ECKELMANN UA 400 User manual

Firmware V3.15

21.04.2021

Docu 2.0

Operating instruction

Case Controller UA 400

Universal Controller for thermostatic expansion Valves (TEV)

The series UA 400 includes the following expansion stages: UA 400 CC

Firmware V3.15

21.04.2021

2/401

Eckelmann AG

Business Unit Refrigeration and Building Automation

Berliner Straße 161

65205 Wiesbaden

Germany

Telephone +49 611 7103-700

Fax +49 611 7103-133

www.eckelmann.de

Board of Management: Dipl.-Ing. Peter Frankenbach (Spokesman),

Dipl.-Wirtsch.-Ing. Philipp Eckelmann, Dr.-Ing. Marco Münchhof

Chairman of the Supervisory Board: Hubertus G. Krossa

Deputy Chairman of the Supervisory Board: Dr.-Ing. Gerd Eckelmann

Registration court / registration number

District court Wiesbaden, HRB 12636

Before commissioning and use, please check that this is the latest version of the document. With the

publication of a new version of the documentation, all previous versions lose their validity. The current operating

manual and information such as data sheets, more detailed documentation and FAQs are available for you on-

line in E°EDP (Eckelmann ° Electronic Documentation Platform) at

www.eckelmann.de/elds

You reach all relevant documents for this component directly using the QR code:

https://edp.eckelmann.de/edp/lds/_NbH4owBiFn

Information on safety and connection instructions are described in detail in chapter ”Industrialsafety notes”.

Copyright: All rights to any use whatever, utilisation, further development, forwarding and creation of copies

remain with the Eckelmann AG company. In particular, neither the contract partners of Eckelmann AG nor other

users have the right to distribute or market the IT programs/program parts or modified or edited versions

without express written permission. To some extent, names of products/goods or designations are protected for

the respective manufacturer (registered trademarks etc.); in any case, no guarantee is assumed for their free

availability/permission to use them. The information provided in the description is given independently of any

existing patent protection or other third-party rights.

Errors and technical modifications are expressly reserved.

Firmware V3.15

21.04.2021

3/401

Table of Contents

1 Conventions.............................................................................................................................................9

1.1 Warning signs, symbols and text formatting used in this manual.....................................................9

1.2 Explanation of text formatting .............................................................................................................10

2 Safety instructions ................................................................................................................................ 11

2.1 Disclaimer in the event of non-compliance ........................................................................................12

2.2 Requirements for the personnel ..........................................................................................................12

2.3 Intended use ..........................................................................................................................................13

2.4 Five safety rules according to DGUV Regulation 3............................................................................13

2.5 Electrostatic-sensitive components and control components (ESD)..............................................14

2.5.1 ESD - Rules for handling and working ....................................................................................................14

2.6 Abbreviations used ...............................................................................................................................14

3 System Design of UA 400 .....................................................................................................................15

3.1 Application.............................................................................................................................................15

3.2 Hardware ................................................................................................................................................16

4 Applications of UA 400 .........................................................................................................................17

4.1 Versions .................................................................................................................................................17

4.2 Controller types.....................................................................................................................................18

4.3 Updating firmware.................................................................................................................................20

5 Function of UA 400 / UA 410.................................................................................................................21

5.1 Starting characteristics ........................................................................................................................ 21

5.1.1 First start- reset controller to factory settings ..........................................................................................21

5.1.2 Restart - restart of the controller..............................................................................................................21

5.2 Selection of the temperature sensors.................................................................................................22

5.2.1 Necessary and optional sensors .............................................................................................................23

5.3 Controller function ................................................................................................................................25

5.4 Cooling ...................................................................................................................................................25

5.4.1 Temperature control by supply and return air in single-zone operation ..................................................25

5.4.2 Temperature control by supply and return air in two-zone operation ......................................................27

5.4.3 Temperature control by cold-room air sensor..........................................................................................28

5.4.4 Continuous running monitoring ...............................................................................................................29

5.4.5 Minimum on and off time .........................................................................................................................29

5.4.6 E*COP+ (SDS TEV) ................................................................................................................................29

5.4.7 Two temperature zones...........................................................................................................................30

5.4.8 Heating circuit control..............................................................................................................................30

5.4.9 Operation of cooling relay .......................................................................................................................30

5.4.10 Start delay after fan .................................................................................................................................31

Firmware V3.15

21.04.2021

4/401

5.4.11 Emergency operation ..............................................................................................................................31

5.5 Defrosting ..............................................................................................................................................31

5.5.1 Typesofdefrosting–anoverview........................................................................................................... 31

5.5.2 Defrost in general ....................................................................................................................................32

5.5.3 Discharge gas defrosting (hot gas defrosting).........................................................................................38

5.5.4 Brine defrosting .......................................................................................................................................39

5.5.5 Master/slavemode–defrostsynchronisationviaCANbus....................................................................40

5.5.6 Master/slavemode–defrostsynchronisationviawiring.........................................................................43

5.5.6.1 Master/slave mode for the synchronisation of the zones of a single controller.......................................44

5.5.6.2 Master-slave mode for the synchronisation of multiple controllers .........................................................45

5.5.6.3 Necessary settings for the master / slave mode .....................................................................................46

5.5.6.4 Special features and constraints .............................................................................................................46

5.5.7 Defrost sequence (DS) via CAN bus.......................................................................................................48

