Ecolab GEOCENTER User manual

GEOCENTER

Installation and Operation Manual

Dispenser Complete 9223-1091

26392/0406/0409 Copyright Ecolab Inc. 2009 9223-2610

This page intended

to be blank.

iii

TABLE OF CONTENTS

GEOCENTER

Installation and Operation Manual

Section . . .

1.0 PREFACE ......................................................................................................... 1

2.0 INTRODUCTION............................................................................................... 2

3.0 SPECIFICATIONS ............................................................................................ 3

3.1 Dimensions............................................................................................... 3

3.2 Access Requirements .............................................................................. 3

3.3 Product Pickup and Discharge ................................................................. 3

3.4 Electrical Requirements ........................................................................... 3

3.5 Plumbing Requirements ........................................................................... 4

3.6 Components Supplied .............................................................................. 4

3.7 Components Not Supplied ....................................................................... 4

4.0 INSTALLATION PROCEDURES...................................................................... 5

4.1 Pre-Planning the Installation .................................................................... 5

4.2 Installing the Transformer......................................................................... 5

4.3 Mounting the GeoCenter.......................................................................... 5

4.4 Mounting Sensor in Wash Tank................................................................ 5

4.5 Geosystem Detergent Dispenser Installation........................................... 5

4.6 VANGUARD Wash Max Installation ......................................................... 5

4.7 Geosystem Rinse Dispenser.................................................................... 6

4.8 Rinse Injector Connections ...................................................................... 6

4.9 Hydraulic Connections and Visual Flow Indicator .................................... 6

5.0 ELECTRICAL CONNECTIONS........................................................................ 7

5.1 Transformer Wiring................................................................................... 7

5.2 440 Volt Machine Power Supply............................................................... 8

5.3 S-2000 Sensor Wire Connections ............................................................ 8

5.4 Geosystem Detergent Dispenser Wiring Connections ............................. 8

5.5 Geosystem Solid Rinse Reservoir Connections....................................... 8

5.6 VANGUARD Wash Max Wiring Connections ........................................... 8

5.7 Two Pole Probe Wire Connections........................................................... 8

6.0 SYSTEM ADJUSTMENTS ............................................................................... 9

6.1 Cell/Sensor Selection ............................................................................... 9

6.2 Concentration Adjustment ........................................................................ 9

6.3 Feed Adjustment Potentiometers ............................................................. 9

6.4 Sonalert®Volume Adjustment................................................................. 10

6.5 Sonalert®Alarm Delay ............................................................................ 10

6.6 Rinse Speed Control .............................................................................. 10

6.7 Timed Feed ............................................................................................ 10

6.8 Feed Delay ............................................................................................. 10

iv

7.0 SYSTEM OPERATING FEATURES ............................................................... 11

7.1 Power Lights............................................................................................11

7.2 Feed Light ...............................................................................................11

7.3 100% Light ..............................................................................................11

7.4 Temperature Compensation ....................................................................11

7.5 Optional Jumper Settings ........................................................................11

8.0 SERVICE ........................................................................................................ 12

8.1 Regular Inspection ................................................................................. 12

8.2 Squeeze Tube Replacement Instructions............................................... 12

9.0 TROUBLESHOOTING.................................................................................... 13

9.1 Unit does not operate - No Power Light. ................................................ 13

9.2 Unit does not feed - Power Light and Feed Light on.............................. 13

9.3 Unit does not feed - Power Light on, Feed Light not on......................... 14

9.4 Feeds continuously - Feed Light not on. ................................................ 14

9.5 Feeds continuously - Feed Light on. ...................................................... 14

9.6 Fluctuating titration. ................................................................................ 15

9.7 Excessive detergent consumption.......................................................... 15

9.8 Rinse Injector does not activate. ............................................................ 15

9.9 Rinse Injector runs, no rinse additive being injected.............................. 16

9.10 Rinse Injector runs continuously ............................................................ 16

9.11 Rinse Injector will not prime. .................................................................. 16

9.12 Excessive squeeze tube wear. ............................................................... 16

9.13 Fuse on Speed Rinse P.C. board is blowing repeatedly......................... 16

10.0 REPLACEMENT PARTS................................................................................ 17

11.0 OPTIONAL PRESSURE SWITCH INSTALLATION....................................... 18

1

1.0 PREFACE

This manual has been written to present the basic installa-

tion and operation characteristics of the GeoCenter. This

manual applies, in its entirety, to current units.

Guidelines will be suggested in reference to the preferred

method of installation, however, the variety of equipment

and the surrounding physical environment will dictate the

actual installation of the GeoCenter.

WARNING: These installation and servicing in-

structions are for use by qualied personnel only.

The installation must be made in accordance with

local plumbing and electrical codes.

