Ecolab ALLIGATOR ALLOCATOR 100 User manual

ALLIGATOR ALLOCATOR

Installation and Operation Manual

22739/0302/0804 Copyright Ecolab Inc. 2004 9448-2635

R

ALLIGATOR ALLOCATOR

Installation and Operation Manual

Section...

1.0 PREFACE.........................................................................................................1

2.0 INTRODUCTION...............................................................................................1

3.0 SPECIFICATIONS ............................................................................................2

3.1 Dimensions (Dispenser) ...........................................................................2

3.2 Access Requirements ..............................................................................2

3.3 Components Supplied ..............................................................................2

3.4 Components Not Supplied .......................................................................2

3.5 Dimensions (Pump Shelf with Pump)...................................................... 3

3.6 Services Required....................................................................................3

3.7 Equipment Supplied .................................................................................3

3.8 Dimensions (Pump Bracket).....................................................................3

3.9 Description ...............................................................................................3

4.0 INSTALLATION................................................................................................4

5.0 OPERATION.....................................................................................................5

5.1 System Prime and Start-up ......................................................................5

6.0 TROUBLESHOOTING......................................................................................6

6.1. Pumps will not run when palm buttons on the dispenser are depressed. 6

6.2. Pumps run too slow..................................................................................6

6.3 Pumps run too fast. ..................................................................................6

6.4 Pumps run but do not prime. ....................................................................6

6.5 Time Totalizer needs to be reset..............................................................6

7.0 REPLACEMENT PARTS..................................................................................7

iii

1.0 PREFACE

Thismanual has been written to present the basic installa-

tionandoperationalcharacteristicsoftheAlligatorAllocator

Model 100. This

manual applies, in its entirety, to cur-

rent units.

Guidelines will be suggested in reference to the preferred

method of installation, however, the variety of equipment

and the surrounding physical environment will dictate the

actual installation of the Alligator Allocator.

WARNING - These installation and servicing in-

structions are for use by qualified personnel

only. The installation must be made in accor-

dance with local plumbing codes.

2.0 INTRODUCTION

TheAlligator Allocator is a manual allocation system which

is easy to install and operate. This system offers manual

allocation control to dispense two different concentrated

products from the shipping container into a use container.

Operation of the system is controlled by the manual push

buttons on the front of the dispenser. Dispensing duration

is maintained as long as the push buttons are depressed.

The only required utility for operation is a source of air.

Electricity and water are not needed!

Depressingthepalmbutton also appliesairpressure to the

pressure switches which closes the circuit to run the Time

Totalizer.TheTimeTotalizershaveaaninternalbattery,no

external power is needed.

1

3.0 SPECIFICATIONS

W

H

D

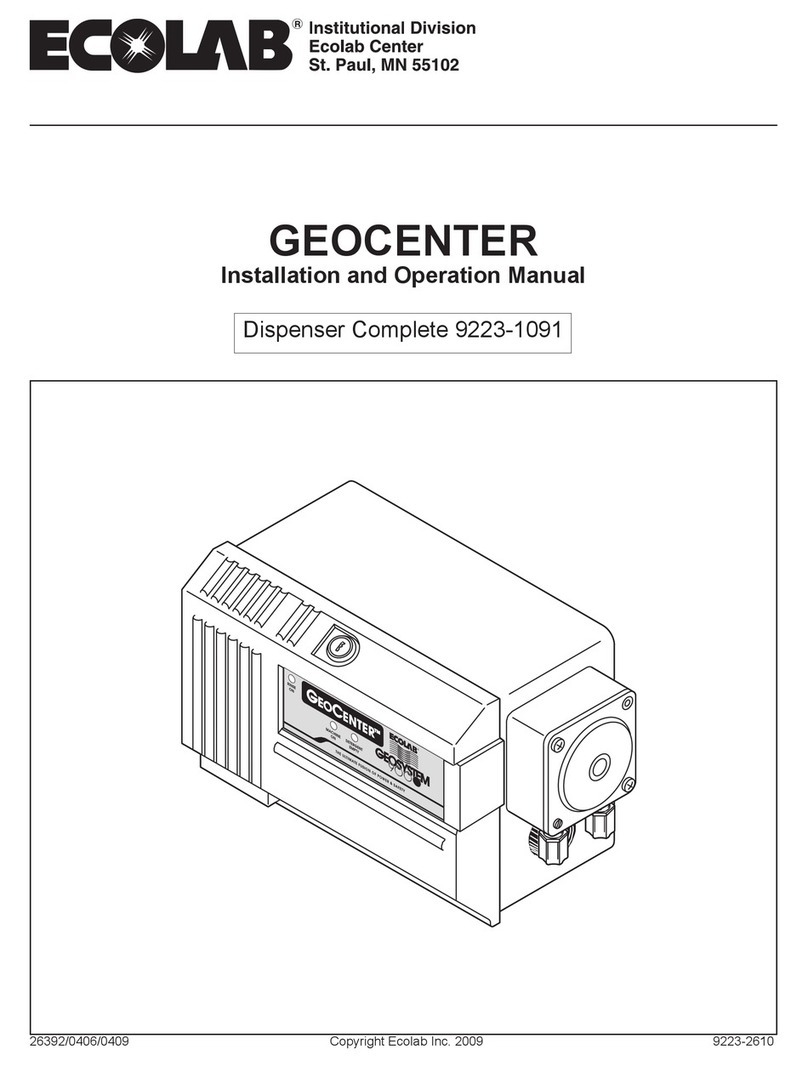

Alligator Allocator Dispenser

3.1 Dimensions (Dispenser)

• Height (H) : 15" (38.1 cm)

