7

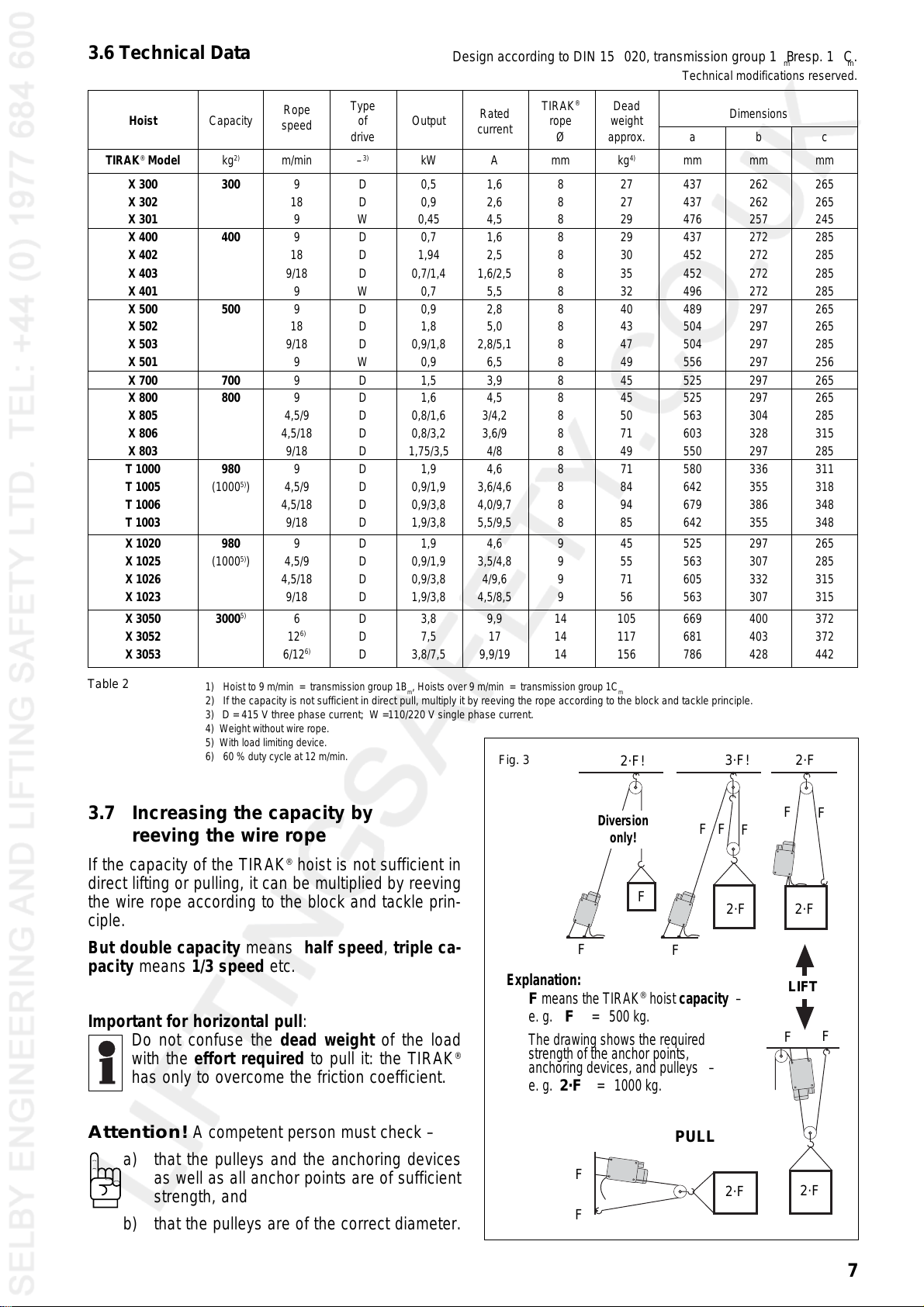

Rope Type TIRAK

®

Dead

Rated Dimensions

Hoist Capacity speed of Output rope weight

current

drive Ø approx. a b c

TIRAK

®

Model kg

2)