2

2.0 INTRODUCTION

The GeoCenter is a self contained detergent monitoring

and dispensing controller combined with a rinse injector in

the same cabinet.

The system includes two (2) separate printed circuit control

boards, one each for the detergent control system and the

rinse injector, transformers for each, and a solenoid valve.

These components are contained in a housing that is com-

pact in size but provides easy access for adjustments and

servicing.

The Detergent Control System features include:

• S-2000 SENSOR must be used with the Geosystem

products.

• Two Pole Probe for soft to medium hard water and where

soft metals are not being washed in the machine.

The controller provides overshoot control by “pulse feeding”

detergent when wash tank concentration is near the desired

control point. Visual indicators signal concentration status

of the wash tank.

• A “FEED” light will illuminate when concentration is

below the set level.

• A “100%” light will illuminate when at or above the set

time to titrate the wash solution.

Consistent detergent control is achieved over a wide range

of wash tank temperatures through the temperature com-

pensation feature when using the S-2000 Sensor.

The detergent controller also indicates low power supply

to the system.

The Rinse Injector System features Include:

• Double roller peristaltic pump

• Squeeze tubes with different delivery rates for high or

low volume requirements.

• Variable speed DC motor, 3-36 RPM.

• Regulated DC Speed Rinse Control P.C. Board.

• Selector switch to run continuously or to time out within

51 seconds.

• Start delay of 0-10 seconds.

3

6" MIN (US)

30 cm (INT'L)

WATER FLOW

H

D

W

3.0 SPECIFICATIONS

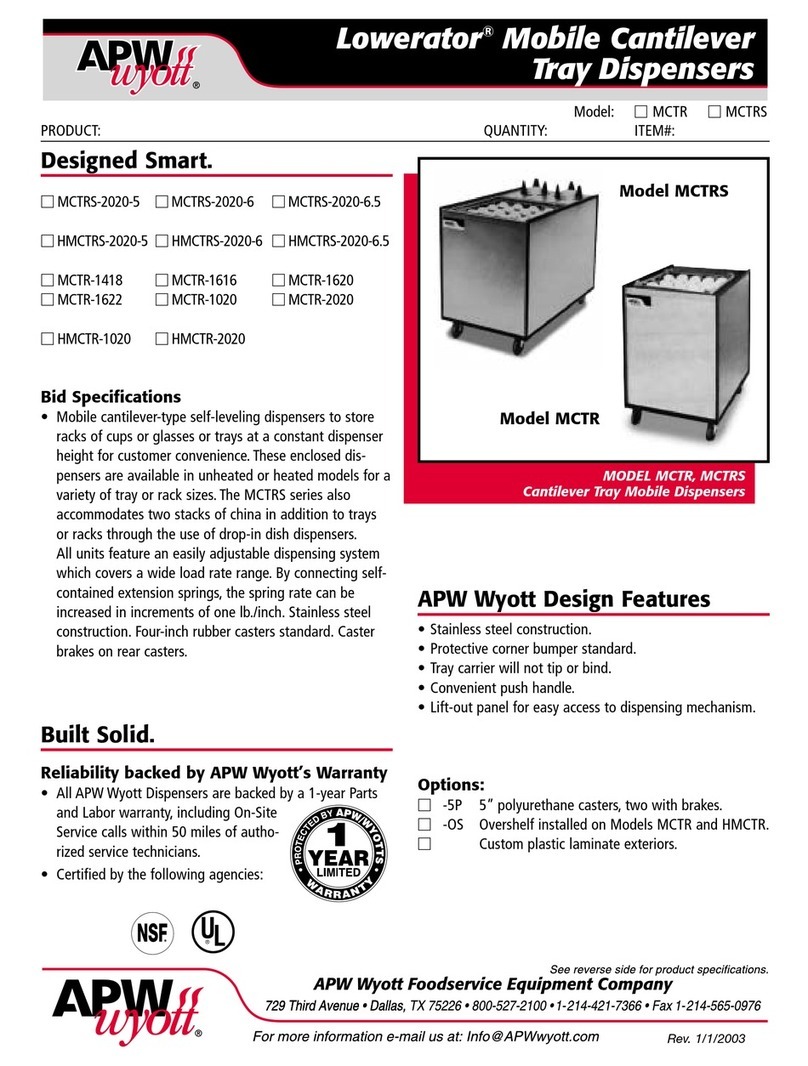

System Diagram

3.4 Electrical Requirements

source supplied through two 30 VA transformers. The

transformer primaries can be either 115 or 230 volts. One

transformer provides power for the detergent control and

the other provides power for the rinse injector.