5.5.8 Fan control with case and cold-room controllers.....................................................................................52

5.5.8.1 Fan control on multidecks .......................................................................................................................52

5.5.8.2 Fan control - Controller type UA 131 .......................................................................................................52

5.5.8.3 Fan control - controller type UA 131 LS with enhanced fan control ........................................................53

5.5.8.4 Fan control - Controller type UA 131 DD.................................................................................................57

5.5.8.5 Fan control - Controller type UA 141 E....................................................................................................57

5.5.9 Fan control with cold-room controllers ....................................................................................................58

5.5.9.1 Cold-room with defrost heater - Controller type UR 141 TK (LT) only.....................................................59

5.5.9.2 Cold-room without defrost heater - Controller type UR 141 NK (NT) only ..............................................60

5.5.9.3 Heating circuit (controller type UR 141 TK (LT) or NK (NT) only) ...........................................................60

5.6 Humidification - Controller type UA 141 only .....................................................................................61

5.7 Antisweat heaters..................................................................................................................................61

5.8 Automatic on/off control.......................................................................................................................64

5.9 Door contact ..........................................................................................................................................65

5.10 Manual shutdown ..................................................................................................................................66

5.11 Registration of external alarms (e.g. CO2 alarm)...............................................................................66

5.12 Emergency power operation ................................................................................................................67

5.13 Setpoint toggle (day / night operation) ...............................................................................................68

5.14 Light control ..........................................................................................................................................69

5.15 Refrigeration point disabling ...............................................................................................................69

5.16 Forced cooling.......................................................................................................................................69

5.17 Operating data archiving ......................................................................................................................70

5.17.1 Temperature recording ............................................................................................................................ 70

5.17.2 Temperature recording to EU Regulation 37/2005..................................................................................71

5.17.3 Recording of messages and alarms........................................................................................................ 71

Firmware V3.15

21.04.2021

5/401

5.18 BT 30 temperature display ...................................................................................................................72

6 UA 400 installation and start-up...........................................................................................................75

6.1 Installation .............................................................................................................................................75

6.1.1 DIN rail mounting of the case/cold-room controller .................................................................................76

6.1.1.1 Mounting on the DIN rail..........................................................................................................................77

6.1.1.2 Disassembling from the DIN rail..............................................................................................................79

6.1.2 Handling of the spring terminals..............................................................................................................80

6.2 Basic settings ........................................................................................................................................81

6.2.1 Setting the CAN bus address ..................................................................................................................81

6.2.2 Setting of the controller type and master/slave mode .............................................................................83

6.3 Terminal assignment for 230 V AC power supply ..............................................................................85

6.3.1 Status LEDs ............................................................................................................................................86

6.4 Basic configuration of the controller ..................................................................................................88

6.4.1 Naming of the controller ..........................................................................................................................92

6.5 Battery replacement..............................................................................................................................93

6.6 Firmware Update ...................................................................................................................................95

6.6.1 Requirements for firmware update..........................................................................................................96

6.6.2 Installing firmware update .......................................................................................................................98

6.6.2.1 Update for controller with 9-pole DIP switch ...........................................................................................98

6.6.2.2 Update for controller with 8-pole DIP switch .........................................................................................102

6.6.3 Rectification of driver problems .............................................................................................................106

7 Pin and Terminal Assignments of UA 400.........................................................................................107

7.1 Terminal diagram.................................................................................................................................107

7.2 Terminal assignment of the 230 V AC power supply .......................................................................108

7.3 Terminal assignment of the 230 V AC relay outputs........................................................................109

7.4 Mode of operation of the relay and transistor outputs.................................................................... 111

7.5 Terminal assignment of the 230 V AC digital inputs........................................................................ 113

7.6 Terminal assignment of the 0..10 V analogue outputs .................................................................... 115

7.7 Terminal assignment of the CAN bus terminals............................................................................... 116

7.8 Terminal assignment of the 24 V DC transistor outputs ................................................................. 117

7.9 Terminal assignment of the DISPLAY interface................................................................................ 118

7.10 Terminal assignment of the 4..20 mA analogue inputs.................................................................... 119

7.11 Terminal assignment of the analogue inputs for temperature sensors.........................................120

7.11.1 Sensor identification ..............................................................................................................................122

7.12 Assignment of the USB port ..............................................................................................................123

7.13 Terminal assignment of the CI 320/TTY interface ............................................................................124

7.14 Wiring of the master-slave function for defrost synchronization...................................................125

8 Operation of UA 400 ............................................................................................................................126

Firmware V3.15

21.04.2021

6/401

8.1 Operation possibilities........................................................................................................................126

8.2 Local operation with a BT 300 x operator interface.........................................................................127

8.2.1 Lock-down of the setpoint change.........................................................................................................127

8.3 Remote control via a terminal ............................................................................................................129

8.3.1 Menus and operating screens...............................................................................................................130

8.3.2 Calling the controller menu via remote control......................................................................................134

8.3.2.1 System Centre.......................................................................................................................................134

8.3.2.2 Store computer CI 3x00 / operator terminal AL 300 ..............................................................................135

8.3.3 Deactivating the input lock-down...........................................................................................................137

8.3.3.1 Store computer CI 3x00 / operator terminal AL 300 ..............................................................................137

8.3.3.2 System centre CI 4x00 ..........................................................................................................................137

