EFD 780S Series User manual

US: 888-333-0311

UK: 0800 585733

Mexico: 001-800-556-3484

780S Series Spray Valves

VALVEMATE™7040 Controller

Operating Manual

®

A NORDSON COMPANY

If you require any assistance or have spe-

cific questions, please contact us.

US: 888-333-0311

Telephone: 401-434-1680

Fax: 401-431-0237

E-mail: [email protected]

Mexico: 001-800-556-3484

UK: 0800 585733

EFD Inc.

977 Waterman Avenue, East Providence, RI 02914-1342 USA

Sales and service of EFD Dispense Valve Systems is available

through EFD authorized distributors in over 30 countries.

Please contact EFD U.S.A. for specific names and addresses.

Contents

Introduction ..................................................................2

Specifications ..............................................................3

How The Valve and Controller Operate ......................4

Controller Operating Features ....................................5

Typical Setup ..............................................................6

Setup ........................................................................7-8

Adjusting the Spray......................................................9

Programming Nozzle Air Delay ..................................10

Spray Patterns ..........................................................11

Troubleshooting Guide ........................................12-13

Valve Maintenance................................................14-16

780S Exploded View..................................................17

Input / Output Connections..................................18-19

Connecting More than One 7040 Controller..............20

7040 Schematic and Replacement Parts ..................21

Warranty ....................................................................22

Meets CSA and CE standards.

780/7040-MAN ©2003 EFD Inc.

This manual is for the express and sole use of EFD valve purchasers and users,

and no portion of this manual may be reproduced in any form.

EFD and VALVEMATE are trademarks of EFD Inc.

Teflon is a registered trademark of DuPont.

2 / Introduction

Introduction

The 780S Series precision Low Volume Low Pressure

(LVLP) liquid spray valves are manufactured to the

highest quality standards. The VALVEMATE™7040

controller features an adjustable nozzle air flow

regulator and a microprocessor-based timed air pres-

sure output for controlling the ON time of the 780S

valve.

This equipment is produced to very close tolerances to

ensure proper and reliable operation. Each valve and

controller has been thoroughly tested prior to shipping.

The 780S and VALVEMATE™7040 are simple to use

and will operate many millions of cycles without main-

tenance. Spray valve cleaning is accomplished by

purging with the appropriate solvent.

To obtain the maximum performance from this fine

equipment, please read through these instructions

carefully.

Note: All stainless steel valve parts are passivated.

Specifications and technical details are subject to

engineering changes without prior notification.

VALVEMATE™7040 Controller

Cabinet size: W 7.5" x D 5.6" x H 2.7"

(W 19 x D 14 x H 7 cm)

Net weight: 3.1 lb (1.4 kg)

Air input required: 70 psi (4.8 bar) minimum

Input voltage: 100/120/220 VAC selectable

Power required: 50/60 Hz 14/12VA

Foot pedal voltage: 5 VDC

Time range: .001 to 99.9 seconds

Timing control: Microprocessor-based CMOS logic

Time cycle repeat 0.00005 seconds

Time reset: Less than 20 milliseconds

Initiation: Dry contact closure or 5 to 24 VDC signal

Output pressure:

Actuating air 70 psi (4.8 bar)

Nozzle air 1 to 30 psi (0.07 to 2.07 bar)

Cycle rate: Exceeds 600 per minute

Cycle end feedback circuit: N.C. solid-state switch

5 to 24 VDC, 250 mA maximum load

Specifications

780S Spray Valve

Size: 4.120" x 1.060" dia. (104.6 x 26.9 mm)

Weight: 780S: 8.3 oz (235 g)

780S-SS: 14.3 oz (405 g)

Air cylinder body: 780S-SS: Type 303 stainless steel

780S: Hard-coated aluminum

Fluid chamber: 780S-SS: Type 303 stainless steel

780S: Hard-coated aluminum

Piston: Type 303 stainless steel

Piston return spring: Type 303 stainless steel

Needle and Nozzle: Type 303 stainless steel

Air cap: 780S-SS: Type 303 stainless steel

780S: Plated brass

Needle packings: Teflon®

Packing spring: Stainless steel

Liquid inlet hole: 1/8 NPT female

Mounting: 1/4-28 UNF tapped hole

Operating frequency: Exceeds 400 per minute

Air pressure required: 70 psi (4.8 bar)

Minimum mounting center distance: 1.067" (27.1 mm)

Standard nozzle diameter: 0.046" (1.17 mm)

Optional nozzle sizes: 0.028" (0.71 mm)

0.014" (0.36 mm)

Spray patterns: Round (standard)

Fan (optional)

