EG&G 128A Service manual

MODEL

128A

LOCK-IN

AMPLIFIER

SEE SAFETY NOTICE

PRECEDNG SECTION I

;EFORE OPERATING INSTRUMENT

OPERATING

AND

SERVICE

MANUAL

M128A; 9/83·500·MIC

MODEL

128A

LOCK-IN

AMPLIFIER

OPERATING

AND

SERVICE

MANUAL

n

~~

G

BROOKDEAL

ELECTRONICS

~~

.:;;;;;

~

I:..

PRINCETON

APPL/ED

RESEARCH

Copyright

©1983 EG&G PRINCETON APPLIED RESEARCH

Printed

In U.S.A.

SHOULD YOUR EQUIPMENT REQUIRE SERVICE

A. Contact the factory

(6091452-2111)

or

your

local factory

representative to discuss the problem. In many cases it

will be possible to expedite servicing by localizing the

problem to a particular plug-in

circuit

board.

B. If it is necessary to send any equipment back to the fac-

tory, we need the following information.

(1) Model number and serial number.

(2) Your name (instrument user).

(3) Your address.

(4) Address to

which

instrument should be returned.

(5) Your telephone number and extension.

(6) Symptoms (in detail,

including

control

settings).

(7) Your purchase order number for repaircharges (does

not apply to repairs in warranty).

(8) Shipping

instructions

(if you wish to authorize ship-

ment by any method

other

than normal surface

transportation).

C. U.S. CUSTOMERS-·-Ship the equipment being returned

to:

EG&G PRINCETON APPLIED RESEARCH

7 Roszel Road

(Off Alexander Road, East of Route 1)

Princeton, New Jersey

D. CUSTOMERS OUTSIDE OF

U.S.A.-To

avoid delay in

customs clearance of equipment being returned, please

contact the factory or the nearest factory

distributor

for

complete shipping information.

E. Address correspondence to:

EG&G PRINCETON APPLIED RESEARCH

P. O. Box 2565

Princeton, NJ 08540

Phone:

6091452-2111

TELEX: 84 3409

WARRANTY

EG&G PRINCETON APPLIED RESEARCH warrants each in-

strument of

its

manufacture to be free from defects in material

and workmanship. Obligations under

this

Warranty shall be

limited

to replacing, repairing or giving credit for the purchase

price, at our option, of any instrument returned, freight

prepaid, to our factory

within

ONE year of delivery to the

original purchaser, provided

prior

authorization for such return

has been given by our authorized representative.

This Warranty shall not apply to any instrument which our in-

spection shall

disclose

to our satisfaction, has become detec-

tive or unworkable due to abuse, mishandling, misuse, acci-

dent, alteration, negligence, improper installation or

other

causes beyond our control.

Instruments

manufactured by

others, and included in or supplied

with

our equipment, are not

covered by

this

Warranty but carry the original manufacturer's

warranty which is extended to our customers and may be more

restrictive. Certain subassemblies, accessories or corn-

ponents may be specifically excluded from

this

Warranty, in

which case such exclusions are listed in the

Instruction

Manual supplied

with

each instrument.

We reserve the right to make changes in design at any time

without

incurring any obligation to install same on

units

previously purchased.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION HEREIN. THIS WARRANTY IS IN LIEU OF, AND

EXCLUDES ANY AND ALL OTHER WARRANTIES OR REPRE·

SENTATIONS, EXPRESSED, IMPLIED OR STATUTORY, IN·

CLUDING MERCHANTABILITY AND FITNESS, AS WELL AS

ANY AND ALL OTHER OBLIGATIONS OR LIABILITIES OF

EG&G PRINCETON APPLIED RESEARCH, INCLUDING, BUT

NOT LIMITED TO, SPECIAL OR CONSEQUENTIAL DAMAGES.

NO PERSON, FIRM OR CORPORATION IS AUTHORIZED TO

ASSUME FOR EG&G PRINCETON APPLIED RESEARCH ANY

ADDITIONAL OBLIGATION OR LIABILITY NOT EXPRESSLY

PROVIDED FOR HEREIN EXCEPT IN WRITING DULY EXE-

CUTED BY AN OFFICER OF EG&G PRINCETON APPLIED

RESEARCH.

Section

II

III

IV

V

TABLE

OF CONTENTS

CONDENSED

OPERATING

INSTRUCTIONS

CHARACTER

ISTICS

2.1

Introduction

2.2 Specifications

INITIAL

CHECKS

3.1

Introduction

3.2 Equipment Needed

3.3 Procedure

OPERATING

INSTRUCTIONS

4.1

Introduction

4.2 Preliminary Considerations

4.2A

Power Requirements

4.2B Fusing

.....

4.2C Warm-Up Period

4.20

Operating Frequency

4.2E

Grounding...

4.2F Noise

.....

4.3 Operating the Model 128A

4.3A

Introduction..

4.3B Reference Channel

4.3C Signal Channel

4.30

Output

Channel Controls

4.4 Mixer

Function

and Harmonic Sensitivity

4.5 Interface Connector .

4.6 Battery Operation .

4.7 Operation

with

the Internal Reference Oscillator

4.7A

Introduction

4.7B Operation . . . . . . . . . . .

4.7C Installation .

4.8 Operation

with

the Internal Tuned

Amplifier

4.8A

Introduction

4.8B

Operation.........

4.8C Installation .

4.9 More Reference Channel Operating Hints

4.9A

Reference Channel Slewing Rate

4.9B

Phase

Errors

with

Small Reference Signals

ALIGNMENT

.

5.1

Introduction

5.2 Required Equipment

5.3 Preliminary Steps

5.4 Procedure

5.4A

+15 V

Adjust

(R310),

-15

V Check, and +5 V Check

5.4B Reference Board Adjustments

5.4C Signal Board

Adjustment

5.40

Mixer Adjustments

5.4E Other Adjustments

Page

1-1

11-1

11-1

11-1

111-1

111-1

111-1

111-1

IV-l

IV-l

IV-l

IV-l

IV-l

IV-l

IV-l

IV-l

IV-3

IV-5

IV-5

IV-5

IV-6

IV-8

IV-9

IV-10

IV-10

IV-l0

IV-10

IV-10

IV-ll

IV-12

IV-12

IV-13

IV-15

IV-15

IV-15

IV-15

vi

V-l

V-l

V-l

V-l

V-l

V-l

V-3

V-3

V-4

VI

VII

Number

1·1

IV·l

IV-2

'V-3

IV-4

IV-5

IV·6

IV·7

IV-8

IV-9

IV-10

rvu

IV·12

IV-13

IV·14

IV·15

vi

Number

IV-l

.V-2

TROUBLESHOOTING

6.1 Introduction

6.2 Equipment Required

6.3 Initial Steps . . . .

6.4 Power Supply Checks

6.5

Reference Checks

6.6 Signal Channel Amplifiers

6.6A Preamplifier

6.6B Intermediate AC Amplifiers

6.6C Final AC Amplifier

6.7 Mixer

6.8 DC Amplifiers .

SCHEMATICS, Table of

FIGURES

Model 128A Lock-In Amplifier .

Ground-Loop Suppression by Ten-Ohm Input Ground

Differential Measurement of "Single-Ended" Signal

Differential Measurement of

"Off-Ground"

Signal

Example of Everything

"Done

Wrong"

Errors Depicted in Figure IV-4 Corrected

Typical Model

l28A

Noise Figure Contours

Pulse Train as Reference Drive

Net Phase

Shift

Between Signal and Reference Channels as a

Function

of Frequency

Amplitude and Phase Characteristics of Hi-Pass Filter

Amplitude and Phase Characteristics of Low-Pass Filter

Examples of

Output

Filter Interactions . . . . .

Mixer

Output

for In-Phase and Quadrature Signals

Internal Oscillator Board Installed .......

Tuned Amplifier Installed .

Phase/Amplitude Characteristics of Tuned Amplifier

Model 128A Adjustments and

Testpoints

.....

TABLES

Interface Connector Pin Assignments

Frequency Range as a Function of Capacitors

ii

VI-'

VI-'

VI·'

VI-'

VI·'

VI-'

VI·2

VI-2

VI-2

VI-2

VI-2

VI-2

VII·'

Page

.

1-2

IV-l

IV-'

IV-2

IV-2

IV·3

IV·3

IV·5

IV-6

IV-7

IV-7

IV-8

IV-9

IV·12

IV·13

IV·14

. V·2

Page

IV·l0

IV·l1

SAFETY CONSIDERATIONS

A. INTRODUCTION

The apparatus to

which

this

instruction

manual

applies has been supplied in a safe

condition.

This manual

contains

some

information

and warn-

ings that have to be

followed

by the userto ensure

safe operation and to retain the apparatus in a

safe condition. The described apparatus has been

designed

for

indoor

use.

B. INSPECTION

Newly received apparatus should be

inspected

for

shipping damage. If any is noted,

immediately

notify EG&G PARC and file aclaim

with

the car-

rier. The shipping

container

should be saved

for

possible

inspection

by the carrier.

