 17 UA 412 S is used in the documentation for both

. Exceptions for the UA 413 S are explicitly listed.versions

The UA 412 S case controller is suitable for regulation and monitoring of semi-plugin cases. The respective

appropriate insert type for multidecks using the R410a or R290 refrigerant can be set using the DIP switches

on the controllers (see chapter ). The factory Setting of the controller type and master/slave mode, page 45

settings for the desired application that have been tried and tested in practical use are then loaded. The data

for the following E*LDS system components are exchanged via the CAN bus:

System centre / store computer

- Archiving of the operating data

- Alarm and message management

- Connection to the LDSWin PC software for analysis, configuration and evaluation

Pump controller PS 3010 L

As required, a BT 300 x operator interface and up to 4 BT 30 temperature displays can be connected; see also

chapter Connection / terminal assignment UA 412 S., page 64

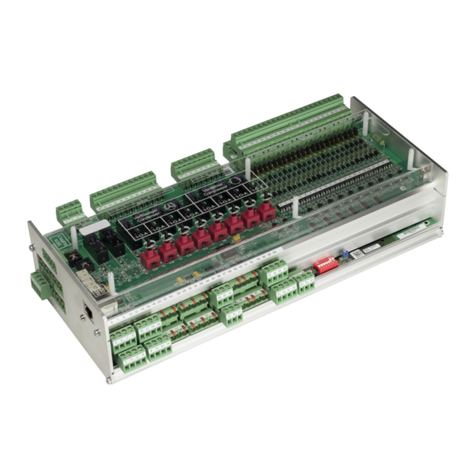

3.2 Hardware

The case controller is housed in a plastic casing for DIN rail mounting and does not require any further optional

expansion modules. Up to 99 case controllers can be used in the E*LDS system. As required, a BT 300

operator Interface and up to 4 BT 30 temperature displays can be connected. For the direct parametrisation

via LDWin or for a firmware update, the controller can be connected to a laptop or PC via the USB port. The

application areas of the case controller are described in more detail in chapter .Versions, page 17

The following graphic clarifies the system design of the UA 412 S (complete design) / UA 413 S case controller:

KGL Operating Manual – UA 412 S 2019-01-14 /14 122

Interfaces:

CAN bus:

Communication in the E*LDS system

DISPLAY:

Connection for BT 300 operator interface and up to four BT 30 temperature displays

USB:

- For performing a firmware update

- Direct parametrisation via LDSWin

Inputs:

4 x digital inputs

230 V AC, floating

5 x inputs for connection of 2-wire NTC temperature sensors

5 x inputs for connection of 2-wire Pt1000 temperature sensors

Analogue inputs

- Only UA 412 S: 2 x 4..20 mA

- Only UA 413 S: none

Outputs:

3 x relay outputs

230 V AC / 6 A (changeover contact)

4 x relay outputs

230 V AC / 6 A (normally open contact)

2 x transistor outputs

24 V AC / 50 mA

Analogue outputs

- Only UA 412 S: 2 x 0..10 V

- Only UA 413 S: 1 x 0..10 V

Real-time clock

KGL Operating Manual – UA 412 S 2019-01-14 /15 122

Real-time clock

Only UA 412 S: with power reserve, lithium cell

Details about the different features of the UA 412 S and UA 413 S controllers are explained in

chapter . The connection and terminal assignments are in the chapter Versions, page 17 Connection

The designation UA 412 S is used in the documentation / terminal assignment UA 412 S., page 64

for both controller versions. Exceptions for the UA 413 S are explicitly listed.

KGL Operating Manual – UA 412 S 2019-01-14 /16 122

4 Applications UA 412 S

4.1 Controller types

Different controller types and their application areas in the UA 412 S case controller are summarised in the

table below:

Controller type Applications

Case controller SPIR410 Semi-plugin controller for NT multidecks using the R410a refrigerant

One refrigerant circuit with

a speed-controlled compressor

SPIR290 Semi-plugin controller for NT multi decks using the R290 refrigerant

Up to four refrigerant circuits with

a) up to four speed-controlled compressors (parallel combined) or

b) up to four staged compressors

For definition of the basic control action, can be set, which is set using the only one controller type DIP switch

:S3

Special feature: Two device generations are available. The DIP switch S3 provides a quick distinguishing

feature:

Characteristic: 9-pole DIP switch Characteristic: 8-pole DIP switch

Example: Setting of the coding switches for the controller type SPIR290; for details, see chapter Necessary

.settings for the master / slave mode, page 31

Controller type DIP switch S3 (switch positions of the coding switches 1 .. 9)

1 2 3 4

Master /

Slave

mode

56789

Normal Operation /

Firmware Update

Case controller SPIR410 ON OFF OFF ON

/OFF

OFF OFF OFF OFF ON

SPIR290 OFF ON OFF ON

/OFF

OFF OFF OFF OFF ON

Operation with an unsupported DIP switch setting is not permitted. In the event of change of the

controller type, all parameters are reset to their factory settings.

The controller can be operated via

a central computer e.g. via network / modem with connection to the system centre / store computer,

the system centre, a store computer or an operator terminal,

a local BT 300 operator interface via the DISPLAY interface on the controller or

a laptop (PC) with the PC software LDSWin connected via USB.

KGL Operating Manual – UA 412 S 2019-01-14 /17 122

4.2 Versions

The designation UA 412 S is used in the documentation for both versions. Exceptions for the UA 413

S are explicitly listed.

