EG&G ORTEC 485 User manual

100

MIDLAND

ROAD

OAK

RIDGE,

TENN.

37830

PHONE

(615)

482-1GGB

TWX

81G-572-1G7B

INSTRUCTION

MANUAL

485

AMPLIFIER

n

(z:oi\/ii=»ArsiY

INSTRUCTION

MANUAL

485

AMPLIFIER

Serial

No.

Purchaser

Date

issued.

I

Ci;

CD

F=1

(=>

CD

F=l

AT"

E

CD

100

MIDLAND

RDAD

DAK

RIDGE,

TENN.

37830

PHDNE

[615)

482-4411

TWX

81D-572

-1078

©

ORTEC

Incorporated

1968

Printed

In

U.S.A.

TABLE

OF

CONTENTS

Page

WARRANTY

PHOTOGRAPH

1.

DESCRIPTION

1 1

1.1

General

Description

1 1

1.2

Pole-Zero

Cancellation

1

1

1.3

Active

Filter

1

3

2.

SPECIFICATIONS

2

1

2.1

General

Specifications

2

1

2.2

Amplifier

Specifications

2

1

3.

INSTALLATION

3

1

3.1

General

Installation

Considerations

3

1

3.2

Connection

to

Preamplifier

3

1

3.3

Connection

of

Test

Pulse

Generator

3

1

3.4

Connection

to

Power

-

Nuclear

Standard

Bin,

ORTEC

401A/402A

3

2

3.5

Output

Connections

and

Terminating

Considerations

3

2

3.6

Shorting

the

Amplifier

Output

3

2

4.

OPERATING

INSTRUCTIONS

4

1

4.1

Controls

and

Connectors

4

1

4.2

Initial

Testing

and

Observation

of

Pulse

Waveforms

4

2

4.3

General

Considerations

for

Operation

with

Semiconductor

Detectors

4

2

4.4

Operation

in

Spectroscopy

Systems

4

7

4.5

Typical

System

Block

Diagrams

4

10

5.

CIRCUIT

DESCRIPTION

5

1

5.1

General

Block

Diagram

5

1

5.2

Circuit

Description

5

1

5.3

Circuit

Modifications

for

Special

Applications

5

3

6.

MAINTENANCE

6

1

6.1

Test

Equipment

Required

6

1

6.2

Pulser

Modifications

for

Overload

Tests

6

2

6.3

Pulser

Tests

and

Calibration

6

4

6.4

Tabulated

Test

Point

Voltages

SCHEMATIC

485-0101-S1

ORTEC

485

Amplifier

Schematic

LIST

OF

FIGURES

AND

ILLUSTRATIONS

Page

Figure

1.1

Differentiation

In

a

Non-Pole-Zero

Cancelled

Amplifier

Figure

1.2

Differentiation

(Clipping)

in

a

Pole-Zero

Cancelled

Amplifier

Figure

1.3

Pulse

Shapes

for

Good

Signal-to-Noise

Ratios

Figure

1.4

ORTEC

485

Active

Filter

Figure

4.1

Measuring

Amplifier

and

Detector

Noise

Resolution

Figure

4.2

Resolution

Spread

Versus

External

Input

Capacity

Figure

4.3

Amplifier

and

Detector

Noise

Versus

Bias

Voltage

Figure

4.4

Measuring

Resolution

with

a

Pulse

Height

Analyzer

Figure

4.5

Measuring

Detector

Current-Voltage

Characteristics

Figure

4.6

Silicon

Detector

Back

Current

Versus

Bias

Voltage

Figure

4.7

High

Resolution

Alpha

Particle

Spectroscopy

System

Figure

4.8

High

Resolution

Gamma

Spectroscopy

System

Using

a

Lithium

Drifted

Germanium

Detector

Figure

4.9

Scintillation

Counter

Gamma

Spectroscopy

System

Figure

4.10

High

Resolution

X-Ray

Spectroscopy

System

Figure

4.11

Gamma

Ray-Gamrtia

Coincidence

Experiment

-

Block

Diagram

Figure

4.12

Gamma

Ray-Charged

Particle

Coincidence

Experiment

-

Block

Diagram

Figure

4.13

Gamma

Ray

Pair

Spectrometer

-

Block

Diagram

Figure

5.1

485

Amplifier

Block

Diagram

Figure

5.2

ORTEC

485

Attenuator

Networks

Figure

6.1

Pulser

Modification

for

Overload

Tests

Figure

6.2

Pulser

Pole'zero

Cancellation

Figure

6.3

Method

for

Measuring

Nonlinearity

Figure

6.4

Method

for

Measuring

Crossover

Walk

1-2

1

-2

1

-4

1-5

4-3

4-3

4

4

4

4

4

4

4

4

4

4

4

5

5

6

6

6

6

4

5

6

6

7

8

9

10

11

11

12

1

2

1

2

3

3

A

NEW

STANDARD

TWO-YEAR

WARRANTY

FOR

ORTEC

ELECTRONIC

INSTRUMENTS

ORTEC

warrants

its

nuclear

instrument

products

to

be

free

from

defects

in

workmanship

and

materials,

other

than

vacuum

tubes

and

semiconductors,

for

a

period

of

twenty-four

months

from

date

of

shipment,

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replacement,

at

ORTEC

option,

will

be

made

without

charge

at

the

ORTEC

factory.

Shipping

expense

will

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors,

as

made

by

their

manufacturers,

will

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

liability

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibility

for

modification

of

previously

manufactured

units.

Since

installation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

liabilities

associated

with

methods

of

installation

other

than

specified

in

the

instructions,

or

installation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

ORTEC

instruments

not

in

warranty

may

be

returned

to

the

factory

for

repairs

or

checkout

at

modest

expense

to

the

customer.

Standard

procedure

requires

that

returned

instruments

pass

the

same

quality

control

tests

as

those

used

for

new

production

instruments.

Please

contact

the

factory

for

instructions

before

shipping

equipment.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

damage

claims

and

in

providing

replacement

equipment

if

necessary.

-i

V,-

.

■,Vj.;'

.

ORTEC®

^

MODEL

485

€

AMPLIFIER

COARSE

GAIN

16

FINE

GAIN

PZ-TRIM

POS

UNIPOLAR

t>

■#•

NEG

BIPOLAR

INPUT

OUTPUT

@

HH

i■

M-A

-I.

-

?5'-

-

■

*.?!■■

■

•

1

-1

ORTEC

485

AMPLIFIER

1.

DESCRIPTION

1.1

General

Description

The

ORTEC

485

Amplifier

is

a

functional

design

utilizing

integrated

circuits

to

provide

a

general

purpose

amplifier

at

minimum

cost.

The

low

input

noise,

dynamic

gain

range,

and

pulse

shaping

networks

allow

operation

with

semiconductor

detectors

and

scintillation

detectors

in

a

wide

variety

of

applications.

The

performance

capability

of

the

485

coupled

with

its

low

cost

will

allow

a

wide

range

of

uses

in

such

fields

as

research,

counting

rooms,

monitoring

applications,

and

instructional

laboratories.

The

instrument

has

a

single

linear

output

which

can

be

switch

selected

for

either

unipolar

or

bipolar

pulse

shape.

The

first

differentiation

network

has

variable

pole-zero

cancellation

which

can

be

adjusted

to

match

preamplifiers

with

greater

than

40/itsec

decay

times.

