GSK928TEⅡTurning CNC System User Manual

I

Contents

Suggestions for Safety .....................................................................................................................1

Operation............................................................................................................................................7

Chapter One Overview................................................................................................................7

Chapter Two Technical Specifications.......................................................................................8

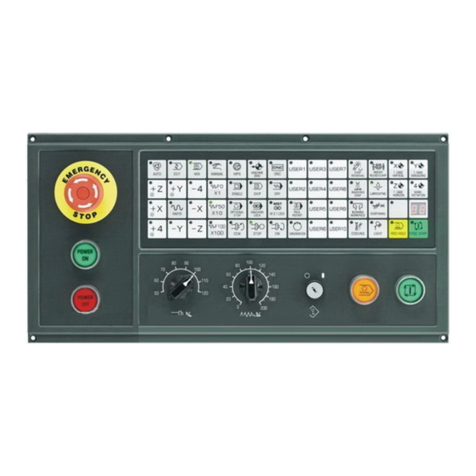

Chapter Three Operator Panel ...................................................................................................9

Chapter Four System Operation ..............................................................................................14

4.1 System ON/OFF ................................................................................................................14

4.2 CNC System Operating Mode ...........................................................................................15

4.3 EDIT Mode.........................................................................................................................15

4.4 Manual Mode .....................................................................................................................28

4.5 AUTO Mode.......................................................................................................................47

4.6 Parameter Setting..............................................................................................................58

4.7 Tool Offset Setting Mode....................................................................................................69

4.8 Diagnosis ...........................................................................................................................70

4.9 Alarm of Emergency Stop and Overtravel..........................................................................74

4.10 Drive Unit Switch Control .................................................................................................75

Programming...................................................................................................................................76

Chapter 1 Programming Fundamentals ..................................................................................76

1.1 Coordinate Axis and its Direction .......................................................................................76

1.2 Machine Zero.....................................................................................................................76

1.3 Programming Coordinate...................................................................................................76

1.4 Workpiece Coordinate System...........................................................................................78

1.5 Reference Point .................................................................................................................78

Chapter 2 Program Structure ...................................................................................................79

2.1 Character ...........................................................................................................................79

2.2 Word ..................................................................................................................................79

2.3 Block Number ....................................................................................................................80

2.4 Block ..................................................................................................................................80

2.5 Program Structure..............................................................................................................80

Chapter 3 Commands and their Functions.............................................................................81

3.1 G commands — Preparatory Function .........................................................................81

3.2 M function — Miscellaneous Function...........................................................................113

3.3 S function — Spindle Function ...................................................................................... 118

3.4 T Function — Tool Function ........................................................................................ 119

3.5 F function — Feedrate Function .................................................................................120

Chapter Four Programming Rules.........................................................................................121