WARNING!

THE PROTECTIVE GROUNDING COULD BE

RENDERED INEFFECTIVE IN DAMAGED AP-

PARATUS.

DAMAGED

APPARATUS

SHOULD NOT BE ·OPERATED UNTIL ITS

SAFETY HAS BEEN VERIFIED BY QUALI-

FIED SERVICE PERSONNEL. DAMAGED AP-

PARATUS WAITING FOR SAFETY VERI-

FICATION SHOULD BE TAGGED TO INDI-

CATED TO A POTENTIAL USER THAT IT

MAY BE UNSAFE AND THAT IT SHOULD

NOT BE OPERATED.

C. SAFETY MECHANISM

As defined in IEC Publication 348 (Safety Require-

ments

for

Electronic

Measuring

Apparatus), the

Model 128A is Class Iapparatus, that is, apparatus

that depends on

connection

to a protective con-

ductor

to earth ground for

equipment

and operator

safety. Before any

other

connection

is made to the

apparatus, the protective earth terminal shall be

connected to a protective conductor. The protec-

tive connection is made via the earth ground

prong of the M128A's power cord plug. This plug

shall only be inserted

into

asocket

outlet

provid-

ed with the required earth ground contact. The

protective action

must

not be negated by the use

of an extension cord

without

aprotective conduc-

tor, or by use of an

"adapter"

that

doesn't

main-

tain earth ground

continuity,

or by any

other

means.

The power cord plug provided is of the type illus-

trated in Figure 1. If

this

plug is

not

compatible

with the available power

SOCkets,

the plug or

power cord should be replaced

with

an approved

type of

compatible

design.

WARNING!

IF IT IS NECESSARY TO REPLACE THE

POWER CORD OR THE POWER CORD

PLUG, THE REPLACEM ENT CORD OR PLUG

MUST HAVE THE SAME POLARITY AS THE

ORIGINAL. OTHERWISE A SAFETY HAZARD

FROM

ELECTRICAL

SHOCK,

WHICH

COULD RESULT IN PERSONAL INJURY OR

DEATH, MIGHT RESULT.

L=

LINE

OR

ACTIVE

CONDUCTOR (ALSO CALLEU

"LlV£"

OR

"HOT")

N=

NEUTRAL

OR

IDENTIFIED

CONDUCTOH

E=EARTH OR SAFETY GROUND

Figure 1. POWER CORD PLUG WITH POl.ARITY INDICATIONS

D. POWER VOLTAGE SELECTION AND

LINE FUSES

Before

plugging

in the

power

cord, make sure that

the

equipment

is set to the voltage of the ac

power

supply.

CAUTION!

THE APPARATUS DESCRIBED IN THIS

MANUAL

MAY BE DAMAGED IF IT IS SET

FOR OPERATION FROM 110 V AC AND

TURNED ON WITH 220 V AC APPLIED TO

THE POWER INPUT CONNECTOR.

Adetailed

discussion

of how to

check

and.tt

nec-

essary, change the power-voltage

setting

follows.

The line voltage is selected by means of a rear-

panel

switch.

FOR SAFETY, UNPLUG THE

POWER CORD WHEN CHECKING THE LINE

VOLTAGE SETTING OR WHEN CHECKING THE

FUSES. FUSES SHOULD ONLY BE CHANGED BY

QUALIFIED SERVICE PERSONNEL WHO ARE

AWARE OF THE HAZARDS INVOLVED. Depend-

ing on the

switch

position,

either

"115"

or

"230"

(both are printed on the

swltchj-wl!l

be

visible

to

the viewer. For operation from a line voltage from

100 V ac to 130 V ac, 50-60 Hz,

"115"

should

show.

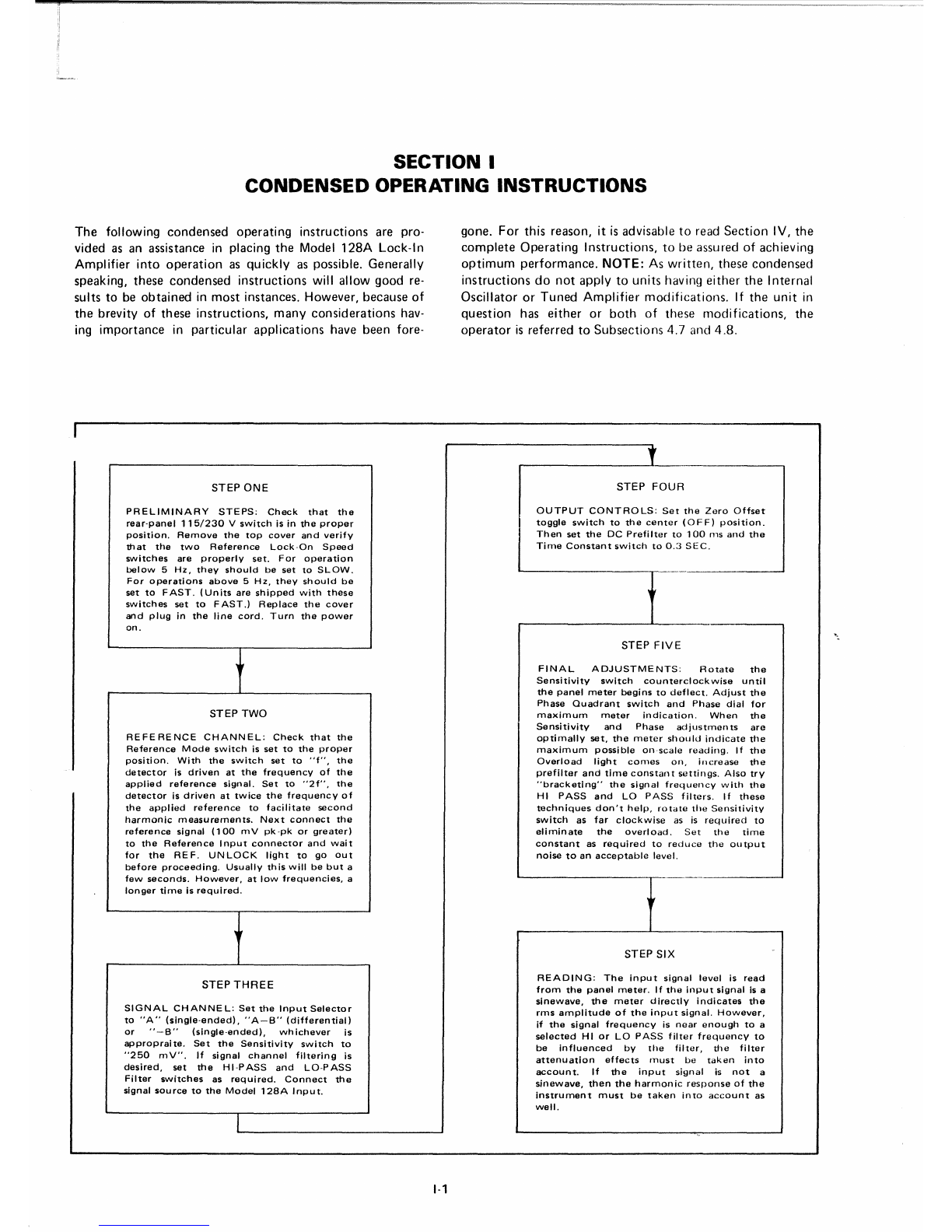

SECTION I

CONDENSED OPERATING INSTRUCTIONS

The

following

condensed

operating

instructions

are pro-

vided as an assistance in placing

the

Model

128A

Lock-In

Amplifier

into

operation

as

quickly

as possible.

Generally

speaking,

these

condensed

instructions

will

allow

good

re-

sults

to be

obtained

in

most

instances.

However,

because

of

the

brevity of

these

instructions,

many

considerations

hav-

ing

importance

in

particular

applications

have

been

fore-

STEP ONE

PRELIMINARY

STEPS;

Check

that

the

rear-panel

115/230

V

switch

is in

the

proper

position.

Remove

the

top

cover

and

verify

that

the

two

Reference

Lock-On

Speed

switches

are

properly

set.

For

operation

below

5

Hz,

they

should

be

set

to

SLOW.

For

operations

above

5

Hz,

they

should

be

set

to

FAST.

(Units

are

shipped

with

these

switches

set

to

FAST.)

Replace

the

cover

and

plug

in

the

line

cord.

Turn

the

power

on.

STEP TWO

REFERENCE

CHANNEL:

Check

that

the

Reference

Mode

switch

is

set

to

the

proper

position.

With

the

switch

set

to

"f",

the

detector

is

driven

at

the

frequency

of

the

applied

reference

signal.

Set

to

"2f",

the

detector

is

driven

at

twice

the

frequency

of

the

applied

reference

to

facilitate

second

harmonic

measurements.

Next

connect

the

reference

signal

(100

m V pk -pk

or

greater)

to

the

Reference

Input

connector

and

wait

for

the

REF.

UNLOCK

light

to

go

out

before

proceeding.

Usually

this

will

be

but

a

few

seconds.