Excellent

overload

performance

is

accom

plished

by

the

use

of

pole-zero

techniques.

In

addition,

the

amplifier

contains

an

active

filter

shaping

network

which

optimizes

the

signal-to-noise

ratio

and

minimizes

the

overall

resolving

time.

The

485

can

be

used

for

crossover

timing

when

used

in

conjunction

with

an

ORTEC

407

Crossover

Pickoff

or

a

420

Timing

Single

Channel

Analyzer.

The

420

Timing

Single

Channel

Analyzer

output

has

a

minimum

of

walk

as

a

function

of

pulse

amplitude

and

incorporates

a

variable

delay

time

on

the

out

put

pulse

to

enable

the

crossover

pickoff

output

to

be

placed

in

time

coincidence with

other

outputs.

The

485

has

complete

provisions,

including

power,

for

operating

any

ORTEC

solid

state

preamplifier

such

as

the

109A,

113,

and

118A.

Preamplifier

pulses

should

have

a

rise

time

of

0.25;usec

or

less

to

properly

match

the

amplifier

filter

network,

and

a

decay

time

of

greater

than

40)usec

for

proper

pole-zero

cancellation.

The

input

impedance

is

1000

ohms.

When

long

preamplifier

cables

are

used,

the

cables

can

be

terminated

in

series

at

the

preamplifier

end

or

in

shunt

at

the

amplifier

end

with

the

proper

resistance.

The

output

impedance

of

the

485

is

about

0.5

ohm.

The

output

can

be

connected

to

other

equipment

by

either

a

single

cable

going

to

all

equipment

and

shunt

terminated

at

the

far

end

(and

series

ter

minated

at

the

amplifier

if

reflections

are

a

problem)

or

separate

cables

to

each

instrument

with

each

cable

series

terminated

at

the

amplifier.

(See

Section

3.5.)

Gain

changing

is

accomplished

by

constant

impedance

T

attenuators.

By

using

this

technique,

the

bandwidth

of

the

feedback

amplifier

stages

involved

in

gain

switching

remains

essentially

constant

regardless

of

gain

and

therefore

rise

time

changes

with

gain

switching

(which

cause

crossover

walk)

are

limited

to

small

capacitance

effects

across

the

attenuators.

The

485

is

one

NIM

standard

module

wide.

The

unit

has

no

self-contained

power

supply;

power

is

ob

tained

from

a

NIM

standard

Bin

and

Power

Supply

such

as

the

ORTEC

401A/402A.

The

485

design

is

consistent

with

other

modules

in

the

ORTEC

Modular

Nuclear

Instrumentation

Series;

i.e.,

it

is

not

possible

to

overload

the

bin

power

supply

with

a

full

complement

of

ORTEC

modules

in

the

bin.

Since

twelve

485

amplifiers

can

be

contained

and

powered

in

one

Bin

and

Power

Supply,

the

485

is

particularly

suited

to

experiments

requiring

many

amplifiers.

1.2

Pole-Zero

Cancellation

Pole-zero

cancellation

is

a

method

for

eliminating

pulse

undershoot

after

the

first

differentiating

network.

The

technique

employed

is

described

by

referring

to

the

waveforms

and

equations

shown

in

Figure

1.1

and

1.2.

In

a

non-pole-zero

cancelled

amplifier,

the

exponential

tail

on

the

preamplifier

output

signal

(usually

50

to

500/tsec)

causes

an

undershoot

whose

peak

amplitude

is

roughly:

Undershoot

Amplitude

_

Differentiation

Time

Differentiated

Pulse

Amplitude

Preamplifier

Pulse

Decay

Time

1

-2

(V

^max

®

200409

Undershoot

First

Charge

loop

clipping

P"

"

with

network

undershoot

Equations:

-t

Emax

^

1

s

F

X

=

f

I

(s);

Laplace

Transform

'^max

1 1

I

>

/.

r-

-t

^max

—

Ti

-

To

/^.

u

-r

d

To

e

-T^e

=

Ci

where

Ti

=

R

i

Cj

T

o-T,

Figure

1-1.

Differentiation

in

a

Non-Pole-Zero

Cancelled

Amplifier

><K

<1

So

(t)

e

T

K

ii

S—

—VNA*

>R3

Rj

i

r

-1-^

«!

(t)

No

Undershoot

Pole-zero

,

cancelled

_

Clipped

pulse

Charge

loop

x

-

vvithout

clipping

output

network

undershoot

1

K

Pole

zero

cancel

by

letting

s

+

——

s

+

■

T

o

R2C1

or:

^max^'^'^G(t)=e,

(t)

s

-I-

^

X

=

E\

(s);

Laplace

Transform

-max

1

"

Ri

-rR2

^^T^

'""RiRjC,

Emax

Efy^gx

Ri

-r

R2

1

s

+

„

„

„

s

+

R

R1

R2

£,

(s);

where

Rp

=

^^

]R2

Cj

RpCi

-t

200410

Figure

1-2.

Differentiation

(Clipping)

in

a

Pole-Zero

Cancelled

Amplifier

1-3

For

a

l^isec

differentiation

time

and

a

50jusec

preamplifier

pulse

decay

time,

the

maximum

undershoot

is

2%

and

decays

with

a

BOfisec

time

constant.

Under

overload

conditions,

this

undershoot

is

often

sufficiently

large

to

saturate

the

amplifier

during

a

considerable

portion

of

the

undershoot,

causing

excessive

deadtime.

This

effect

can

be

reduced

by

increasing

the

preamplifier

pulse

decay

time

(which

generally

reduces

the

counting

rate

capabilities

of

the

preamplifier)

or

compensating

for

the

undershoot

by

using

pole-zero

cancellation.

Pole-zero

cancellation

is

accomplished

by

the

network

shown

in

Figure

1.2.

The

pole

(

^

^

)

due

to

b

-(•

1

/Tq

the

preamplifier

pulse

decay

time

is

cancelled

by

the

zero

(S

+

K/R^Ci)

of

the

network.

In

effect,

the

dc

path

across

the

differentiation

capacitor

adds an

attenuated

replica

of

the

preamplifier

pulse

to

just

cancel

the

negative

undershoot

of

the

clipping

network.

Total

preamplifier

-

amplifier

pole-zero

cancellation

requires

that

the

preamplifier

output

pulse

decay

time

be

a

single

exponential

decay

and

matched

to

the

pole-zero

cancellation

network.

The

variable

pole-zero

cancellation

network

allows

accurate

cancellation

for

all

preamplifiers

having

40^isec

or

greater

decay

times.

The

network

is

factory

adjusted

to

BO^isec

which

is

compatible

with

all

ORTEC

FET

preamplifiers.

Improper

matching

of

the

pole-zero

cancellation

network

will

degrade

the

overload

performance

and

cause

excessive

pile-up

distortion

at

medium

counting

rates.

Improper

matching

causes

either

an

undercompensation

(undershoot

is

not

eliminated)

or

an

overcompensation

(output

after

the

main

pulse

does

not

return

to

the

baseline

and

decays

to

the

baseline

with

the

preamplifier

time

con

stant).

The

pole-zero

trim

is

accessible

from

the

front

panel

of

the

485

and

can

easily

be

adjusted

by

observing

the

baseline

with

a

monoenergetic

source

or

pulsar

having

the

same

decay

time

as

the

preamp

lifier

under

overload

conditions.

