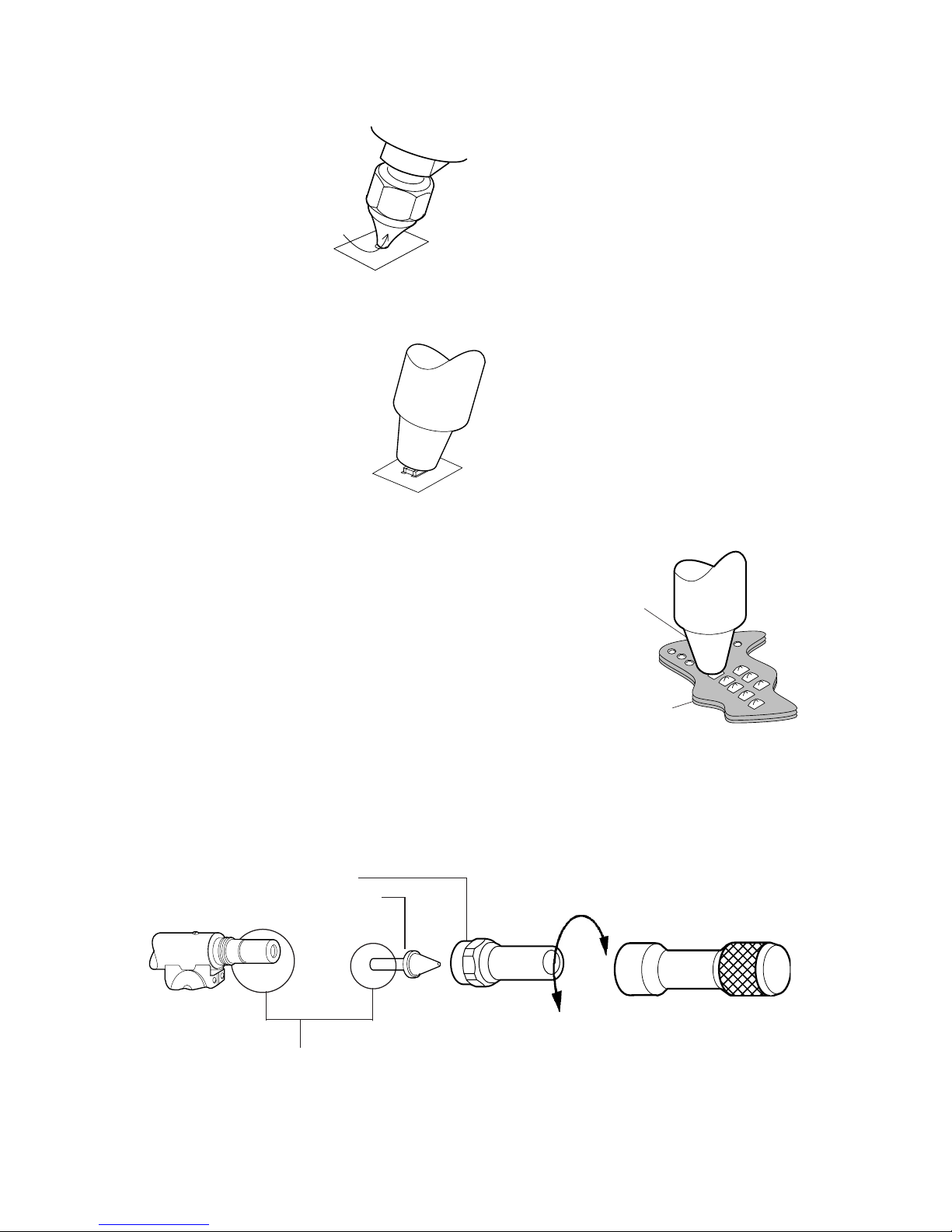

TO REPLACE O- RINGS INSIDE VALVE ASSEM-

BLY

a) Unscrew Lock Nut at the end of the HT500

Handle.

b) Remove Handle Cover.

c) Slide out Valve Assembly while placing your nger

over the Spring Seat. BE CAREFUL NOT TO LET

THE SPRING AND THE SPRING SEAT SHOOT

OUT FROM THE HOUSING

d) Clean all parts with alcohol only.

e) Replace OS730 O-Ring Set (set of 3).

f) Lube new O-rings with OL111 O-Ring Lube.