• Width (W) : 13" (33 cm)

• Depth (D) : 5" (12.7 cm)

NOTE-Thewidthofthecabinetincludestheprotruding

inlet and outlet water manifold fittings.

3.2 Access Requirements

For ease of operation the cabinet should be placed such

that the palm buttons are 4 - 5' (1.2 - 1.5 meters) above the

floor.

3.3 Components Supplied

• Alligator Allocator Dispenser

• Positronic IV Pumps and Cabinets (2)

• Viton anti-siphon Valves and Kits (2)

• 55 Gallon Drum Probes (2)

• Positronic IV Pump Mounting Bracket

• Anti-siphon Valve Holder

• Fill Hoses (2)

• Jug Holder

3.4 Components Not Supplied

• 1/4" air Polyflo tubing (P/N 8501-5105)

•

3/8" ID reinforced pump suction and discharge tub-

ing (P/N 8501-5410).

• Use containers

2

WD

H

Positronic IV Pump Shelf with Pump

3.5 Dimensions (Pump Shelf with Pump)

•Height (H): 8-1/4" (3.21 cm)

•Width (W): 7-3/4" (19.7 cm)

•Depth (D): 9-1/2" (24.1 cm)

3.6 Services Required

Compressed air: MAX 80 psig (5.5 bars)

MIN 40 psig (2.7 bars)

AIR FLOW 3 scfm (1.4dm3/s)

3.7 Equipment Supplied

Thepumpbracketissuppliedwiththesystem.Productinlet

andoutletelbowsandtheairconnectionfittingaresupplied

with the pump. Also included is the pump shelf and mount-

ing fasteners.

D

W

H

3.8 Dimensions (Pump Bracket)

•Height (H): 4-3/8" (11.1 cm)

•Width (W): 23-1/8" (58.7 cm)

•Depth (D): 3/4" (1.9 cm)

3.9 Description

This bracket is capable of supporting (3) pump shelves.

Positronic IV Pump Bracket

3

4.0 INSTALLATION

Figure 1

TO

AIR SUPPLY

FlowFlow

DISPENSER

PUMPS AND

PUMP SHELVES

PUMP SHELF

MOUNTING BRACKET

USE CONTAINER

HOLDER

DRAIN TUBE

FLOOR DRAIN

55 GALLON

PRODUCT

CONTAINER

ANTI-SIPHON VALVE

HOLDER

ANTI-SIPHON

VALVE

AIR LINES TO

PUMP

PRODUCT PICKUP

PROBE

PRODUCT SUC-

TION LINE

KNURLED

KNOB

FLOW ARROW

POINTS DOWN

BRACKET

ANTI-SIPHON

VALVE BRACKET

PRODUCT DISCHARGE

HOSES

Note: These installation and servicing instructions are

for use by authorized personnel only. The installation

mustbemadeinaccordancewithlocalplumbingcodes.

1. Remove the components of the Alligator Allocator

system from the shipping containers. Connect the

pressure regulator assembly to the Alligator Allocator.

2. Mountthesystemtothewall,adjacenttotheairsupply,

using the mounting hardware provided in the installa-

tion kit.

Refer to the Installation Diagram.

Note: For ease of operation the palm buttons of the

dispenser should be 4 to 5 feet (1.2 to 1.5 meters)

above the floor.

3. Place anti-siphon valves into holder. Refer to Figure 1.

Note: The bracket is captive. To install the anti-

siphon valves turn the knurled knob in front of the

anti-siphon valve holder so the bracket is loose.

Install the anti-siphon valves and tighten bracket

untilthevalvesaresecuredintheanti-siphonvalve

holder.

4. Connect the air, suction, discharge and use container

drain tube per the installation diagram.

System Diagram

4

5.0 OPERATION

5. Observe the product flow through the system, into the

anti-siphon valve and the use container.

6. Observe that the Time Totalizers advance when the

palm buttons are depressed and the pumps are run-

ning.

7. To"reset"theTimeTotalizers,pushthe"reset"buttons

on the front of the Time Totalizers.

5.1 System Prime and Start-up

1. Insert the ball foot probe into the product drums.

2. Insert use containers into use container holder (insure

producthosesareinsertedintoneckofusecontainers).

3. If timer is not on; Remove plastic insulation tab from

timer and press reset button on face of timer. Display

should come on.

