Ecoflo ESE40W User manual

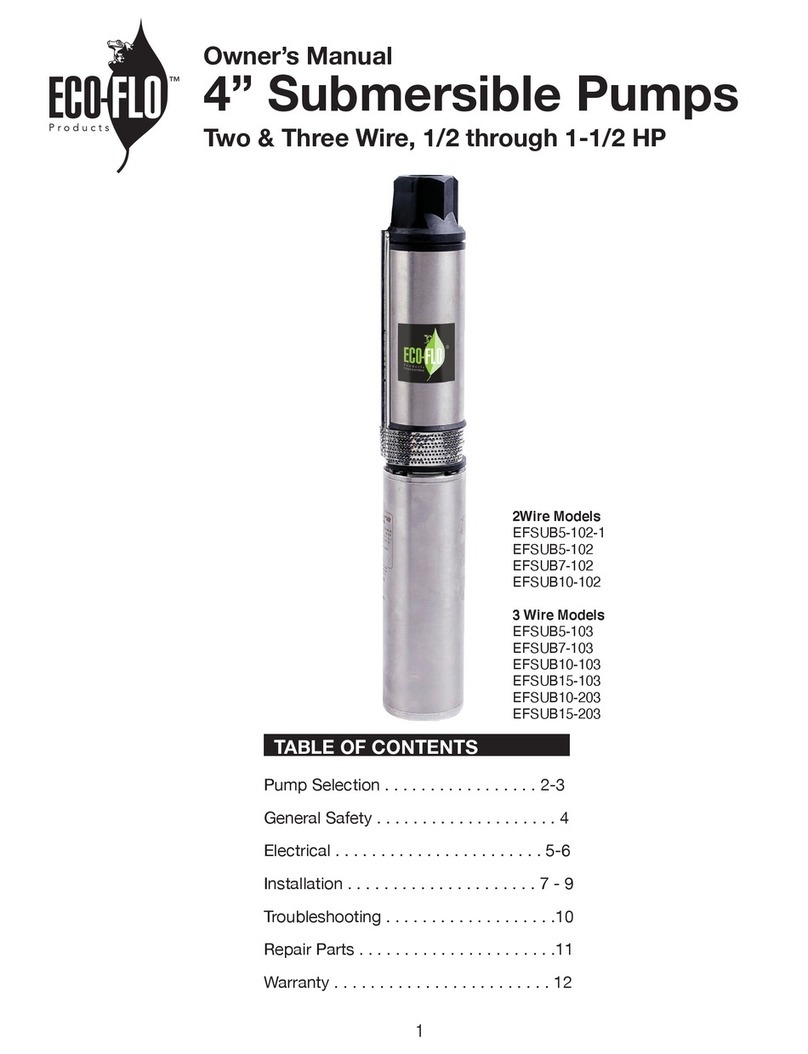

Owner’s Manual

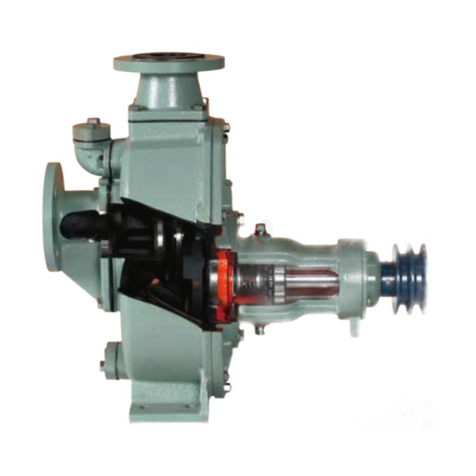

ESE Series

Cast Iron

Sewage Pumps

General Safety . . . . . . . . . . . . . . . . . . . . 2

Specications. . . . . . . . . . . . . . . . . . . . . 3

Installation. . . . . . . . . . . . . . . . . . . . 4 & 5

Troubleshooting . . . . . . . . . . . . . . . . . . . 6

Repair Parts . . . . . . . . . . . . . . . . . . . . . . 7

Warranty . . . . . . . . . . . . . . . . . . . . . . . . 8

TABLE OF CONTENTS

A sump pump is an electrical device designed to

operate in inherently wet environments.