8.3.4 Activating service mode ........................................................................................................................138

8.3.4.1 System centre CI 4x00 Service-Mode...................................................................................................138

8.3.4.2 Store computer CI 3x00 - Service-Mode ...............................................................................................138

9 Menu structure UA 400 .......................................................................................................................139

9.1 Controller type UA 111 - menu tree....................................................................................................139

9.1.1 Main menu UA 111 ................................................................................................................................142

9.1.2 Menu 1 Actual Values UA 111................................................................................................................143

9.1.3 Menu 2 Setpoints UA 111 ......................................................................................................................147

9.1.4 Menu 3 Clock UA 111 ............................................................................................................................155

9.1.5 Menu 4 Messages UA 111.....................................................................................................................158

9.1.6 Menu 5 Archive UA 111 .........................................................................................................................159

9.1.7 Menu 6 Configuration UA 111................................................................................................................160

9.2 Controller type UA 111 D - menu tree ................................................................................................170

9.2.1 Main menu UA 111 D.............................................................................................................................173

9.2.2 Menu 1 Actual Values UA 111 D ............................................................................................................174

9.2.3 Menu 2 Setpoints UA 111 D...................................................................................................................177

9.2.4 Menu 3 Clock UA 111 D.........................................................................................................................182

9.2.5 Menu 4 Messages UA 111 D .................................................................................................................185

9.2.6 Menu 5 Archive UA 111 D......................................................................................................................186

9.2.7 Menu 6 Configuration UA 111 D ............................................................................................................187

9.3 Controller type UA 121 - menu tree ...................................................................................................196

9.3.1 Main menu UA 121................................................................................................................................199

9.3.2 Menu 1 Actual Values UA 121 ...............................................................................................................200

9.3.3 Menu 2 Setpoints UA 121......................................................................................................................205

9.3.4 Menu 3 Clock UA 121............................................................................................................................213

9.3.5 Menu 4 Messages UA 121 ....................................................................................................................217

9.3.6 Menu 5 Archive UA 121.........................................................................................................................218

Firmware V3.15

21.04.2021

7/401

9.3.7 Menu 6 Configuration UA 121 ...............................................................................................................219

9.4 Controller type UA 131 / UA 131 LS - menu tree ...............................................................................229

9.4.1 MainmenuUA 131 /UA 131 LS ............................................................................................................232

9.4.2 Menu1ActualValuesUA 131 /UA 131 LS............................................................................................233

9.4.3 Menu2SetpointsUA 131 /UA 131 LS ..................................................................................................238

9.4.4 Menu3ClockUA 131 /UA 131 LS ........................................................................................................246

9.4.5 Menu4MessagesUA 131 /UA 131 LS.................................................................................................248

9.4.6 Menu5ArchiveUA 131 /UA 131 LS .....................................................................................................249

9.4.7 Menu6ConfigurationUA 131 /UA 131 LS............................................................................................250

9.5 Controller type UA 131 DD - menu tree .............................................................................................259

9.5.1 Main menu UA 131 DD..........................................................................................................................262

9.5.2 Menu 1 Actual Values UA 131 DD.........................................................................................................263

9.5.3 Menu 2 Setpoints UA 131 DD ............................................................................................................... 268

9.5.4 Menu 3 Clock UA 131 DD .....................................................................................................................275

9.5.5 Menu 4 Messages UA 131 DD..............................................................................................................277

9.5.6 Menu 5 Archive UA 131 DD...................................................................................................................278

9.5.7 Menu 6 Configuration UA 131 DD.........................................................................................................279

9.6 Controller type UA 141 - menu tree ...................................................................................................288

9.6.1 Main menu UA 141................................................................................................................................291

9.6.2 Menu 1 Actual Values UA 141 ...............................................................................................................292

9.6.3 Menu 2 Setpoints UA 141......................................................................................................................297

9.6.4 Menu 3 Clock UA 141............................................................................................................................304

9.6.5 Menu 4 Messages UA 141 ....................................................................................................................308

9.6.6 Menu 5 Archive UA 141.........................................................................................................................309

9.6.7 Menu 6 Configuration UA 141 ...............................................................................................................310

9.7 Controller type UA 141 NK - menu tree .............................................................................................319

9.7.1 Main menu UR 141 NK .........................................................................................................................322

9.7.2 Menu 1 Actual Values UR 141 NK.........................................................................................................323

9.7.3 Menu 2 Setpoints UR 141 NK ...............................................................................................................328

9.7.4 Menu 3 Clock UR 141 NK .....................................................................................................................336

9.7.5 Menu 4 Messages UR 141 NK..............................................................................................................340

9.7.6 Menu 5 Archive UR 141 NK ..................................................................................................................341

9.7.7 Menu 6 Configuration UR 141 NK.........................................................................................................342

9.8 Controller type UA 141 TK - menu tree .............................................................................................352

9.8.1 Main menu UR 141 TK..........................................................................................................................355

9.8.2 Menu 1 Actual Values UR 141 TK .........................................................................................................356

9.8.3 Menu 2 Setpoints UR 141 TK................................................................................................................362

9.8.4 Menu 3 Clock UR 141 TK......................................................................................................................371

Firmware V3.15

21.04.2021

8/401

9.8.5 Menu 4 Messages UR 141 TK ..............................................................................................................375

