EFKA AB60D14725

1 Table of Adapter Cords

Setting the functional sequence using parameter 290

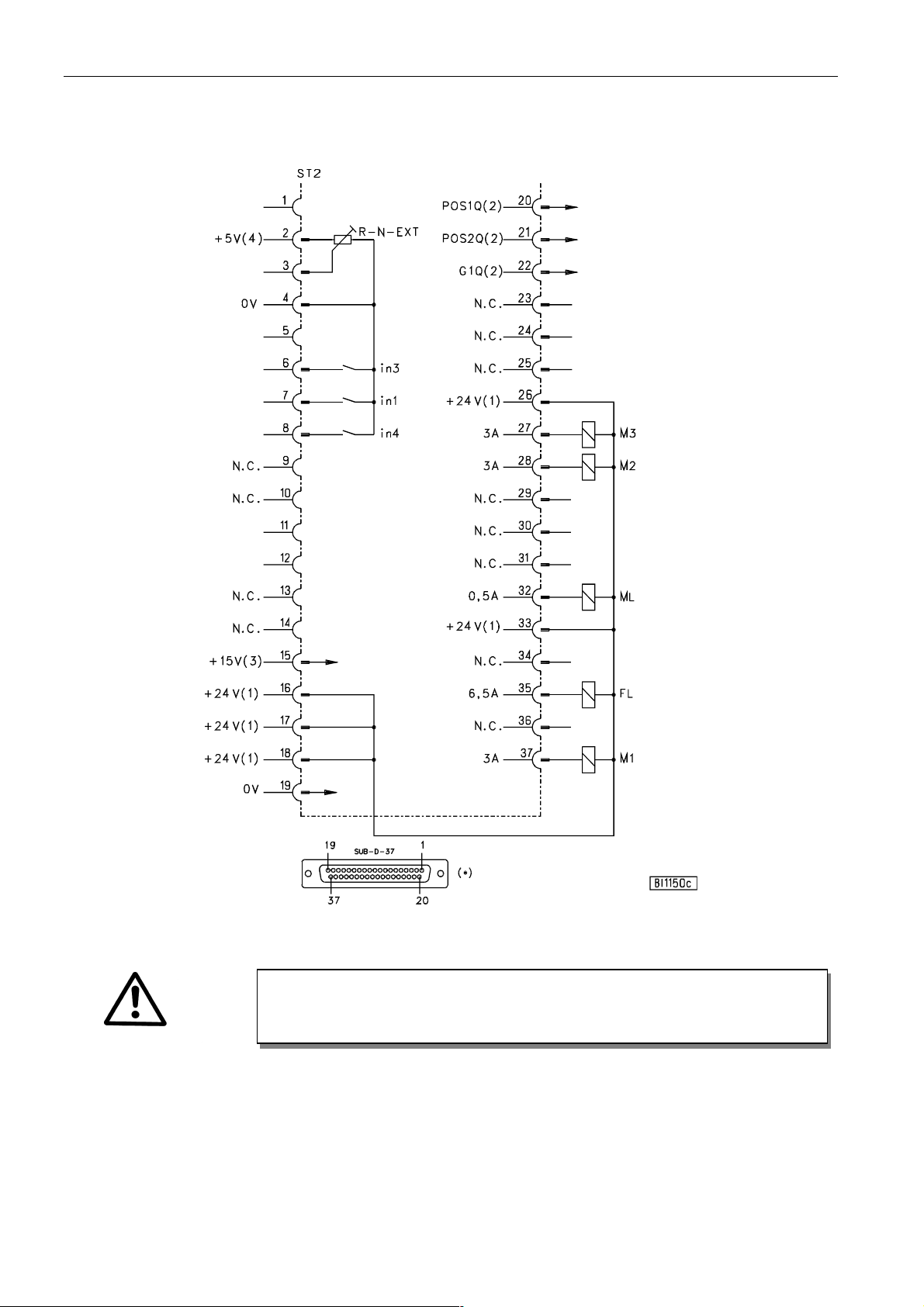

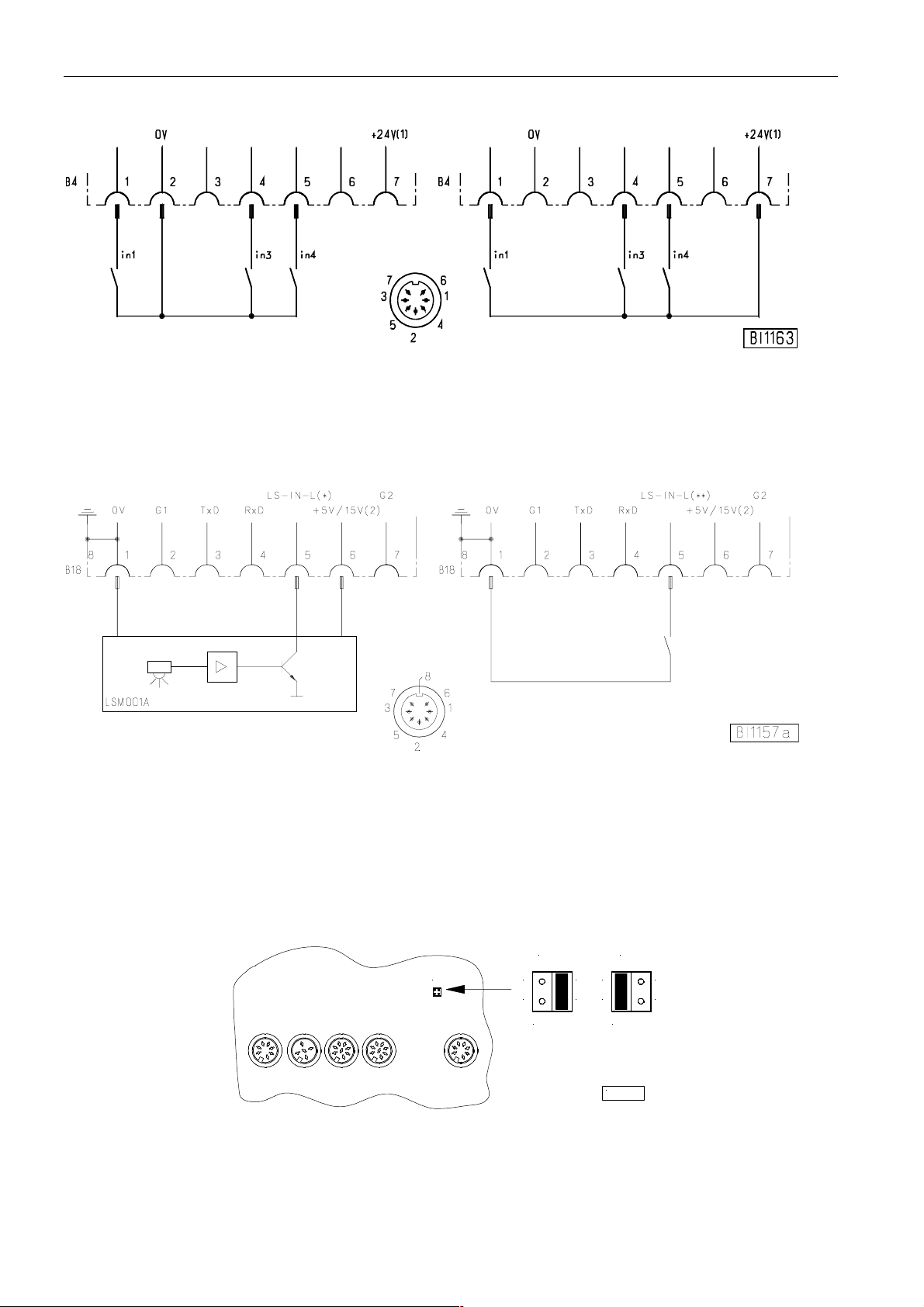

Mode Designation Adapter Outputs Inputs

Power transistors

FL M1 M2 M3 ML in1 in3 in4

ST2/35 ST2/37 ST2/28 ST2/27 ST2/32 ST2/7 ST2/6 ST2/8

0 Lockstitch; e. g.

Brother (737-113, 737-913) 1112814 FL FA1 + FA2 FW - - NHT -

Aisin (AD3XX, AD158, 3310; EK1) 1112815 FL FA1 + FA2 FW - - NHT -

Pfaff (563, 953, 1050, 1180) 1112841 FL FA1 FA2 FW ML - - FLEX

Dürkopp Adler (210, 270) 1112845 FL FA1 + FA2 FW - - NHT EST

1 Lockstitch; e. g. Singer (591, 211U, 212U) 1112824 FL - FA2 FW - NHT - -

2 Lockstitch; e. g. Singer (212 UTT) 1112824 FL - FA FSPL - NHT - -

3 Lockstitch; e. g. Dürkopp Adler (467) FL FA FSPL FW ML NHT - -

4 Chainstitch;

Union Special

(34000 and 36200 replacement for US80A) 1112865 FL - FA-V FW ML LSP LSP ENTK

(CS100 and FS100) 1112905 FL - FA-V FW ML LSP LSP -

5 Chainstitch; parallel sequence

Yamato (VC series) 1112818 FL FA - FW - LSP - -

Yamato (VG series) 1113178 FL FA - FW - LSP - -

Kansai (RX 9803) 1113130 FL FA - FW ML LSP - -

Pegasus (W500/UT) 1112821 FL FA FA FW - LSP - -

Brother (FD3-B257) 1112822 FL FA FA FW - LSP ENTK -

Global (CB2803-56) 1112866 FL - - FA - LSP - -