ALWAYS USE EXTREME CAUTION

when installing or maintaining this product!

Need Help: Call 1-877-326-3561 for assistance;

Do Not Return to Store

Important Safety Instructions

Carefully read and follow all safety

instructions in this manual and on pump.

SAVE THESE INSTRUCTIONS – This manual

contains important instructions that should be

followed during installation, operation, and

maintenance of the product.

Save this manual for future reference.

Safety Labels

This is the safety alert symbol. When you

see this symbol on your pump or in this manual,

look for one of the following signal words and be

alert to the potential for personal injury!

Indicates a hazard which, if

not avoided, will result in death or serious injury.

Indicates a hazard which,

if not avoided, could result in death or serious

injury.

Indicates a hazard which, if

not avoided, could result in minor or moderate

injury.

NOTICE indicates practices not related to

personal injury.

Keep safety labels in good condition. Replace

missing or damaged safety labels.

General Safety

Risk of burns. Do not

touch an operating motor. Motors are de-

signed to operate at high temperatures. To

avoid burns when servicing pump, allow it to

cool for 20 minutes after shut-down before

handling.

Do not allow pump or any system compo-

nent to freeze. To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system com-

ponents.

Wear safety glasses at all times when work-

ing on pumps.

Risk of explosion. Pump

body may explode if used as a booster

pump.

2

GENERAL SAFETY

STOP Before you start

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

3

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

APPLICATIONS

Ideal for Below Grade Toilets, Laundry Facilities and for Use at Construction Sites.

SPECIFICATIONS & PERFORMANCE

Capacity Cord Solids

Model HP Volt Ph Amps (GPH at 0’) Max Head Construction Impeller Length Pumped

ESE40M 4/10 115 1 11.0 6600 26’ Cast Iron Thermoplastic 20’ 2”

ESE40W 4/10 115 1 11.0 6600 26’ Cast Iron Thermoplastic 20’ 2”

ESE50M 1/2 115 1 12.0 7800 27’ Cast Iron Thermoplastic 20’ 2”

ESE50W 1/2 115 1 12.0 7800 27’ Cast Iron Thermoplastic 20’ 2”

ESE60M 6/10 115 1 12.0 9910 26’ Cast Iron Thermoplastic 20’ 2”

ESE60W 6/10 115 1 12.0 9910 26’ Cast Iron Thermoplastic 20’ 2”

281.8 [11.10]

212[8.35]

2"NPT

49.9 [1.97]

138.8 [5.47]

380.4 [14.99]

137.4 [5.41]

INSTALLATION

ELECTRICAL WIRE CONNECTION

OVERLOAD PROTECTION

Do not work on pump until

power is unplugged.

Do not cut off ground pin or

use an adapter tting.

Do not use an extension cord.

The pump power cord should be connected to a

separately fused, grounded line with a minimum

capacity of 15 amps. It can be connected to non-

fuse breaker at the recommended amperes.

1. Before installing or servicing this pump, be

certainpump’spowersourceisdisconnected.

2. Installation and electrical wiring must adhere

to state and local codes and must be

completed before priming pump. Check

appropriate community agencies, or contact

local electrical and pump professionals.

3. Call an electrician when in doubt. Pump

should be connected to a separate 15

amp circuit breaker or 15 amp fuse block.

Note that plugging into existing outlets may

cause low voltage at motor. This could cause

blown fuses, tripping of motor overload or

burned out motor.

4. A permanent ground connection from pump

to the grounding bar at the service panel is

mandatory. These sump pumps come with a

grounding conductor and a grounding-type

attachment plug. Do not connect pump to

a power supply until permanently grounded.