3 / Specifications

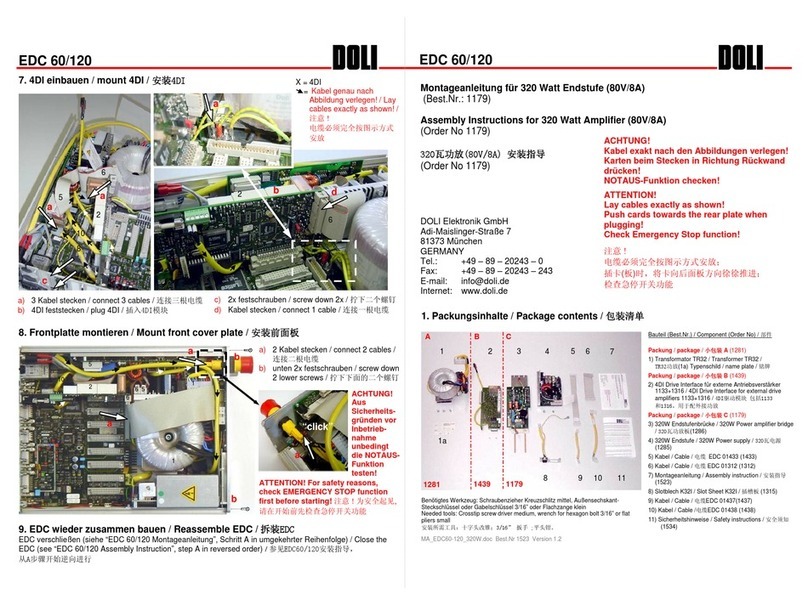

How The Valve and Controller Operate

open position

The 780S is a normally closed, air actuated needle

type spray valve that uses a Low Volume Low

Pressure (LVLP) design for high transfer efficiency

without overspray or airborne mist.

Air pressure from the VALVEMATE™7040 controller at

70 psi (4.8 bar) acts on a piston

➀

that retracts the nee-

dle ➁from its nozzle seat ➂and allows liquid to flow

from the nozzle ➃. At the same time, nozzle air, also

from the 7040, is turned on and flows from an annulus

➄around the liquid nozzle.

This adjustable nozzle air creates a pressure drop

around the nozzle, causing the liquid to atomize into

fine droplets.

When the timed actuating air from the 7040 shuts off,

the piston spring moves the needle onto the nozzle

seat, shutting off liquid flow. A preset nozzle air delay

ensures that no liquid remains on the nozzle after the

valve closes, eliminating after-deposit spatter.

The amount sprayed is controlled by the valve open

time, reservoir pressure and needle stroke. Area of

coverage is determined by the nozzle size and the dis-

tance between the 780S nozzle and the work surface.

closed position

4 / How The Valve and Controller Operate

Piston and needle

➀

Nozzle seat

➂

Needle

➁

Annulus

➄

Nozzle

➃

Piston and needle assembly

Fluid

Nozzle air

Operating air

1. Cycle

Press to initiate one complete dispense

cycle. Press this button again to interrupt a

timed cycle. Press and hold while in the time

override mode for continuous cycle. Release

to stop.

2. Time override

Press to override time control. Display will

show (---). While in this mode, dispensing is

manual using the cycle button, voltage initi-

ate source or foot pedal (optional, #2015A).

3. Decimal

Press to move decimal and change time

range maximums from .999 to 9.99 or 99.9.

Decimal does not appear in the display while

in the .999 second range.

4. Program

Press to clear display to zeros. Display

flashes bright/dim while in program mode.

Press cycle button and hold until proper

amount is sprayed. Total spray time will be

displayed. Press program button again to

lock in spray time.

5. Time set

Press to change time setting up or down.

Press and release to advance one digit at a

time, or press and hold to scroll quickly.

6. Foot pedal connector

If using the optional foot pedal, press the

pedal momentarily to initiate the 7040 con-

troller. To interrupt a timed dispense cycle,

press the pedal again.