1.3

Active

Filter

When

only

grid

current

and

shot

noise

(gate

current

and

drain

thermal

noise

for

an

FET)

are

considered,

the

best

signal-to-noise

ratio

occurs

when

the

two

noise

contributions

are

equal

for

a

given

pulse

shape.

Also

at

this

point,

there

is

an

optimum

pulse

shape

for

the

optimum

signal-to-noise

ratio.

Unfor

tunately,

this

shape

(the

cusp

shown

in

Figure

1.3)

is

not

physically

realizable

and

very

difficult

to

simulate.

A

pulse

shape

that

can

be

simulated

(the

Gaussian

in

Figure

1.3)

requires

a

single

RC

differentiate

and

n

equal

RC

integrates,

where

n

approaches

infinity.

The

Laplace

transform

of

the

transfer

function

is:

^

^

GS

=,=

X

n

°o

t^Rc]

h

Rc]

where

the

first

term

is

the

single

differentiate

and

the

second

term

is

the

n

integrates.

The

485

active

filter

attempts

to

simulate

this

transfer

function

with

the

simplest

possible

circuit.

The

485

active

filter

circuit

is

shown

in

Figure

1.4.

The

major

attraction

of

the

active

RC

filter

is

the

simple

synthesis

of

a

complex

pulse

shape

resulting

in

a

significant

reduction

in

size,

complexity

and

cost.

For

a

given

resolving

time

(RC),

the

time

response

of

the

filter

network

depends

only

on

K

(see

the

circuit

equations

in

Figure

1.4).

For

K

=

1,

the

transfer

function

simplifies

to:

1

1

eo_

R^C^

_

R^C^

which

is

an

n

=

2

approximation

to

the

Gaussian

pulse

shape

(see

Figure

1.3).

For

K

=

2

(the

actual

case

for

the

ORTEC

filter),

the

transfer

function

becomes:

Bq,

R'^C^

R^C^

ei

■J

c2

r-.

-

2s

2

i;

i+jir-

i-i1

i=V^

S

+ +

^ ^

'

I

Icj.

'

I

'

V

RC

R^C^

1

-4

CUSP

-t/RC

t/RC

t

>0

t

<

0

GAUSSIAN

(S+l/RC)

(S+l/llC)

n

GAUSSIAN

APPROXIMATION

FOR

n=2

1

(S+l/RC)

(S+1/RC)^

200362

ACTIVE

FILTER

V

rcA

rc/

j=xFT

Figure

1-3.

Pulse

Shapes

for

Good

Signal-to-Nolse

Ratios

1-5

In

this

case,

the

complex

roots

cause

an

underdamped

effect

which

reduces

the

resolving

time

and

results

in

a

more

symmetrical

pulse

shape

(see

Figure

1.3).

The

485

is

manufactured

with

1/isec

time

constants

(R

=

1000f2,

C

=

lOOOpF,

C/K

=

500pF).

These

time

constants

can

be

changed

to

suit

the

experiment.

See

Section

5.3

for

details

on

this

modification.

R

R

e:

e„

-Wv-

C

-L

*

£

^

K

Equations:

K

SC

K

®o

-

ea

—

ea

K

"K

+

SRC

ei

-

ea ea

-

eo

ea

-

Bq

SC

Eliminating

ea

and

solving

for

the

transfer

function:

R^

eo

®i

.

2S

.

K

+

^

+

RC

R2C2

Figure

1.4.

ORTEC

485

Active

Filter

2-1

2.

SPECIFICATIONS

2.1

General

Specifications

2.1.1

The

485

is

intended

for

use

with

a

Nuclear

Standard

Bin

such

as

the

ORTEC

401A/402A.

Two

watts

of

power

is

required

for

the

operation

of

the

485

in

the

quiescent

condition.

The

401A/-

402A

can

be

operated

on

either

115

or

220

volts

ac,

50-60

Hz;

if

it

is

used

with

220

volts

ac,

the

manual

for

the

401A/402A

must

be

referred

to

in

order

to

ensure

that

correct

connections

have

been

made

before

operation

on

220

volts

ac

is

attempted.

The

instrument

is

supplied

from

the

factory

wired

for

115

volts

ac

operation.

The

power

input

connector

to

the

401A/402A

is

a

NEMA

standard

3-wire

grounding

type.

Preamplifier

power

of

±12V

and

±24V

is

available

on

the

485

rear

panel

connector,

CN3.

All

signal

inputs

and

outputs

are

on

BNC

connectors

which

are

mounted

on

the

front

panel.

2.1.2

The

instrument

is

intended

for

rack

mounting

in

a

401A/402A

Nuclear

Standard

Bin,

but

the

Nuclear

Standard

Bin

is

suitably

packaged

for

cabinet

installation

if

desired.

The

weight

of

the

485

is

2

pounds

and

its

outside

dimensions

are

approximately

8.75

inches

high

by

1.35

inches

wide

by

9.75

inches

deep.

2.2

Amplifier

Specifications

INPUT:

Input

pulse

should

have

less

than

0.25Msec

rise

time

for

best

filter

action,

40;usec

minimum

decay

time

for

pole-zero

cancellation,

^2\l

maximum,

6V

maximum

to

prevent

saturation

before

differentiation,

1000

ohms

impedance,

dc-coupled

OUTPUT:

Positive

or

bipolar,

0-1OV

linear

with

11.5V

saturation

into

1000

ohms.

0-9V

linear

with

10V

saturation

into

100

ohms,

0.5

ohm

output

impedance

SHAPING:

Active

network

filter

resulting

in

approximately

Gaussian

shape,

peak

amplitude

at

1.5/isec

for

unipolar

and

l.ljusec

for

double

clip,

crossover

at

2.5;usec

for

bipolar

MAXIMUM

GAIN:

640

GAIN

CHANGE

RANGE:

107:1

total,

32:1

in

factors

of

2

by

switches

with

1%

accuracy,

3:1

continuous

fine

control

LINEARITY:

±0.15%

over

specified

linear

range

NOISE:

10/uV

at

maximum

gain

and

single

clip,

12/xV

at

maximum

gain

and

double

clip,

both

referred

to

input

SHORT

CIRCUIT

LIMITS:

The

amplifier

will

sustain

a

direct

short

on

the

output

for

an

indefinite

period

for

counting

rates

up

to

10^

Hz

COUNTING

RATE:

Less

than

0.5%

gain

shift

and

0.25%

resolution

spread

fullwidth

at

half

maximum

for

a

pulser

peak

above

a

50K

cts/sec

'

^

'Cs

background

OVERLOAD:

Recovery

within

2%

of

rated

output

from

600

times

overload

in

2.5

non-overloaded

pulse

widths

(25iisec)

at

maximum

gain

and

specified

input

CROSSOVER

WALK:

±3

nsec

for

10:1

dynamic

range

with

1;usec

bipolar

shaping

(including

amplifier

and

ORTEC

420

Timing

Single

Channel

Analyzer)

OPERATING

TEMPERATURE:

0

to

50^0

TEMPERATURE

STABILITY:

0.02%/oc

POWER

REQUIRED:

(Supplied

by

401A/402A

Power

Supply)

+24

V,

35

mA;

-24

V,

20

mA;

+12

V,50

mA;-12

V,

70

mA.

3-1

3.