If the primary voltage is 440 volts, two separate, externally

mounted transformers will be required. The 24 volt secondary

wiring of one transformer will be connected directly to the

Detergent Controller P.C. Board.The 24 volt secondary of the

second transformer will be connected directly to the Rinse

Speed Control P.C. Board. Both the internal transformers

can be removed when wiring for a 440 volt installation.

IMPORTANT: Make sure the power source is turned off

3.1 Dimensions

3.2 Access Requirements

Mounting location must allow cabinet cover to swing down

the right side to service the peristaltic pump, and on the left

for electrical service.

3.3 Product Pickup and Discharge

exceed 10' (3 meters) in length. The maximum discharge

tubing length of 150' (45 meters) will accommodate

remote installations of the GeoCenter. If tubing length

exceeds 50' (15 meters) the tubing must be replaced with

SOLENOID VALVE

(REFER TO FIGURE 4-4 ON

PAGE 6.)

DETERGENT CONTROLLER

P.C. BOARD

RINSE SPEED

CONTROL P.C. BOARD

TRANSFORMER ASSEMBLY

(REFER TO FIGURE 5-2 ON

INJECTION POINT

TO GEOSYSTEM

RINSE DISPENSER

S-2000

SENSOR

VISUAL FLOW INDICATOR

4

3.7 Components Not Supplied

• Geosystem Detergent Dispenser

• Geosystem Rinse Dispenser

• Wiring and wiring connectors

• 440 volt transformers (if required)

• Two Pole Probe

• VANGUARD Wash Max

• Pressure Switch

before beginning wiring connections or servicing the

high voltage portion of the system.

codes and Ecolab®Installation Standards. All high voltage

Wiring from the power source to the transformer must be

enclosed in conduit, seal-tite or other housing approved for

damp locations.

3.5 Plumbing Requirements

Water supply tubing from the source to the solenoid valve

at the GeoCenter, and from the solenoid valve to the

copper tubing.

Refer to the Installation and Operation Manual of the

Geosystem Detergent Dispenser used for this application

to aid in the installation of the GeoCenter.

3.6 Components Supplied

• Detergent Controller P.C. Board

• Solenoid Valve

• 2 30 VA Transformers

• Cell Wash Tank Connector

• Rinse Speed Control P.C. Board

• S-2000 cell with 12 foot cable

5

Figure 4-1

4.0 INSTALLATION PROCEDURES

4.1 Pre-Planning the Installation

There is no substitute for planning the installation prior to

beginning the work, minutes in planning may save hours in

installation time. The following items should be taken into

• Allow visual displays on the front of the cabinet to be in

full view of the operator.

• Permit shortest possible tube, wire, and conduit

lengths

• Provide accessibility for adjustments and servicing.

heat as possible.

The following items should be taken into consideration before

installing the Sensor. The sensor should be located in an

• A minimum 2" (5 cm) from the tank bottom, sidewall,

• As far as possible (2" minimum) (5 cm) from heater

elements or coils.

• Protection from physical hazards.

• For constant submersion of all parts of the sensor in

the wash water. This is a particular concern on shallow

tank machines.

NOTE: The S-2000 Sensor is provided with a 12' cable

and mounts from the inside of the washtank. Sufcient

clearance on the inside is required to allow insertion/

removal of the sensor.

NOTE: A S-2000 sensor with 24' cable is available where

necessary (9212-2316).

4.2 Installing the Transformer

1. Mount the plastic transformer enclosure assembly into

the plastic GeoCenter enclosure. (Refer to Figure 4-1).

4.3 Mounting the GeoCenter

1. Mount the GeoCenter cabinet to the wall using the

supplied screws, washers and plastic wall anchors. The

GeoCenter cabinet may also be installed on top of the

dish machine, using the universal mounting brackets,

and may be the preferred location in some installations.

The installa

tion should be secure, neat and square, refer to

Figure 4-1.

4.4 Mounting Sensor in Wash Tank

Review Item 4.1, Pre-planning the Installation, before the

installation begins.

IMPORTANT: Before drilling the hole check for

obstructions both inside and outside of the wash

tank.

SCREW

2. Properly DEBURR the hole.

3. Attach the sensor connector to the tank using the pro-

vided metal lock nut and the stainless steel and rubber

washers on both the inside and outside surfaces of

the tank wall. Regardless of which sensor is used, the

packing nut end of the tank connector must be on the

outside of the machine wall, refer to Figure 4-2.

4. Position the sensor by sliding it through the connector

opening and tightening the packing nut.

4.5 Geosystem Detergent Dispenser

Installation

1. Install the desired Geosystem Detergent Dispenser

following the installation instructions provided for that

unit.

4.6 VANGUARD Wash Max Installation

1. Install the desired VANGUARD Wash Max following the

installation instructions provided for that unit.

