2

1. The installation and use environment must meet relevant international,

national, and local standards for lithium batteries, and are in accordance

with the local laws and regulations.

2. Ensure that the battery is not accessible to children and away from daily

working or living areas,

3. When installing the battery in a garage, keep it away from the drive way.

4. Install the battery in a dry and well-ventilated environment. Secure the

battery on a solid and flat surface.

5. Install the battery in a sheltered place or install an awning over it to avoid

direct sunlight or rain.

6. Install the battery in a clean environment that is free from sources of

strong infrared radiation, organic solvents, and corrosive gases.

7. For areas prone to natural disasters such as floods, debris flows,

earthquakes, and typhoons/hurricanes, take corresponding precautions for

installation.

8. Keep the battery away from fire sources and heat sources. Do not place

any flammable or explosive materials around the battery.

9. Keep the battery away from water sources such as taps, sewer pipes, and

sprinklers to prevent water seepage.

10. Do not install the battery in a position where it is easy to touch as the

temperature of the chassis and heat sink is high when the battery is

running.

11. To prevent fire due to high temperature, ensure that the vents and the

cooling system are not blocked when the battery is running.

12. Do not expose the battery to flammable or explosive gas or smoke. Do not

perform any operation on the battery in such environments.

13. This product is designed for residential scenarios. Do not install the battery

on a moving object, such as ship, train, or car.

14. In backup power scenarios, do not use the battery for the following

situations:

- Medical devices substantially important to human life

- Control equipment such as trains and elevators, which may cause

personal injury

- Computer systems of social and public importance

- Other devices similar to those described above

15. Do not install the battery outdoors in salt-affected areas because it may

corrode. A salt-affected area refers to the region within 500 meters from

the coast or prone to sea breeze.

INSTALLATION ENVIRONMENT REQUIREMENTS

• The batteries cannot be transported by rail or air.

• Comply with maritime transport & road transport rules.

• Being dampened by rains, snows, or falling into water

• Falling or mechanical impact

• Being upside-down or tilted.

TRANSPORTATION REQUIREMENTS

types, ensure that they are at least 30 mm away from each other. Mutual

entanglement or cross-deployment is not allowed.

4. Ensure that the cables used in a grid-tied PV power system are properly

connected and insulated and meet specifications.

1. After system installing and connecting electrical, power on the battery

system in a timely manner to avoid capacity loss or irreversible damage to

the batteries.

2. Correctly set the battery operation management parameters.

3. The customer or a third party is not allowed to use the batteries beyond

the scenarios specified by the Company: such as connecting extra loads

to the battery, or using with other batteries, including but not limited to

batteries of other brands, or batteries of different rated capacities, etc.

4. Battery operating environment or external power parameters MUST meet

environment requirements: such as the actual operating temperature of

the battery meets the specifications; the power grid is stable, etc.) to avoid

damage to the battery.