Distinguishing features of the case controllers:

UA 412 S AC * UA 413 S CC *

For DIN rail mounting • •

For integration in the CAN bus of the E*LDS system • •

Suitable for standalone operation •-

With integrated real-time clock (lithium cell power reserve) •-

Analogue inputs 4..20 mA 2 -

Analogue outputs 0..10 V 2 1

Abbreviations used

CC stands for (C = with CAN bus and C = DIN rail mounting).

CAN bus and abinet / DIN rail mountingC

AC stands for (All = with CAN bus and real-time clock and C

All in one and abinet / DIN rail mountingC

= DIN rail mounting).

* Special feature: The controller is available in two device generations; the DIP switch provides a

quick distinguishing feature:

1st generation: since 2011 (8-way DIP switch)

2nd generation: from Oct. / Nov. 2018 (9-way DIP switch)

Note: The range of functions described in this operating manual refers to both device generations.

4.3 Firmware Update

The case controller is supplied with the current firmware, ready for operation. Future software versions can be

loaded into the case controller as required by means of a firmware update, and thus updated.

KGL Operating Manual – UA 412 S 2019-01-14 /18 122

Caution: data loss! In some cases, a change of the firmware version can result in the loss of all

specified setpoints in the case controller!

As a precaution, the settings therefore be backed up by saving then in the LDSWin must previously

PC software. After the firmware update, the saved settings can be reloaded into the controller from

LDSWin. A software update must only be performed by trained personnel is only to be carried out by

trained personnel or at the factory by the manufacturer. More details about firmware updates can be

found in .chapter Firmware Update, page 54

KGL Operating Manual – UA 412 S 2019-01-14 /19 122

1.

2.

3.

4.

5.

6.

7.

5 Function UA 412 S

The parameters referred to in this chapter are described in more detail in the chapter Menu structure,

the respective controller. In general, it is not necessary to change the default values of of page 86

these parameters. Parameters that cannot be changed are indicated in the text as fixed parameters.

5.1 Starting characteristics

The following are distinguished for any start-up of the controller:

First start

Restart

5.1.1 First start- reset controller to factory settings

Caution: data loss! A first start causes all parameters to be reset to the factory settings!

The first start can be initiated using the following procedure:

Disconnect controller from the power supply for safety reasons (see also chapter Setting of the

) make a note of the DIP switch S3 settings (e.g. OFF-controller type and master/slave mode, page 45

ON-OFF-...).

Adjust settings at the DIP switch S3 (e.g. OFF-OFF-OFF-...).

Power on the controller again and wait approx. 1 minute while the controller starts up.

Disconnect controller from the power supply for safety reasons (see also chapter Setting of the

).controller type and master/slave mode, page 45

Reset DIP switch S3 to the noted starting position.

Switch on controller again.

The settings of the controller have been reset to the factory settings.

A first start is also performed when a different controller version (e.g. UA 400 UA 410 D UA 400 E UA

410 L) is loaded on the controller via firmware update (see chapter ). Battery replacement, page 52

A sensor scan (Menu 6-1) be performed during commissioning or after a first start! The sensor must

scan is the only possibility to define the sensors to be monitored; see chapter Necessary and optional

.sensors, page 20

5.1.2 Restart - restart of the controller

For a restart, the device is restarted with all configured parameters and the CAN bus address set on the

decade switches and . A restart can be initiated using the following procedure:S1 S2

disconnection and reconnection of the power supply

5.2 Selection of the sensor type.

The case controller uses 2-wire NTC temperature sensors and 2-wire Pt1000 temperature sensors for the

regulation.

KGL Operating Manual – UA 412 S 2019-01-14 /20 122

The first 5 temperature sensors (1..5) be identical in their type and of the type NTC and can be adjusted must

using the parameter (menu 6-2-5, set to "L243" at the factory). The following NTC sensor types

Sensor type

are supported:

L243 (K243) temperature range -50 .. 50 °C

(the sensor K243 can also be used instead of the sensor L243 as the characteristic curves of both

sensors are identical)

K277 temperature range -50 .. 50 °C

5K3A1 temperature range 0 .. 100 °C

The next 5 temperature sensors (6..10) be of the type PTC:must

Design as Pt1000

For details, see chapter For information Assignment of the analogue inputs for temperature sensors., page 72

about the dimensions of the sensors, see chapter Mechanical data of the temperature sensors L243 / 5K3A1,

.page 121

The sensors must be mounted carefully. If sensor cables are exclusively laid within the refrigerated

case to be monitored, and sources of interference (e.g. parallel power lines) are not anticipated, then

it is possible to dispense with shielding. Otherwise, interference in the sensor cables must be

prevented using suitable measures.

5.2.1 Necessary and optional sensors

Dependent on the controller type, there are necessary and optional temperature sensors for the case

controller. A sensor scan is performed automatically during the first start of the controller. The number of

scanned sensors can be checked in the menu (6-1) or with the LDSWin PC software. Thereby, not connected

sensors can be excluded from the monitoring for sensor failure.

This manual suits for next models

1

Table of contents

Other ECKELMANN Controllers manuals

ECKELMANN

ECKELMANN Case Controller UA 4 E Series User manual

ECKELMANN

ECKELMANN UA 400 User manual

ECKELMANN

ECKELMANN VS 3000 User manual

ECKELMANN

ECKELMANN VS 3010 BS User manual

ECKELMANN

ECKELMANN UA 410 D User manual

ECKELMANN

ECKELMANN UA 410 L User manual

ECKELMANN

ECKELMANN VS 3015 CT User manual

ECKELMANN

ECKELMANN UA 300 D User manual

ECKELMANN

ECKELMANN VS 3015 C User manual

ECKELMANN

ECKELMANN WRG 3010 E User manual