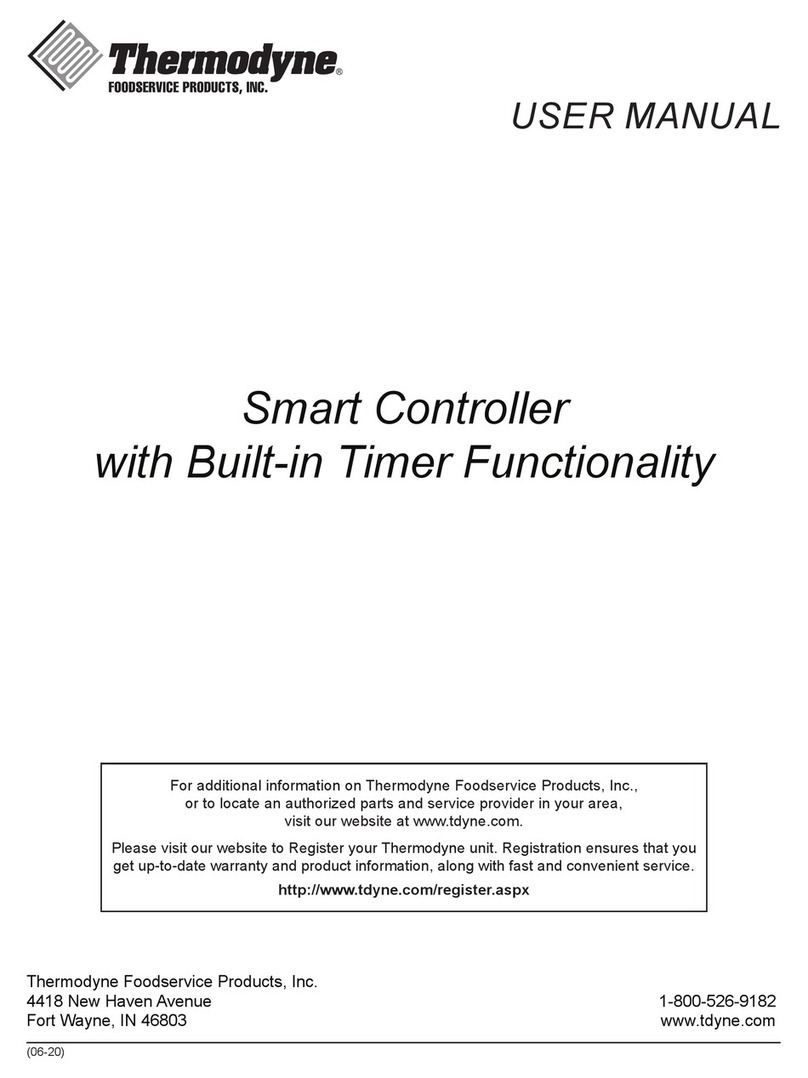

Controller Operating Features

5 / Controller Operating Features

Nozzle

air regulator

Nozzle

air gauge 12

3

5

Power

switch 6

Air input

quick-coupler

70 psi (4.8 bar)

minimum input

pressure

Valve

operating

air output

(white)

Nozzle

air output

(black)

Output A

Output B

Air

exhaust

9 pin D connector

I/O interface

(see page 18 for details)

Input power

cord receptacle

(see page 7

for details)

120

4

VALVEMATE

7040

Caution: Always depressurize the reservoir before

opening. To do this, slide the shutoff valve on the

air line away from the reservoir. If using an EFD

tank, open the pressure relief valve as well. Before

opening the reservoir, check the pressure gauge to

verify that pressure is zero (0).

On all EFD cartridge reservoirs, the unique thread-

ed design provides fail-safe air pressure release

during cap removal.

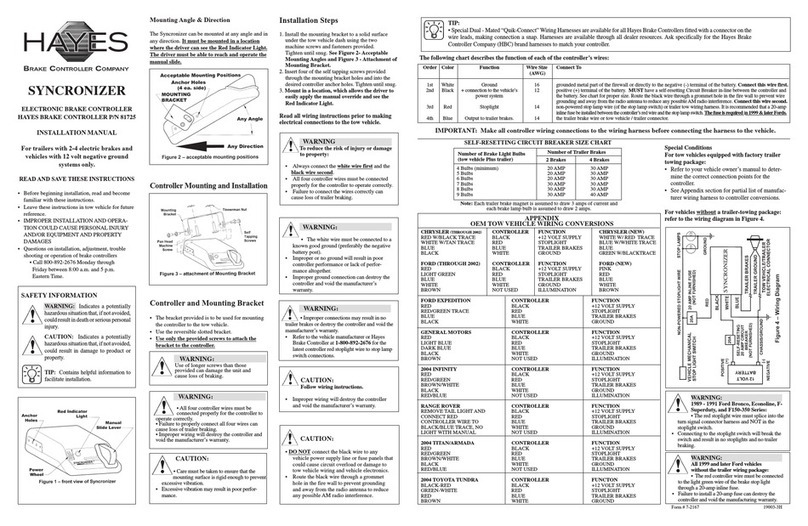

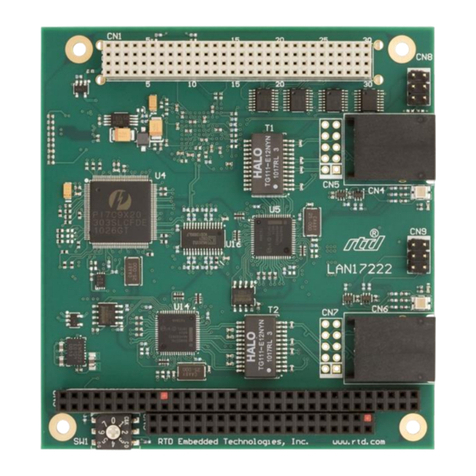

Typical Setup

6 / Typical Setup

5 micron filter regulator

Fluid feed hose

#7543BP (installed)