For maximum safety, connect pump to a circuit

equipped with a fault interrupter device when

positioningthepump’sgroundingwire.

5. Voltage of power supply must match the

voltage of the pump.

6. Before installing pump, clear sump basin of

any water, debris or sediment.

Sump basin must be vented

in accordance with local

plumbing codes. These Sump pumps are not

designed for and CANNOT be installed in loca-

tions classied as hazardous.

7. The following may cause injury and/or severe

damage to pump and will void the warranty.

(a) Using an extension cord.

(b) Cutting o the ground pin or using an

adapter tting.

(c) Working on pump or switch while

plugged in.

(d) Removing motor housing, unscrewing

impeller, or otherwise removing impeller seal.

(e) Running the pump continuously.

(f) Pumping chemicals or corrosive liquids.

(g)Pumpinggasolineorotherammableliquids

8. Plastic PVC pipe can be installed in the

outlet piping. Drain hose, galvanized steel

or copper pipe may be used if desired.

All piping must be clean and free of all

foreign matter to prevent clogging.

9. Pump will be inadequate if suspension

liquids contain solid particles larger than 2”.

Verify that the voltage and

frequency of the pump shown

on the nameplate corresponds to those available on

the mains. The installer must make sure that the

electric system is grounded in accordance with code.

• Foroutdooruseitisnecessarytousecablewith

alengthofatleast8’.Theplugandconnection

should be protected from water splashes. Before

using the pump, always inspect it visually

(especially power cable and plug)

• Donotusepumpifitisdamaged

• Ifthepumpisdamaged,haveitinspectedbyan

authorized service center.

• Makesurethatelectricconnectionsareprotected

fromooding.Protecttheplugandthepower

cable from heat or sharp edges.

The power cable must be

replacedbyqualiedpersonnel

only. Grounding: The plug of the power cable has a

double grounding contact, so that grounding can be

performed by simply inserting the plug.

This pump series has a built in thermal protection

switch. The pump stops if an overload condition

occurs. The motor restarts automatically after it has

cooled down. If it doesn’t start automatically, unplug

the pump and plug it back in.

4

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

Entry pipe

INSTALLATION

5

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

Always install a union in the discharge

line, just above the sump pit to allow for

easy removal of the pump for cleaning

or repair.

A check valve must be used in the

discharge line to prevent back ow of

liquid into the basin. The check valve

should be a free ow valve that will eas-

ily pass solids.

CAUTION: For best performance of

check valves when handling solids

install in a horizontal position or at an

angle of not more then 45°. Do not in-

stall check valve in a vertical position as

solids may settle in valve and prevent

opening start-up.

When check valve is used, drill a relief

hole 3/16” in diameter in the discharge

pipe. This hole should be located be-

low the oor line between the pump

discharge and the check valve. Unless

such a relief hole is provided, the pump

could “air-lock” and will not pump water

even though it will run.

A gate valve should follow the check

valve to allow periodic cleaning of the

check valve or removal of the pump.

The remainder of the discharge line

should be as short as possible with a

minimum of turns to minimize friction

head loss. Do not restrict the discharge

to sizes below 2’.

Sewage and euent applications will

require a separate sump vent. A con-

nection is provided on top of the sump

or cover which must be piped to the

existing building vent or extended out-

side with its own standpipe.

For automatic operation, pump must be plugged or wired into re-

mote oat switch or liquid level controller. Installation instructions

included with switches and controllers should be referred to for

installation.

Pump will run continuously if plugged directly into an electrical out-

let. Care should be taken to prevent pump running in a dry sump.

Pump must be installed in a suitable gas tight basin which is at

least 24” in diameter and 30” deep and vented in accordance with

local plumbing codes. Pump must be placed on a hard level sur-

face. Never place pump directly on clay, earth or gravel surfaces.