S-2000 SENSOR

SENSOR

CABLE

Figure 4-2

6

6" MIN (US)

30 cm (INT'L)

WATER FLOW

Visual Flow

Indicator

TUBE

TUBE

TUBE CLAMP

INDICATOR TUBE

TUBE CLAMP

TUBE

TUBE

Figure 4-3

4.7 Geosystem Rinse Dispenser

1. Install the Geosystem Rinse Dispenser following the

installation instructions provided for that unit.

4.8 Rinse Injector Connections

Identify the point at which rinse additive will be injected into

refer to Figure 4-3.

NOTE: The injection point has to be installed a minimum

of 6" (15.2 cm.) below the vacuum breaker with the cabinet

mounted at or below that point. In many International

accounts the minimum distance beneath the vacuum

breaker is 30 cm. (11.8"). Install tting using Teon tape

or pipe sealant to prevent leakage.

4.9 Hydraulic Connections and Visual Flow

Indicator

refer

to Figure 4-3.

Note: The visual ow indicator is required for NSF

listing.

2.

3. Insert this injection tubing assembly fully into the outlet

end of the Flow Indicator tube, also called the sight

tube.

4. Secure all connections with the clamps provided.

5. Complete the outlet of the Visual Flow Indicator in the

Refer to Figure 4-3.

IMPORTANT: When the product is being injected into

the nal rinse line, movement of the product will be

visible in the ow indicator tube. The dishmachine

operator must be instructed to observe the Flow

Indicator periodically to insure that product is in

fact being dispensed.

with the rinse injector to the inlet side of the pump.

the inlet side of the solenoid valve located at the bottom

on the GeoCenter cabinet, refer to Figure 4-4.

solenoid valve to the Geosystem Detergent Dispenser.

Refer to the Installation and Operation Manual of the

Geosystem Detergent Dispenser used to determine

WATER IN

SOLENOID

VALVE

TO GEOSYSTEM

DETERGENT

DISPENSER

VACUUM

INJECTION

FITTING

VALVE

PRESSURE

TO

GEOSYSTEM

RINSE

DISPENSER

Figure 4-4

7

NOTES:

1. JP1 and JP2 jumpers in " PEN" position

2. FIELD WIRING

3. FACTORY WIRING

RINSE SPEED CONTROL

P.C. BOARD

T

I

M

E

D

R

U

N

DELAYSPEED

TIME

F

R

O

N

T

115/230

VAC

B

A

C

K

24 VAC

BOTTOM

TRANSFORMER

G

R

A

Y

G

R

A

Y

(+)

(-)

MOTOR

R

E

D

B

L

A

C

K

Y

E

L

L

O

W

Y

E

L

L

O

W

115 V AC WIRING

RED

BLUE

YELLOW

BLACK

115 VAC

24 VAC

SECONDARY

SIDE

RED

YELLOW

BLUE

230 V AC WIRING

BLACK

24 VAC

SECONDARY

SIDE

230 VAC

F

R

O

N

T

TWO-POLE

CELL

R

E

D

B

L

A

C

K

/

S

H

I

E

L

D

B

L

U

E

/

S

H

I

E

L

D

W

H

I

T

E

B

R

O

W

N

2

4

V

D

C

SONALERT

ALARM

DETERGENT CONTROLLER P.C. BOARD

S-2000

SENSOR

O

R

A

N

G

E

B

A

C

K

F

R

O

N

T

SOLENOID

VALVE

BLUE

BLUE

+

-

115/230

VAC

B

A

C

K

24 VAC

WIRE NUTS

RESERVOIR

LID SWITCH

TOP

TRANSFORMER

2

4

V

A

C

O

R

A

N

G

E

V

I

O

L

E

T

B

L

A

C

K

R

E

D

V

I

O

L

E

T

+

-

1 2 3 4 5 6 7 8

SOLID

RINSE

RESERVOIR

RED

BLACK

GREEN

WHITE

HI S26

ON

10 11 12 13 14 15 16 17 18 19 20 21 22 23

OFF

FEED

ALARM

VOLUME

ALARM DELAY

TITRATION

ALARM

100%

POWER

LED LED

JP2

FEED OFF

FEED ADJUST

5.0 ELECTRICAL CONNECTIONS

Figure 5-1

5.1 Transformer Wiring

The GeoCenter is shipped with two (2) 30 VA transformers,

one for the detergent control system and the other for the

rinse injector. Install the assembly into the GeoCenter

according to Figure 5-2.

Both transformers in the GeoCenter should be connected

to the single power source, refer to Figure 5-1.

On Door Type Dishmachines, two (2) separate power

sources from the dishmachine are required.

A power source that is activated during the wash cycle of

the machine should be connected to the top transformer.

Make sure to wire the transformer for the proper voltage,

refer to Figure 5-1.