INSTALLATION

3.1

General

Installation

Considerations

The

485,

used

in

conjunction

with

a

401A/402A

Bin

and

Power

Supply,is

intended

for

rack

mounting;

therefore,

it

is

necessary

to

ensure

that

vacuum

tube

equipment

operating

in

the

same

rack

with

the

485

has

sufficient

cooling

air

circulating

to

prevent

any

localized

heating

of

the

all-semiconductor

circuitry

used

throughout

the

485.

The

temperature

of

equipment

mounted

in

racks

can

easily

exceed

120OF

(50OC)

unless

precautions

are

taken.

3.2

Connection

to

Preamplifier

The

preamplifier

output

signal

is

connected

to

the

485

BNC

connector

CN1,

labeled

INPUT.

The

input

impedance

seen

at

the

input

is

1000

ohms

and

is

dc-coupled

to

ground;

therefore,

the

output

of

the

preamplifier

must

be

either

ac-coupled

or

have

no

dc

voltage

under

no

signal

conditions.

The

485

incorporates

pole-zero

cancellation

in

order

to

enhance

the

overload

characteristics

of

the

amplifier.

Thistechnique

requires

matching

the

network

to

the

preamplifier

decay

time

constant

in

order

to

achieve

perfect

compensation.

The

network

is

variable

and

factory

adjusted

to

50^tsec

to

match

all

ORTEC

FET

preamplifiers.

If

another

preamplifier

is

used

or

more

careful

matching

is

desired,

the

trim

is

accessible

from

the

front

panel.

Adjustment

is

easily

accomplished

by

using

a

monenergetic

source

and

observing

the

amplifier

baseline

after

each

pulse

overload

condition.

Preamplifier

power

of-h24V,

-t-12V,

-12V,

and

-24V

is

available

on

the

preamp

power

connector,

CN3.

When

using

the

485

with

a

remotely

located

preamplifier

(i.e.,

preamplifier-to-amplifier

connection

through

25

feet

or

more

of

coaxial

cable),

ensure

that

the

characteristic

impedance

of

the

transmission

line

from

the

preamplifier

output

to

the

485

input

is

matched.

Since

the

input

impedance

of

the

485

is

1000

ohms,

sending

end

termination

will

normally

be

preferred;

i.e.,

the

transmission

line

should

be

series

terminated

at

the

output

of

the

preamplifier.

All

ORTEC

preamplifiers

contain

series

terminations

which

are

either

93

ohms

or

variable.

3.3

Connection

of

Test

Pulse

Generator

3.3.1

Connection

of

Pulse

Generator

to

the

485

Through

a

Preamplifier

The

satisfactory

connection

of

atest

pulse

generator

such

as

the

ORTEC

419

or

equivalent

depends

primarily

on

two

considerations:

(1)

the

preamplifier

must

be

properly

connected

to

the

485

as

discussed

in

Section

3.2,

and

(2)

the

proper

input

signal

simulation

must

be

applied

to

the

preamplifier.

To

ensure

proper

input

signal

simulation,

refer

to

the

instruction

manual

for

the

particular

preamplifier

being

used.

3.3.2

Direct

Connection

to

Pulse

Generator

to

the

485

Since

the

input

of

the

485

has

1000

ohms

input

impedance,

the

test

pulse

generator

will

normally

have

to

be

terminated

at

the

amplifier

input

with

an

additional

shunt

resistor.

In

addition,

if

the

test

pulse

generator

has

a

dc

offset,

a

large

series

isolating

capacitor

is

also

required,

since

the

input

of

the

485

is

dc-coupled

to

the

first

amplifier

stage.

The

ORTEC

204

or

419

Test

Pulse

Generators

are

designed

for

direct

connection.

When

either

of

these

units

is

used,

it

should

be

terminated

with

a

100

ohm

terminator

at

the

amplifier

input.

(The

small

error

due

to

the

finite

input

imped

ance

of

the

amplifier

can

normally

be

neglected.)

3.3.3

Special

Test

Pulse

Generator

Considerations

for

Pole-Zero

Cancellation

The

pole-zero

cancellation

network

in

the

485

is

factory

adjusted

for

a

50^isec

decay

time

to

match

ORTEC

FET

preamplifiers.

When

a

tail

pulser

(such

as

the

204

or

419)

is

connected

directly

to

one

of

the

amplifier

inputs,

the

pulser

should

be

modified

to

obtain

a

50^isec

decay

time

if

overload

tests

are

to

be

made

(other

tests

are

not

affected).

See

Section

6.2

for

details

on

this

modification.

3-2

If

a

preamplifier

is

used

and

a

tail

pulser

connected

to

the

preamplifier

pulser

input,

similar

precautions

are

necessary.

In

this

case,

the

effect

of

the

pulser

decay

must

be

removed;

i.e.,

a

step

input

should

be

simulated.

Details

for

this

modification

are

given

in

Section

6.2.

3.4

Connection

to

Power

-

Nuclear

Standard

Bin,

ORTEC

401A/402A

The

485

contains

no

internal

power

supply;

therefore,

it

must

obtain

power

from

a

Nuclear

Standard

Bin

and

Power

Supply

such

as

the

401A/402A.

Turn

power

off

when

inserting

or

removing

modules.

The

ORTEC

Modular

Nuclear

Instrument

Series

is

designed

so

that

it

is

not

possible

to

overload

the

bin

power

supply

with

a

full

complement

of

modules

in

the

Bin.

This

may

not

be

true

when

the

Bin

contains

modules

other

than

those

of

ORTEC

design,

and

in

this

case,

check

the

power

supply

voltages

after

insertion

of

the

modules.

The

401A/402A

has

test

points

on

the

power

supply

control

panel

to

monitor

the

dc

voltages.

3.5

Output

Connections

and

Terminating

Considerations

The

485

linear

output

can

be

switch

selected

for

either

a

unipolar

or

a

bipolar

output.

The

unipolar

output

should

be

used

for

high

resolution

spectrometry

applications

with

semiconductor

detectors.

The

bipolar

output

should

be

used

in

applications

requiring

high

counting

rates

or

crossover

timing.

Typical

system

block

diagrams

for

a

variety

of

experiments

are

described

in

Section

4.

The

source

impedance

of

the

0-10

volt

standard

linear

outputs

of

most

ORTEC

modules

is

approxi

mately

1

ohm.

Interconnection

of

linear

signals

is

thus

non-critical,

since

the

input

impedance

of

circuits

to

be

driven

is

not

important

in

determining

the

actual

signal

span,

e.g.,

0-10

volts,

delivered

to

the

following

circuit.

Paralleling

several

loads

on

a

single

output

is

therefore

permissible

while

preserving

the

0-10

volt

signal

span.

Short

lengths

of

interconnecting

coaxial

cable

(up

to

approximately

4

feet)

need

not

be

terminated.

However,

if

a

cable

longer

than

approximately

4

feet

is

necessary

on

a

linear

output,

it

should

be

terminated

in

a

resistive

load

equal

to

the

cable

impedance.

Since

the

output

impedance

is

not

purely

resistive

and

is

slightly

different

for

each

individual

module

when

a

certain

given

length

of

coaxial

cable

is

connected

and

is

not

terminated

in

the

characteristic

impedance

of

the

cable,oscillations

will

occasionally

be

observed.

These

oscillations

can

be

suppressed

for

any

length

of

cable

by

properly

terminating

the

cable,

either

in

series

at

the

sending

end

or

in

shunt

at

the

receiving

end

of

the

line.