9.8.6 Menu 5 Archive UR 141 TK...................................................................................................................376

9.8.7 Menu 6 Configuration UR 141 TK .........................................................................................................377

10 Decommissioning and disposal ........................................................................................................387

10.1 Decommissioning / Demounting .......................................................................................................387

10.2 Disposal ...............................................................................................................................................387

11 Alarms and Messages of UA 400 .......................................................................................................388

11.1 Alarm signalling and monitoring .......................................................................................................390

11.1.1 Cold-room door open alarm ..................................................................................................................390

11.1.2 High or low temperature alarm ..............................................................................................................390

11.1.3 Alarm in the event of the absence of a defrost......................................................................................391

11.1.4 Sensor break alarm ...............................................................................................................................391

11.1.5 Suppression of sensor break alarm during defrosting...........................................................................391

11.1.6 Hardware fault alarm .............................................................................................................................392

11.1.7 Individual allocation of priorities ............................................................................................................393

11.1.8 Alarm routes ..........................................................................................................................................395

11.1.9 Termination of alarm.............................................................................................................................. 395

11.1.10 Restart...................................................................................................................................................395

11.2 Messages .............................................................................................................................................396

11.2.1 Transient alarms and messages ...........................................................................................................396

11.2.2 Message log ..........................................................................................................................................396

12 Specifications of UA 400.....................................................................................................................397

12.1 Electrical data ......................................................................................................................................397

12.2 Mechanical Data ..................................................................................................................................399

12.3 Mechanical data of the temperature sensor L243 / 5K3A1..............................................................400

13 Order numbers and accessories of UA 400 / UA 410.......................................................................401

13.1 Case controller ....................................................................................................................................401

13.2 Components ........................................................................................................................................401

Firmware V3.15

21.04.2021

9/401

•

•

•

•

•

1 Conventions

1.1 Warning signs, symbols and text formatting used in this manual

Explanation of the warning signs, symbols and text formatting used in this operating and service manual:

DANGER

WARNING

CAUTION

*IfanyofthesesymbolsDANGER/WARNING/CAUTION is recognized, the user must refer to the operating

manual in order to understand the type of potential HAZARD and the required actions for avoiding the

HAZARD. Carefully observe all health and safety instructions and use particular caution in these situations.

Failure to observe the DANGER/WARNING/CAUTION symbols will cause injury (in the worst case,

severe injury or death) and/or damage to property!

ATTENTION

NOTICE

DANGER

Instructions with this symbol and/or the signal word DANGER warn the user of situations that will

cause severe injury or death if the specified instructions are not observed! *

WARNING

Instructions with this symbol and/or the signal word WARNING warn the user of situations that may

cause severe injury or death if the specified instructions are not observed! *

CAUTION

Instructions with this symbol and/or the signal word CAUTION warn the user of situations that may

cause moderate or minor injury if the specified instructions are not observed! *

ATTENTION

Instructions with this symbol and/or the signal word ATTENTION warn the user of situations that may

cause damage to property if the specified instructions are not observed! The ATTENTION symbol

highlights guidelines and regulations, instructions and proper working procedures that must be

particularly observed in order to prevent damage to and destruction of components or malfunctioning.

Failure to observe the ATTENTION symbol will cause damage to property!

NOTICE

Instructions with this symbol and/or the signal word NOTICE provide tips and useful additional

information.

Firmware V3.15

21.04.2021

10/401

•

•

•

1.

2.

3.

4.

1.

2.

ELECTRIC SHOCK

Risk of fatal electric shock!

This symbol warns of danger from dangerous voltage with possible consequences such as severe injury and death. If this

symbol is seen, the user must refer to the operating manual in order to understand the type of potential HAZARD and the required

actions for avoiding the HAZARD. Carefully observe all health and safety instructions and use particular caution in these

situations.

Failure to observe the WARNING symbol will cause injury (in the worst case, severe injury or death) and/or damage to

property!

ESD - Electrostatic-sensitive components and control components

DISPOSAL

Potential negative impact on people and the environment due to non-environmentally friendly disposal.

The strike-through dustbin symbol indicates the duty to dispose of items properly. Do not dispose of this product with other

domestic waste. Please inform yourself about the local regulations for the separate disposal of electrical and electronic products.

The correct disposal of your old equipment protects people and the environment from possible negative impact.

Failure to observe the DISPOSAL symbol will cause damage to people and the environment!

1.2 Explanation of text formatting

Safety instructions or hazard warnings are composed of four elements:

Thesymbol with text (e.g. for DANGER),

a concise description of the hazard and

a description of the possible consequences.

Where applicable, a catalogue with measures for avoiding the hazard.

For example:

A general instruction consists of two elements:

Thesymbol with text (including NOTICE, if applicable) and

the text of the instruction:

For example:

Risk of destruction of the control component / controller!

Electronic components and control components (e.g. circuit boards) are sensitive to electrostatic charges. Circuit boards may only

be replaced when the power supply is disconnected. Always hold circuit boards by the edges. The guidelines for the handling of

electrostatic-sensitive components and control components must be observed at all times.

Failure to observe the ESD symbol will cause damage to property!

DANGER

Warning of dangerous electrical voltage! Risk of fatal electric shock!

Beware of external voltage at the digital inputs and outputs! Connections/plug connectors of the device

may only be plugged in, removed and/or wired when no voltage is present.