for 1/4" OD tube

Pressurized reservoir

with air regulator

ValveMate™

7040 Controller

Plant air

70 psi (4.8 bar)

minimum

Material

Constant air

Pulsed air for valve operation

Pulsed nozzle air

VALVEMATE

7040

20

0

5

Control air line

Air tee

White quick connect

Flexible air line

Fluid inlet fitting

Pressure relief valve

Black quick-connect

Shutoff valve

To pressurizeTo exhaust

#7610BP (included)

for 3/8" OD tube

Voltage value

Spare fuse

Cartridge window

(check voltage indicated)

supply.

4. Install the air tee with barb fitting

(#1116) in the output of the filter regulator

and, using the screw clamp provided, install

the black hose with coupling to the barb fit-

ting. The quick-connect on the air tee is

used to provide air pressure to the air pres-

sure regulator on EFD fluid reservoirs. This

connection will be made in step 10.

5. Remove the cap plug from the air input

of the VALVEMATE™7040 and attach the

input air hose coupling onto the controller

air input fitting. Adjust the filter regulator to

70 psi (4.8 bar).

6. Mount the 780S valve with an EFD

Universal Valve Mount (#7002VM) or other

appropriate fixture.

7. Connect the fluid feed hose to the

reservoir outlet and the 780S inlet port

using appropriate fittings shown on the

Setup Schematic, page 6.

8. The 780S is equipped with nozzle and

control air hoses with male quick-connects

that plug into the VALVEMATE™7040. Plug

the control air hose labeled “A” into output

“A” (white) on the rear panel of the 7040

and the nozzle air hose labeled “B” into

output “B” (black), also located on the 7040

rear panel.

9. Check that all connections are tight and

attached to the proper output.

10. Fill the fluid reservoir. After filling,

secure the cover and connect the reser-

voir air pressure regulator to the air tee

by using the connecting hose (#2310S).

First, attach the black male quick-con-

nect on the connecting hose to the

reservoir regulator and then attach the

other end with the white male quick-

connect to the air tee.

Setup

Input Power

1. View cartridge window in power cord

receptacle to ensure that fuse voltage

value matches your input voltage.

If it does not match, remove the fuse car-

tridge. Then remove the fuse holder

from the cartridge, rotate the holder and

position the correct voltage to show

through the cartridge window. Replace

the cartridge into the power cord recep-

tacle and ensure that both sides snap

securely into position.

Connect the power cord.

Initiate Connection

2. The 7040 is normally operated by apply-

ing a 5 to 24 VDC pulse to terminal pins

1 and 2, or providing contact closure

across pins 5 and 7. Alternatively, a foot

pedal may be ordered (#2015A) and

plugged into the connector located on

the rear panel. Detailed electrical

schematic and diagrams are shown on

pages 18 and 19.

3. Connect the VALVEMATE™7040 to plant

air by first installing the EFD five-micron

filter regulator (#2000F755) to your air

7 / Setup

220

120

100

NEXT

Tamper Resist Option

Note: The area of spray coverage is determined by

the distance between the spray valve nozzle and

the work surface. Refer to the chart on page 11 to

determine this distance.

11. Set the reservoir pressure regulator

according to the fluid viscosity. For

example, low viscosity fluids require only

1 to 3 psi (0.07 to 0.2 bar). Higher pres-

sures are required for more viscous flu-

ids.

12. Close needle stroke control knob, fully

(clockwise), then set at one turn open.

This is a starting point only. Final setting

will be determined by the desired

flow rate.

13. Check the nozzle air gauge. If not at

zero, turn the regulator knob clockwise

to turn off the nozzle air.

Note: Regulator knobs on EFD tanks and conrollers

have a push-to-lock, pull-to-unlock feature.

14. Place a container under the valve

to collect the fluid during this setup

procedure.

15. Turn on the power switch. Press the

time override button to place the 7040

into the manual mode (---).

16. Press and hold the cycle button or

optional foot pedal. Continue to hold

until the fluid lines and the valve are

primed and purged of all air.

The 780S valve can be ordered in a tamp-

er resist configuration to limit unauthorized

adjustment.

In the TR configuration, stroke adjustment

can only be made when a special stroke

control knob is inserted into the stroke

mechanism.

A tamper resist stroke kit can also be

ordered as a retrofit for existing valves.