To

properly

terminate

the

cable

at

the

receiving

end,

it

may

be

necessary

to

consider

the

input

impedance

of

the

driven

circuit,

choosing

an

additional

parallel

resistor

to

make

the

combina

tion

produce

the

desired

termination

impedance.

Series

terminating

the

cable

at

the

sending

end

may

be

preferable

in

some

cases,

where

receiving

end

terminating

is

not

desirable

or

possible.

When

series

terminating

at

the

sending

end,

full

signal

span,

i.e.,

amplitude,

is

obtained

at

the

receiving

end

only

when

it

is

essentially

unloaded

or

loaded

with

an

impedance

many

times

that

of

the

cable.

This

may

be

accomplished

by

inserting

a

series

resistor

equal

to

the

characteristic

impedance

of

the

cable

internally

in

the

module

between

the

actual

amplifier

output

on

the

etched

board

and

the

output

connector.

This

impedance

is

in

series

with

the

input

impedance

of

the

load

being

driven,

and

in

the

case

where

the

driven

load

is

900

ohms,

a

decrease

in

the

signal

span

of

approximately

10%

will

occur

for

a

93-ohm

transmission

line.

A

more

serious

loss

occurs

when

the

driven

load

is

93

ohms

and

the

transmission

system

is

93

ohms.

In

this

case,

a

50%

loss

will

occur.

BNC

connectors

with

internal

terminators

are

available

from

a

number

of

connector

manufacturers

in

nominal

values

of

50,

100,

and

1000

ohms.

ORTEC

stocks

in

limited

quantity

both

the

50

and

100

ohm

BNC

terminators.

The

BNC

terminators

are

quite

convenient

to

use

in

conjunction

with

a

BNC

tee.

3.6

Shorting

the

Amplifier

Output

The

output

of

the

485

is

ac-coupled

with

an

output

impedance

of

about

0.5

ohm.

If

the

output

is

shorted

with

a

direct

short-circuit

and

the

amplifier

counting

rate

exceeds

10,000

counts

per

second,

the

output

stage

will

eventually

heat

up

sufficiently

to

destroy

itself

(about

one

minute

for

10

cts/sec).

The

amplifieroutput

may

be

shorted

indefinitely

without

catastrophic

damage

at

rates

below

lO"

cts/sec.

4-1

4.

OPERATING

INSTRUCTIONS

4.1

Controls

and

Connectors

4.1.1

Description

FINE

GAIN:

A

single-turn

fine

gain

control

is

provided

for

a

dynamic

range

of

3:1.

The

Fine

Gain

factor

is

selectable

from

X3

through

X10.

COARSE

GAIN:

Coarse

gain

control

is

provided

by

a

rotary

switch.

The

binary

selector

switch

covers

the

range

of

X2

to

X64.

UNIPOLAR-BIPOLAR:

Either

unipolar

or

bipolar

output

pulses

are

switch

selectable.

The

gains

are

matched

in

both

modes

to

approximately

±2.5%.

PZ-TRIM:

A

trim

potentiometer

is

provided

to

adjust

the

pole-zero

cancellation

network

for

varying

preamplifier

decay

times.

INPUT:

A

front

panel

BNC

connector

for

preamplifier

pulses

having

either

polarity.

Preamplifier

pulses

should

have

less

than

0.25;usec

rise

time

and

a

50/isec

decay

time.

POS-NEG:

A

switch

to

accommodate

either

positive

or

negative

input

signals

from

a

preamplifier.

OUTPUT:

A

front

panel

BNC

connector

providing

a

low

impedance

shaped

output,

with

a

test

probe

adjacent

for

oscilloscope

monitoring.

PREAMP:

A

connector

providing

±12

and

±24

volts

for

preamplifier

power.

This

furnishes

direct

compatibility

for

all

ORTEC

transistor

and

FET

preamps.

4.1.2

Front

and

Rear

Panel

Connector

Data

Connector

See

Dwg

485-0101-S1

Generic

Designation

Test

Point

Output

or

Input

Impedance

Shape

and

Amplitude

Limitations

CN-1

INPUT

No

1000J2

Positive

or

negative.

Less

than

0.25^tsec

rise

time

and

SOjusec

decay

time

is

rec

ommended,

although

faster

rise

and

slower

decay

times

can

be

handled.

6V

maxi

mum

linear,

12V

absolute

maximum

CN-2

CN-3

OUTPUT

PREAMP

POWER

TP-1

No

0.5J2

dc

Positive

or

bipolar,

0-10V

linear

with

11.5V

satura

tion

into

lOOOrZ,

0-9V

linear

with

10V

saturation

into

100J2,

approximate

Gaussian

shape

Pin

1:

Gnd

Pin

6:

-24V

Pin

7:

+24V

Pin

9:

-12V

Pin

4:

+12V

4-2

4.2

Initial

Testing

and

Observation

of

Pulse

Waveforms

Refer

to

Section

6

for

information

on

testing

performance

and

observing

waveforms

at

front

panel

test

points.

4.3

General

Considerations

for

Operation

with

Semiconductor

Detectors

4.3.1

Calibration

of

Test

Pulser

The

ORTEC

204,

419,

or

480

Precision

Pulse

Generators,

or

equivalent,

may

easily

be

calibrated

so

that

the

maximum

pulse

height

dial

reading

(1000

divisions)

is

equivalent

to

a

10-MeV

loss

in

a

semiconductor

radiation

detector.

The

procedure

utilizing

the

419

is

as

follows:

(1)

Connect

the

detector

to

be

used

to

the

spectrometer

system;

i.e.,

preamp,

main

amplifier,

and

biased

amplifier.

(2)

Allow

particles

from

a

source

of

known

energy

(a-particles,

for

example)

to

fall

on

the

detector.

(3)

Adjust

the

amplifier

gains

and

the

bias

level

of

the

biased

amplifier

to

give

a

suitable

output

pulse.

(4)

Set

the

pulser

PULSE

HEIGHT

potentiometer

at

the

energy

of

the

a-particles

striking

the

detector

(e.g.,

for

a

5.1

MeV

a-particle,

set

the

dial

at

510

divisions).

(5)

Turn

on

the

pulser

and

use

the

NORMALIZE

potentiometer

and

the

attenuators

to

set

the

output

due

to

the

pulser

to

the

same

pulse

height

as

the

pulse

obtained

in

(3)

above.

(6)

The

pulser

is

now

calibrated;

the

dial

reads

in

MeV

if

the

number

of

dial

divisions

is

divided

by

ICQ.