NOTICE

The current operating manual is available online from the E°EDP (Eckelmann ° Electronic

Documentation Platform) at www.eckelmann.de/elds.

Firmware V3.15

21.04.2021

11/401

•

•

•

•

•

•

•

•

•

•

•

•

2 Safety instructions

This operating manual is part of the device. It must be kept in the vicinity of the controller as well as for future

use so that it can be consulted when required. The operating manual must be available to the operating and

maintenance personnel at all times in order to avoid operating errors. The safety regulations, instructions and

information must be strictly observed and complied with. During repairs on the entire E*LDS system, the

accident prevention regulations and general safety regulations must be strictly complied with. Important

information (safety instructions and hazard warnings) are indicated by appropriate symbols, see chapter

Conventions. Follow these instructions in order to prevent accidents and danger to life and limb, as well as

damage to the E*LDS system!

Always observe the following information:

Workontheelectricalsystemmayonlybeperformedbyauthorised, skilled personnel (accordingtothe

definition of skilled persons in DIN/VDE 0105 and IEC364) while observing the applicable

- VDE regulations

-Localsafetyregulations

-Intended Use

-FivesafetyrulesaccordingtoDGUVRegulation3

-ESDmeasures

-Operatingmanuals

For safety reasons, the equipment must not be used for any applications other than described in the

operating manual and only for the intended use.

Before using the device, check whether it is suitable for your application with regard to its limit values.

The equipment must be installed in an electrically shielded area within the switch cabinet.

Before connecting the device, it must be checked whether the power supply is suitable for the device.

When using uncoded plug connectors, it is possible to connect them so that there is a danger to life and

limb! If this cannot be ruled out, coded plug connectors must be used.

Specified ambient conditions (e.g. humidity and temperature limits, see chapter Technical Data) must be

observed and complied with at all times to prevent malfunction.

Before switching on the device, check the correct wiring of the connections.

The device must never be operated without its housing. Before opening the housing, the device must be

de-energised.

Note the maximum load of the relay contacts, see chapter Technical Data.

Note that all supply lines from and to the device, particularly those of the CAN bus and Modbus, must be

shielded or installed sufficiently far away from live cables. This prevents faulty measurements and protects

the device against electrical interference via the analogue inputs. Connection in parallel of RC elements is

recommended for applications with critical environment.

Contact the supplier in the case of any malfunction.

DANGER

Warning of dangerous electrical voltage! Danger of electric shock!

Beware of external voltage at the digital inputs and outputs! Connections/plug connectors of the device

may only be plugged in, removed and/or wired when no voltage is present.

Firmware V3.15

21.04.2021

12/401

2.1 Disclaimer in the event of non-compliance

These operating instructions contain information on the commissioning, function, operation and maintenance

ofthecontrolsandoftheassociatedcomponents.

2.2 Requirements for the personnel

Special technical knowledge is required for planning, programming, installation, putting into service and

maintenance work. This work may only be performed by skilled, specially trained personnel. The installation,

putting into service and maintenance personnel must have training that authorises them to perform

interventions in the system and the automation system. The planning and programming personnel must be

familiar with the safety concepts of automation technology. Working on electrical systems requires special

technical knowledge. Work on electrical systems may only be performed by instructed electrically skilled

persons or under the guidance or supervision of such persons. The applicable regulations (e.g. DIN EN 60204,

EN 50178, DGUV Regulation 3, DIN-VDE 0100/0113) must be observed. The operating personnel must be

instructed in how to handle the system / machine and the controller and must be familiar with the operating

instructions.

WARNING

Warning of damage to goods!

In our experience, the transmission of fault messages is not yet functional during the putting into

service (no internet connection, no telephone line installed, etc.). It is strongly recommended in such

cases to monitor the controller via the CAN bus using a system centre, a store computer or an operator

terminal and to enable the transmission of fault messages, for example using a GSM modem via a

mobile telephone system. In standalone operation, or as an alternative to monitoring via system

centre / store computer / operator terminal, an available alarm contact on the controller must be used

to enable the transmission of fault messages via a telephone network.

For more information, refer to E*LDS basics, safety instructions, CAN bus & Modbus.

Observance of these operating instructions is a prerequisite for safe and trouble-free operation.

Firmware V3.15

21.04.2021

13/401

•

•

•

•

•

•

•

2.3 Intended use

This control system may only be used for the purpose for which it is intended: The UA 400 CC / UA 400 AC

control system has been designed for use as case controller in commercial and industrial refrigeration systems

with the intended functional scope as described in these operating instructions, and it is to be used under the

environmental conditions in these instructions.

Read the safety instructions and the instructions for installation and putting into service, operation and

maintenance. THEN start the commissioning and/or operation of the machine / system.

The safety and functionality of the machine / system are only guaranteed for this intended application.

Never use the machine / system, its components, control components or parts for any other purpose.

The system must not be put into operation until conformity with the applicable EU Directives has been

established for the entire system.

2.4 Five safety rules according to DGUV Regulation 3

The following rules must be strictly observed!

1. Disconnect: The entire system to be worked on must be disconnected from the power supply at all poles.

2. Secure against reconnection: Attach information signs to the disconnected operating equipment stating:

What has been disconnected.

Reason for the disconnection.

Name of the person who made the disconnection.

Reconnection must be prevented using a suitable lock (e.g. padlock).