Valve Assembly

Handle

Cover

Lock Nut

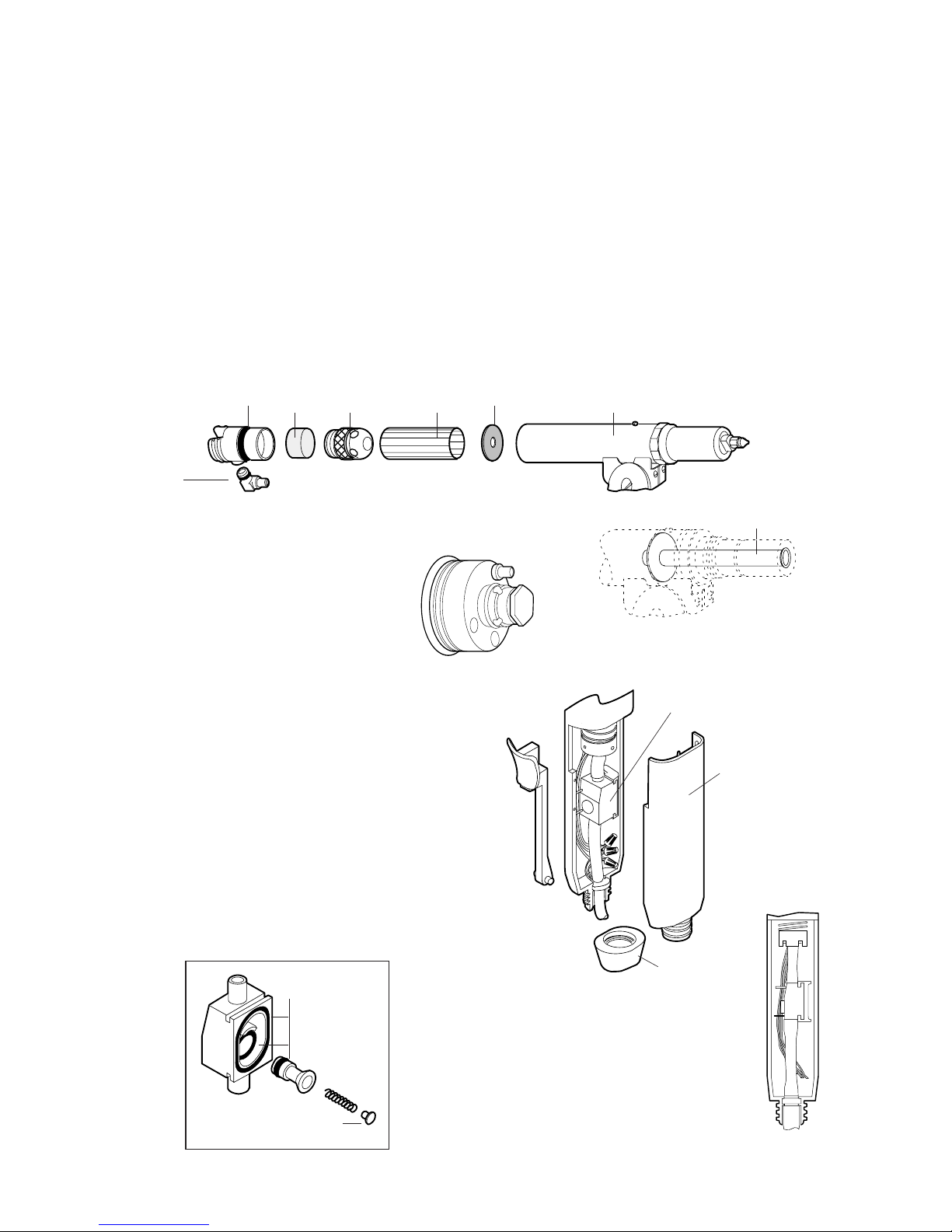

DAILY MAINTENANCE WEEKLY MAINTENANCE

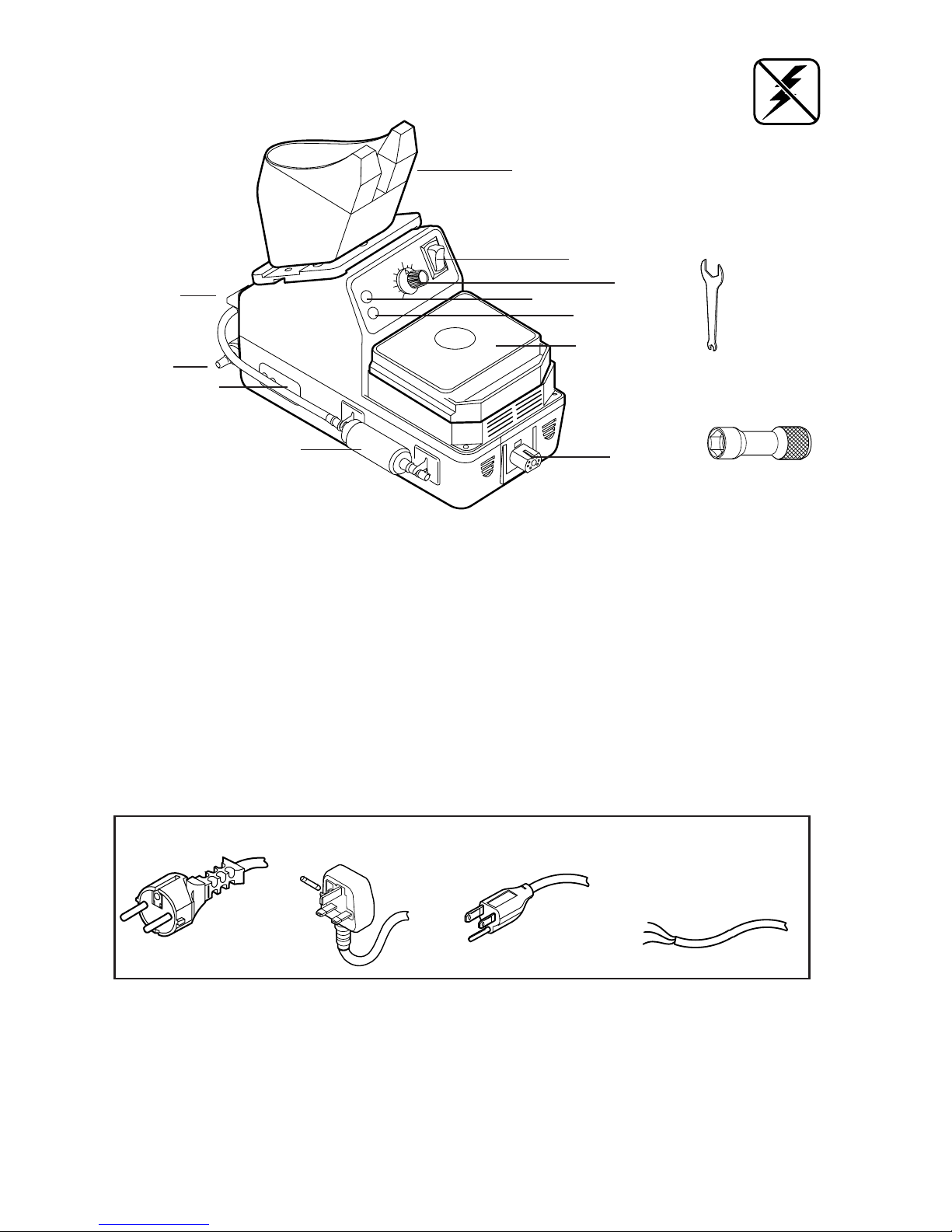

SC525 MS229 OS133

©®®©

AF625

©

OS731

FC639

©OS132

When installing OS133, the HT01

should go thru the OS133.

®Desoldering

Head Housing

• Remove and inspect Tip and Heater Assy.

• Inspect all Filters

• Remove solder debri from Desoldering Head

Housing

• Inspect Valve Assy.

• Inspect all O-Rings and Seals

TO REPLACE FILTER & O-RING INSIDE

DESOLDERING HEAD ASSY.

1. Pull out FC639 from Housing.

2. Unscrew SC525 from FC639 to remove AF625.

3. Insert new AF625 inside SC525 and screw back

on.

4. Clean and apply OL111 on OS731 & OS132

O-Ring.

