Table of contents

ii Version 2.02 29. Nov. 2007

3.22.4 Control algorithm with step controller 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.22.5 Calculating setpoint with step controller 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.22.6 Condenser fan control times with step controller 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.22.7 Control algorithm with continuous control 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.22.8 Calculating setpoint with continuous control 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.22.9 Heat recovery mode 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.23 HP setpoint increase 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.24 Fan protection / HP base load rotation 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.25 Monitoring condenser fan motors 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.26 Starting characteristics 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.26.1 First start 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.26.2 Restart 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.27 Monitoring refrigerant level 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.28 Monitoring burst disk 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.29 Monitoring external alarm / speed adjuster 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.30 Disabling refrigeration points 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31 Discharge gas defrosting 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.1 Setpoints for discharge gas defrosting 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.2 Actual values for discharge gas defrosting 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.3 Manual control of D2D 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.4 Sequence of joint Z2 discharge gas defrosting 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.5 Sequence of Z2 display case discharge gas defrosting 35. . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.6 Sequence of Z2 coldroom discharge gas defrosting 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.7 Sequence of Z1 discharge gas defrosting 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.8 Sequence of Z2 discharge gas defrosting with defrost mode set to

El. With UA 300 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.31.9 Discharge gas defrosting in fault conditions 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

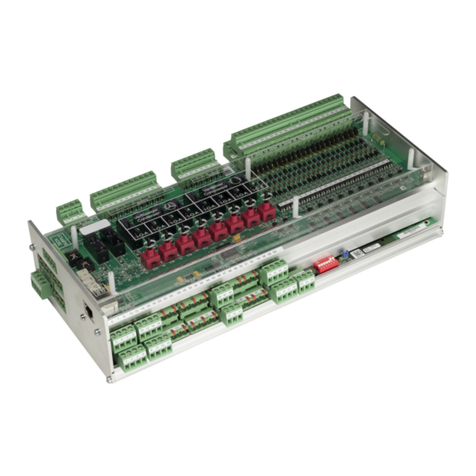

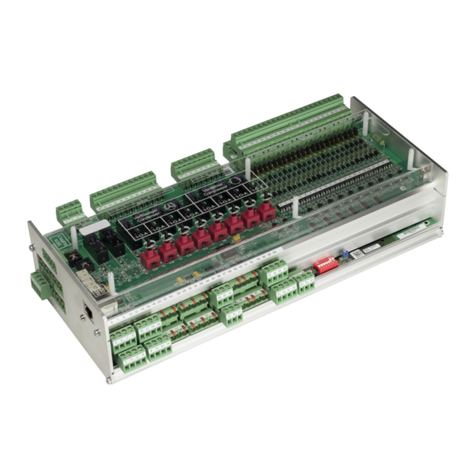

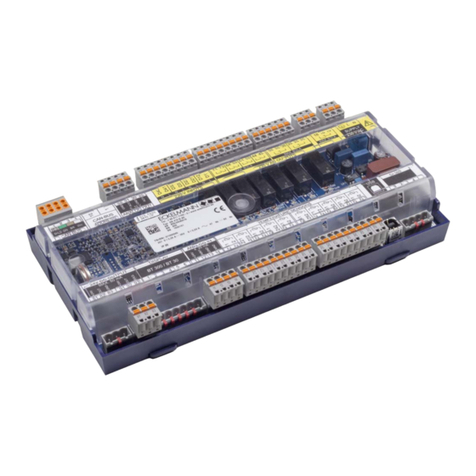

4 Installation and Startup of VS 3000 BS 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Connection and safety notes 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

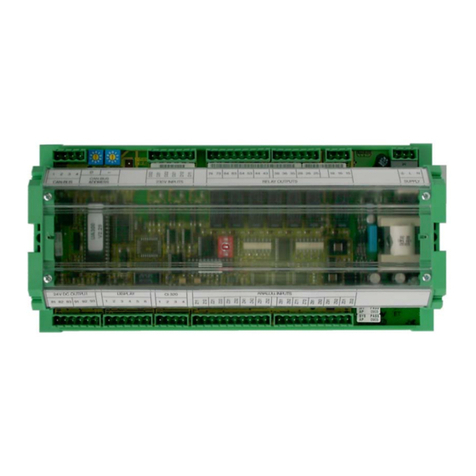

4.2 DIN rail mounting 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Basic parameter settings on hardware 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Basic settings with S1 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Basic settings with S2 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Basic parameter settings in software 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

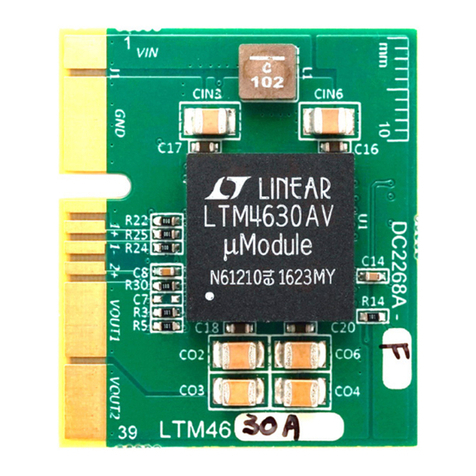

4.5 Commissioning of speed controlled condenser fans / compressors 45. . . . . . . . .

4.5.1 Procedure for commissioning an installation 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Replacing the battery 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .