Ecoflo Water Ace WASBB User manual

Owner’s Manual

12 Volt Battery Backup

Sump Pump System

General Safety . . . . . . . . . . . . . . . . . 2 & 3

Contents & Tools. . . . . . . . . . . . . . . . . . . 4

Installation. . . . . . . . . . . . . . . . . . . . 4 & 6

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Testing & Operation . . . . . . . . . . . . . . . . 7

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . 8

TABLE OF CONTENTS

General Safety

Risk of burns. Do not touch

an operating motor. Motors are designed to op-

erate at high temperatures. To avoid burns when

servicing pump, allow it to cool for 20 minutes

after shut-down before handling.

Do not allow pump or any system component to

freeze. To do so will void warranty.

Pump water only with this pump.

Periodically inspect pump and system

components.

Wear safety glasses at all times when working

on pumps.

Risk of explosion. Pump

body may explode if used as a booster pump.

Avoid exposing controls or

batterytoanyopenameor

sparks. Batteries can generate explosive gases.

2

A sump pump is an electrical device designed to

operate in inherently wet environments.

ALWAYS USE EXTREME CAUTION

when installing or maintaining this product!

Need Help: Call 1-844-394-2604 for assistance;

Do Not Return to Store

Important Safety Instructions

Carefully read and follow all safety

instructions in this manual and on pump.

SAVE THESE INSTRUCTIONS – This manual

contains important instructions that should be

followed during installation, operation, and

maintenance of the product.

Save this manual for future reference.

Safety Labels

This is the safety alert symbol. When you

see this symbol on your pump or in this manual,

look for one of the following signal words and be

alert to the potential for personal injury!

Indicates a hazard which, if

not avoided, will result in death or serious injury.

Indicates a hazard which,

if not avoided, could result in death or serious

injury.

Indicates a hazard which, if

not avoided, could result in minor or moderate

injury.

NOTICE indicates practices not related to

personal injury.

Keep safety labels in good condition. Replace

missing or damaged safety labels.

GENERAL SAFETY

STOP Before you start

Provide proper ventilation. The battery enclo-

sures should be designed to prevent accumu-

lation and concentration by hydrogen gas in

“pockets” at the top of the compartment. Vent

the battery compartment from the highest point.

Aslopedlidcanalsobeusedtodirecttheow

to the vent opening location. To reduce the risk

of the battery explosion, follow all the instruc-

tions of the battery supplier or any equipment

you intend to use in the vicinity of batteries.

Use the correct insulated

tools to make AC/DC

wiring connections.

Do not install battery/controls

onornearammablemateri-

als (plywood, chemicals, gas online etc.)

Personal Precautions:

Someone should be within

the range of your voice to

come to your aid when you work near batteries.

Have plenty of fresh water

and soap nearby in the event

that battery acid contact skin, clothing or eyes.

Wear complete eye and

clothing protection.

Avoid touching eyes while

working near batteries. Wash

your hands when done.

If battery acid comes in

contact with skin or clothing,

wash immediately with soap and water.

KNOWING YOUR SYSTEM

The battery pack acts as a reserve to ensure

continuous supply of power whenever mains

supply from utility power is not available. The

controls are used to charge the batteries when

normal utility power is available and converts the

battery’s DC to AC voltage to run the pump when

utility power is lost.

BATTERY SAFETY

A battery can present a risk of severe burn and

injury from high short circuit current. The follow-

ing precautions should be observed when work-

ing on batteries.

1.Donotdisposeofbatteryinare.Thebattery

may explode.

3

2. Do not open or mutilate the battery. Released

electrolyte is harmful to the skin and eyes. It

may be toxic.

3. The electrolyte is a dilute sulfuric acid that is

harmful to the skin and eyes. It is electrically

conductive and corrosive. The following

procedures should be observed:

a.Ifelectrolytecontactstheskin,washito

immediately.

b.Ifelectrolytecontactstheeyes,ush

thoroughly and immediately with water. Seek

medical attention.

c. Spilled electrolyte should be washed down

with a suitable acid neutralizing agent. A

common practice is to use a solution of

approximately one pound (500 grams)

bicarbonate of soda to approximately one

gallon (4 liters) of water. The bicarbonate

of soda solution be added until the evidence

of reaction (foaming) has ceased. The result

ingliquidshouldbeushedwithwaterand

the area dried.

4. Do not reverse the battery connections, as it

will blow the battery fuse. A power cord has

been provided to connect the controls to an

incoming AC wall outlet.

BATTERY REQUIREMENTS

Your unit operates on 12VDC battery power

when in the power fail mode. A UL recognized

deep cycle marine battery should be used. There

are two principal types of batteries: starting and

deepcycle.Thereareseveraldierenttypesof

battery constitutions including liquid lead acid,

nickel iron, nickel cadmium, alkaline and mainte-

nance free. Batteries can be sealed or vented.

Starting Batteries

Starting batteries are designed for high crank-

ing power but not deep cycling. Do not use them

with your back-up sump pump. They will simply

not last long in a deep cycle application.

Deep Cycle Batteries

Deep cycle batteries are best suited for use with

the battery back-up sump pump. They are de-

signed to have the majority of their capacity used

before recharge. Available in many sizes and

types, be sure to use at least a 80AH battery.

BATTERIES NOT INCLUDED

4

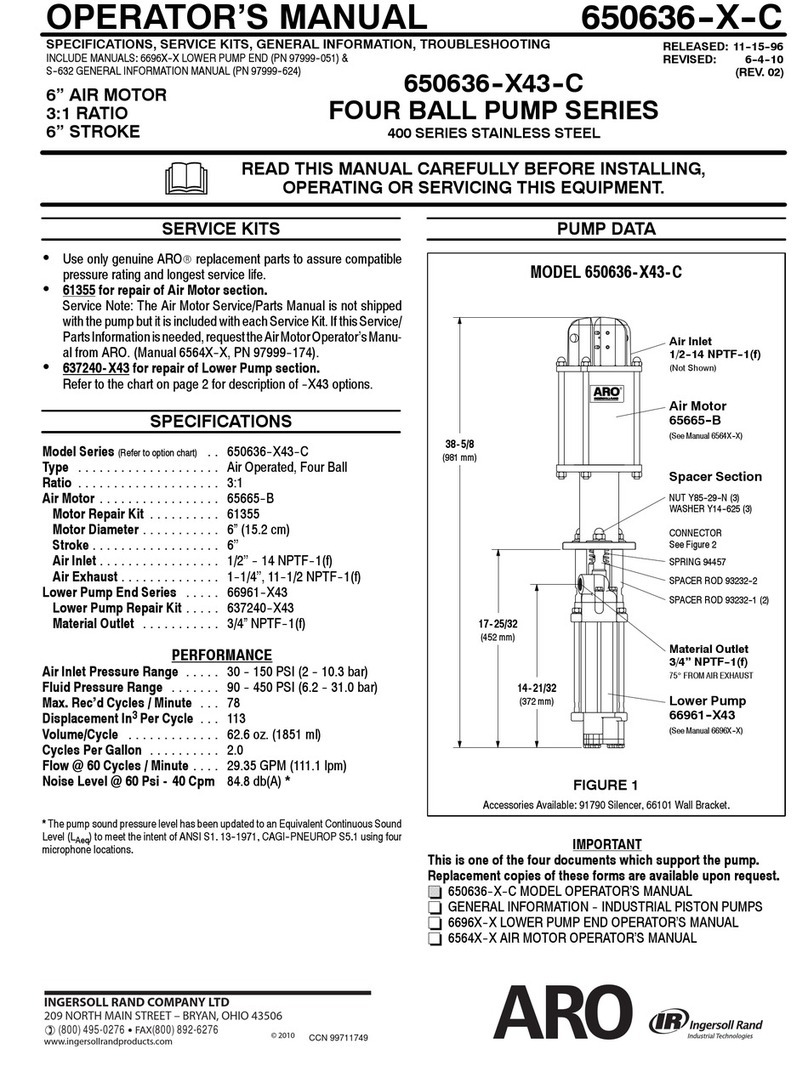

1 - 12 volt battery backup sump pump

1 - Control/alarm panel

1 - Float switch

1 - 12 volt battery charger

1 - Extra fuse

2 - Battery terminal post clamps

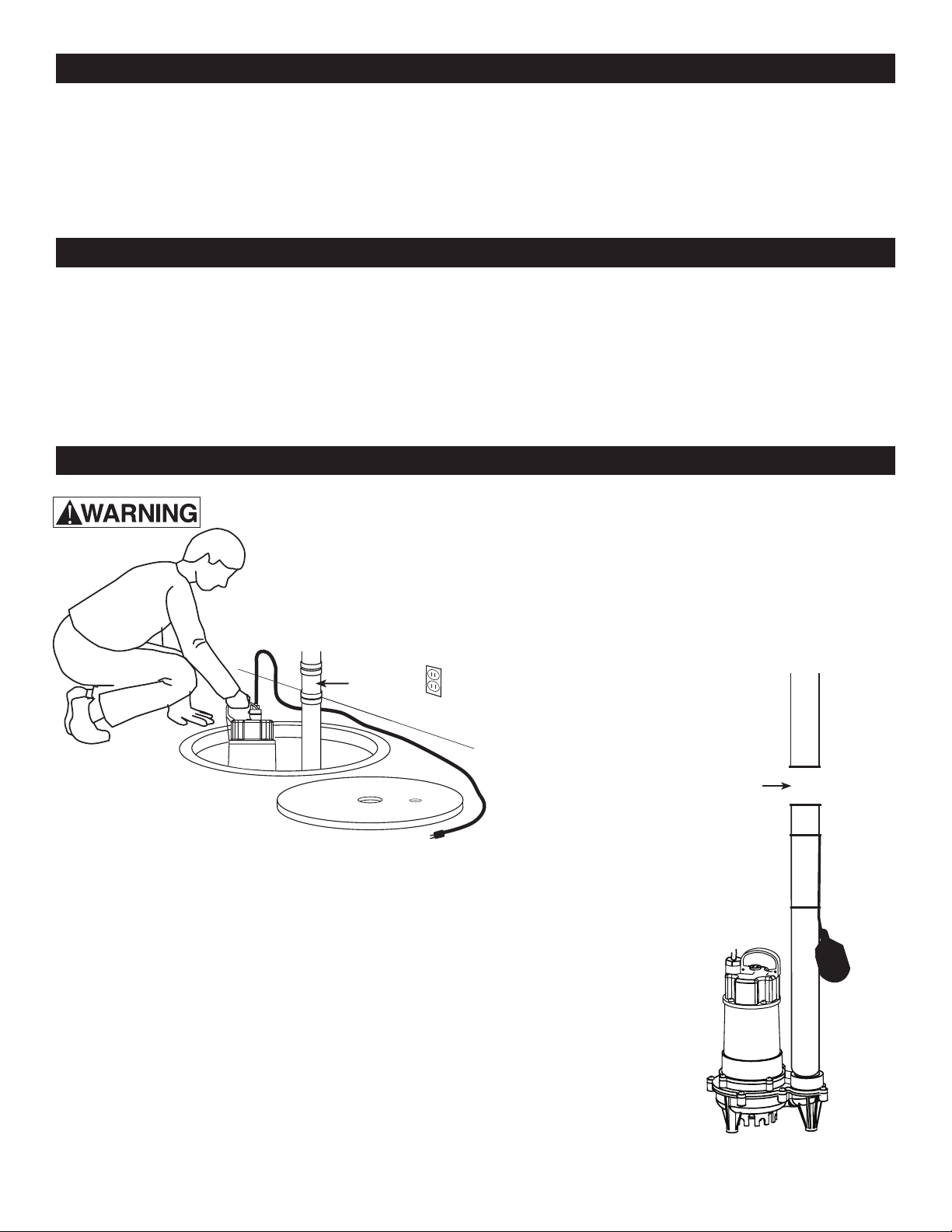

STEP 1:

Disconnect check valve or coupling from the discharge pipe and primary

sump pump. Then remove primary sump pump and pipe assembly from

sump and place in a well lit work area. Re-install check valve at the sump

discharge or base. Be sure check valve is below the back up pump.

STEP 2:

Holdtheautomaticoatswitchupintheonposition.Markthatlocationon

the discharge pipe. From that mark, measure up the pipe 2” and mark the

pipeagain.Atthesecondmark,cutoasectionofthedischargepipeas

described below, to allow space for the supplied pump installation tee.

Ifdischargeis1-1/4”pipe,cuto1-1/2”ofpipe.

Ifdischargeis1-1/2”pipe,cuto2”ofpipe.

TOOLS:

Adjustable wrench or socket wrench

Screwdriver

Hack saw or PVC pipe cutters

File or sandpaper for sanding cut pipe

Clean cloth for wiping water debris

MATERIALS:

PVC cement and primer

One 12 Volt Group 24 Deep Cycle Marine

Battery

2 - Wire ties

1 - Plastic battery case (Battery not included)

1 - Dual pipe size (1-1/2” or 1-1/4”) PVC tee

with a 1” threaded check valve tting for

installing the pump

4 - Mounting screws

DISCONNECT ELECTRICAL POWER FROM PRIMARY SUMP PUMP

Check Valve

Cut out

section of pipe

2”

CONTENTS

TOOLS & MATERIALS NEEDED

INSTALLATION

327.8 [12.92]

ECD25W

ECD33W

ECD50W

221.8[8.73] SWITCH OFF

401.8[15.82] SWITCH ON

ECD75W

REF50W

357.8 [14.10]

251.8[9.91] SWITCH OFF

431.8[17.0] SWITCH ON

{

5

STEP 3:

Thread the Battery Backup Sump Pump onto thedual size pipe tee provided. Once

the pump is threaded tight and oriented parallel to the discharge pipe, turn the pipe

to the 2 o’clock position to prevent air from being trapped in the pump housing.

Then cement the installation tee to the discharge pipe with PVC primer and PVC

cement.

STEP 5:

Attach the automatic

oat switch to the

discharge pipe so that

the switch is tethered

1-1/4” from the dis-

charge pipe. Use the

supplied wire straps

to mount the oat

switch cord to the

discharge pipe.

INSTALLATION

Check

Valve

Backup Pump

Suction Inlet

Float Sensor

Discharge Pipe

1-1/4”

Tether

3

4

5

12

1

2

The top of the Battery Backup Pump

should be at least 4” below the top of the

sump and at least 1” above the highest

water level of the primary sump pump.

Connect the remaining discharge pipes,

check valve and couplings.

STEP 4:

Replace primary

sump pump and

Battery Backup

Pump assembly

into the sump

basin.

REPLACEMENT PARTS

Part Number Description No.

EF091EBBS14 Battery Box* 1

EF091EBBS15 Control 2

EF091EBBS16 12V. Transformer/Plug 3

EF091EBBS17 Pump - 2700GPH 4

EF091EBBS18 Float Switch 5

EF091EBBS19 Inline Tee 6

EF091EBBS20 Check Valve 7

* Battery Box does not include battery or control.

7

6

4

5

2

3

1

6

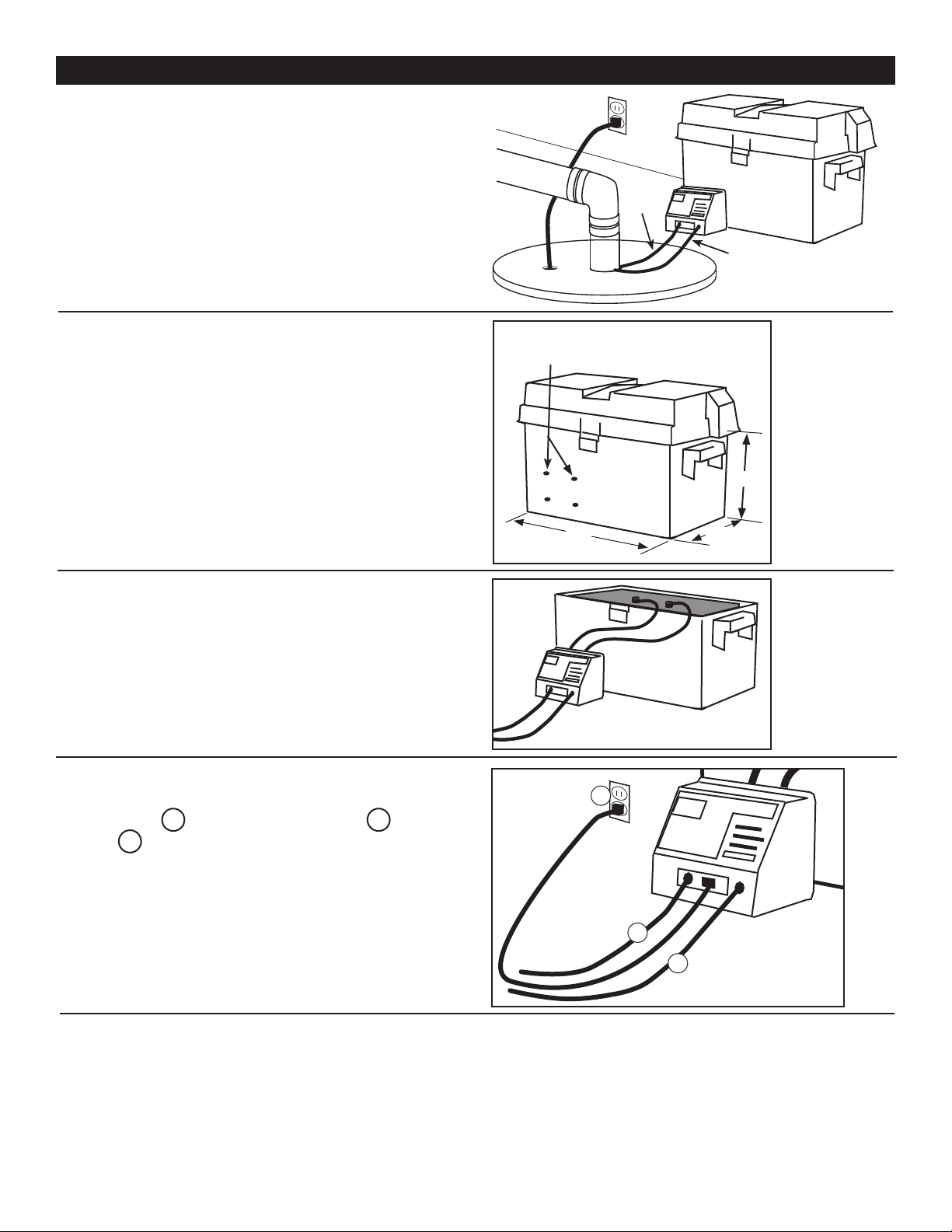

STEP 1:

Mount the Control/Alarm Panel to the battery case

using the four mounting screws provided. Battery

case has four mounting holes predrilled for easy

installation of control panel.

For best results, use a Group 24, marine battery.

Battery dimensions should not exceed : 9” high

(including post) x 12” long x 6-1/2” wide.

YOUR BATTERY BACKUP SUMP PUMP SYSTEM IS READY.

STEP 2:

Insert marine battery into battery case. Attach

the RED and BLACK wires from the back of the

control/alarm panel to each of the battery clamps

provided. Then connect battery clamps to the

battery. RED WIRE to the POSITIVE (+) terminal

and the BLACK WIRE to the NEGATIVE (-)

terminal.

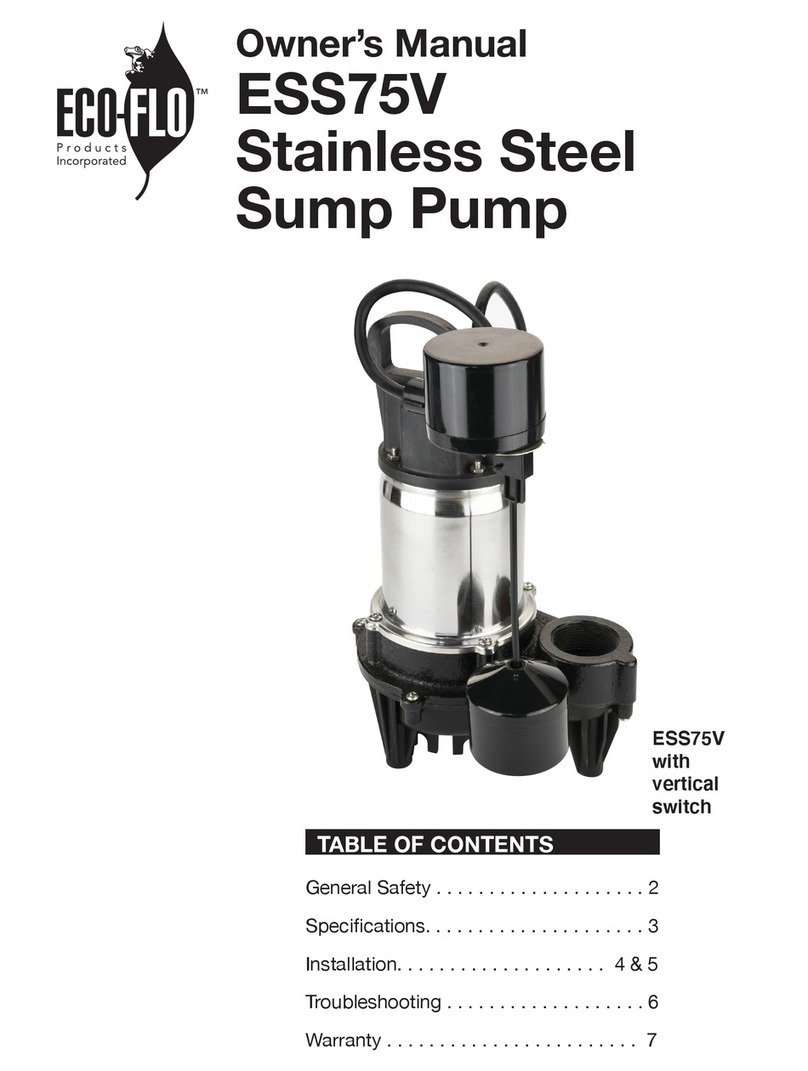

STEP 4:

Turn the alarm switch on the control/alarm panel to the OFF position and plug the 12 volt transformer in a GFCI

outlet. If a GFCI outlet is unavailable, have an electrician install one for you. Once proper power is supplied, turn

the alarm switch to the on position. Then plug the primary sump pump to its power source.

BATTERY & CONTROL/ALARM PANEL ASSEMBLY

STEP 3:

Plug in the designated components to the control/

alarm panel, A battery backup pump, B the oat

switch, C and the 12 volt transformer.

Pre-drilled

Mounting Holes

6 -1/ 2”

12”

9”

B Float Switch

Pump Cord A

Power C

STEP 6:

Feedthepumpandoatswitchcordsthrough

the sump pump vent or utility hole and cover the

sump with the sump cover.

Power

Cord

Float

Switch

Cord

7

STEP 1:

Disconnect the power to the primary sump pump so the only pump available is the Battery Backup Sump Pump.

STEP 2:

With a garden hose or buckets of water ll the sump basin with water. At the designated level of water, the Bat-

tery Backup Sump Pump should activate and the ALARM and ALARM INDICATOR LIGHT should come on. This

indicates the system is working.

STEP 3:

Press the RESET button on the control/alarm panel and reconnect power to the primary sump pump. The test is

complete.

NOTE: If the Battery Backup Sump Pump failed to activate, review the complete instructions.

The Battery Backup Sump Pump is designated as an emergency back up pump in the event your primary sump

pump fails or if there is a loss of power to your primary sump pump.

THE BATTERY BACKUP SUMP PUMP IS NOT INTENDED FOR USE AS A PRIMARY SUMP PUMP.

PRIMARY SUMP PUMP FAILURE

In the event your primary sump pump fails or loses power, the Battery Backup System will automatically activate

when the oat switch reaches the ON position. When it turns on, a alarm will sound and the alarm indicator will

light. When the water in the sump basin recedes and the pump turns off, the alarm will continue to sound until you

depress the ON/OFF switch to the on/off switch to the ON position and press the RESET button.

BATTERY LOW

In the event 12 volt battery charge should drop lower than 11 volts, the alarm will sound and the BATTERY LOW

indicator will light. Press the ON/OFF switch to OFF position, disconnect power to the 12 volt transformer from the

GFCI outlet and disconnect the pump and oat switch cords from the alarm/control panel plugs. Have the bat-

tery checked, serviced or replaced if necessary. Once 12 volt battery is serviced or replaced, reconnect all plugs,

cables and power and follow the Test Procedures listed in this owners manual.

BATTERY CHARGING/CHARGED

When the battery is not at full charge capacity, the BATTERY CHARGING indicator will light. The battery charger

is simply recharging the battery to its full charged capacity. Once the battery has reached full charging capacity

(13 volts) the CHARGED indicator will light.

If neither the BATTERY CHARGING or CHARGED indicator lights are on, check all wire connections and plugs to

ensure proper hook up.

LEADS REVERSED

If you connect the battery cable to the wrong battery terminal, the LEADS REVERSED indicator will light. Simply

remove the battery cable and reconnect to the proper battery terminals. The RED WIRE is connected to the posi-

tive (+) terminal and the BLACK wire is connected to the negative (-) terminal.

You must replace the 1 amp fuse with the extra fuse provided. Simply turn the fuse cover counter clockwise until

the burnt fuse is exposed. Replace the fuse and thread the fuse cover, turning clockwise.

BATTERY MAINTENANCE

The 12 volt marine battery should be tested every four to six months. It is recommended to replace the battery

every three to four years. Follow the battery manufacturers recommendations for proper battery maintenance and

battery replacement.

TESTING THE SYSTEM

NORMAL OPERATION

8

WARRANTY

Retain Original Purchase Receipt for Warranty Eligibility

Limited Warranty

Manufacturer warrants to the original consumer purchaser (“Purchaser” or “You”) that its products are free from defects in

material and workmanship for a period of twelve (12) months from the date of the original consumer purchase. If, within

twelve (12) months from the original consumer purchase, any such product shall prove to be defective, it shall be repaired

or replaced at manufacturer’s option, subject to the terms and conditions set forth herein. Note that this limited warranty

applies to manufacturing defects only and not to ordinary wear and tear. All mechanical devices need periodic parts and

service to perform well. This limited warranty does not cover repair when normal use has exhausted the life of a part or

the equipment.

The original purchase receipt and product warranty information label are required to determine warranty eligibility. Eligibil-

ity is based on purchase date or original product – not the date of replacement under warranty. The warranty is limited to

repair or replacement of original purchased product only, not replacement product (i.e. one warranty replacement allowed

per purchase).

Purchaser pays all removal, installation, labor, shipping, and incidental charges.

Claims made under this warranty shall be made by returning the product to the retail outlet where it was purchased or to

the factory immediately after the discovery or any alleged defect. Manufacturer will subsequently take corrective action as

promptly as reasonably possible. No requests for service will be accepted if received more than 30 days after the warranty

expires. Warranty is not transferable and does not apply to products used in commercial/rental applications.

General Terms and Conditions; Limitations of Remedies

You must pay all labor and shipping charges necessary to replace product covered by this warranty. This warranty does

not apply to the following: (1) acts of God; (2) products which, in manufacturer’s sole judgment, have been subject to

negligence, abuse, accident, misapplication, tampering, or alteration; (3) failures due to improper installation, operation,

maintenance or storage; (4) atypical or unapproved application, use or service; (5) failures caused by corrosion, rust or

other foreign materials in the system, or operation at pressures in excess of recommended maximums.

This warranty sets forth manufacturer’s sole obligation and purchaser’s exclusive remedy for defective products.

MANUFACTURER SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES

WHATSOEVER. THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS

AND IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. THE FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND

BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an

implied warranty lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specic legal

rights and You may also have other rights which vary from state to state.

1899 Cottage Street

Ashland, Ohio 44805

Telephone: 1-844-394-2604

Table of contents

Other Ecoflo Water Pump manuals

Ecoflo

Ecoflo PUP62 User manual

Ecoflo

Ecoflo EFSUB5-102-1 User manual

Ecoflo

Ecoflo PUP57 User manual

Ecoflo

Ecoflo PUP61 User manual

Ecoflo

Ecoflo EFSWJ5 User manual

Ecoflo

Ecoflo RSE Series User manual

Ecoflo

Ecoflo SUP64 User manual

Ecoflo

Ecoflo SHALLOW WELL User manual

Ecoflo

Ecoflo EPP33 User manual

Ecoflo

Ecoflo CDSP-20 User manual

Ecoflo

Ecoflo E130V6 User manual

Ecoflo

Ecoflo CDSP-20 User manual

Ecoflo

Ecoflo ECD30W User manual

Ecoflo

Ecoflo EFLS10P User manual

Ecoflo

Ecoflo SEP75W User manual

Ecoflo

Ecoflo SPP25W User manual

Ecoflo

Ecoflo PUP60 User manual

Ecoflo

Ecoflo EFWIFI33 User manual

Ecoflo

Ecoflo ESS75V User manual

Ecoflo

Ecoflo SUP55PC User manual