4. Depress each of the palm buttons, one at a time, to

buttons are depressed, air flows thru the product con-

trol valves to the product pumps. Air also is applied to

the pressure switches which close the circuit to the

Time Totalizers. The Time Totalizers have internal

batteries therefore no external power is needed.

Note: Adjust the air regulator on the dispenser to a

flow rate and pump speed you are comfortable

with.

AIR

IN

PALM

BUTTONS

PRESSURE

REGULATOR

TIME

TOTALIZERS

TIME TOTALIZER

RESET BUTTONS

PRODUCT

CONTROL

VALVES

PRESSURE

SWITCHES

5

Symptom

6.0 TROUBLESHOOTING

ActionCause or Failure Mode

6.1. Pumps will not run when palm

buttons on the dispenser are

depressed.

6.2. Pumps run too slow.

6.3 Pumps run too fast.

6.4 Pumps run but do not prime.

6.5 Time Totalizer needs to be

reset.

1. No "air" to the system.

1. Air pressure regulator set too low.

1. Airpressureregulatorsettoohigh.

1. Airleaksonsuctionsideofpumps.

2. Anti-siphon valve is backwards.

1. Reset buttons on back of Total-

izer.

•Check air source

•Adjust pressure regulator

•Check the manual air valves in

dispenser

•Adjust pressure regulator to a

higher pressure

•Adjustpressureregulatortoalower

pressure

•Checksuctiontubingandconnec-

tions for air leaks.

•Observedirectionofflowarrowon

antiphon valve and turn around if

necessary.

•Open door of dispenser and de-

presstheresetbuttonsontheback

of totalizer.

6

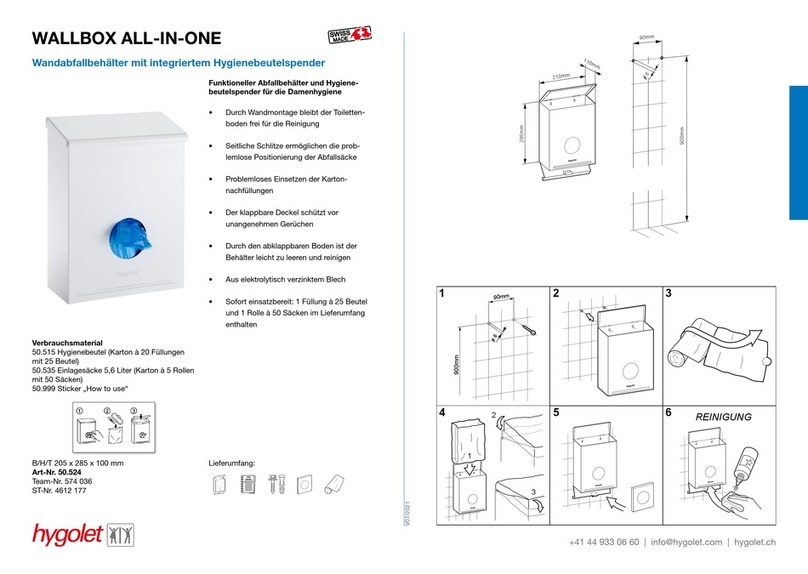

7.0 REPLACEMENT PARTS

REF.

NO. PART NO. DESCRIPTION

1 8301-4001 TIME TOTALIZER

2 8602-8008 CAP 1/2" BRZ

3 9229-9064 PUSH BUTTON

4 9229-9072 PUSH BUTTON SLEEVE

5 8539-0094 PRESSURE GAUGE

6 8553-3354 ELB 1/4P-FX1/4MNPT BRS

7 8420-0294 RGLTR SRLV 1/4 AIR

8 8617-8019 NPL HEX 1/4X1/4 BRNP

9 8614-8582 BSHG 1/2X1/4 BRNP

10 8603-8031 CPLG HEX 1/2 BRNP

11 8702-9047 KEY 176

REF.

NO. PART NO.

• PART NOT SHOWN

DESCRIPTION

12 8702-0335 LOCK

13 8331-2017 LOCK NUT CND 1/2

14 8862-5272 RNG RTNR 1/2 SST EXT

15 8553-3347 ELB 1/4P-FX1/8MNPT BRS

16 8620-8006 TEE BR 1/8 BRNP

17 8305-2225 SW PRESS 4PSI 1/8MNPT NO

18 8614-8558 BSHG 1/4X1/8 BRNP

19 9229-0014 CONTROL VALVE

20 8617-8019 NPL HEX 1/4X1/4 BRNP

21 9229-2309 MANIFOLD ASM

22 8311-3654

•9204-1128

•9204-1150

•9204-1000

BSHG UNIV 1 NYL

ANTI-SIPHON VLV KIT - VITON

ANTI-SIPHON VLV KIT - EPDM

ANTI-SIPHON VLV KIT - SILICONE

2

3, 4 5

6

7

10 9 8

1

21

20

19

18

12

13, 14

15 16 17 15 16 17

DETAIL A

SEE DETAIL A

11

22

7

Table of contents

Other Ecolab Dispenser manuals