However,

at

low

frequencies,

a

longer

time

is

required.

STEP

THREE

SIGNAL

CHANNE

L:

Set

the

Input

Selector

to

"A"

(single-ended),

"A-B"

(differential)

or

"-B"

(single-ended),

whichever

is

appropraite.

Set

the

Sensitivity

switch

to

"250

mV".

If

signal

channel

filtering

is

desired,

set

the

HI-PASS

and

LO-PASS

Filter

switches

as

required.

Connect

the

signal

source

to

the

Model

128A

Input.

1-1

gone.

For

this

reason,

it is advisable

to

read

Section

IV,

the

complete

Operating

Instructions,

to

be

assured

of achieving

optimum

performance.

NOTE:

As

written,

these

condensed

instructions

do

not

apply

to

units

having

either

the

Internal

Oscillator

or

Tuned

Amplifier

modifications.

If

the

unit

in

question

has

either

or

both

of

these

modifications,

the

operator

is

referred

to

Subsections

4.7

and

4.8.

STEP

FOUR

OUTPUT

CONTROLS;

Set

the

Zero

Offset

toggle

switch

to

the

center

(OFF)

position.

Then

set

the

DC

Prefilter

to

100

ms

and

the

Time

Constant

switch

to

0.3

SEC.

STEP

FIVE

FINAL

ADJUSTMENTS:

Rotate

the

Sensitivity

switch

counterclockwise

until

the

panel

meter

begins

to

deflect.

Adjust

the

Phase

Quadrant

switch

and

Phase

dial

for

maximum

meter

indication.

When

the

Sensitivity

and

Phase

adjustments

are

optimally

set,

the

meter

should

indicate

the

maximum

possible

on-scale

reading.

If

the

Overload

light

comes

on,

increase

the

prefilter

and

time

constant

settings.

Also

try

"bracketing"

the

signal

frequency

with

the

HI

PASS

and

LO

PASS

filters.

If

these

techniques

don't

help,

rotate

the

Sensitivity

switch

as

far

clockwise

as is

required

to

eliminate

the

overload.

Set

the

time

constant

as

required

to

reduce

the

output

noise

to

an

acceptable

level.

STEP SIX

READING:

The

input

signal

level

is

read

from

the

panel

meter.

If

the

input

signal

is a

sinewave,

the

meter

directly

indicates

the

rms

amplitude

of

the

input

signal.

However,

if

the

signal

frequency

is

near

enough

to

a

selected

HI

or

LO

PASS

filter

frequency

to

be

influenced

by

the

filter,

the

filter

attenuation

effects

must

be

taken

into

account.

If

the

input

signal

is

not

a

sinewave,

then

the

harmonic

response

of

the

instrument

must

be

taken

into

account

as

well.

1-2

a:

w

u.

-'

Q.

~

~

~

c

0t

-'

~

co

N

...

-'

W

0

i

...

e

::l

'"

u::

SECTION

II

CHARACTERISTICS

2.1 INTRODUCTION

The

Model

128A

Lock-In

Amplifier

enables

the

accurate

measurement

of

signals

contaminated

by

broad-band

noise,

power

line

pickup,

frequency

drift,

or

other

sources

of

interference. It

does

this

by

means

of an

extremely

narrow

band

detector

which

has

the

center

of

its

passband

locked

to

the

frequency

of

the

signal

to

be

measured.

Because

of

the

frequency

lock

and

narrow

bandwidth,

large

improvements

in signal-to-noise

ratio

can

be achieved,

allowing

the

signal

of

interest

to

be

accurately

measured,

even in

situations

where

it is

completely

masked

by noise.

Signals applied

to

the

input

(single-ended or

differential)

1

routed

through

aseries of amplifiers

which

allow

..rll-scale sensitivity ranges

down

to

one

microvolt.

Switch

selectable low-pass

and

high-pass filters allow

considerable

noise

reduction

ahead

of

the

phase-sensitive

detector.

This

pre-detector

noise

reduction

can

be

further

enhanced

by

making

use of

the

optional

plug-in (internal) selective

amplifier. At

the

phase

sensitive

detector,

the

signal is

compared

with

the

reference

signal derived

from

the

experiment.

Only

those

signal

components

which

are

synchronous

with

the

reference

yield

a

net

dc

detector

output.

Noise

and

other

non-synchronous

signals

do

not

contribute

a

net

dc

output,

but

only

ac

fluctuations

which

can

be

reduced

to

any

arbitrary

value

according

to

the

amount

of filtering

selected

with

the

Time

Constant

switch.

This switch allows

time

constants

as large as

100

seconds

to

be

selected,

with

provision for achieving larger

externally

determined

time

constants

if necessary.

Post-detector

dc

amplifiers drive

the

panel

meter

and

signal

output

connectors.

Other

features

include

provision

for

calibrated

zero

suppression of up to

10

x full scale, a

two-position

dc

prefilter,

and

the

capability

of driving

the

reference

input

the

detector

at

double

the

frequency

of

the

signal

applied to

the

Reference

Input

connector

to

facilitate

second

harmonic

measurements.

An

optional

plug-in

oscillator

(internal)

is available for use in

applications

where

the

experiment

does

not

produce

a

reference

signal itself,

but

is capable

of

being

driven

by a signal

furnished

by

the

Lock-In Amplifier.

With its wide range of capabilities

and

ease

of

operation,

the

Model

128A

Lock-In

Amplifier

should

find

extensive

application

in

situations

where

the

accurate

measurement

of signals is

complicated

by

the

presence

of

noise and

interference.

2.2 SPECIFICATIONS

SIGNAL

CHANNEL

(1) INPUT

TYPE

Single-ended

or

differential

as

selected

by

front-panel

switch.

11-'

(2)

INPUT

IMPEDANCE

100

Mr2

shunted

by

no

more

than

20

pF.

(3)

SENSITIVITY

12 full-scale ranges in

1-2.5-10

sequence

from

1

J.1V

to

250

mV.

(4) FREClUENCY

RANGE

0.5

Hz

to

100

kHz.

(5) COMMON MODE

REJECTION

At least

100

dB

at

1kHz.

(6) MAXIMUM COMMON MODE

VOLTAGE

3 V

pk-pk

to

20

kHz;

then

--6

dB/octave

above

20

kHz.

(7)

DETECTOR

BIAS

Internal

network

allows dc bias

current

of

either

polarity

to

be

provided

at

the

"A"

Input

to

facilitate

operation

with

diode

detectors

which

require

biasing.

(See page VII-3

and

Parts

Location

Diagram

on

page

VII-2.)

(8) NOISE

At 1 kHz

the

signal

channel

noise will

not

exceed

10

nV/H

zY2.

(9) LOW PASS

FILTER

Switch

selectable

6

dB/octave

low-pass filter

which

can be

set

to 3 dB

down

frequencies

of

100

Hz,

10

kHz, or MAX

(greater

than

100

kHz).

(10)

HIGH PASS

FILTER

Switch

selectable

6

dB/octave

high-pass filter

which

can be

set

to

3 dB

down

frequencies

of

50

Hz, 5 Hz,

or MIN

(below

0.5

Hz).

(11)

OVERLOAD

DETECT

Front-panel

indicator

lights if

applied

signal plus noise

is large

enough

to

cause

overload

at

any

of several

critical

overload

monitor

points.

(12)

GAIN

STABILITY

(13) GAIN

LINEARITY

0.05%.

(14)

OVERALL

GAIN ACCURACY

±2%.

REFERENCE

CHANNEL

The

Model

128A

reference channel

automatically

locks

onto

and

tracks

an

applied

reference signal over the

entire

operating

frequency

range of

the

instrument.

As a result,

the

instrument

is

immune

to

frequency

and phase

shifts

as

long as

the

reference and signal to be recovered change

together.

(1)

TRACKING

RANGE

5 Hz to

100

kHz (FAST) or

0.5

Hz to

100

kHz

(SLOW) as

determined

by

the

setting

of

two

internal

switches.

Faster

lock-on

time

and slewing

rate

obtained

with

switches

set

to

FAST

make

this range

preferable

except

when

operating

below 5 Hz.

(2) MODES

Either

of

two

modes, f and 2f, can be selected by

means of a front-panel switch. In

the

"f"

position,

the

phase-sensitive

detector

is driven at

the

same

frequency

as

the

applied reference signal. In

the

"2f"

position,

the

phase-sensitive

detector

is driven at twice

the

frequency

of

the applied reference signal

to

facilitate

second

harmonic

measurements.

(3) INPUT IMPEDANCE

10

Mrl

shunted

by

no

more

than

20

pF.

(4) MINIMUM

REFERENCE

SIGNAL

REQUIREMENT

100

mV pk-pk,

any

waveshape crossing its

mean

only

twice each cycle. Minimum

time

required on

either

side

of

the

mean

is

100

ns.

Amplitude

excursions

must

be at least

50

mV on each side

of

the

mean.

Maximum

input

signal is 5 V (pk-to-rnean}. Best phase

accuracy

is

obtained

with

a 1 V rms sinewave.