The power source for the rinse injector should be connected

to the bottom transformer. Make sure to wire the transformer

for the proper voltage.

8

Figure 5-2

5.2 440 Volt Machine Power Supply

NOTE: Most 440 volt machines will provide a source of

115 or 220 volts for the dispenser supply. If only 440 volts

is available, it will be necessary to externally mount two

440 to 24 volt transformers. The transformers shipped

with the GeoCenter will not be used, and it is suggested

that these transformers not be installed.

1. Remove the built-in transformers from the GeoCenter

Cabinet, refer to Figure 5-2.

2. Connect one of the 24 volt leads, using a butt-

connector or a wire nut, from the external transformer

to the two VIOLET wires normally connected to the top

transformer.

3. Connectthe singleORANGEwiretotheothertransformer

lead.

4. Connect one of the 24 volt leads using a butt connector

to one of the GRAY wires normally connected to the

bottom transformer.

5. Connect the other wire in the same manner.

5.3 S-2000 Sensor Wire Connections

1. Attach the BROWN wire to terminal #15, refer to Figure

5-1.

5. Attach the RED wire to terminal #11.

6. Ensure JP1 and JP2 on the PC Board are only installed

on one pin.

5.4 Geosystem Detergent Dispenser Wiring

Connections

The Geosystem Detergent Dispenser features a switch on

the lid to interrupt detergent feed if the lid is opened. (Use

a 2 conductor cable between the GeoCenter and Detergent

units).

At the GeoCenter (Refer to Figure 5-1 on page 7):

• Wire nut the leads from the 2 conductor cable to the

5.5 Geosystem Solid Rinse Reservoir Connec-

tions

The Geosystem Solid Rinse injector reservoir features a

lid switch to interrupt water spray to the rinse additive if the

lid is opened.

TRANSFORMER

ASSEMBLY

-

nals #1 & #2 on the green Phoenix connector.

• The black and red wires are connected to terminals #4

IMPORTANT: RED must be connected to #7. BLACK

must connect to #4.

NOTE: This refers only to the Solid Rinse Additive dis-

penser. Hook up the Geomax unit for use with liquid

rinse additives.

5.6 VANGUARD Wash Max Wiring Connec-

tions

The VANGUARD Wash Max features a safety switch on

the lid to interrupt detergent feed if the lid is opened. A 20'

two conductor cable is connected to the unit to help instal-

lation.

At the VANGUARD GeoCenter (Refer to Figure 5-1 on

BLUE wires provided with the wire nuts.

5.7 Two Pole Probe Wire Connections

1. At the Two Pole Probe, connect the cell wiring to the

2 screws terminals. Leave enough slack in the wire to

allow removal of the cell from the connector without

having to disconnect the wire (refer to Figure 5-1).

2. At the GeoCenter connect the cell wires to TERMINALS

#10 and #11.

3. Ensure JP2 on the PC Board is installed in the "S26"

position.

9

6.0 SYSTEM ADJUSTMENTS

DETERGENT CONTROLLER P.C. BOARD

Figure 6-1

6.1 Cell/Sensor Selection

Ensure jumper JP2 on the detergent controller PC board is

sensor operation, the jumper should only be installed on

ONE pin of JP2.

For two-pole probe operation, the jumper should be installed

on the right two pins of JP2, labeled "S26".

6.2 Concentration Adjustment

Concentration versus Conductivity

When the detergent is dissolved in the wash tank, it produces

a certain concentration of product. A given concentration

of product will, in turn, produce a corresponding conductiv-

ity

the detergent controller. The controller attempts to reach

a desired solution concentration by using the conductivity

signal to control when to feed detergent product into the

wash tank.

wash tank water. The detergent controller cannot distinguish

between the conductivity signal produced by the water and

that produced by the dissolved detergent.

For this reason, the setting of the TITRATION DIP switch

should be viewed as a starting point that may require adjust-

ing once the wash tank is titrated.

Titration Adjustment

Adjustment of the wash tank concentration is done using

the six position TITRATION DIP switch on the detergent

controller PC board. The individual positions on this DIP

switch are labeled 1 through 6. Sliding a position to the left

will turn that position ON. Sliding a position to the right will

turn that position OFF. When a position is ON, the detergent

controller will add detergent to the wash tank according to

POSITION ON 1 2 3 4 5 6

APPROX. #

APPROX. #

When multiple positions are ON, the detergent controller

will add all positions together to achieve the desired tank

concentration.