Part # Description

780S-TR Tamper resist spray valve

.046

7544SS Tamper resist stroke kit

Stroke Control Reference

8 / Setup

The Stroke Control Reference allows you

to calibrate the stroke control setting or

document the dispensing process.

To calibrate, close the stroke control knob

all the way. Loosen the set screw and turn

the reference ring so the zero on the ring

aligns with one of the two reference marks

on the valve body. When the set screw is

tightened, the valve is calibrated.

Existing 780S Series valves are easily

upgraded with the Stroke Control

Reference Kit (#780SR-KIT).

Set Screw

Reference

Mark

Stroke

Reference

Ring

Stroke

Control

Knob

Removable

stroke control

knob

Stroke

mechanism

9 / Adjusting the Spray

Adjusting the Spray

Check to be sure steps 11 through 16 under Setup have

been completed, then proceed to adjust the spray.

1. Using the needle stroke control knob ➀on the

780S valve, set the fluid flow rate to one or two

drops per second. Check flow rate by actuating

the controller in the time override mode. Make

valve stroke adjustments when the controller is off.

2. Set the nozzle air pressure on the VALVEMATE™

7040 controller to 10 psi and actuate the controller.

The valve will produce a fine spray.

To change fluid flow, use the needle stroke control

knob ➀.

To change nozzle air, use the nozzle air pressure

regulator ➁. Higher pressures will provide finer spray.

To Make Timed Deposits

Return to the time control by pressing the time override

button ➂. The display should show the time setting.

Adjust the deposit time to 0.5 seconds by using the

time set ➃and decimal ➄buttons. (See page 5 for

operation of these buttons.)

Press the cycle button ➅. The 7040 will open the valve

for 0.5 seconds. Adjust time up or down and test

deposits until desired output is obtained.

Optimal results will be obtained with the proper combi-

nation of time setting, needle stroke control knob, and

reservoir and nozzle air pressure.

➀

VALVEMATE

7040

➁

➂

➃

➄

➅

10 / Programming Nozzle Air Delay

Programming Nozzle Air Delay

The nozzle air time delay can be changed from the

factory setting of 0.24 seconds to fine-tune the shutoff

characteristics of the 780S spray valve.

When making small deposits of low viscosity fluid, it

may be necessary to shorten the time delay to eliminate

a hollow center in the deposit.

To change the time delay:

1. Turn the power switch off.

2. Press and hold the time override button while turning

power switch on.

3. The display will read "SEL" (select). Release the time

override button.

4. Press either the up or down time set buttons once

and release. The current nozzle air delay setting will

be displayed. (The delay is preset to 0.24 seconds

for all new controllers.)

5. Press the up or down time set button again to

program the new nozzle air delay. (Available range

is 0.00 to 2.50 seconds.)

6. To exit the nozzle air delay program mode, momen-

tarily press the time override button. The spray time

setting will be displayed.

Note: The VALVEMATE™7040 controller will not operate while

in the nozzle air delay program mode.