(5) LOCK-ON TIME

A

function

of internal

switch

setting

as follows.

Selected

Range Lock-On

Time

SLOW (0.5 Hz to

100

kHz)

20

sec. per

octave

FAST (5 Hz to

100

kHz) 2 sec. per octave

(6) PHASE

Calibrated Phase

controls

allow the phase of

the

reference drive to

the

Phase-Sensitive

Detector

to be

set at any angle relative to

the

input

signal.

The

controls

consist of a Phase Dial with arange of

100°

and a Phase

Quadrant

switch

which

provides

incremental phase shifts of

90°.

The

phase

shift

11-2

accuracy of

the

dial is

better

than

0.2

0over the

entire

frequency

range.

The

resolution

of

the

dial is

better

than

0.10. The

incremental

phase shiffs provided by

the

Quadrant

switch are

accurate

to

0.2°.

The

overall

phase accuracy of

the

instrument,

including

shifts

in

both

the reference and signal channels, is typically

better

than

50.

(7)

DETECTOR

BIAS

Internal

network

allows de bias

current

of

either

polarity

to be provided at

the

REF.

IN

connector

to

facilitate

operation

in

situations

where

the

reference

signal is

taken

from

diodes requiring biasing. (See page

VII-6 and Parts Location Diagram

on

page VII-5.)

PHASE

SENSITIVE

DETECTOR,

DC

AMPLIFIER

(1)

OUTPUT

DRIFT

(2)

OVERLOAD

CAPABILITY

1000

times full scale up to a

maximum

at

the

input

of

650

mV rms. Overload capability is

defined

as

the

ratio, at

the

input

of the Model

128A,

of

the

maximum

pk-pk

non-coherent

signal

which

can be

applied

without

overloading the Model

128A

to

the

pk-pk

coherent

signal required to yield full scale

Model

128A

output.

Note

that,

expressed as

the

ratio

of

the

pk-pk

non-coherent

signal

to

the

rms value of

the

coherent

signal

required

for full-scale

output,

this

number

can be as

great

as

2800.

Maximum

acceptable

signal is a

650

mV rms sinewave.

(3)

NON-COHERENT

REJECTION

50

ppm

maximum.

Non-coherent

rejection is

defined

as

that

offset

which

results

from

applying a

non-coherent

signal having a

pk-pk

amplitude

1000

times

the

pk-pk

amplitude

of

the

coherent

signal

required

to

obtain

full-scale

output.

Example: With a

non-coherent

signal applied having a

pk-pk

amplitude

1000

times

the

pk-pk

coherent

signal

required

to

obtain

full-scale

output,

there

will

occur

an

offset

at

the

output

caused by

the

non-coherent

input

signal.

The

amplitude

of this

offset

will be no

greater

than:

50 X

10-

6X

1000

=50 X

10-

3of f.s.

output

=50 mV (f.s. =1 V)

(4) TIME

CONSTANT

Front-panel switch allows selection of 6

dB/octave

filter

time

constants

of 1 ms, 10 ms, and .1 s

through

100

s in 1-3-10 sequence. Also MIN (time

constant

:::=0.7

ms) and EXT, which allows

time

constants

longer

than

100

s to be achieved by means of

external

capacitors. A

separate

front-panel

toggle switch allows

another

6

dB/octave

filter to be

inserted,

if desired.

This filter has a

time

constant

of

either

100

ms or 1 s,

whichever is selected.

(5)

ZERO

OFFSET

A

calibrated,

ten-turn,

Zero

Offset

dial,

with

up to

ten

times full-scale

capability

is provided.

(6) FULL-SCALE

OUTPUT

±1 V.

(7)

OUTPUTS

(a) Panel

meter,

± full scale.

(b)

Front-panel

BNC

connector.

One volt

out

corresponds

to full-scale panel

meter

deflection.

Output

resistance is

600

ohms.

(c) Rear-panel

Recorder

Out

binding posts,

spaced

to

accept

standard

double-banana

connector.

Output

resistance is

600

ohms.

GENERAL

(1) AMBIENT

OPERATING

TEMPERATURE

RANGE

(2)

AUXILIARY

POWER

OUTPUT

±15.5

Vregulated dc

at

20 mA is

provided

at

rear-panel

connector.

(3) POWER

REQUIREMENTS

100-130

Vac

or

200-260

Vac,

50-60

Hz. May also be

powered

from

±24 Vde

source

(such as

batteries).

Power

consumption:

15

watts.

(4) SIZE

17-3/4"

W x

3-1/2"

Hx

14"

D

(45

cm

W x 9 cm H x

36 cm D).

11-3

(5)

WEIGHT

14 Ibs

(6.4

kg).

(6)

MODIFICATIONS

(a) Model

128A/97

Monitor

Modification

Three

rear-panel BNC

connectors

are installed

which

permit

monitoring

of:

(1)

Output

of

Signal

Channel

before

demodulation

(please

note

that

the

Signal Channel

monitor

is provided as

part

of

the

Tuned

Amplifier

modification

as well), (2)

Squarewave

output

of Reference

Channel,

and

(3) Full-wave

demodulated

Mixer

output

before

Time

Constant

filter.

(b) Model

128A/98

Tuned

Amplifier Modification

Internal plug-in

board

is available

which

provides

a

tuned

bandpass

or

notch

characteristic

at a

Q-of-5.

The

frequency

can be

adjusted

over a 3: 1

range by

means

of

arear-panel

adjustment,

and

can be

set

to

any

frequency

from

1 Hz to

100

kHz by changing

capacitors

mounted

on

component

clips

located

on

the plug-in

circuit

board.

(c) Model

128A/99

I

nternal

Oscillator

Modification

An internal low

distortion

oscillator

is available

which

provides asinewave

output

adjustable

from

0-to-l0

V pk-pk

at

600

ohms.

The

frequency

is

adjustable

over

about

a 3: 1 range by

means of a rear-panel

adjustment,

with

the

actual

frequency

range

spanned

by

the

adjustment

being

determined

by a pair of

internal

capacitors

mounted

on

the

oscillator

circuit

board.

Operation

from

about

1 Hz

to

100

kHz is

possible. This

option,

in

conjunction

with

the

2f

mode

of

operation,

is

particularly

useful for

harmonic

detection

where

the

modulation

frequency

must

be at

one

half

the

detected

frequency.

SECTION

III

INITIAL

CHECKS

3.1 INTRODUCTION

The

following

procedure

is

provided

to facilitate initial

performance

checking

of

the

Model 128A. In general, this

procedure

should

be

performed

after

inspecting

the

instrument

for

shipping

damage

(any

noted

to

be

reported

to

the

carrier

and

to

Princeton

Applied

Research

Corporation),

but

before

using

the

instrument

for

experimental

measurements.

Should

any

difficulty

be

encountered

in carrying

out

these checks,

contact

the

factory

or

one

of

its representatives. It

might

be

noted

that

it is

not

the

purpose

of these

checks

to

demonstrate

that

the

instrument

meets

all specifications,

but

rather

simply

to

show

that

it is

functioning

normally.

If normal

indications

e

obtained

for

the

functions

checked,

one

may

reasonably

assume

that

those

functions

which

are

not

checked

are

working

properly

as well.

3.2 EQUIPMENT NEEDED

(1) Sinewave Oscillator

to

provide

a

100

mV rms sinewave

at 1 kHz.

NOTE:

If

the

instrument

to

be

checked

is

equipped

with

the

Tuned

Amplifier

modification,

then

the

oscillator

will have

to

provide a

100

mV rms

sinewave at

the

tuned

frequency.

If

the

instrument

in

question

is

equipped

with

the

Internal Oscillator

modification,

no

external

oscillator will be

required.

Th is applies

whether

or

not

the

unit

is

equipped

with

the

Tuned

Amplifier

modification.

(2) General

purpose

oscilloscope. This

item

is

required

only in

the

case

of

units

having

the

Tuned

Amplifier

modification.

'3) Suitable cables

for

interconnecting

the

above instru-

ments.

3.3 PROCEDURE

(1) Check

the

position

of

the

rear-panel

115/230

switch.

Be sure

the

number

showing

in

the

window

corre-

sponds

to

the

line voltage

to

be used.

(2) With the Power switch

set

to

OFF,

plug in

the

line

cord.

(3)

Set

the

Model

128A

controls

as follows.

Input

Selector: A

Sensitivity:

100

mV

Filters

HI-PASS: MIN.

LO-PASS: MAX.

Phase

Quadrant

switch:

270°

Phase dial:

90°

Mode: f

Zero

Offset

switch:

OFF

(center

position)

111·1

dial:

1.00

(one

turn

from

fully

counterclockwise

position)

Time

Constant:

.3 SEC.

DC Prefilter:

OUT

Reference

Tracking-Rate

switches

(two

internal

switches);

FAST

(unless

unit

is

equipped

with

Tuned

Amplifier'

or Internal Oscillator set for

frequency

below

5 Hz, in

which

case

switches

should

be

set

to SLOW). NOTE:

Instruments

are

normally

shipped

with

these

switches set

to

FAST.