Example using Standard Drops:

1. Assume a desired tank concentration of 14 standard

drops is required. Start by turning positions 1and 2and

3ON

2. Allow the detergent controller to feed until the 100%

TITRATION ADJUSTMENT

SONALERT®ALARM DE-

LAY ADJUSTMENT

SONALERT®

ALARM VOLUME

ADJUSTMENT

SELECTION

FEED ADJUST PO-

TENTIOMETERS

Note: JP1 and JP2

jumpers in "open"

position.

solution.

3. If the actual titration measurement is only 10 drops, the

wash tank water conductivity is already adding a read-

ing of 4 drops to the measurement. The TITRATION

additional detergent to the tank.

4. Turn positions 2and 3OFF and position 4ON. This

results in positions 1and 4

5. Repeat step 2. This should now provide the desired

concentration.

6.3 Feed Adjustment Potentiometers

of the set point, the dispenser will provide an “on-off” pulse

feed mode to control overshoot.

These potentiometers determine the duration of the “on-off”

pulses. This allows for minimum overshoot dependent upon

the detergent dispensing rate, refer to Figure 6-1.

The normal setting (as factory set) is both pots being in the

full counter-clockwise position, providing for a 1 second “on”

pulse and a 1 second “off” pulse. This is desirable for most

operating conditions.

These are adjustable up to a maximum of 12 seconds. If

the detergent delivery rate is very slow, such as might be

encountered with low feed water temperature to the reservoir,

it may be desirable to increase the “on” pulse time.

In a very large wash tank, it may be desirable to increase

the “off” to allow the detergent to disperse evenly throughout

the wash tank before further feeding occur.

10

RINSE SPEED CONTROL P.C. BOARD

6.4 Sonalert®Volume Adjustment

1. Turn all alarm delay switches off.

2. Put the unit into a feed mode by temporarily turning on

additional titration switches and disrupting detergent feed

by holding open the Geosystem Detergent Dispenser

lid.

3. When the Sonalert®is activated, set the volume using

volume, refer to Figure 6-1.

The Sonalert®volume should be loud enough to be heard

over the normal noise levels in the dish room , and yet not

too loud that it may disturb customers in the dining room.

6.5 Sonalert®Alarm Delay

1. Set the alarm delay by using the 10 position dip switch,

refer to Figure 6-1.

NOTE: On Door Type Machines, the delay should be

approximately 30-35 seconds to allow it to be activated

before the wash cycle is complete.

NOTE: On Conveyer Machines, (unless equipped with

a D-ENERGIZER or other time-out device) the delay

should be a minimum of 2 minutes.

6.6 Rinse Speed Control

This is the normal mode of operation as a dishmachine

rinse injector. Thru the pressure switch, the pump is ac-

speed control, the injection rate of the rinse additive can be

controlled throughout the entire rinse cycle, refer to Figure

6-2. Injection rate can also be adjusted by use of alternate

INJECTION RATES

PUMP SPEED

Tube Size 3 RPM (minimum) 36 RPM ( m axi -

mum)

* Tubing provided with GeoCenter unit.

NOTE: 1cc = 1 ml

Figure 6-2

POTENTIOMETERS

PUMP SPEED

POTENTIOMETER

NOTE: The best injection rates are achieved in the 10-20

revolution per minute range. It is recommended to select

the tubing that allows mid range operation.

6.7 Timed Feed

In this mode of operation, the dispenser will activate for a

pre-set period of time. This would be used when dispensing

control is determined by volume, refer to Figure 6-2.

Note that the TIME FEED and the SPEED CONTROL

modes can be used together. For example, if the injector

setting the TIME FEED for just a few seconds longer than

the normal rinse time, this will be the maximum length of

6.8 Feed Delay

This feature can be used with either the SPEED CONTROL

or TIME FEED mode.This is adjustable from 0 to 10 seconds,

and delays the pump activation for that period of time after

the unit is activated, refer to Figure 6-2.

11

7.0 SYSTEM OPERATING FEATURES

DETERGENT CONTROLLER P.C. BOARD

Figure 7-1

7.1 Power Lights

The “POWER” light on the front of the unit is lit when the

this occurs, it may be necessary to locate an alternate power

source. The power light for the rinse injector is illuminated

whenever the rinse injector is operating.

7.2 Feed Light

This light will be illuminated whenever the wash tank con-

centration is BELOW the control set point.

7.3 100% Light

This lightwill illuminatewheneverthewashtankconcentration

is at, or above, the control set point, refer to Figure 7-1.

NOTE: This light will ash at the appropriate time the

wash solution should be titrated. This will verify the

desired control set point.

7.4 Temperature Compensation

The concentration of the dissolved detergent in the wash

the conductivity signal produced by a given concentration

varies noticeably with water temperature. In general, the

higher the wash tank temperature, the higher the conductiv-

ity signal. This can cause the detergent controller to feed

less detergent product when the wash tank temperature

increases and more when it decreases.