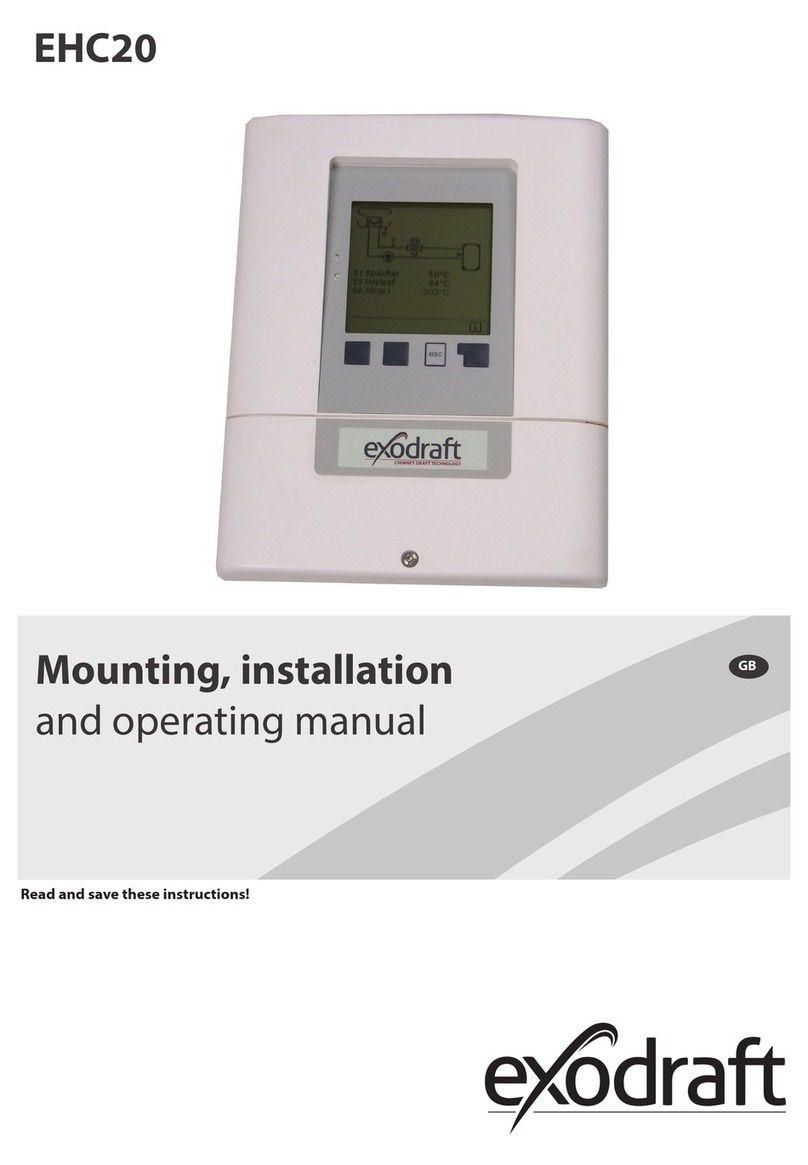

Spray Patterns

Nozzle Distance from the Work Surface:

Nozzle Distance from the Work Surface:

Fan Pattern Spray Area Coverage

Round Pattern Spray Area Coverage

11 / Spray Patterns

1" 2" 3" 6"

Nozzles 25.40 mm 50.80 mm 76.20 mm 152.40 mm

#7857-46SS

Standard

0.046" 0.250" 0.500" 0.750" 1.500"

(1.17 mm) 6.35 mm 12.70 mm 19.05 mm 38.10 mm

#7857-46WA-SS

Wide-angle

0.046" 0.750" 1.500" 2.000"

Not

(1.17 mm) 19.05 mm 38.10 mm 50.80 mm

Recommended

#7857-28SS

0.028" 0.200" 0.400" 0.600" 1.200"

(0.71 mm) 5.08 mm 10.16 mm 15.24 mm 30.48 mm

#7857-14SS

0.014" 0.170" 0.340" 0.500" 1.000"

(0.36 mm) 4.32 mm 8.64 mm 12.70 mm 25.40 mm

1" 2" 3" 6"

Nozzles 25.40 mm 50.80 mm 76.20 mm 152.40 mm

#7857F-46SS

0.046" 1.000" 1.500" 2.000" 3.250"

(1.17 mm) 25.40 mm 38.10 mm 50.80 mm 82.60 mm

#7857F-28SS

0.028" 0.400" 0.800" 1.200" 2.400"

(0.71 mm) 10.16 mm 20.32 mm 30.48 mm 60.96 mm

#7857F-14SS

0.014" 0.340" 0.680" 1.000" 2.000"

(0.36 mm) 8.64 mm 17.27 mm 25.40 mm 50.80 mm

#7857-46WF-SS

0.046" 1.500" 2.500" 3.250" 6.500"

(1.17 mm) 38.10 mm 63.50 mm 82.60 mm 165.10 mm

Round Fan

Side view of

fan air cap

Fluid flows from the nozzle

but will not spray.

Fluid continuously drips from the

nozzle after the valve shuts off.

Valve does not provide clean shutoff,

leaving a buildup on the nozzle.

No fluid flow.

12 / Troubleshooting Guide

Troubleshooting Guide

Valve Trouble Possible cause and correction

If valve operating pressure is too low, the valve will not

open. Increase air pressure to 70 psi (4.8 bar) minimum.

The reservoir air pressure may not be high enough.

Increase pressure.

The nozzle may be clogged. Clean the nozzle.

The stroke adjustment control may be closed. If it is

closed, open counterclockwise one turn.

The control and the nozzle air lines may be reversed.

Check for proper connection (see Setup Schematic on

page 6).

Nozzle air pressure may be too low. Increase air pres

sure.

Nozzle air time delay is too short. Increase time.

A continuous drip can be caused by improper seating of

the needle in the nozzle seat. Remove the nozzle, clean

the needle and nozzle, replace worn or damaged parts.

If the liquid chamber has not been fully turned onto the

air cylinder body during reassembly, the needle will not

seat in the nozzle. Check to be sure the liquid chamber

is properly installed (see Maintenance Instructions on

pages 14-16).

Needle packings may be binding due to leakage, pre-

venting the needle from fully closing. Disassemble the

valve in accordance with the Maintenance Instructions.

Replace the packings if there is evidence of leakage.

Nozzle air pressure may be too low. Increase air pres-

sure.