Pump can be installed with ABS, PVC, polyethylene or galvanized

steel pipe. Proper adapters are required to connect plastic pipe to

pump.

Air bleed hole

.

To control panel

Check valve

Gate valve

Union

Discharge pipe

Vent

TROUBLESHOOTING CHECKLIST (Caution: shut off power to pump)

PROBLEMS

PUMPDOESNOTRUN

ANDMAKESHUMMING

SOUND

PUMPRUNSBUTDOES

NOT DELIVER WATER

PUMPRUNSAND

PUMPS

OUTSUMP,BUTDOES

NOTSTOP

PUMPRUNSBUTONLY

DELIVERSASMALL

AMOUNTOFWATER

FUSEBLOWSOR

CIRCUITBREAKER

TRIPSWHEN

PUMPSTARTS

MOTORRUNSFORA

SHORTTIME,THEN

STOPS

POSSIBLE CAUSES/SOLUTIONS

• Line circuit breaker is o, or fuse is blown or loose

• Water level in sump has not reached turn-on level as indicated in

installation drawing.

• Pump cord is not making contact in receptacle.

• Float is stuck. It should operate freely in basin.

• If all of the above are OK, then the motor could be malfunctioning.

• Check if valve is installed backwards.

Arrow on valve should point direction of ow

• Discharge shut-o valve (if used) may be closed.

• Impeller or volute openings are fully or partially clogged.

Remove pump and clean.

• Pump is air-locked. Start and stop several times by plugging and

unplugging cord. Check for clogged vent hole in pump case.

• Inlet holes in pump base are clogged. Remove pump and clean the

openings.

• Vertical pumping distance is too high. Reduce distance or change the

discharge ttings of the pump.

• Float is stuck in up position. Be sure oat operates freely in basin.

• Defective oat switch. Replace oat switch.

• Pump is air-locked. Start and stop several times by plugging in and

unplugging cord. Check for clogged vent hole in pump case.

• Vertical pumping distance is too high. Reduce distance or change the

discharge tting of the pump. Inlet holes in pump base are clogged.

Remove pump and clean the strainer and openings.

• Impeller or volute openings are fully or partially clogged.

Remove pump and clean.

• Pump impeller is partially clogged with tar or paint, causing motor to

run slow and overload. Remove pump and clean.

• Pump impeller is partially clogged causing motor to run slow and

overload. Remove pump and clean.

• Motor stator may be defective.

• Fuse size or circuit breaker may be too small. (must be 15 amps).

• Impeller or volute opening are fully or partially clogged.

Remove pump and clean .

• Inlet holes in pump base are clogged. Remove pump and clean the

openings.

• Pump impeller is partially clogged causing motor to run slow and

overload. Remove pump and clean.

• Motor stator may be defective.

• Impeller or volute openings are fully or partially clogged.

Remove pump and clean. Also clean the strainer if one is installed.

6

For parts or assistance, call ECO-FLO Customer Service at 1-877 326-3561

ELECTRICAL PRECAUTIONS

Before servicing a pump, always shut o the main power breaker and

then unplug the pump. Make sure you are not standing in water and are

wearing insulated protective sole shoes, under ooded conditions. Contact your local electric

company or a qualied licensed electrician for disconnecting electrical service prior to pump

removal

7

1899 Cottage Street, Ashland, Ohio 44805

Telephone: 1-877-326-3561

Fax: 1-877-326-1994

www.ecooproducts.com

Retain Original Purchase Receipt for Warranty Eligibility

Limited Warranty

Manufacturerwarrantstotheoriginalconsumerpurchaser(“Purchaser”or“You”)thatitsproductsarefreefromdefects

in material and workmanship for a period of twenty-four (24) months from the date of the original consumer purchase. If,

within twenty-four (24) months from the original consumer purchase, any such product shall prove to be defective, it shall

berepairedorreplacedatmanufacturer’soption,subjecttothetermsandconditionssetforthherein.Notethatthislimited

warranty applies to manufacturing defects only and not to ordinary wear and tear. All mechanical devices need periodic

parts and service to perform well. This limited warranty does not cover repair when normal use has exhausted the life of a

part or the equipment.