5. Batteries shall not be frequently over-discharged.

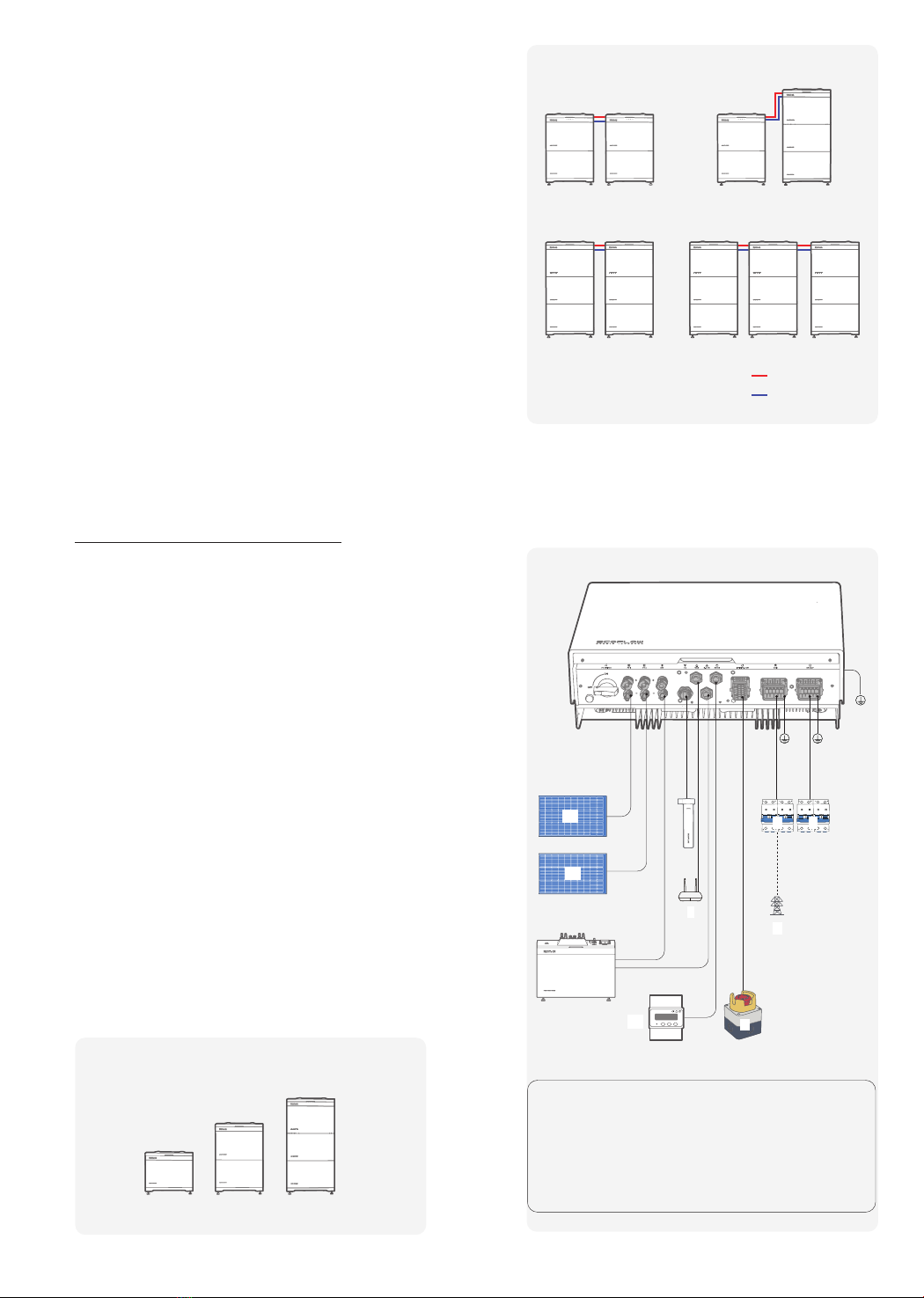

6. Batteries shall be correctly expanded (maximum 45.9 kWh).

7. Batteries shall not fully charged for a long time.

8. Maintain batteries based on the this manual, such as check battery

terminals regularly.

9. Do not use batteries that have exceeded the warranty period.

10. Capacitive discharge: can be reduced to safety voltage within 10 seconds.

BATTERY SAFETY

BASIC REQUIREMENTS

BASIC REQUIREMENTS

BATTERY EMERGENCY MEASURES

DANGER

• Do not expose batteries at high temperatures or around heat-generating

sources. The battery may cause a fire if overheated.

• Do not disassemble, alter, or damage batteries. For example, do not insert

foreign objects into batteries or place batteries in water or other liquids.

• The fire hazard of the battery energy storage system is high. Consider the

following safety risks before handling batteries:

- Battery electrolyte is combustible, toxic, and volatile.

- Battery thermal runaway can generate flammable gas and harmful gas

such as CO and HF.

- The concentration of flammable gas generated from battery thermal

runaway may cause deflagration and explosion.

• Obvious battery abnormalities, such as electrolyte leakage and structural

deformation, indicate potential safety risks. Contact your installer or

professional personnel to remove and replace the battery.

• The batteries must be stored separately inside the packaging. Do not store

batteries together with other materials or in the open air. Do not stack

batteries too high (Allows stacking of up to three packs).

• Do not remove the battery packaging before use.

• Move batteries in the correct direction. Do not place a battery upside down

or tilt it.

• Protect batteries from impact.

• Do not perform welding or grinding work around batteries to prevent fire

caused by electric sparks or arcs.

• Use batteries within the temperature range specified in this manual.

• Do not use damaged batteries (such as damage caused when a battery

is dropped, bumped, or dented on the enclosure). Damaged batteries

may release flammable gases. Do not store damaged batteries near

undamaged products.

• Do not place damaged batteries in close proximity to flammable materials.

Do not approach the damaged batteries unless you are a professional.

• Monitor damaged batteries during storage for signs of smoke, flame,

electrolyte leakage, or heat.

• Do not place irrelevant objects on the top of the equipment or insert them

into any position of the equipment.

• Remove any metal objects from yourself before operating batteries, such

as watches and rings.

• Do not place the battery module in a fire, water or other liquids.

• Do not use water to clean electrical components of the equipment.

• Avoid contact with leaked liquids or gases in the case of battery leakage

or abnormal odor. Do not approach the battery. Contact professionals

immediately. Professionals must wear safety goggles, rubber gloves, gas

masks, and protective clothing.

• Electrolyte is corrosive and can cause irritation and chemical burns. Should

you come into direct contact with the battery electrolyte, do as follows:

- Inhalation: Evacuate contaminated areas, get fresh air immediately, and

seek immediate medical attention.

- Eye contact: Immediately flush your eyes with water for at least 15

minutes, do not rub your eyes, and seek medical attention immediately.

- Skin contact: Wash the affected areas immediately with soap and water

and seek medical attention immediately.

- Ingestion: Seek immediate medical attention.

• If the battery catches fire, extinguish the fire with sand, carbon dioxide, or

dry powder fire extinguishers.

• Do not contact with high-voltage components during fire fighting to

prevent the risk of electric shock.

• If any part of the batteries is submerged in water, do not touch the

batteries to avoid electric shock.

• Do not use batteries that have been soaked in water. Contact a battery

recycling company for disposal.

• If a battery pack is dropped or violently impacted during installation,

internal damage may occur. Do not use such battery packs; otherwise,

safety risks such as cell leakage and electric shock may arise. Contact the

professionals to transfer the battery to an open and safe place, or contact a

recycling company for disposal.

• The operation and service life of the battery depend on the operating

temperature. Install the battery at a temperature equal to the ambient

temperature or in a better environment.

• The operating temperature of the battery ranges from –20°C to +50°C. If

the battery is installed in a cold environment, the built-in thermal control

system starts to heat the battery to achieve better performance. The

heating process consumes rechargeable power, which reduces the system

energy efficiency for a short time in cold weather.

• If the battery is stored in a cold environment (for example, 0°C) before

installation, the battery needs some time (< 30mins) to heat up before

it can be charged. You are advised to place the battery in a warm place

before installation.

• When the ambient temperature of the battery is higher than +45°C or

lower than –10°C, the battery charge and discharge power will be derated.