The air passageway between the nozzle and air cap

may be obstructed. Remove the air cap, and clean the

air cap and nozzle.

If the fluid viscosity is too high, it will not atomize.

Reduce viscosity.

NEXT

Be sure that there is power at the wall receptacle. Check

the input power fuse. If the fuse has blown, check the

voltage value in the fuse cartridge window. Be sure that

it matches the input voltage.

Ensure that the external voltage to the circuit is between

5 and 24 VDC and that the load does not exceed 250 mA.

If the circuit has been overloaded, the fuse may have

blown. See internal diagram on page 21 and replace if

necessary.

Response delay in pneumatic circuit does not allow the

valve to open when time is at or below 0.015 seconds.

Increase time.

1. Valve operating pressure lower than 60 psi (4.1 bar)

can cause inconsistent output. Check to be sure

pressure is set at 70 psi (4.8 bar).

2. Check VALVEMATE™7040 and reservoir air pres-

sure readings to be sure air pressure is not varying.

3. Air bubbles in the material can cause inconsistency.

For best results, remove all air bubbles.

Timer seems inoperative. Check to be sure time override mode is off.

If trouble cannot be corrected, or if you need further assistance, please call us. In the U.S., 888-

333-0311. In the U.K., phone 0800 585733. In Mexico, 001-800-556-3484.

Inconsistent deposits.

Valve does not spray

below .015 second time setting.

End-of-Cycle Feedback Circuit

is not functioning.

No power.

13 / Troubleshooting Guide

VALVEMATE™7040 Trouble Possible cause and correction

Note: The EFD timer is very reliable. Any failure will be total,

so that no inconsistency is possible. Most questions regarding

the timer are resolved by simply turning the time override

mode off.

Maintenance Tools

6" adjustable wrench

snap ring pliers

packing extraction tool #7803

Caution: Always release the reser-

voir pressure and disconnect the

power before performing any mainte-

nance on the system. On all EFD

tanks, there is a pressure relief valve

that should be activated before open-

ing the tank to ensure that all pres-

sure is bled off.

Valve Maintenance

Normal cleaning is accomplished by purging with

appropriate solvent. The air cap and nozzle can be

removed, soaked in solvent and reinstalled without

demounting the valve. (Refer to Exploded View on page

17.)

To thoroughly clean valve chamber and replace needle

packings:

1. Remove the needle stroke control knob and spring

to prevent damage to the needle and nozzle during

reassembly.

2. Remove the air cap retainer, then the air cap, nozzle

and fittings from the liquid chamber.

3. Remove the fluid chamber from the air cylinder

body by turning counterclockwise until free. Then

remove the O-ring from the fluid chamber.

4. Clean the fluid chamber, air cap and nozzle in

appropriate solvent.

5. Remove the needle packings from the fluid cham-

ber, using tool #7803 supplied with the valve. Insert

through nozzle end of the fluid chamber and gently

push out the packings (see Figure 1).

Do not use sharp instruments to scrape or clean

these components. Scratches may cause the valve

to leak.

6. Remove any remaining packings and the spring

14 / Valve Maintenance

Figure 1

Pushing needle packings

from the fluid chamber.

Packing

extraction

tool

#7803

Fluid

chamber

O-ring

Teflon

needle

packings

Teflon

packing

seat

Metal

packing

expander

NEXT

Note: The small O-ring on the bottom of the air cylinder body

is held in place by a flat retaining washer that also serves as

the packing spring seat. It may come out with the spring.

Ensure that it is back in place before reinstalling the packing

spring (see Figure 2).

15 / Valve Maintenance

Figure 2

Proper assembly order for reinstalling needle packings.

from the needle.

7. Clean the needle with a cloth dampened in solvent.

8. Lubricate the needle with Nye Lubricant #865 gel and

reinstall the needle packing spring and packings in

accordance with Figure 2 below.

9. Install a new O-ring (#7517) on the fluid chamber.

Screw the air cylinder onto the fluid chamber. Hand

tighten only. The chamber can be backed off 1/2 turn

from the air cylinder body to orient fittings.

10. Reinstall the nozzle, air cap, retainer and fittings.

Reinstall the needle stroke control and spring. Turn

back to the desired setting.

Metal

packing

expander

Air cylinder

body Retaining

washer Teflon

packing

seat

O-ring

Spring Teflon

needle

packings

NEXT

16 / Valve Maintenance

Note: The piston and needle assembly is replaced

as a unit and cannot be disassembled.

To reseat the needle and nozzle assembly:

1. Disconnect or shut off all air to the valve.

2. Rotate the stroke adjustment knob to

the closed position by turning clockwise.

3. Rotate the stroke adjustment further

clockwise one additional reference mark

to compress the needle into the nozzle.