The S-2000 Sensor incorporates a thermistor that measures

the wash tank temperature. The detergent controller PC

board uses this temperature measurement to automatically

adjust the detergent feed to maintain a desired concentration

over a wide range of wash tank temperature.

Due to limitations in sensor technology, the thermistor in the

S-2000 sensor responds slowly to changes in wash tank

temperature. Under certain conditions this slow response

can cause the detergent controller to respond improperly to

changes in wash tank temperature and feed erratically.

If erratic detergent feed is occurring, the temperature

compensation feature of the S-2000 sensor can be re-

moved by disconnecting the sensor brown wire from

terminal #15 on the detergent controller PC board.

NOTE - This will cause the desired detergent concentra-

tion to drop signicantly, which will require resetting the

TITRATION DIP switch according to Section 6.2.

NOTE - When using a two-pole cell, temperature com-

pensation is not functional, so detergent concentration

will vary with wash tank temperature. For this reason,

it is important to adjust titration using a two-pole cell

ONLY when the wash tank is at the correct operation

temperature.

7.5 Optional Jumper Settings

There are two additional jumper settings on the detergent

controller PC board that are not normally used in standard

installations. The function of these additional jumpers is

JP1 - FEED OFF - Installing this jumper will stop deter-

gent feed when the empty product alarm is active. To

start the unit feeding again the product container must

be relled and power to the unit must be turned OFF

and back ON again.

JP2 - HI (left two pins of JP2) - Installing this jumper will

multiply the TITRATION DIP switch position settings by

a factor of 10 times. This allows the use of very high

detergent concentrations that exceed the maximum

setting of 63 drops. For example, turning ON position 3

and 4 with this jumper installed will result in a desired

titration of about 120 drops.

12

8.0 SERVICE

8.1 Regular Inspection

1. Inspect the pump squeeze tube. If visible worn or

cracking, replace the squeeze tube even if it is working

properly at the time.

NOTE: Properly lubricate the tubing with the silicon

lubricant provided.

2. Inspect all tubing connections for leaks, cracks or loose

8.2 Squeeze Tube Replacement Instructions

1. Loosen tube nuts and pick-up discharge ends of squeeze

tube.

2. Remove the plastic cover from the face of the peristaltic

pump.

3. Pull both ends of the squeeze tube away from pump

body until tubes slips over the rollers.

4. Clean inside of pump body, wiping to remove particle

matter and accumulation of old lubricant.

5. Inspect the roller assembly closely for signs of wear or

cracking.

driver and rotate the roller assembly clock-wise to assist

in the placement of the tubing.

silicon grease lubricant.

NOT over tighten since plastic can stress crack if excess

of force is applied.

to check proper function of the new squeeze tube.

13

9.0 TROUBLESHOOTING

Symptom Action

1. Check for 24 volt power on terminals #20 and #21. If 24

volt power is present, replace Detergent Controller P.C.

Board.

2. If no 24 volt power at #20 and 21, check for high voltage

at machine power source.

a. If high voltage power, check wiring to transformer,

replace as required.

b. If no high voltage power, check power source or use

an alternate power source.

1. Check for 24 volt power at terminals #20 and #23. If 24

volt power is not present, replace Detergent Controller

P.C. Board.

2. If 24 volts is present, check the valve and valve circuit.

a. Check for water to the valve.

b. Disconnect the outlet tubing from the valve. If water

to the reservoir, or in the reservoir spray nozzle.

c. The valve will not open if the static water pressure is

greater than 120 psi. Use an alternate water source

or install a pressure reducing valve.

3. If 24 volts is not present at valve coil, there is a break in

power between the P.C. Board and the valve.

a. Tie together the 2 white wires. If detergent now feeds,

the reservoir safety switch (or wiring) is defective.

b. If bypassing the safety switch does not allow the valve

to operate, check the wiring and connections between

terminals #20 and #21 and the valve.

9.1 Unit does not operate - No Power Light.

9.2 Unit does not feed - Power Light and Feed

Light on.

14

used. (No jumper for S-2000, S26 position installed for

two-pole cell).

2. CheckTITRATION DIP switch setting. Temporarily increase

the setting to see if feed occurs.

3. If Two Pole Probe is used, remove the wire from terminal

#10. If detergent now feeds, the cell or cell wiring is shorted.

Repair or replace as needed.

4. If S-2000 Sensor is used, temporarily remove the brown

wire from terminal #15. If feed occurs, the thermistor in the

sensor may have failed and the sensor must be replaced.

As a backup, the unit can be run in this condition, although

temperature compensation will not function. Reset the

5. If S-2000 Sensor is used, remove the blue and white wires

from terminals #13 and #14. Temporarily place a jumper

a. If detergent feed occurs, replace the S-2000 sensor.

b. If detergent feed does not occur, replace the detergent

controller PC board.

the solenoid valve.