Power.

ON

(4) Applies

only

to

units

not

equipped

with

the

Internal

Oscillator

modification.

If

the

Model

128A

has this

modification,

go

to

step

5.

Connect

the

output

of

the

external

oscillator

(set for

100

mV rms sinewave

out

at 1 kHz)

to

both

the

"A"

and

Reference

Inputs. If

the

unit

in

question

has

the

Tuned

Amplifier

modification,

set

the

oscillator

to

the

tuned

frequency

specified

when

the

unit

was

ordered.

(5) Applies

only

to

units

having

the

Internal Oscillator

modification.

Connect

a

cable

from

the

rear-panel

REF.

OSC.

OUT

connector

to

the

front-panel

"A"

Input.

There

is no

need

to

connect

th is signal to

the

Reference

Input

connector

(labeled MONITOR in

units

equipped

with

the

Oscillator

modification).

The

connection

to

the

Reference

Channel of

the

Model

128A

is

made

internally

at

the

factory.

The

rear-panel

REF.

AM-

PLITUDE

adjustment

should

be

set

so

that

the

amplitude

of

the

signal at

the

REF.

OSC.

OUT

connector

is

100

mV rms. An

accurate

ac

voltmeter

may be useful

for

setting

this

level (units leave the

factory

set

for

a

nominal

100

mV rrns

out).

(6) Applies

only

to

units

having

the

Tuned

Amplifier

modification.

In

the

case

of

units

not

having

this

modification,

go d irectl y

to

step

7.

(a)

Connect

the

oscilloscope to

the

rear-panel SIG.

MON.

connector.

(b)

Vary

the

frequency

of

the

signal applied to

the

"A"

Input

(use

the

rear-panel

REF.

OSC.

FREQ.

ADJ.

control

in

units

equipped

with

an Internal

Oscillator)

for

peak

signal

amplitude

as observed

with

the

oscilloscope.

(7)

Set

the

Phase

Quadrant

switch

to

0°.

Then

adjust

the

Phase dial

for

"0"

panel

meter

indication.

(8)

Set

the

Phase

Quadrant

switch

back

to

270°.

The

panel

meter

should

indicate

full scale to

the

right ±a

few

percent

of full scale.

The

accuracy

of

th is readinq

will

depend

on the

amplitude

accuracy of the signal

applied

to

the

"A"

Input.

(9)

Adjust

the

amplitude

of

the

signal applied to

the

"A"

Input

as required to

obtain

exactly

full-scale panel

meter

indication.

(10)

Set

the

Phase

Quadrant

switch to

180°.

The

panel

meter

should

indicate

"0"

±5%

of

full scale.

(11)

Set

the

Phase

Quadrant

switch

to

90°.

The

panel

meter

should

indicate

negative full scale ±5% of full

scale.

(12)

Set

the

Phase

Quadrant

switch to

270°

to restore

the

111-2

positive full-scale panel

meter

indication.

(13)

Set

the

Zero

Offset

toggle switch to "+".

The

panel

meter

indication

should

go to

"0"

±5% of full scale.

(14) Begin

rotating

the

Offset

dial

counterclockwise.

The

panel

meter

indication

should

increase linearly, track-

ing

the

dial setting. When

the

dial is fully

counter-

clockwise,

the

panel

meter

should

indicate full scale

±5%. Reset

the

Zero

Offset toggle switch to

the

center

(OFF)

position.

This

completes

the

initial checks. If

the

indicated results

were

obtained,

one

can be reasonably sure

that

the Model

128A

is

functioning

normally.

SECTION

IV

OPERATING

INSTRUCTIONS

4.1 INTRODUCTION

Even

though

operation

of

the

Model

128A

is

straight-

forward,

there

are a

number

of

factors

of

which

the

operator

should

be aware

to

be assured of achieving

optimum

performance

in all

situations.

This

section

of

the

manual

treats

these

considerations

in

some

detail.

Topics

covered include

grounding,

noise

performance,

harmonic

sensitivity,

operation

in

conjunction

with

the

plug-in

accessories,

and

others.

For

an overall

"quick

look"

at

how

the

instrument

is

operated,

the

operator

is

referred

to

Section

I,

the

condensed

operating

instructions.

4.2

PRELIMINARY

CONSIDERATIONS

4.2A

POWER

REQUIREMENTS

The

Model

128A

requires

100-130

V ac

or

200-260

V ac,

50-60

Hz.

The

power

consumption

is

15

watts.

The

unit

may also be

powered

by

batteries

by

applying

±24 V

to

the

appropriate

pins

of

the

rear-panel octal-

connector

(see

BATTERY

OPERATION,

page

IV-l0).

Arear-panel slide

switch

determines

whether

the

ac

power

circuits

are

connected

for

operation

from

100-130

V or

from

200·260

V.

For

operation

from

100-130

V,

"115"

should

show

in

the

window.

For

operation

from

200-260

V,

"230"

should

show.

4.28

FUSING

The

Model

128A

is

protected

by a single fuse

mounted

on

its rear panel. A

slow-blow

1/4

A fuse is used for

operation

from

115

V. A slow-blow

1/10

A fuse is used for

operation

from

230

V.

It

occasionally

happens

that

a

slow-blow

fuse

fails in

shipment

as a

result

of

shock

and

vibration.

Hence,

if

the

fuse is

found

to be bad

when

the

instrument

is

operated

for

the

first

time

it is advisable to

try

and

change

the

fuse. If

normal

operation

follows,

chances

are

there

are

no

other

problems.

However, if

the

replacement

fuse fails,

there

is

something

wrong

which

will have to be

corrected

before

proceeding.

4.2C

WARM-UP

PERIOD

For

most

applications,

five

minutes.

Where it is

desired

to

achieve

the

best

possible gain

and

output

stability,

allow an

hour.

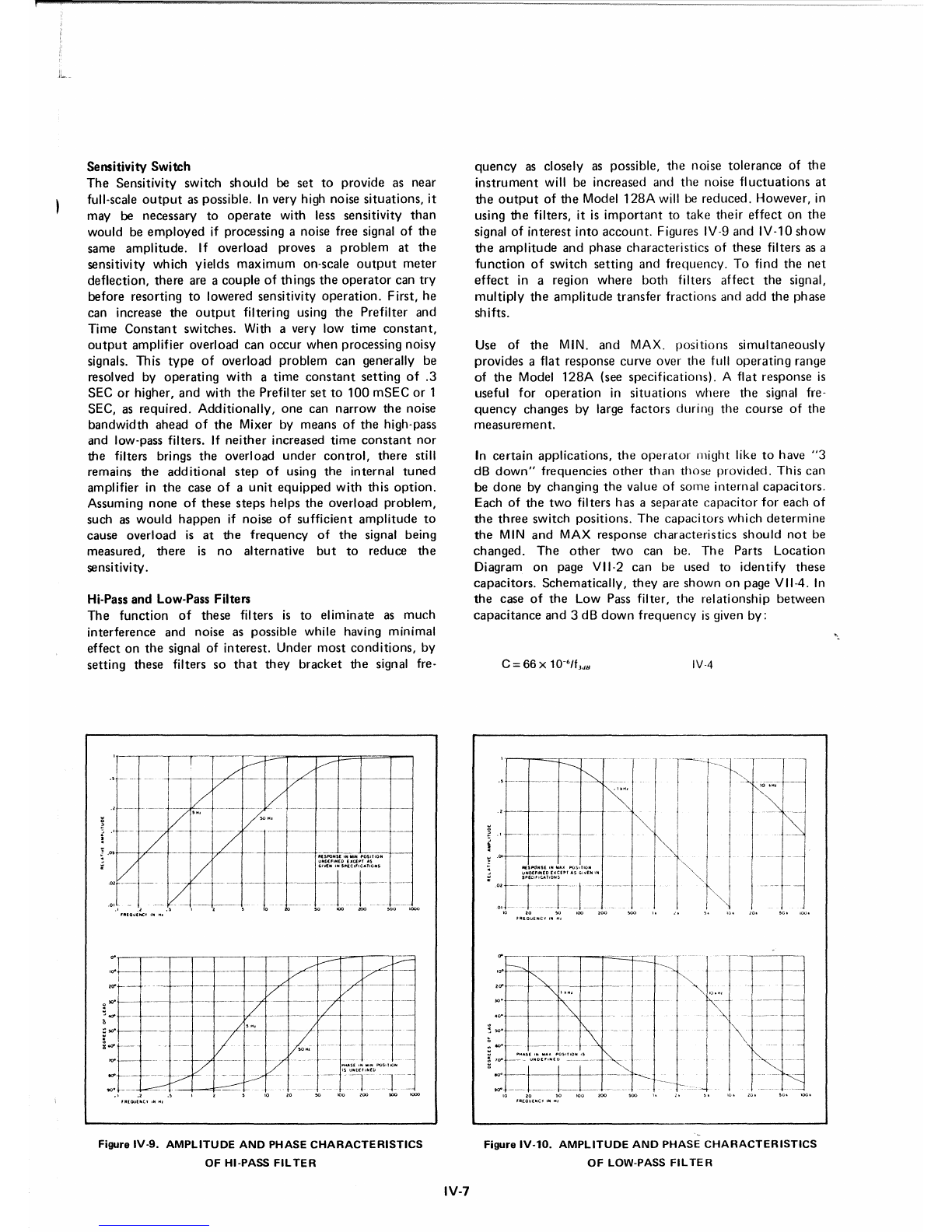

4.20

OPERATING

FREQUENCY

Although

one

can,

in principle,

make

equally

accurate

measurements

at any

frequency

within

the

operating

range

of

the

instrument,

operation

is

simplest

and

least

subject

to

error

over arange having as its

lower

limit,

perhaps

a few

hundred

Hz,

and

as its

upper,

perhaps

10k

Hz.

