- AB AB600A5015 Instruction Manual

2.1 Special Accessories

The special accessories available ex works allow the augmentation and enhancement of functions, operating,

connecting, and mounting options.Since the range of available components is continually expanded, we kindly

ask you to contact us in case of need.

Reflection light barrier module LSM002

Hall sensor module HSM001

Extension cable approx. 1000 mm long for commutation transmitter DC12.. + DC15..

Extension cable approx. 1000 mm long for Netz DC12.. line + DC15..

Potential equalization cord 700 mm long, LIY 2.5 mm2, gray, with spades on both

sides

Foot control type FB302B with three pedals for standing operation, with

approx. 1400 mm connecting cable and plug

Fitting piece for position transmitter

Adapter set for DC12. + DC15.. on PEGASUS model W600

Adapter set for DC12. + DC15.. on PEGASUS Ex/Ext

Adapter set for DC12. + DC15.. on PEGASUS model W1500N, W1600

Undertable mounting kit for DC1200/DC1250

Undertable mounting kit for DC1500/DC1550

Undertable mounting kit for DC1500/DC1550

9-contact SubminD male connector

9-contact SubminD female connector

Half-shell housing for 9-contact SubminD

Adapter set direct drives DC1210 & DC1230

Mounting kit for DC1210 on JUKI M067, M069

Mounting kit for DC1210 on JUKI M068

Mounting kit for DC1210 on PEGASUS EX

Mounting kit for DC1210 on PEGASUS M900

Mounting kit for DC1210 on YAMATO AZ, CZ

Mounting kit for DC1230 on PEGASUS chainstitch

Mounting kit for DC1230 on YAMATO VC, VE, VF, VG

3 Putting into Service

Before putting the control into service, the following must be ensured, checked and/or adjusted:

Selection of motor type using parameter 467

The correct installation of the drive, position transmitter and accompanying devices, if necessary

The correct selection of the trimming operation using parameter 290

If necessary, the correct adjustment of the direction of motor rotation using parameter 161

The correct selection of the functions of keys (inputs) using parameters 240...246

The setting of the transmission ratio between motor shaft and machine shaft using parameter 272

The setting of the type of position sensor using parameter 270

If necessary, the adjustment of the positions using parameter 171

if necessary, the setting of the positions using parameter 171 (possible with all settings of parameter 270)

The correct positioning speed using parameter 110

The correct maximum speed compatible with the sewing machine using parameter 111

The setting of the remaining relevant parameters

Begin sewing in order to save the set values

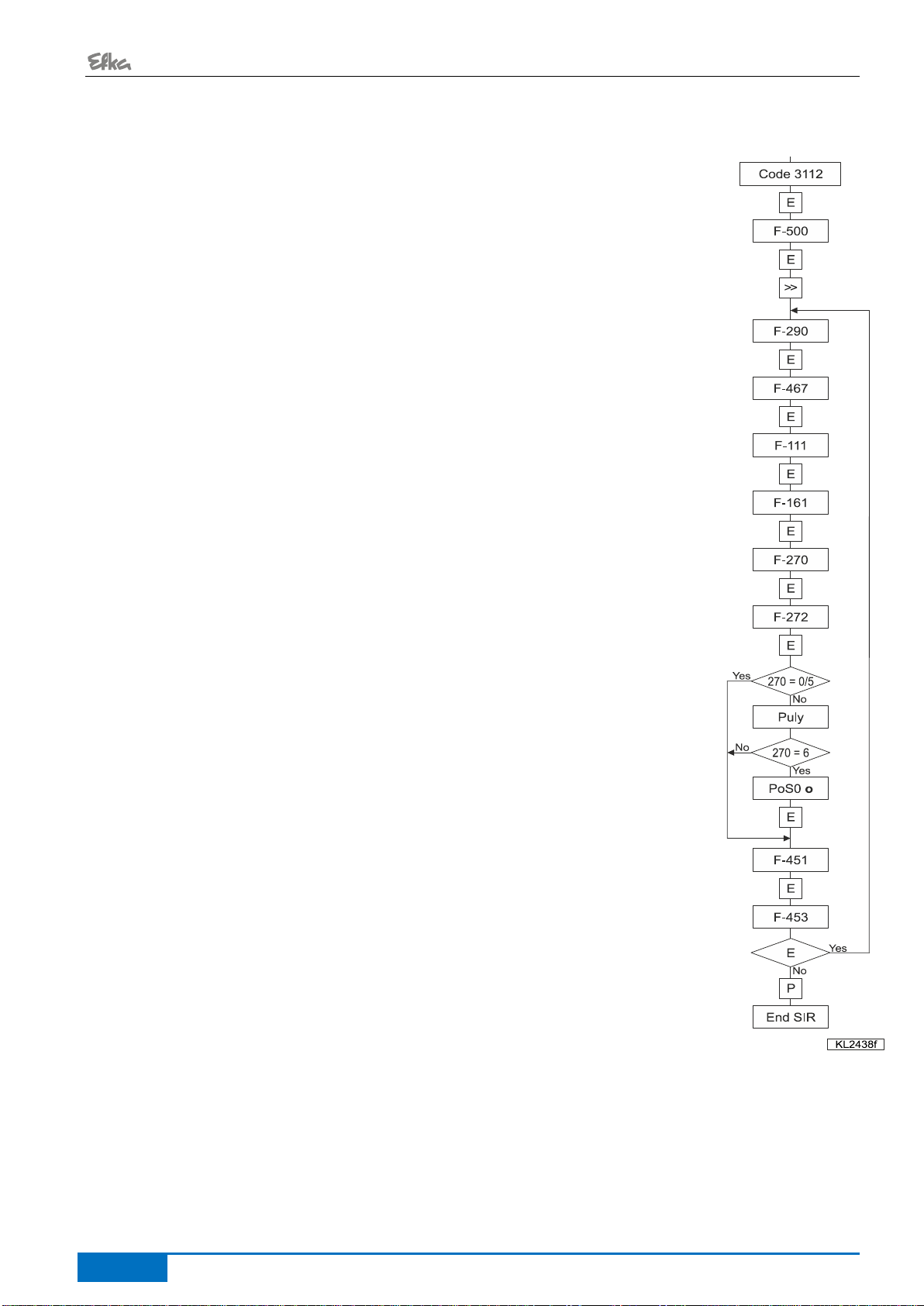

4 Setting and Putting into Service with the Aid of the Fast Installation

Routine (SIR)

Call-up of the Fast Installation Routine SIR

The Fast Installation Routine (SIR) passes through all parameters necessary for programming the functional

sequence and the positions.