3. Prove dead (authorised skilled personnel only):

Check voltmeter just before use.

Prove dead on all poles at the disconnection point.

Prove dead on all poles at the work area.

4. Ground and short-circuit:Allelectricalpartsattheworkareamust be grounded and then short-

circuited.

5. Cover or block off adjacent live parts:Ifthereisliveequipmentadjacenttotheworkarea,itmustbe

covered using appropriate materials (e.g. insulation blankets / plates).

DANGER

Warning of dangerous electrical voltage! Warning of dangerous electrical voltage! Danger of

electric shock!

Beware of a possible external power supply! BEFORE connecting and disconnecting it must be

checked that no voltage is present at the controller! Connections/plug connectors of the device may

only be plugged in, removed and/or wired when no voltage is present.

Firmware V3.15

21.04.2021

14/401

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

2.5 Electrostatic-sensitive components and control components (ESD)

All electrostatic-sensitive components and control components (referred to as "ESD" below) are labelled with

the warning sign shown. Electrostatic charges arise from friction of insulating materials (e.g. floor covering,

items of clothing made of synthetic fibres etc.). Even small charges can result in damage to or destruction of

components. Such damage is not always immediately noticeable; in some cases, it does not lead to failure until

after a certain operating time.

2.5.1 ESD - Rules for handling and working

Transport and store ESDs only in the protective packaging provided.

Avoid materials that may produce electrostatic discharge, for example

Plastic containers and table tops

Synthetic fibre clothing

Plastic-soled shoes

Plastic file covers

Styrofoam packaging

Computer monitors, etc.

Preferably wear the following:

Cotton work clothes

ESD shoes with conductive soles or leather soles

Use the following:

Conductive flooring

ESD workstations equipped with suitable tools (grounded soldering guns, antistatic wrist straps, etc.)

Conductive ESD bags, conductive plastic containers, IC tubes or cartons lined with conductive foam

Containers and worktops made of wood, metal or conductive plastics or paper bags

2.6 Abbreviations used

DGUV Regulation 3 - Accident Prevention Regulation for Electrical Systems and Equipment

(previously: BGV A3-Employer’sLiabilityAssociationRegulationforOccupationalHealthandSafety)

DINDeutschesInstitutfürNormung e.V. (German Standardisation Institute)

EDP: Electronic Documentation Platform of Eckelmann AG

ESDElectrostatic-SensitiveDevice

ESDElectro-staticdischarge (ElectroSensitiveDevices)

IECInternationalElectricCommittee

VDEVerbandderElektrotechnikElektronik Informationstechnik e.V. (German Association for Electrical,

Electronic and Information Technologies)

ATTENTION

Risk of destruction of the control component / controller! Electronic components

and control components (e.g. circuit boards) are sensitive to electrostatic

charges.Therefore, the guidelines for handling electrostatic-sensitive components and

control components must be strictly observed.

Firmware V3.15

21.04.2021

15/401

•

•

3 System Design of UA 400

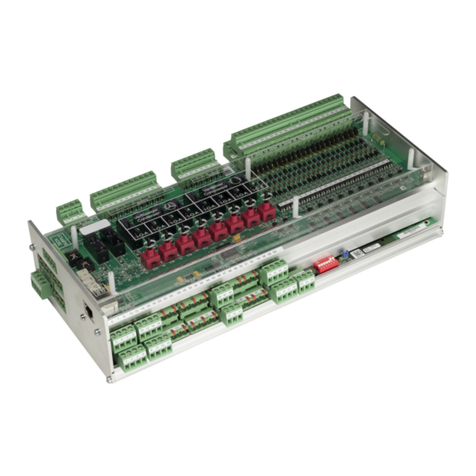

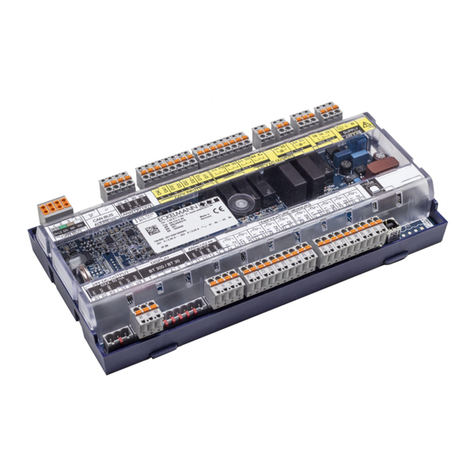

Figure: UA 400 AC - full configuration

3.1 Application

The UA 400 case controller for thermostatic expansion valves (TEV), is suitable for the control and monitoring

of up to two temperature zones in refrigerated display cases and cold rooms for normal cooling and low

temperature refrigeration (NT/LT).

The appropriate application for refrigerated shelves, refrigerated display cases, island freezers and freezer

rooms can be simply set using the DIP switches on the controller. Factory settings for the desired application,

tired and tested in praxis, are then loaded.

The use of the case controller for electronic expansion valves offers decisive advantages thanks to a reduced

pressure difference between the high and low pressure sides, lower superheat at the evaporator as well as

constant conditions for the goods and evaporator thanks to continual regulation. The adaptive suction pressure

control generates further savings potential thanks to the load independent increase in suction pressure.

A range of functions for cost and energy saving such as defrost on demand, latent heat utilisation, intelligent fan

control, enthalpy controlled frame heating and the constant temperature control of the goods are available with

this case controller.