m/min –

3)

kW A mm kg

4)

mm mm mm

X 300 300 9D0,5 1,6 8 27 437 262 265

X 302 18 D 0,9 2,6 8 27 437 262 265

X 301 9W0,45 4,5 8 29 476 257 245

X 400 400 9D0,7 1,6 8 29 437 272 285

X 402 18 D 1,94 2,5 8 30 452 272 285

X 403 9/18 D 0,7/1,4 1,6/2,5 8 35 452 272 285

X 401 9W0,7 5,5 8 32 496 272 285

X 500 500 9D0,9 2,8 8 40 489 297 265

X 502 18 D 1,8 5,0 8 43 504 297 265

X 503 9/18 D 0,9/1,8 2,8/5,1 8 47 504 297 285

X 501 9W0,9 6,5 8 49 556 297 256

X 700 700 9D1,5 3,9 8 45 525 297 265

X 800 800 9D1,6 4,5 8 45 525 297 265

X 805 4,5/9 D 0,8/1,6 3/4,2 8 50 563 304 285

X 806 4,5/18 D 0,8/3,2 3,6/9 8 71 603 328 315

X 803 9/18 D 1,75/3,5 4/8 8 49 550 297 285

T 1000 980 9D1,9 4,6 8 71 580 336 311

T 1005 (1000

5)

)4,5/9 D 0,9/1,9 3,6/4,6 8 84 642 355 318

T 1006 4,5/18 D 0,9/3,8 4,0/9,7 8 94 679 386 348

T 1003 9/18 D 1,9/3,8 5,5/9,5 8 85 642 355 348

X 1020 980 9D1,9 4,6 9 45 525 297 265

X 1025 (1000

5)

)4,5/9 D 0,9/1,9 3,5/4,8 9 55 563 307 285

X 1026 4,5/18 D 0,9/3,8 4/9,6 9 71 605 332 315

X 1023 9/18 D 1,9/3,8 4,5/8,5 9 56 563 307 315

X 3050 3000

5)

6D3,8 9,9 14 105 669 400 372

X 3052 12

6)

D7,5 17 14 117 681 403 372

X 3053 6/12

6)

D3,8/7,5 9,9/19 14 156 786 428 442

3.6 Technical Data

Table 2

1) Hoist to 9 m/min = transmission group 1B

m

, Hoists over 9 m/min = transmission group 1C

m

2) If the capacity is not sufficient in direct pull, multiply it by reeving the rope according to the block and tackle principle.

3)

D = 415 V three phase current; W =110/220 V single phase current.

4) Weight without wire rope.

5) With load limiting device.

6) 60 % duty cycle at 12 m/min.

Design according to DIN 15020, transmission group 1B

m

resp. 1C

m

.

Technical modifications reserved.