2. With power on, check for 24 volts at terminals #20 and

#23. If 24 volts, replace Detergent Controller P.C. Board.

NOTE: First determine if the wash tank concentration is

actually increasing. If not, there is no detergent being

delivered to the machine, or the detergent is not feeding

into the wash tank. Check for: proper water ow to the

dispenser; proper operation of the dispenser spray nozzle;

ow through the injection point into the machine.

1. Try a lower titration setting. If the dispenser stops

a. Check the power supply voltage to terminals #20 and

-

tion to the dispenser transformer.

c. If using the S-2000 Sensor, place a jumper wire across

terminals #12 and #14. If detergent does not stop

feeding, replace Detergent Controller PC board. If

detergent stops feeding, replace the sensor.

2. If the controller does not stop detergent feed when

adjusted to the lowest dispenser setting (all TITRATION

DIP switch positions off):

a. Check the power supply voltage to terminals #20 and

-

tion to the dispenser transformer.

b. If using the Two Pole Probe, place a jumper wire

across terminals #10 and #11. If detergent does not

stop feeding, replace Detergent Controller PC board.

cell wiring.

9.3 Unit does not feed - Power Light on, Feed

Light not on.

9.5 Feeds continuously - Feed Light on.

9.4 Feeds continuously - Feed Light not on.

15

IMPORTANT: Titration can be inuenced by many factors

outside of the detergent controller PC board and cell/sensor.

Some of these factors that should be checked before

troubleshooting the controller board and/or cell/sensor

include:

a. Check that scrap trays are properly installed in the

wash tank. Missing scrap trays can produce exces-

produce varying conductivity readings.

b. Check the conductivity level of the incoming supply

water. The tank titration will vary directly with varying

water quality due to changes in mineral content or

varying TDS.

elements in the wash tank. Excessive AC power

noise from the heaters can effect conductivity

temperature compensation on the detergent con-

troller board to malfunction (S-2000 Only). (See

1. Check the power supply voltage on terminals #20 and

use an alternate power supply to the transformer.

2. If the S-2000 Sensor is used, temporarily remove the

brown wire from terminal #15 and readjust the titration

setting for operation.

3. Check for signs of moisture contamination on the de-

tergent controller board, such as green discoloration or

corrosion on terminal connections or whitish deposits

on the board. Ensure the GeoCenter unit is properly

IMPORTANT: Determine if wash tank concentration is

remaining constant. If it is, detergent over consumption

is due to excessive wash tank dilution (with fresh water),

or all of the detergent is not entering the wash tank (being

diverted to the overow, into the rinse or pre-wash tanks,

etc.)

A detergent dispenser control can only be responsible

for maintaining a consistent detergent concentration. If it

causes the wash tank detergent concentration to increase,

see appropriate symptom above.

1. Check for incoming power of 24 volts AC across terminals

1 and 2 on the Speed Control Board.

a. If no 24 volts AC, check high voltage to transformer.

b. If no high voltage, check power source and

connections.

c. If 24 volts at transformer, carefully check all wires and

connections to Speed Rinse Control P.C. Board.

9.6 Fluctuating titration.

9.7 Excessive detergent consumption.

9.8 Rinse Injector does not activate.

16

2. Check fuse on the board - replace if necessary (1 amp

slow-blow fuse).

3. Check that time delay potentiometer is fully counter

clockwise.

1. Check Rinse Dispenser - Service as necessary.

rinse.

a. If product dispensed. Replace check valve.

b. If no product dispensed. Replace peristaltic tubing.

as needed.

4. Check squeeze tube for wear and replace if in doubt.

problem.

1. Check tubing connections for air leaks.

2. Check for high rinse pressure - optimum is 15-20 psig (1-

1.4 BAR) and cannot be over 35 psig (2.4 BAR).

3. Check squeeze tube for wear and cracks etc.

1. Lubricate, use only silicon grease lubricate.

2. Replace roller assembly.

1. Remove squeeze tube - if fuse does not blow, replace roller

assembly.

2. If fuse blows, disconnect pump motor leads from terminals

3 and 4 activate Rinse Speed Control P.C Board.

a. If fuse blows, replace Speed Rinse Control P.C.

Board.

b. If fuse does not blow, replace pump motor.

9.8 Rinse Injector does not activate

(continued).

9.10 Rinse Injector runs continuously

9.11 Rinse Injector will not prime.

9.12 Excessive squeeze tube wear.

9.13 Fuse on Speed Rinse P.C. board is

blowing repeatedly.

9.9 Rinse Injector runs, no rinse additive be-

ing injected.

Table of contents

Other Ecolab Dispenser manuals