20

Declaration of Conformity

We Nilfisk-ALTO, declare under our sole responsibility that the

products BF3+, BF4+, BF8+, BW3+, BW4+,BW7+, to which this

declaration relates, are in conformity with these Council directives

on the approximation of the laws of the EC menber states:

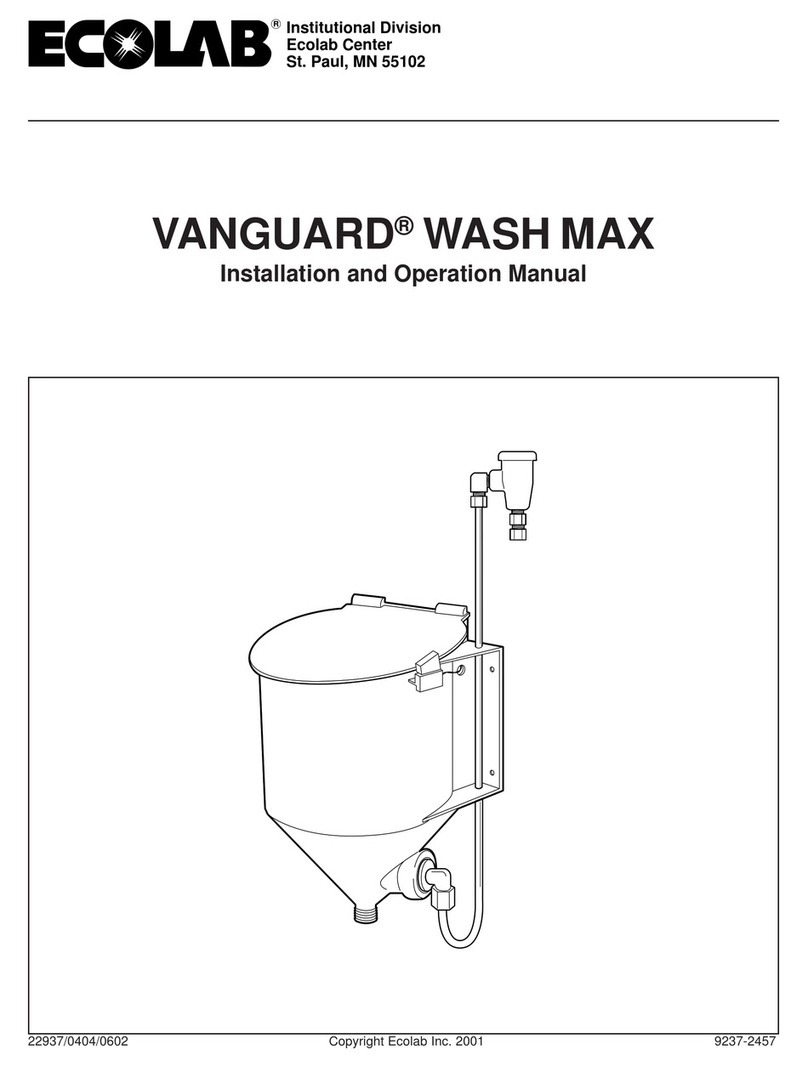

Function: Pumping Station

Model/Type: BF3+, BF4+, BF8+, BW3+, BW4+, BW7+.

Serial number: All

Machinery Directive (2006/42/EC:2006-05-17).

Standard used: EN 60335-2-41/A2:2010

EMC Directive (2004/108/EC:2004-12-15).

Standard used: EN 55014-1/A1:2009 and EN 55014-2/A2:2008

Standard used: EN 61000-3-2/A2:2009 and EN 61000-3-3:2008

Konformitätserklärung

Nilfisk-ALTO, als alleinverantwortlich, erklären hiermit, dass: BF3+,

BF4+, BF8+, BW3+, BW4+,BW7+, in Übereinstimmung mit den

Richtlinien zur Angleichung der Rechtsvorschriften der Mitgliedstaaten

ist:

Funktion: Pumpenstation

Modell/Typ: BF3+, BF4+, BF8+, BW3+, BW4+, BW7+

Seriennummer: Alle

Maschinendirektive (2006/42/EC:2006-05-17).