CAUTION: Make

sure the wires are

not pinched by

Valve Assembly.

Spring Seat

OS730 O-ring set

HT01

OS133

© - Clean

® - Replace

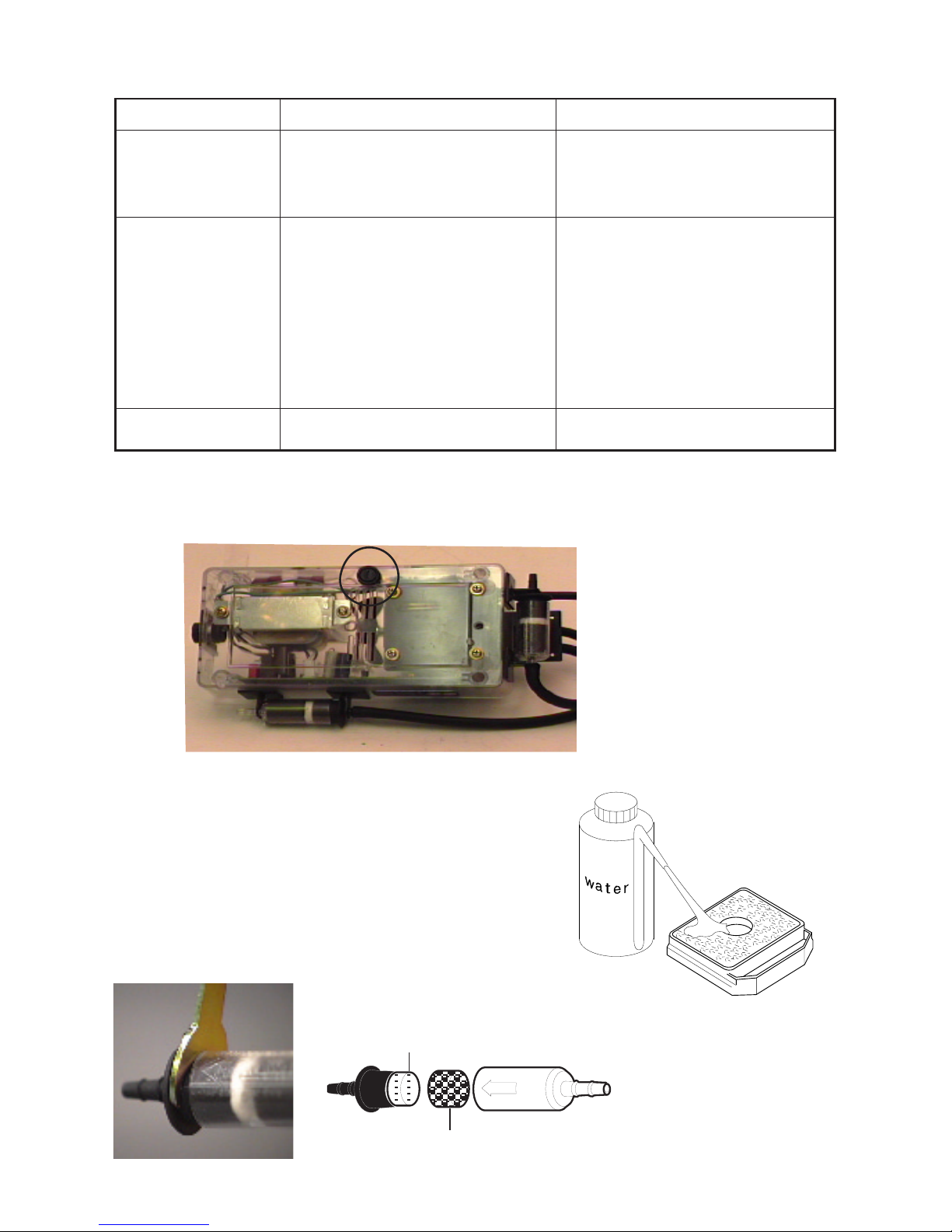

OPTIONAL FC641

Large Filter Cartridge Assembly

1. Pull out FC641 from Housing.

2. Unscrew FC641 remove old AF041.

3. Insert new AF641 inside FC641 and

screw back together.

4. Clean and apply OL111 on OS731 &

OS132 O-Ring.

Page 9