At

very low

frequencies,

phase

offsets

occur

which

could

matter

if

one

is

interested

in

the

absolute

phase of

the

input

signal.

Another

problem

of

low

frequency

operation

is

that

of

l/f

noise, including

both

that

which

develops

in

the

Model

128A

and

that

which

originates

in

the

experiment

itself

to

degrade

the

signal-to-noise

ratio

ahead

of

the

lock-in

amplifier. Increased

response

and

settling

time

could

be a

IV-1

significant

problem

if

one

were

operating

in

conjunction

with

the

optional

plug-in

tuned

amplifier.

At high fre-

quencies,

radiation

and

associated

pick-up

tend

to

be

bothersome.

Another

high

frequency

problem

is

that

of

signal

attenuation

as a result

of

the

input

cable

capacitance.

Th is is especially a

problem

when

working

from

a high

source

resistance.

Other

frequencies

to avoid are

60

Hz

and

its

lower

order

harmonics.

By avoiding

these

frequencies,

the

operator

assures

that

he will be

measuring

the

signal

of

interest

only,

uninfluenced

by

power

frequency

pick-up,

either

internal

or

external.

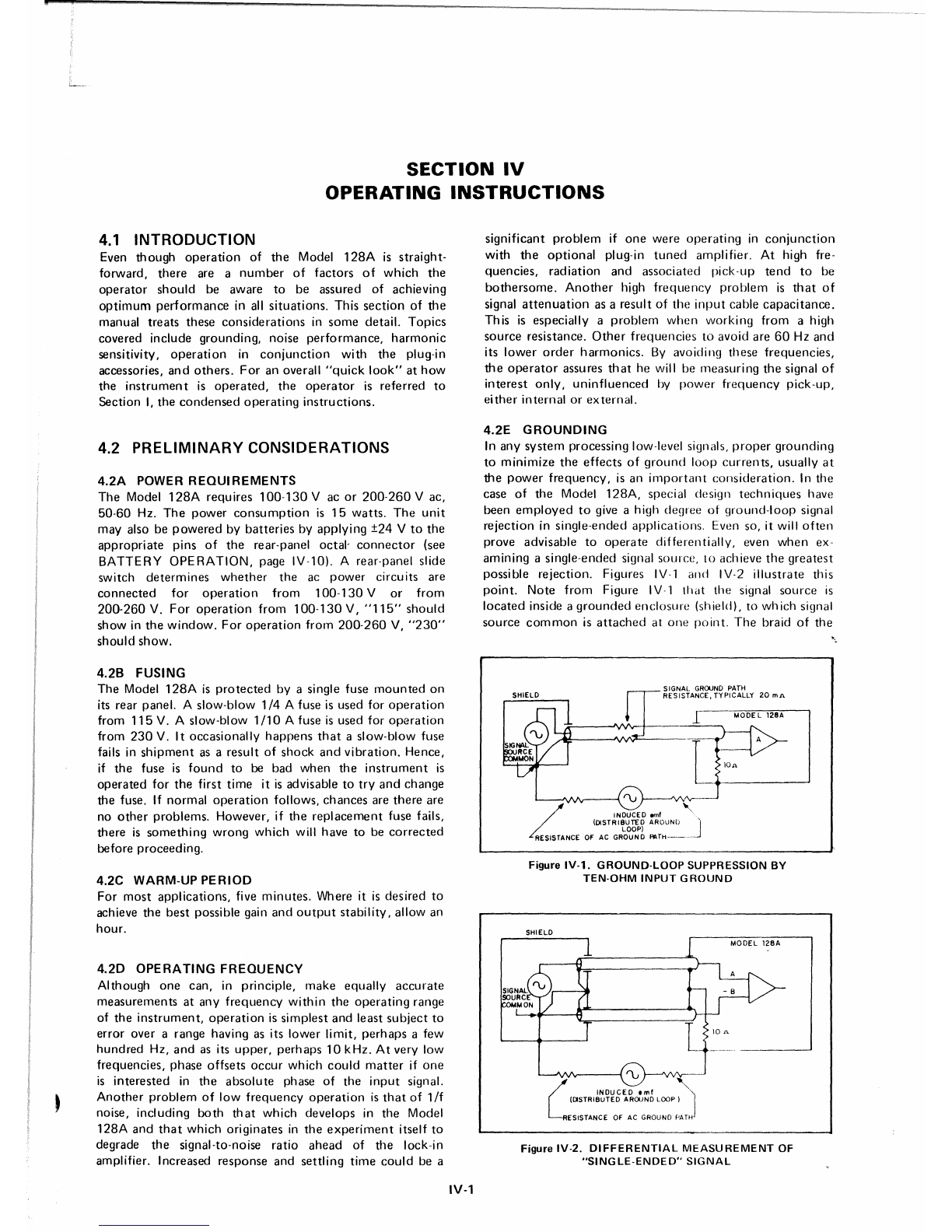

4.2E

GROUNDING

In

any

system

processing low-level signals,

proper

grounding

to

minimize

the

effects

of

ground

loop

currents,

usually

at

the

power

frequency,

is an

important

consideration.

In

the

case of

the

Model

128A,

special design

techniques

have

been

employed

to

give a high

degree

of

ground-loop

signal

rejection

in

single-ended

applications.

Even so, it will

often

prove advisable to

operate

differentiallv.

even

when

ex-

amining

asingle-ended signal

source,

10 achieve

the

greatest

possible

rejection.

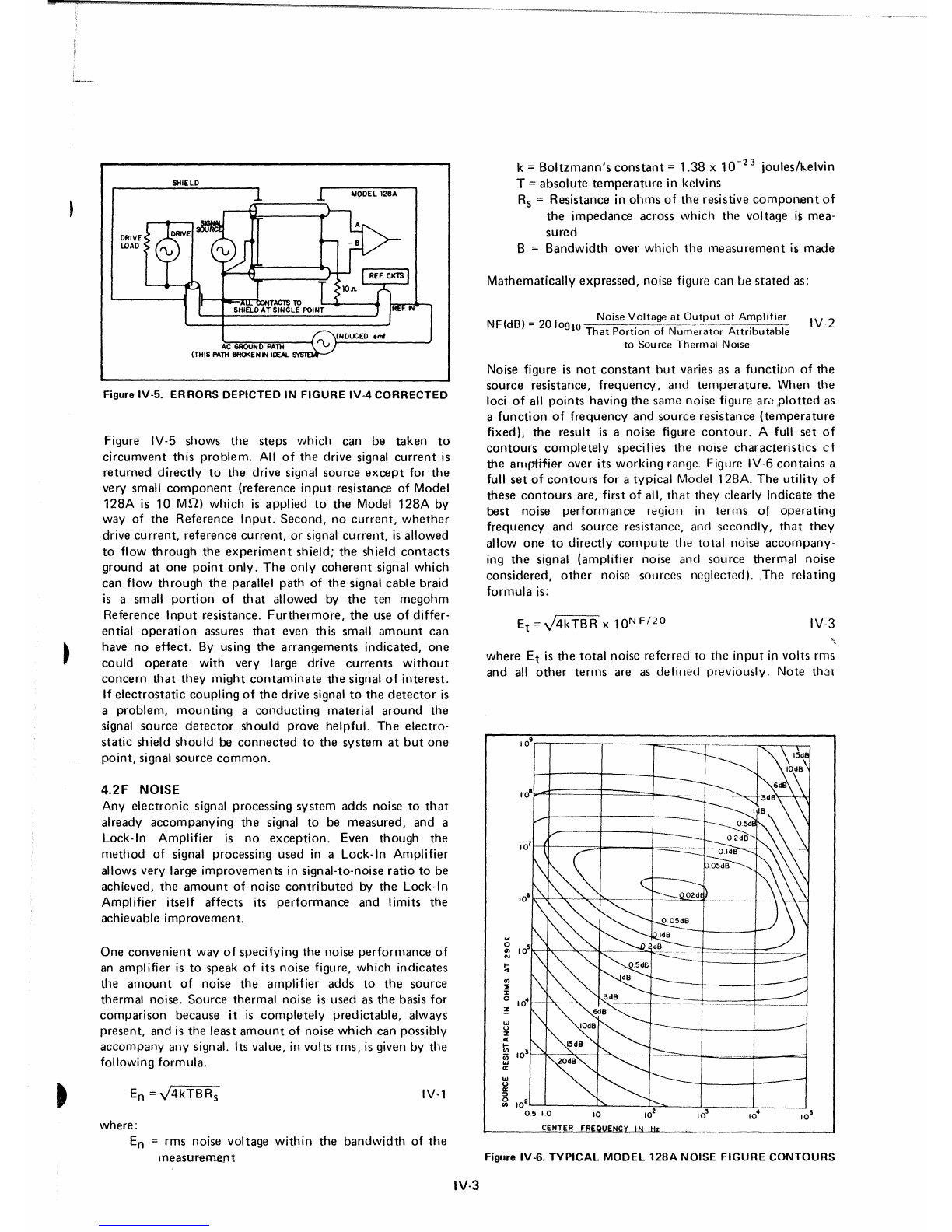

Figures IV-l

and

IV-2

illustrate

this

point.