The original purchase receipt and product warranty information label are required to determine warranty eligibility. Eligibil-

ity is based on purchase date or original product – not the date of replacement under warranty. The warranty is limited to

repair or replacement of original purchased product only, not replacement product (i.e. one warranty replacement allowed

per purchase).

Purchaser pays all removal, installation, labor, shipping, and incidental charges.

Claims made under this warranty shall be made by returning the product to the retail outlet where it was purchased or to

thefactoryimmediatelyafterthediscoveryoranyallegeddefect.Manufacturerwillsubsequentlytakecorrectiveactionas

promptly as reasonably possible. No requests for service will be accepted if received more than 30 days after the warranty

expires. Warranty is not transferable and does not apply to products used in commercial/rental applications.

General Terms and Conditions; Limitations of Remedies

Youmustpayalllaborandshippingchargesnecessarytoreplaceproductcoveredbythiswarranty.Thiswarrantydoes

notapplytothefollowing:(1)actsofGod;(2)productswhich,inmanufacturer’ssolejudgment,havebeensubjectto

negligence, abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation,

maintenance or storage; (4) atypical or unapproved application, use or service; (5) failures caused by corrosion, rust or

other foreign materials in the system, or operation at pressures in excess of recommended maximums.

Thiswarrantysetsforthmanufacturer’ssoleobligationandpurchaser’sexclusiveremedyfordefectiveproducts.

MANUFACTURERSHALLNOTBELIABLEFORANYCONSEQUENTIAL,INCIDENTAL,ORCONTINGENTDAMAGES

WHATSOEVER.THEFOREGOINGLIMITEDWARRANTIESAREEXCLUSIVEANDINLIEUOFALLOTHEREXPRESS

ANDIMPLIEDWARRANTIES,INCLUDINGBUTNOTLIMITEDTOIMPLIEDWARRANTIESOFMERCHANTABILITY

ANDFITNESSFORAPARTICULARPURPOSE.THEFOREGOINGLIMITEDWARRANTIESSHALLNOTEXTEND

BEYONDTHEDURATIONPROVIDEDHEREIN.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamagesorlimitationsonhowlongan

impliedwarrantylasts,sotheabovelimitationsorexclusionsmaynotapplytoYou.ThiswarrantygivesYouspeciclegal

rightsandYoumayalsohaveotherrightswhichvaryfromstatetostate.

WARRANTY

This manual suits for next models

5

Table of contents

Other Ecoflo Water Pump manuals

Ecoflo

Ecoflo ESS75V User manual

Ecoflo

Ecoflo EPP33 User manual

Ecoflo

Ecoflo EFSUB5-102-1 User manual

Ecoflo

Ecoflo PUP60 User manual

Ecoflo

Ecoflo SHALLOW WELL User manual

Ecoflo

Ecoflo SEP75W User manual

Ecoflo

Ecoflo CDSP-20 User manual

Ecoflo

Ecoflo Water Ace WASBB User manual

Ecoflo

Ecoflo CDSP-20 User manual

Ecoflo

Ecoflo SUP54 User manual

Ecoflo

Ecoflo PUP57 User manual

Ecoflo

Ecoflo SUP57 User manual

Ecoflo

Ecoflo EFLS10P User manual

Ecoflo

Ecoflo EPP33 User manual

Ecoflo

Ecoflo RSE Series User manual

Ecoflo

Ecoflo EFSUB10 User manual

Ecoflo

Ecoflo EFLS10 User manual

Ecoflo

Ecoflo PUP61 User manual

Ecoflo

Ecoflo SUP64 User manual

Ecoflo

Ecoflo ECD30W User manual