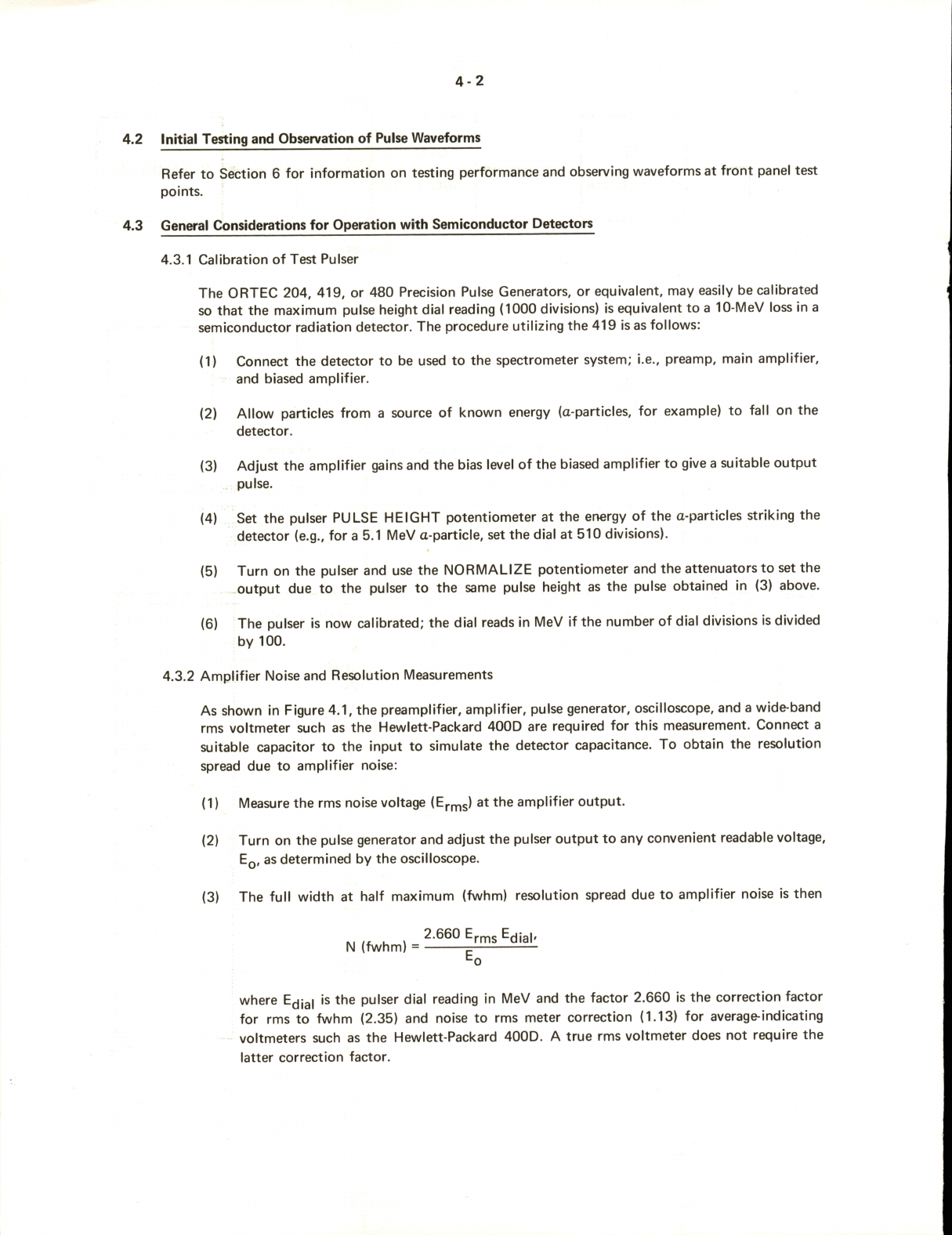

4.3.2

Amplifier

Noise

and

Resolution

Measurements

As

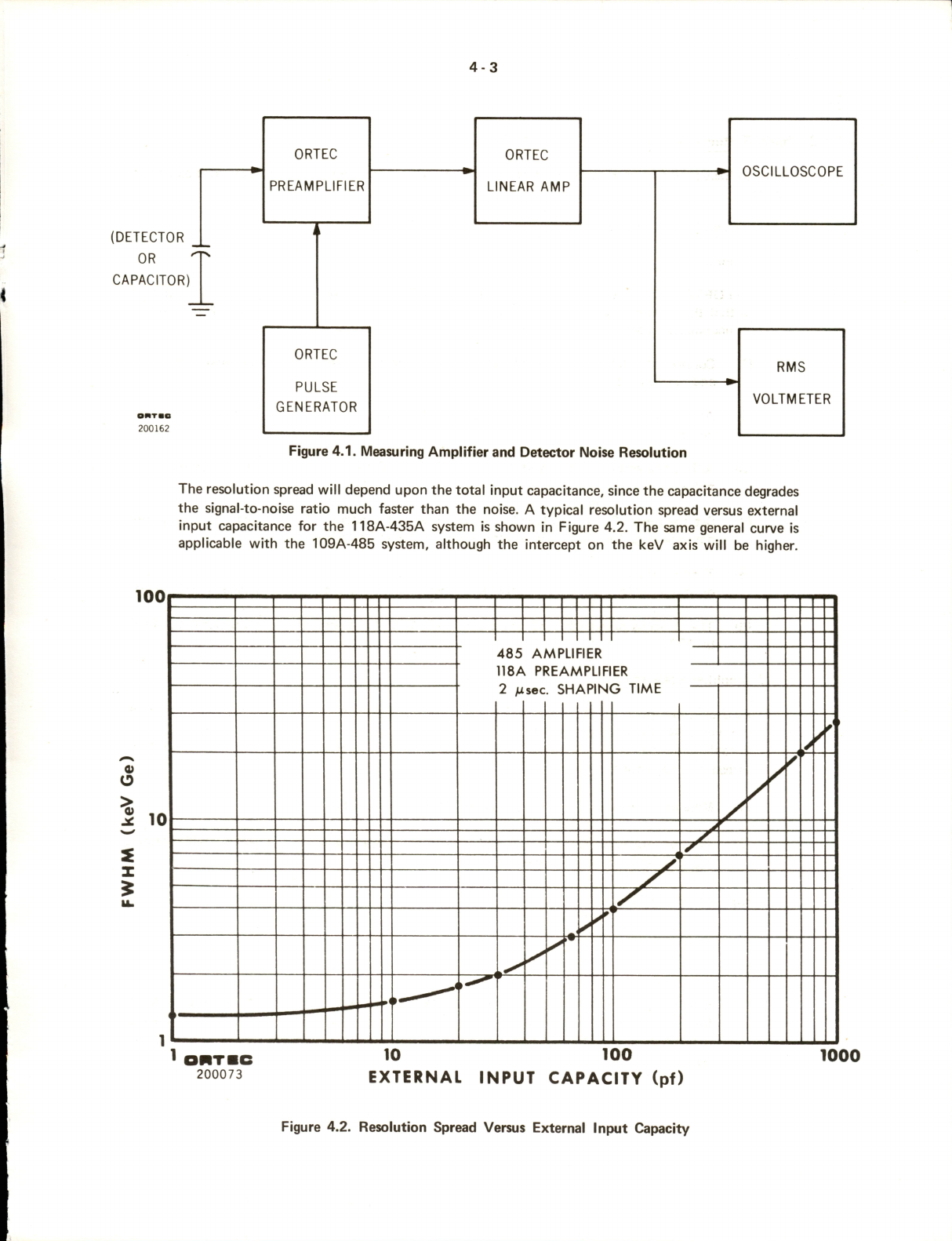

shown

in

Figure

4.1,

the

preamplifier,

amplifier,

pulse

generator,

oscilloscope,

and

a

wide-band

rms

voltmeter

such

as

the

Hewlett-Packard

400D

are

required

for

this

measurement.

Connect

a

suitable

capacitor

to

the

input

to

simulate

the

detector

capacitance.

To

obtain

the

resolution

spread

due

to

amplifier

noise:

(1)

Measure

the

rms

noise

voltage

(Ej-^pg)

at

the

amplifier

output.

(2)

Turn

on

the

pulse

generator

and

adjust

the

pulser

output

to

any

convenient

readable

voltage,

Eq,

as

determined

by

the

oscilloscope.