Note

from

Figure IV-l

that

the

signal

source

is

located

inside a

grounded

enclosure

(shield), to

which

signal

source

common

is

attached

at

one

point.

The

braid of

the

/

'U

,

INDUCED emf

(DISTRIBUTED AROUND

LOOP)

RESISTANCE OF AC GROUND

PATH--J

Figure

IV·l.

GROUND·LOOP

SUPPRESSION

BY

TEN-OHM

INPUT

GROUND

SHIELD

l_

10"

L

INDUCE~.mf

'"

(CJSTRIBUTED AROUND LOOP) J

RESISTANCE OF AC GROUND PATH

Figure

IV-2.

DIFFERENTIAL

MEASUREMENT

OF

"SINGLE-ENDED"

SIGNAL

Figure

IV-4.

EXAMPLE

OF

EVERYTHING

"DONE

WRONG"

The

reduction

of

power

frequency

interference

is

not

the

only

benefit

to be

derived

from

proper

grounding

and

differential

operation.

A

much

more

serious

source

of

interference

is

coherent

interference

at

the

signal

frequency

which

results

when

drive signal

current

is

allowed

to

flow

through

the

braid

of

the

signal

cable.

Figures IV-4

and

IV-5

are

provided

to

illustrate

this

problem

and

the

steps

which

can

be

taken

to

prevent

it.

To

begin

with,

Figure

IVA

shows

the

experiment

with

just

about

everything

possible

"done

wrong".

The

lock-in

amplifier

is

operated

single-

ended.

The

ground

connections

at

the

experiment

are

made

to

the

enclosure,

allowing

currents

to

flow

through

it,

and,

in

particular,

the

drive signal

currents

have

the

opportunity

to

flow th rough

the

braid

of

the

signal cable.

The

drive

signal, in

addition

to

providing

the

reference

input

signal

to

the

Model

l28A,

can be

presumed

to

be driving

other

components

of

the

system

as well.

Depending

on

the

nature

of

the

experiment,

these

currents

could

range

from

very

small to

quite

large,

perhaps

even

amperes

if

the

experiment

involves driving a

low

impedance

coil.

Note

that

the

various

loads

for

the

drive

are

represented

by a single

resistor

returned

to

ground

somewhere

on

the

enclosure.

Most-of

this

drive

signal

current

can

be

presumed

to

flow

through

the

shield

back

to

the

drive

signal

source.

However,

asmall

but

significant

part

of it will

flow

through

the

parallel

path

consisting

of

the

braid

of

the

signal cable,

the ten

ohm

resistor,

and

the

braid

of

the

reference

signal

cable.

The

voltage

drop

of

this

current

across

the

resistance

of

the

signal

cable

brai-J,

even

though

attenuated

by

the

ratio

of

the

ten

ohm

resistor

to

the

braid

resistance, can

constitute

a

serious

source

of

interference

at low signal levels,

particular-

ly in

that

this

interference

is

coherent,

in

phase,

and

directly

adds

to

the

signal of

interest.

It is

not

hard

to

envision

situations

where

this

interference

signal

could

well

be larger at

the

Input

of

the

lock-in

amplifier

than

the

signal

of

interest

itself.

signal

cable

is

grounded

directly

to signal

source

common

as

well,

thereby

assuring

that

no signal

currents

or

ground-

loop

currents

will

flow

through

the

shield,

'a

desirable

condition

for

the

best

possible

shielding.

The

Model

l28A

is

operated

single-ended,

using

the

"A"

input.

Note

that

the

"low"

side of

the

amplifier

input

is

not

grounded

to

the

chassis

directly

but

by

way

of

a

ten

ohm

resistor.

Further

note

that

the

braid

of

the

signal

cable

is

returned

to

this

resistor,

and

not

to

the chassis. A

ground

loop

generator

is

indicated

as

being

connected

between

the

chassis of

the

Model

l28A

and

siqnal

source

common.

This

path

would

ordinarily

consist

of

the

ac

ground

"third

wire",

paralleled

by

the

braids

of

other

cables

connecting

the

system

components.

The

ground

loop

generator

will

cause

currents

at

the

power

frequency

to

flow

through

the

braid of

the

signal cable,

through

the

ten

ohm

resistor,

and

back

through

the

ac

wound

path

to

complete

the

loop.

Because

of

the

ten

ohm

ground

employed

in

the

Model

l28A,

these

currents

are

attenuated

over

what

they

would

be if

the

Model

128A

input

were

returned

directly

to

the

chassis.

More

importantly,

most

of

the

ground

loop

signal is

dropped

across

the

ten

ohm

resistor

and

little

across

the

braid of

the

signal

cable,

the

ratio

being

the

ten

ohms

of

the

resistor to

the

10 to

20

milliohms

(typical)

of

the

braid

resistance, As far as

the

input

of

the

Model

l28A

is

concerned,

the

ground

loop

signal is

reduced

by this

ratio,

and

the

ground

loop

interference

is

thus

perhaps

a

factor

of

five

hundred

or

one

thousand

less

than

would

be

the

case

without

the

ten

ohm

qr

ound.

However, in

some

appl

ications, th is

would

not

be

enough.

Figure IV-2

shows

how

this

same

signal

could

be

measured

operating

the

Model

128A

differentially.

In

this

instance,

the

Model

l28A

Input

Selector

is

set

to

"A-B"

and

two

input

cables

are used,

one

connected

to

the

signal

source

and

the

other

to siqnal

source

common.

At

the

source

end,

the

braid

of

both

cables is

returned

to

signal

source

common.

At

the

lock-in

amplifier

end,

the

ten

ohm

ground

serves to

attenuate

the

wound

loop

currents

and

maintain

a

small

ground

loop

signa!

drop

across

the

braids

the

same

as

in Figure

IV-l.

However,

in

the

first

instance,

the

amplifier

"looked"

at

the

potential

difference

between

the

center

conductor

of

the

cable

and

the

braid.

In

the

second,

it sees

the

potential

difference

between

the

"A"

Input

and

"8"

Input.

The

ground

loop

siqnal

current

flowing

in

the

signal

cable

braid is of no

consequence.

The

very high

common

mode

rejection

of

the

amplifier

assures

that

common

mode

power

frequency

pickup

will

not

be a

problem

either.

However,

when

operating

differentially,

it is

important

to

take

a

little

trouble

to assure

that

common

mode

inter-

ference arising in

ground

loops

is

just

that,

that

is,

without

a

significant

differential

component.

This

should

not

prove

a

problem

as

lonq

as

both

signal

cables

follow

the

same

path,

Figure IV-3

shows

the Model

128A

operated

differentially

to

measure

an

"off

~JI

ound

" siqn al.

The

most

important

consideration

in an

application

of this

type

is to be sure

that

the

common

mode

siqnal

component

is

not

so large as

to

exceed

the

common

mode

input

limit

of

the Model

128A.

(See Specs.)

IV-2

DRIVE

~

~:£"

0'"''''''

,.0'"

-1

AS

FUNCTION

OF

EXPERIMENTAL

PARAMETEI

L..-

...I

Figure

IV-3.

DIFFERENTIAL

MEASUREMENT

OF

"0

FF-GROUND"

SIGNAL

DRIVE

LOAD

k=

Boltzmann's

constant

=

1.38

x

10-

2 3 joules/kelvin

T =

absolute

temperature

in kelvins

Rs=Resistance in

ohms

of

the

resistive

component

of

the

impedance

across

which

the

voltage

iii

mea-

sured

B =

Bandwidth

over

which

the

measurement

is

made

Mathematically

expressed,

noise figure

can

be

stated

as:

NF(dB)

=

2010

9 10 Noise

V.olta~_~~g~!':l_~t

of

Amplifier

That

Portion

of

Numerator

Attributable

IV-2

to

Source

Thermal

Noise

Figure IV-6.

TYPICAL

MODEL

128A

NOISE

FIGURE

CONTOURS

~~

where

Etis

the

total

noise

referred

to

the

input

in volts rrns

and

all

other

terms

are as

defined

previously.