Standarden: EN 60335-2-41/A2:2010

EMC Direktive (2004/108/EC:2004-12-15).

Standarden: EN 55014-1/A1:2009 og EN 55014-2/A2:2008

Standarden: EN 61000-3-2/A2:2009 og EN 61000-3-3:2008

Déclaration de conformité

Nous, Nilfisk-ALTO, déclarons sous notre propre responsabilité que

les produits BF3+, BF4+, BF8+, BW3+, BW4+, BW7+. auxquels se

réfère cette déclaration, sont conformes à ces directives du Conseil

sur le rapprochement des législations des États membres :

Fonction : Station de pompage

Modèle/Type : BF3+, BF4+, BF8+, BW3+, BW4+, BW7+.

Numéro de série : Tous

Directive 2006/42/CE du 17 mai 2006 relative aux machines

Normes appliquées : EN 60335-2-41/A2:2010

Directive CEM (2004/108/CE:2004-12-15).

Normes appliquées : EN 55014-1/A1:2009 et EN 55014-2/A2:2008

Normes appliquées : EN 61000-3-2/A2:2009 et EN 61000-3-3:2008

Dichiarazione di conformità

Nilfisk-ALTO dichiara sotto la sua esclusiva responsabilità che i prodotti

BF3+, BF4+, BF8+, BW3+, BW4+, BW7+. ai quali fa riferimento la

presente dichiarazione, sono conformi alle direttive del Consiglio

concernenti il riavvicinamento delle legislazioni degli stati membri della

UE:

Funzione: Stazione di pompaggio

Modello/Tipo: BF3+, BF4+, BF8+, BW3+, BW4+, BW7+.

Numero di serie: Tutti

Direttiva Macchine (2006/42/CE:2006-05-17).

Standard utilizzato: EN 60335-2-41/A2:2010

Direttiva EMC (2004/108/CE:15.12.04).

Standard utilizzato: EN 55014-1/A1:2009 ed EN 55014-2/A2:2008

Standard utilizzato: EN 61000-3-2/A2:2009 ed EN 61000-3-3:2008

Declaración de Conformidad

Nosotros, Nilfisk-ALTO, declaramos bajo nuestra única

responsabilidad que los productos BF3+, BF4+, BF8+, BW3+,

BW4+, BW7+, a los que se refiere esta declaración cumplen con las

directivas de este Consejo sobre la legislación de los estados

miembros de la CE:

Función: Estación de bombeo

Modelo/tipo: BF3+, BF4+, BF8+, BW3+, BW4+, BW7+.

Número de serie: All

Directiva sobre máquinas (2006/42/EC:2006-05-17).

Normativa usada: EN 60335-2-41/A2:2010

Directiva CEM (2004/108/EC:15.12.04).

Normativa usada: EN 55014-1/A1:2009 y EN 55014-2/A2:2008

Normativa usada: EN 61000-3-2/A2:2009 y EN 61000-3-3:2008

Declaração de Conformidade

A Nilfisk-ALTO declara, por sua exclusiva responsabilidade que os

produtos BF3+, BF4+, BF8+, BW3+, BW4+, BW7+, referidos nesta

declaração, se encontram em conformidade com estas diretivas do

Conselho relativas à aproximação das disposições legislativas dos

Estados-Membros da CE:

Função: Estação de bombagem

Modelo/Tipo: BF3+, BF4+, BF8+, BW3+, BW4+, BW7+.

Número de série: Todos

Diretiva relativa às máquinas (2006/42/CE:2006-05-17).

Norma utilizada: EN 60335-2-41/A2:2010

Diretiva CEM (2004/108/CE:2004-12-15).

Norma utilizada: EN 55014-1/A1:2009 e EN 55014-2/A2:2008

Norma utilizada: EN 61000-3-2/A2:2009 e EN 61000-3-3:2008

110002635A_BF&BW_2012