In order to fully utilise its performance features the controller is typically connected to the CAN bus, through

which it communicates with further control and monitoring components across the entire network.

Via the CAN bus an intelligent data exchange is carried out with the following system components:

System Centre / Store computer: Archiving of the operating data as well as alarm and message

management, Connection to LDSWin for analysis, configuration and evaluation

Pack controller: Data exchange between the E*LDS components, Consumer lock (emergency function in

the event of pack failure)

ABT300xOperatorInterfaceandonetofourBT30TemperatureDisplayscanbeconnectedtothecontroller

when required. Electrical connections are described in Section Pin and Terminal Assignments of UA 400.

Firmware V3.15

21.04.2021

16/401

•

•

•

•

•

•

•

•

•

•

•

•

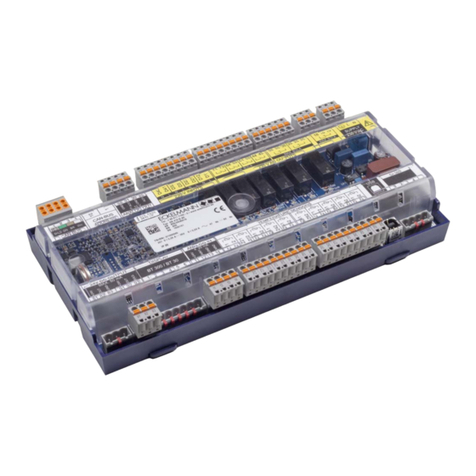

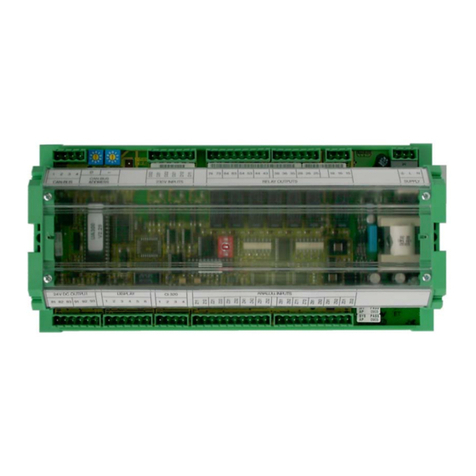

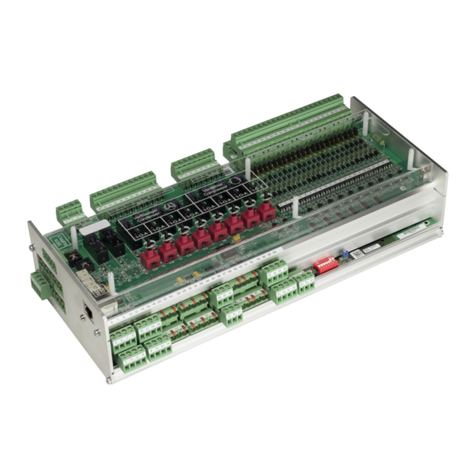

3.2 Hardware

The case controller is housed in a plastic casing for DIN rail mounting and does not require any further optional

expansion modules. Up to 99 case controllers can be used within the LDS system. As required, a BT 300 x

Operator Interface and up to 4 BT 30 Temperature Displays can be connected. For the direct parameterisation

via LDSWin or for a firmware update, the controller can be connected to a laptop or PC via the USB interface.

TheapplicationrangeofthecasecontrollerisdescribedinmoredetailinchapterVersions.

The following diagram illustrates the system architecture of the UA 410 AC case controller (complete):

Ports

CAN bus: Communication in E*LDS-System, new version

DISPLAY: Connection for BT 300x Operator Interface and up to four BT 30 Temperature Displays

CI 320: Communication with LDSWin software / Connection to the legacy system CI 320

USB: For conducting a firmware update

Inputs/outputs

4 digital inputs 230 V AC, floating

10 analog inputs Connection for two-wire NTC temperature sensors

Only UA 410 AC:2 x analogue inputs 4..20 mA - currently without function

Outputs

3 relay output 230 V AC / 6 A (changeover)

4 relay outputs 230 V AC / 6 A (N.O.)

2 transistor outputs 24 V DC / 50 mA (for lighting control and frame heater)

Only UA 410 AC:2 x analogue outputs 0..10 V DC - currently without function

Real-time clock

Only UA 400 AC: Battery-backed, lithium cell

ForprecisedetailsofthedifferentfeaturesofthecontrollersUA400CCandUA400AC

seechapterController types. The connection and terminal configurations are described in

thechapterPin and Terminal Assignments of UA 400.

Firmware V3.15

21.04.2021

17/401

•

•

4 Applications of UA 400

4.1 Versions

Distinguishing features of the case controllers:

UA 400 CC * UA 400 AC *

(complete design)

For DIN rail mounting • •

For integration in the CAN bus E*LDS system • •

Replacement controller for UA 300 • •

Replacement controller for the LDS1 system (connection to the

LDS1 system via the CI320 interface)

•

Suitable for standalone operation •

With integrated real-time clock (lithium cell power reserve) •

With integrated archive memory for data recording •

Abbreviations used

CCstandsforCAN bus and Cabinet / DIN rail mounting(C=withCANbusandC=DINrailmounting).