Note

thar

IV-3

10~

Et

=V4kTBR

X

10NF/20

o

11>

N

~

Ul

2

:r

o

~

""

o

z

c(

Ii;

~

0:

""

U

~

~

102::-:~

__

~~---9:::'-'-_--.-l.-

__

.L,

__

--.J

0.5

10

CENTER fR

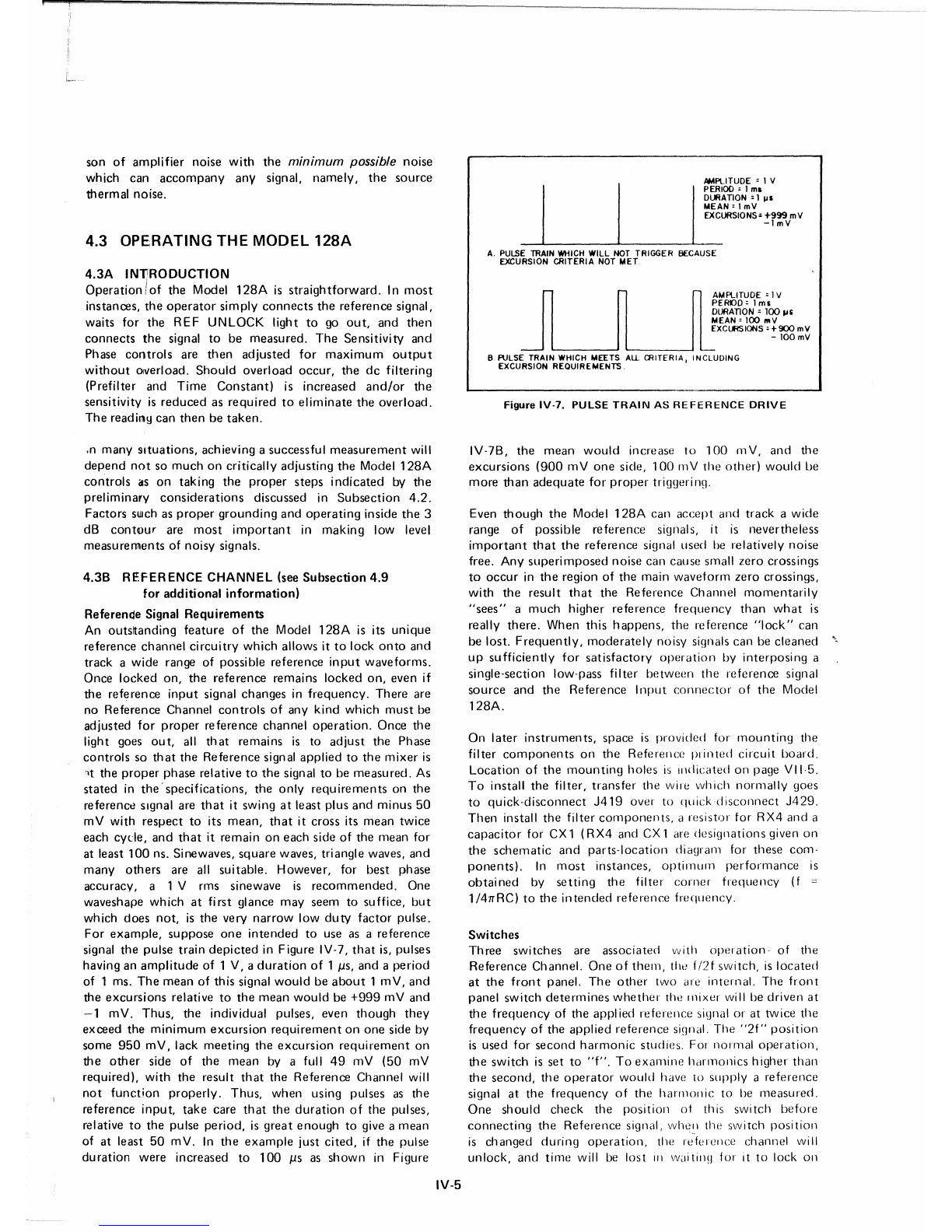

Noise figure is

not

constant

but

varies as a

function

of

the

source

resistance,

frequency,

and

temperature.

When

the

loci

of

all

points

having

the

same

noise figure are

plotted

as

a

function

of

frequency

and

source

resistance

(temperature

fixed),

the

result

is a noise figure

contour.

A full

set

of

contours

completely

specifies

the

noise

characteristics

cf

the

antpti#er

ruler its

working

range. Figure IV-6

contains

a

full

set

of

contours

for a

typical

Model

128A.

The

utility

of

these

contours

are, first of all,

that

they

clearly

indicate

the

best

noise

performance

region in

terms

of

operating

frequency

and

source

resistance,

and

secondly,

that

they

allow

one

to

directly

compute

the

total

noise

accompany-

ing

the

signal

(amplifier

noise

and

source

thermal

noise

considered,

other

noise

sources

neglected).

.The

relating

formula

is:

IV-l

4.2F NOISE

Any

electronic

signal processing

system

adds

noise to

that

already

accompanying

the

signal to be

measured,

and

a

Lock-In

Amplifier

is no

exception.

Even

though

the

method

of signal processing

used

in a Lock-In

Amplifier

allows very large

improvements

in signal-to-noise

ratio

to be

achieved,

the

amount

of noise

contributed

by

the

Lock-In

Amplifier itself

affects

its

performance

and

limits

the

achievable

improvement.

Figure IV-5

shows

the

steps

which

can be

taken

to

circumvent

this

problem.

All

of

the

drive signal

current

is

returned

directly

to

the

drive signal

source

except

for

the

very small

component

(reference

input

resistance of Model

128A

is 10

MS1)

which

is

applied

to

the

Model

128A

by

way of

the

Reference

Input.

Second,

no

current,

whether

drive

current,

reference

current,

or signal

current,

is

allowed

to

flow

through

the

experiment

shield;

the

shield

contacts

ground

at

one

point

only.

The

only

coherent

signal

which

can

flow

through

the

parallel

path

of

the

signal cable braid

is a small

portion

of

that

allowed by

the

ten

megohm

Reference

Input

resistance.

Furthermore,

the

use of

differ-

ential

operati

on assures

that

even th is small

amou

nt

can

have no

effect.

By using

the

arrangements

indicated,

one

could

operate

with

very large drive

currents

without

concern

that

they

might

contaminate

the

signal

of

interest.

If

electrostatic

coupling

of

the

drive signal

to

the

detector

is

a

problem,

mounting

a

conducting

material

around

the

signal

source

detector

should

prove

helpful.

The

electro-

static

shield

should

be

connected

to

the

system

at

but

one

point,

signal

source

common.

Figure IV-5.

ERRORS

DEPICTED

IN

FIGURE

IV-4

CORRECTED

One

convenient

way

of

specifying

the

noise

performance

of

an

amplifier

is

to

speak

of

its

noise

figure,

which

indicates

the

amount

of noise

the

amplifier

adds

to

the

source

thermal

noise.

Source

thermal

noise is used as

the

basis for

comparison

because

it is

completely

predictable,

always

present,

and

is

the

least

amount

of noise

which

can

possibly

accompany

any

signal. Its value, in volts rms, is given by

the

following

formula.

where:

En =rms noise voltage

within

the

bandwidth

of

the

measurement

IV·3

with

anoise figure of 3 dB,

the

amount

of

noise

contributed

by

the

amplifier

is 1.4

times

the

source

thermal

noise.

At

1.4

times

the

thermal

noise,

the

amplifier

noise

just

begins

to

be

noticeable.

At

lower

noise

figures,

the

amplifier

for

all

practical

purposes

may

be

regarded

as

noiseless.

Generally

speaking,

if

one

can

operate

anywhere

inside

the

3 dB

contour,

amplifier

noise

considerations

may

be

neglected.

As critical as

amplifier

noise is in

certain

applications,

it is

nevertheless

possible

to

overemphasize

its general

impor-

tance.

For

example,

if

the

signal

amplitude

is

significantly

higher

than

the

amplifier

noise,

the

subject

becomes

purely

academic.

Similarly,

if

preamplification

is

provided

ahead

of

the

Model

128A,

with

the

result

that

the

amplified

source

noise at

the

input

to

the

Model

128A

is far

greater

than

the

amplifier

noise,

there

is

little

point

in striving to

operate

inside

the

3 dB

contour

of

the

Model

128A.

However,

where

a

preamplifier

is

used,

it is

important

that

these

same

considerations

be

carefully

evaluated

for

the

preamplifier.

In

other

words,

when

using a

preamplifier,

try

to

operate

inside

the

3 dB

contour

of

the

preamplifier.

A

quick

check

of

Fiqure iV-G

followed

by a

computation

of

the

total

noise

(Equation

IV-3)

should

give

one

arealistic

idea of the

importance

of

amplifier

noise

considerations

to

the

measurement

at

hand.

Where

amplifier

noise is a

consideration,

one

should

try

to

operate

inside

the

3 dB

contour

by

appropriately

adjusting

the

operating

frequency

or