Rimoldi (F27) 1113096 FL FW FAO FAU ML - - -

6 Chainstitch; tape cutter/fast scissors FL M1 AH1 AH2 ML - - -

7 Overlock FL M1 M2 AH ML - - -

8 Backlatch;

Pegasus 1113234 - PD≤-1 PD≥1 - - LSP N.AUTO -

9 Backlatch;Yamato (ABT3) 1112826 - PD≤-1 PD≥1 - - LSP N.AUTO -

Backlatch;Yamato (ABT13, ABT17) 1113205 - PD≤-1 PD≥1 - - LSP N12.AU N9.AU

10 Lockstitch; e. g. Union Special 1113199 FL - FA-V FW ML - - -

(63900AMZ replacement for US80A)

11 Reversal of motor rotation with pedal in pos.–2 FL DR-UK PD=-2 ML ML N.POS - -

12 Reversal of motor rotation with input in3 FL DR-UK PD=0 ML ML N.POS DR-UK -

13 Lockstitch; Pfaff (1425) 1113072 FL FA FSPL FW ML NH POS2 DB

14 Lockstitch; e. g.

Juki (5550-6) 1112816 FL FA1+2 - FW - - - -

Juki (5550-7) 1113132 FL FA1+2 FZ FW - - - -

17 Chainstitch; Pegasus FL M1 M2 M3 ML - - -

18 Overlock; Bottoms FL M1 AH M3 ML - - -

19 Lockstitch; Macofrey FL FA-R FA-V FW ML - - -

20 Lockstitch; Juki (LU1510-7) 1113200 FL FA FSPL - - - BIT0 BIT1

22 Lockstitch; Brother (B-891) FL FA FSPL FW ML - - -

ATTENTION!

Before switching functional sequences, detach cables from the inputs and outputs! Please ensure that the

machine installed provides the functional sequence to be set! Then proceed with the setting using

parameter 290!