ACstandsforAll in one and Cabinet / DIN rail mounting(All=withCANbusandreal-timeclockandC=

DIN rail mounting).

* Special feature: The controller is available in two device generations; the DIP switch provides a

quick distinguishing feature:

1st generation: since 2011 (8-way DIP switch)

2nd generation:fromOct./Nov.2018(9-wayDIPswitch)

Note: The range of functions described in this operating manual refers to both device generations.

Firmware V3.15

21.04.2021

18/401

4.2 Controller types

Case controllers for refrigeration points with thermostatic expansion valves contain a range of different

controller types with different fields of application which are summarised as follows:

Controller type Applications

Case

contr

oller

UA 111 Multidecks without defrost heater

UA 111 D Multidecks without defrost heater with twin compressor pack

UA 121 Normal temperature (NT) refrigeration (multidecks, islands, chests, counters) with defrost heater

UA 131 without fan

control

UA 131 with fan

control

Low-temperature (LT) refrigeration (islands, chests, cabinets, freezer set) with defrost heater, NT cases

with defrost heater

UA 131 LS with

enhanced fan control

Low-temperature (LT) refrigeration (islands, chests, cabinets, freezer set) with defrost heater, NT cases

with defrost heater

UA 131 DD The controller type has been specially developed for use in refrigerated cases that are operated on a

refrigeration pack system with 2-pipe hot gas defrost. Since version V2.20, it has replaced the controller

type UA 131 A that was suitable for LT islands with twin compressor pack.

UA 141 Service counters without defrost heater

Cold

room

contr

oller

UR 141 NK NT cold rooms with / without defrost heater

UR 141 TK NT / LT cold rooms with / without defrost heater and hot gas defrost

For definition of the basic control action, only one controller type can be set, which is set using the DIP

switch S3:

Special feature: Two device generations are available. The DIP switch S3 provides a quick distinguishing

feature:

2nd generation controller

(from Oct. / Nov. 2018)

1st generation controller

(since 2011)

Characteristic: 9-pole DIP switch Characteristic: 8-pole DIP switch

Example: Setting of the coding switches for the controller type UA 131 E; for details, see chapter Setting of the

controller type and master/slave mode.

Firmware V3.15

21.04.2021

19/401

•

•

•

•

Controller type or master / slave mode DIP switch S3 (switch positions of the coding switches 1 .. 9)

1234

Master /

Slave mode

5 6 7 8 9

Nor

mal

Ope

rati

on /

Fir

mw

are

Upd

ate

(onl

y

2nd

gen

erat

ion

con

troll

ers)

Case controller

UA 111 OFF OFF OFF ON/OFF OFF OFF OFF OFF ON

UA 111 D OFF ON ON ON/OFF OFF OFF OFF OFF ON

UA 121 ON OFF OFF ON/OFF OFF OFF OFF OFF ON

UA 131 without

fan control

UA 131 with fan

control

(terminals 73/74)

OFF ON OFF ON/OFF OFF

ON

OFF OFF OFF ON

UA 131 LS with

enhanced fan

control

(terminals

15/16/18)

ON ON ON ON/OFF ON OFF OFF OFF ON

UA 131 DD ON ON ON OFF OFF OFF OFF OFF ON

UA 141 ON ON OFF ON/OFF OFF OFF OFF OFF ON

Cold room controller

UR 141 NK OFF OFF ON ON/OFF OFF OFF OFF OFF ON

UR 141 TK ON OFF ON ON/OFF OFF OFF OFF OFF ON

The controller can be operated via

a central computer e.g. via network / modem with connection to the system centre / store computer,

the system centre, a store computer or an operator terminal,

a local BT 300 operator interface x via the DISPLAY interface on the controller or

a laptop (PC) with the PC software LDSWin connected via USB.

Operation with an unsupported DIP switch setting is not permitted. In the event of change of the

controller type, all parameters are reset to their factory settings.

For more details, see chapter Operation of UA 400.

Firmware V3.15

21.04.2021

20/401

4.3 Updating firmware

The case controller is supplied with the current firmware, ready for operation. Future software versions can be

loadedintothecasecontrollerasrequiredbymeansofafirmwareupdate,andthusupdated.

Danger data loss!Insomecasesachangeoffirmwareversioncanleadtothelossofallthesetpoints

in the case controller. As a precaution, the settings must be backed up by saving them to the LDSWin

PCsoftware,priortotheupdate.Afterthefirmwareupdatethebackupsettingscanbereloadedinto

the controller from LDSWin. A software update is only to be carried out by trained staff or factory-side

bythemanufacturer.FurtherdetailsonfirmwareupdatescanbefoundinchapterFirmware Update.

Table of contents

Other ECKELMANN Controllers manuals

ECKELMANN

ECKELMANN VS 300 User manual

ECKELMANN

ECKELMANN VS 3000 BS User manual

ECKELMANN

ECKELMANN UA 300 D User manual

ECKELMANN

ECKELMANN WRG 3010 E User manual

ECKELMANN

ECKELMANN VS 3000 User manual

ECKELMANN

ECKELMANN Case Controller UA 4 E Series User manual

ECKELMANN

ECKELMANN VS 3015 C User manual

ECKELMANN

ECKELMANN UA 410 D User manual

ECKELMANN

ECKELMANN VS 3010 BS User manual

ECKELMANN

ECKELMANN UA 410 L User manual