4. Return the adjustment knob to normal

setting and cycle the valve a few times.

If there is still a slight leak, repeat steps

1 and 2 again.

5. If the leak continues, replace the nozzle.

To replace the piston and needle assembly or

the piston O-ring:

1. Remove the needle stroke control knob

by turning counterclockwise until free.

2. Remove the piston return spring and

thrust washers located on each end of

the spring.

3. Remove the snap ring using snap ring

pliers.

4. Pull the piston and needle assembly out

of the air cylinder using small pliers on

the spring pilot (at the top of the piston).

Note: The piston and needle assembly is replaced

as a unit and cannot be disassembled.

5. Clean the air cylinder body wall and

apply lubricant.

6. Reinstall a new O-ring on the piston,

apply lubricant to the needle and O-ring

then reinstall in the air cylinder.

7. Reinstall the snap ring.

8. To reinstall the piston return spring, first

put one thrust washer over the spring

pilot, then the other thrust washer into

the needle stroke control, followed by

the spring.

9. Reinstall the needle stroke control knob

by aligning the piston return spring with

the spring pilot. Turn the needle stroke

control clockwise until it stops and then

back it out to the desired setting.

Nozzle and Air Cap Assembly

Round pattern Fan pattern Wide fan pattern Round wide-angle

Nozzle Size Stainless Steel Stainless Steel Stainless Steel Stainless Steel

0.046" (1.17 mm) #7857-46SS #7857F-46SS #7857-46WF-SS #7857-46WA-SS

0.028" (0.71 mm) #7857-28SS #7857F-28SS N/A N/A

0.014" (0.36 mm) #7857-14SS #7857F-14SS N/A N/A

17 / 780S Exploded View

A

B

Fluid chamber

#7812-SS (stainless steel)

#7812 (hard-coated aluminum)

Needle stroke reference control

#780SSR-KIT (stainless steel)

#780SR-KIT (aluminum)

Piston return spring #7802

Snap ring #7526

O-ring (Buna-N)

#7519

Air cylinder body

#7811-SS (stainless steel)

#7811 (hard-coated aluminum)

O-ring

#7806

Thrust washer

#7809

Needle packing assembly

#7810

Nozzle air cap retainer

#7819SS (stainless steel)

Nozzle/air cap

(see below)

Nye gel lubricant, 1 gram

foil packet (not shown)

Retaining washer

#7807

O-ring

7517

Packing spring

#7808

Fluid inlet fitting

#7543BP - for 1/4" OD tube

#7610BP - for 3/8" OD tube

Air hose assembly

#7830

Piston and needle

assembly includes

O-ring (Buna N)

#7805-SS

Nozzle O-ring (Viton)

#7825

780S Series

Items included in repair kit

#780S-RK are listed in blue.

Note: 9-pin male connector assembly

is included (replacement part # 7154).

]

]

5-24 VDC

250 mA Max

5-24 VDC

Pin Function

1. Initiate +

2. Initiate -

3. Output +

4. Output -

5. Contact Closure

6. Chassis Ground

7. Contact Closure

8. Not Used

9. Not Used

I/O Connection

The 9-pin D connector

and internal circuitry pro-

vide external initiate and

end-of-cycle feedback sig-

nal. The pin connections

are shown below.

18 / Input / Output

Connections

Input/Output Connections

1. Voltage Initiate Circuit

The VALVEMATE™7040 may be initiated with a 5 to 24

VDC signal across pins 1 and 2. The signal can be

momentary (no less than 0.02 seconds) or maintained.

A new cycle will begin once power is removed and then

applied again. Refer to the schematic on page 19 for

proper installation.

2. End-of-Cycle Feedback Circuit

Upon completion of a dispense cycle, an open collector

circuit closes and remains closed until the next dispense

cycle. This circuit can be utilized to signal back to a

host computer, start another device in sequence or

other operations that need to be tied into completion of

the dispense cycle.

Upon closure, power from an external 5 to 24 VDC

source is allowed to pass through the circuit to operate

a load. The load illustrated is a relay, but this could be

any device that will operate within the 5 to 24 volt range.

Power consumption of the load must not exceed 250

mA.

3. Mechanical Contact Initiate

The VALVEMATE™can be initiated via the closure of

me

chanical contacts such as a relay or switch using pins

5 and 7. Closure of the contacts can be momentary (no

less than 0.02 seconds) or maintained. A new cycle will

begin once the contacts are opened and then closed

again. Refer to the schematic on page 19 for proper

installation.

Note: For applications using more

than one 7040, see page 20 for con-

nection instructions.

6789

12345

NEXT

This manual suits for next models

3

Table of contents

Other EFD Controllers manuals