(3)

The

full

width

at

half

maximum

(fwhm)

resolution

spread

due

to

amplifier

noise

is

then

2.660

Epppg

E(jja|,

N

(fwhm)

Eo

where

Ejjjai

is

the

pulser

dial

reading

in

MeV

and

the

factor

2.660

is

the

correction

factor

for

rms

to

fwhm

(2.35)

and

noise

to

rms

meter

correction

(1.13)

for

average-indicating

voltmeters

such

as

the

Hewlett-Packard

400D.

A

true

rms

voltmeter

does

not

require

the

latter

correction

factor.

4-3

(DETECTOR

OR

CAPACITOR)

200162

LINEAR

AMP

ORTEC

VOLTMETER

RMS

PREAMPLIFIER

ORTEC

PULSE

GENERATOR

ORTEC

OSCILLOSCOPE

Figure

4.1.

Measuring

Amplifier

and

Detector

Noise

Resolution

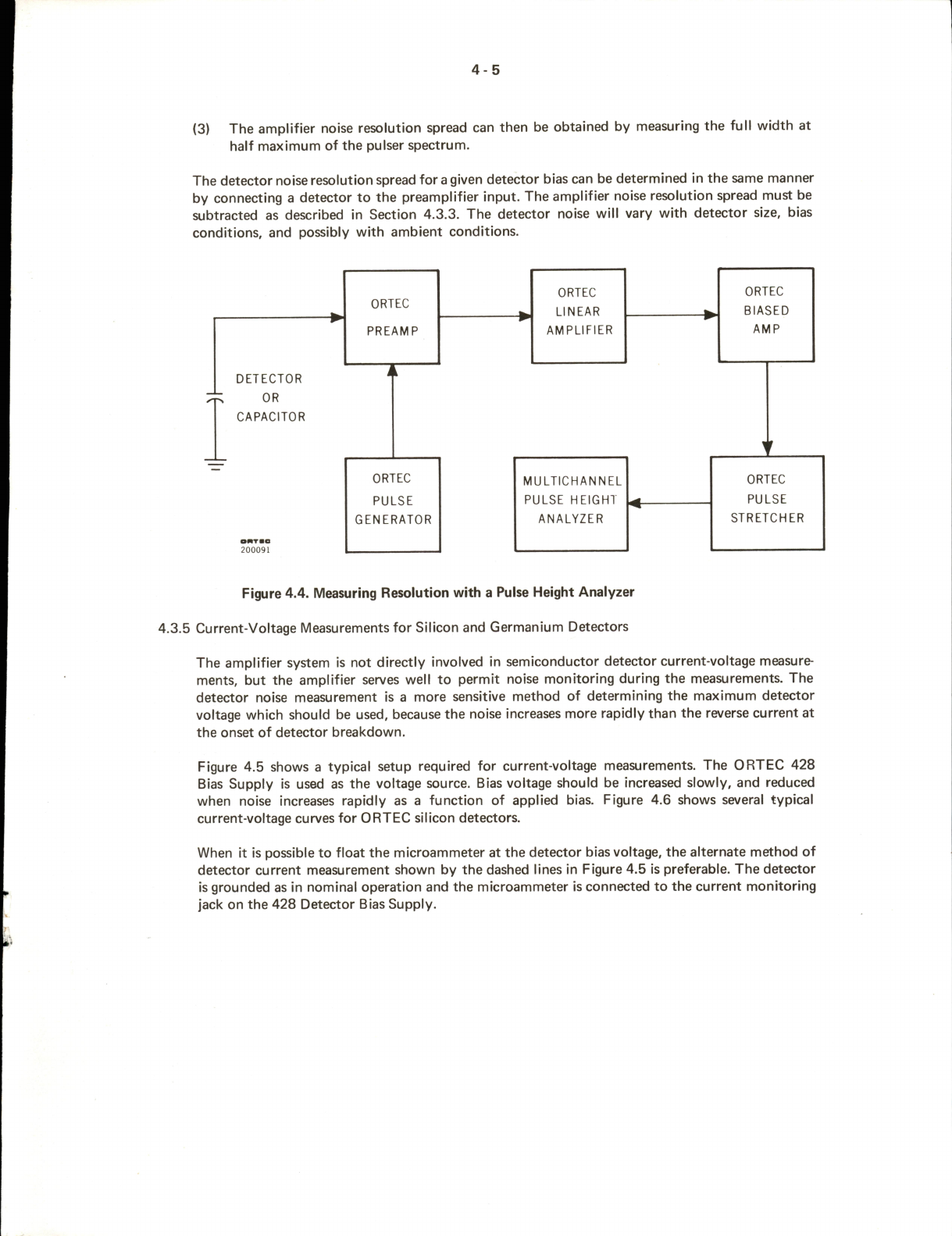

The

resolution

spread

will

depend

upon

the

total

input

capacitance,

since

the

capacitance

degrades

the

signal-to-noise

ratio

much

faster

than

the

noise.

A

typical

resolution

spread

versus

external

input

capacitance

for

the

118A-435A

system

is

shown

in

Figure

4.2.

The

same

general

curve

is

applicable

with

the

109A-485

system,

although

the

intercept

on

the

keV

axis

will

be

higher.

100

0)

O

JC.

S

X

10

485

AMPLIFIER

118A

PREAMPLIFIER

^

M

sec

.

b

'ir

j

MMC

y

f

y

X

a

1

oiiTac

200073

10

100

EXTERNAL

INPUT

CAPACITY

(pf)

1000

Figure

4.2.

Resolution

Spread

Versus

External

Input

Capacity

4

-

4

4.3.3

Detector

Noise

Resolution

Measurements

The

same

measurement

described

in

Section

4.3.2

can

be

made

with

a

biased

detector

instead

of

the

external

capacitor

used

to

simulate

the

detector

capacitance.

The

resolution

spread

will

be

larger

because

the

detector

contributes

both

noise

and

capacitance

to

the

input.

The

detector

noise

resolution

spread

can

be

isolated

from

the

amplifier

noise

spread

if

the

detector

capacity

is

known,

since

Ndet^

+

Namp^

~

'^total^

where

N^Q^^gl

resolution

spread

and

Ngmp's

f^e

amplifier

resolution

spread

with

the

detector

replaced

by

its

equivalent

capacitance.

The

detector

noise

tends

to

increase

with

bias

voltage,

but

the

detector

capacitance

decreases,

thus

reducing

the

resolution

spread.

The

overall

resolution

spread

will

depend

upon

which

effect

is

dominant.

Figure

4.3

shows

curves

of

typical

total

noise

resolution

spread

versus

bias

voltage,

using

the

data

from

several

ORTEC

silicon

semiconductor

radiation

detectors.

.8

</)

I-

_j

o

>

(Si

o

z

(fi

s.

cr

0

A

-

ORTEC

BA-030-007-300

B

-

ORTEC

BA-025-050-100

.

C-

ORTEC

BA-025-100-100

U-

UK1tU

W

E

-

ORTEC

B/I

1-045^50-100

E

■>—

D

.c

—

F

.A

0

MTce

200159

25

100

125

50 75

BIAS

VOLTAGE

Figure

4.3.