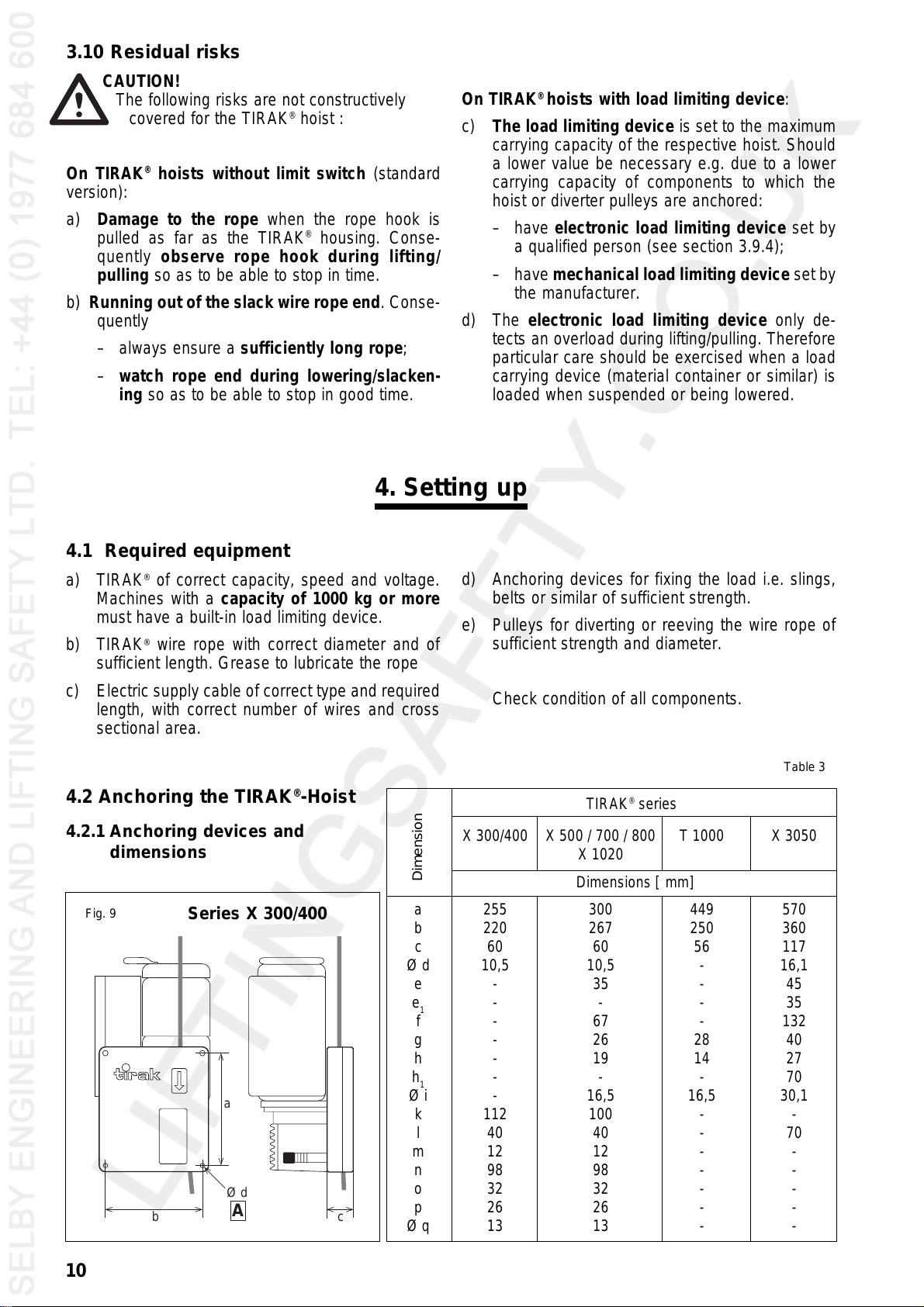

Fig. 3 2·F

3·F!

2·F!

F

F

F

F2·F 2·F

Diversion

only!

F

F

F

F

F

F

2·F

LIFT

F

F

2·F

PULL

Explanation:

F

means the TIRAK

®

hoist capacity –

e. g.

F

= 500 kg.

The drawing shows the required

strength of the anchor points,

anchoring devices, and pulleys –

e. g.

2·F

= 1000 kg.

3.7 Increasing the capacity by

reeving the wire rope

If the capacity of the TIRAK

®

hoist is not sufficient in

direct lifting or pulling, it can be multiplied by reeving

the wire rope according to the block and tackle prin-

ciple.

But double capacity means half speed, triple ca-

pacity means 1/3 speed etc.

Important for horizontal pull:

Do not confuse the dead weight of the load

with the effort required to pull it: the TIRAK

®

has only to overcome the friction coefficient.

Attention!

A competent person must check –

a) that the pulleys and the anchoring devices

as well as all anchor points are of sufficient

strength, and

b) that the pulleys are of the correct diameter.