Amplifier

and

Detector

Noise

Versus

Bias

Voltage

4.3.4

Amplifier

Noise

and

Resolution

Measurements

Using

a

Pulse

Height

Analyzer

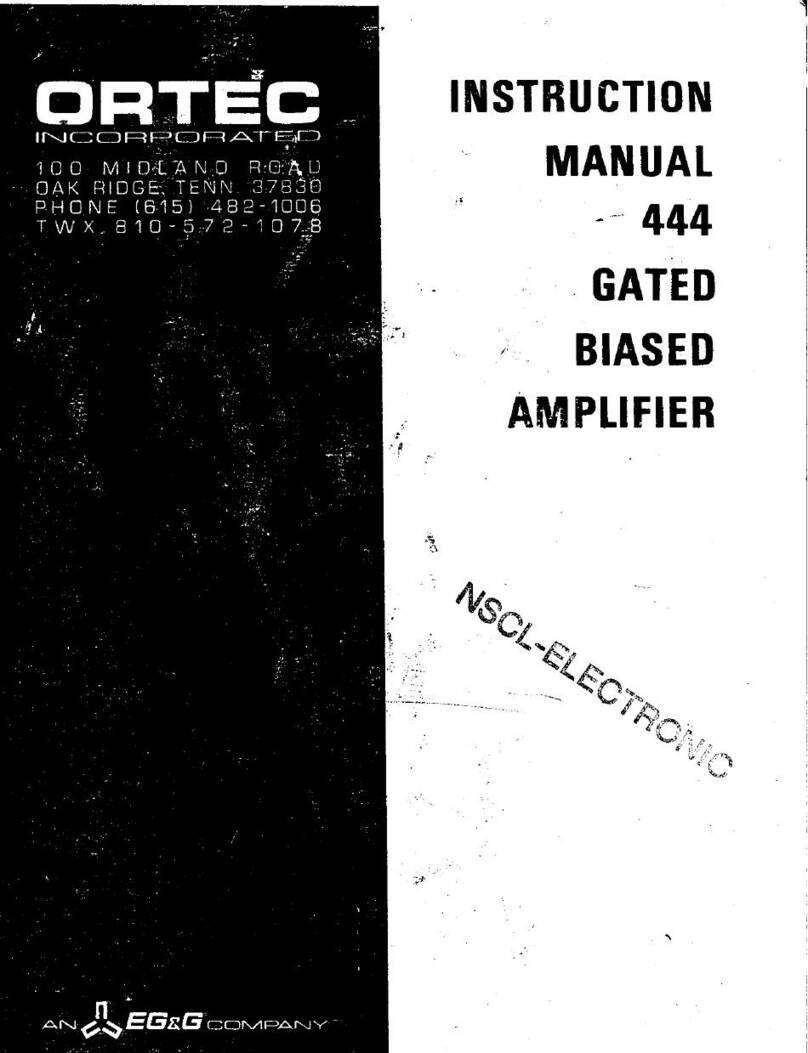

Probably

the

most

convenient

method

of

making

resolution

measurements

is

with

a

pulse

height

analyzer

as

shown

by

the

set-up

illustrated

in

Figure

4.4.

The

amplifier

noise

resolution

spread

can

be

measured

directly

with

a

pulse

height

analyzer

and

the

mercury

pulser

as

follows:

(1)

Select

the

energy

of

interest

with

an

ORTEC

419

Pulse

Generator,

and

set

the

Active

Filter

Amplifier

and

Biased

Amplifier

GAIN

and

BIAS

LEVEL

controls

so

that

the

energy

is

in

a

convenient

channel

of

the

analyzer.

(2)

Calibrate

the

analyzer

in

keV

per

channel,

using

the

pulser

(full

scale

on

the

pulser

dial

is

10

MeV

when

calibrated

as

described

in

Section

4.3.1.).

4-5

(3)

The

amplifier

noise

resolution

spread

can

then

be

obtained

by

measuring

the

full

width

at

half

maximum

of

the

pulser

spectrum.

The

detector

noise

resolution

spread

for

a

given

detector

bias

can

be

determined

in

the

same

manner

by

connecting

a

detector

to

the

preamplifier

input.

The

amplifier

noise

resolution

spread

must

be

subtracted

as

described

in

Section

4.3.3.

The

detector

noise

will

vary

with

detector

size,

bias

conditions,

and

possibly

with

ambient

conditions.

DETECTOR

OR

CAPACITOR

200091

ORTEC

LINEAR

AMPLIFIER

PULSE

GENERATOR

ORTEC

ORTEC

BIASED

AMP

PREAMP

ORTEC

ORTEC

PULSE

STRETCHER

MULTICHANNEL

PULSE

HEIGHT

ANALYZER

Figure

4.4.

Measuring

Resolution

with

a

Pulse

Height

Analyzer

4.3.5

Current-Voltage

Measurements

for

Silicon

and

Germanium

Detectors

The

amplifier

system

is

not

directly

involved

in

semiconductor

detector

current-voltage

measure

ments,

but

the

amplifier

serves

well

to

permit

noise

monitoring

during

the

measurements.

The

detector

noise

measurement

is

a

more

sensitive

method

of

determining

the

maximum

detector

voltage

which

should

be

used,

because

the

noise

increases

more

rapidly

than

the

reverse

current

at

the

onset

of

detector

breakdown.

Figure

4.5

shows

a

typical

setup

required

for

current-voltage

measurements.

The

ORTEC

428

Bias

Supply

is

used

as

the

voltage

source.

Bias

voltage

should

be

increased

slowly,

and

reduced

when

noise

increases

rapidly

as

a

function

of

applied

bias.

Figure

4.6

shows

several

typical

current-voltage

curves

for

ORTEC

silicon

detectors.

When

it

is

possible

to

float

the

microammeter

at

the

detector

bias

voltage,

the

alternate

method

of

detector

current

measurement

shown

by

the

dashed

lines

in

Figure

4.5

is

preferable.

The

detector

is

grounded

as

in

nominal

operation

and

the

microammeter

is

connected

to

the

current

monitoring

jack

on

the

428

Detector

Bias

Supply.

4-6

I

MICRO-

I

'

«"MCTCD

I

I

^

I'l

1*1

b

h

O

RTEC

DETECTOR

BIAS

SUPPLY

w

I

>

I

I

I

CURRENT

MONITORING

JACKS

DETECTOR

BYPASS

CAPACITOR

ORTEC ORTEC

RMS

PREAMPLIFIER

AMPLIFIER

VOLTMETER

MICRO-

AMMETER

ORTEC

200093

Figure

4.5.

Measuring

Detector

Current-Voltage

Characteristics

I

r

I I

ORTEC

BA-030-007-300

ORTEC

BA-025-050-100

ORTEC

BA-025-100-100

ORTEC

BA-030-200-100

ORTEC

BA-045-450-100

50

70

BIAS

VOLTAGE

Figure

4.6.

Silicon

Detector

Back

Current

Versus

Bias

Voltage

Table of contents

Other EG&G Amplifier manuals

EG&G

EG&G ORTEC 535 Service manual

EG&G

EG&G 113 Service manual

EG&G

EG&G ORTEC 444 User manual

EG&G

EG&G ORTEC 572 Service manual

EG&G

EG&G ORTEC 118A User manual

EG&G

EG&G ORTEC 452 User manual

EG&G

EG&G ORTEC 414A Service manual

EG&G

EG&G ORTEC 113 Service manual

EG&G

EG&G 128A Service manual

EG&G

EG&G ORTEC 427 User manual