EG&G ORTEC 474 Service manual

n

Model

474

Tinning

Filter

Amplifier

Operating

and

Service

Manual

Model

474

Timing

Filter

Amplifier

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

12"

on

rear

panel

Printed

in

U.S.A.

2946

02C

0979

STANDARD

WARRANTY

FOR

EG&G

ORTEC

INSTRUMENTS

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

one

year

from

the

date

of

delivery.

EG&G

ORTEC

s

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

or

use

of

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

oives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

purchase

order

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obligation

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

EG&G

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing

or

by

telephone

[(615)

482-4411],

of

the

nature

of

the

fault

of

the

instrument

being

returned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

CONTENTS

Page

WARRANTY

PHOTOGRAPHS

1.

DESCRIPTION

1

2.

SPECIFICATIONS

.

i

2.1.

Performance

1

2.2.

Controls

1

2.3.

Input

2

2.4.

Outputs

2

2.5.

Electrical

and

Mechanical

2

3.

INSTALLATION

2

3.1.

General

2

3.2.

Connection

to

Power

2

3.3.

Input/Output

Connections

2

4.

OPERATING

INSTRUCTIONS

2

5.

CIRCUIT

DESCRIPTION

3

6.

MAINTENANCE

3

6.1.

Corrective

Maintenance

3

6.2.

Factory

Service

3

7.

APPLICATION

NOTES

4

7.1.

General

4

7.2.

Constant-Fraction

Timing

with

Germanium

Detectors

4

7.3.

Nanosecond

Fluorescence

Spectrometry

5

Schematic

474-0201-SI

ILLUSTRATIONS

Fig.

7.1.

Gamma-Gamma

Coincidence

System

Using

a

Plastic

Scintillator

and

and

a

Large

Ge(Li)

Coaxial

Detector

5

Fig.

7.2.

Nanosecond

Decay

Time

Fluorescence

Spectrometer

System

6

Fig.

7.3.

Lifetime

Spectrum

of

Quinine

Sulfate

in

Sulfuric

Acid

6

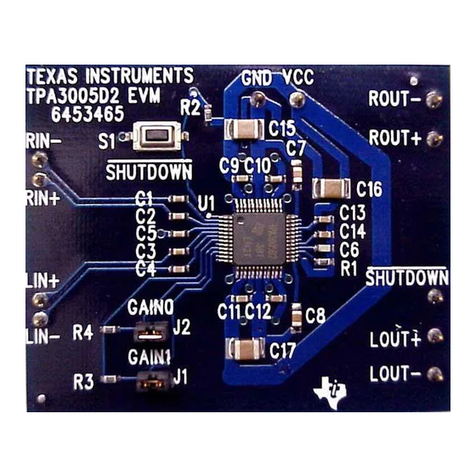

FILTER

RMP

COARSE

6AIN

FINE

6AtN

■-

•2*

.

INTEORATEInSCC

I

Q

■■■

..■

■■

:§^;r•

:^r''■

•v^

'

-;.V"

ORTEC

474

TIMING

FILTER

AMPLIFIER

1.

DESCRIPTION

The

ORTEC

474

Timing

Filter

Amplifier

is

a

NIM-standard

module

for

use

where

a

wide-band

fast,

variable

RC

filter

amplifier

with

high

drive

and

variable

gain

is

needed.

Fea

tures of

the

474

include

a

wide

gain-control

range,

sepa

rately

selectable

RC

integrate

and

differentiate

time

constants

in

the

nanosecond

region,

pole-zero

com

pensation,

and

drive

capability

sufficient

for

use

with

son

or

icon

systems.

The

input

signals

are

dc

coupled

into

an

impedance

of

about

icon.

The

acceptable

amplitude

range

for

the

linear

input,

to

retain

its

linearity,

is

Oto

±1

V.

The

474can

operate

with

an

input

dc

offset

where

the

maximum

total

input

signal

range,

including

the

offset,

does

not

exceed

the

limits

of

±5

V.

Input

signals

may

be

either

positive

or

negative

unipolar,

or

they

can

be

bipolar

with

either

a

positive

or

negative

lobe

leading.

The

output

polarity

can

be

switch-selected

to

either

duplicate

or

invert

the

input

polarity.

Protection

is

provided

for

input

voltages

of

up

to

±100

V

at

a

10%

duty

cycle

integrated

over

1

second.

The

gain

for

midband

frequencies

can

be

set

at

any

value

from

X2

through

X250,

using

six

coarse

gain

settings

and

a

fine

gain

control,

which

is

a

single-turn

potentiometer.

The

gain

factors

are

selected

to

provide

range

overlap

and

to

assure

continuously

adjustable

gain

control

through

out

the

full

range.

Two

6-posltlon

switches

permit

the

separate

selection

of

RC-integrate

and

RC-dlfferentlate

time

constants.

The

integrate

time

constant

can

deselected

from

10

ns

(switch

set

at

Out)

through

500

ns.

The

differentiate

time

constant

can

be

selected

from

20

ns

through

500

ns

or,

when

set

at

Out,

at

150

MS.

Thus

the

input

pulses

can

be

reshaped

to

provide

a

consistent

risetlme

and

decay

time

for

compati

bility

with

the

application

requirements.

The

linear

output

pulses

can

be

either

unlpolaror

bipolar,

depending

on

the

type

of

Input

pulses

that

are

furnished

to

the

474.

When

the

front

panel

toggle

switch

selects

Invert,

the

output

Is

the

opposite

polarity

to

the

input

or,

when

the

toggle

switch

selects

Noninvert,

the

polarities

are

the

same.

The

474

is

capable

of

driving

a

500

load

up

to

±5

V

with

no

degradation

of

the

performance

specifi

cations.

The

ORTEC

474

Timing

Filter

Amplifier

Is

a

NIM-standard

single-width

module;

the

front

panel

measures

1.35

by

8.714

In.,

which

is

in

accordance

with

TID-20893

(Rev).

It

is

intended

for

installation

and

operation

in

a

standard

enclosure,

suoh

as

the

ORTEC

401/402

Series

of

Bins

and

Power

Supplies.

The

module

accepts

all

of

its

required

operating

power

from

the

power

supply

that

Is

attached

to

the

bin.

2.

SPECIFICATIONS

2.1.

PERFORMANCE

INPUT

AMPLITUDE

RANGE

0

to

±1

V

linear

signal,

0

to

±5

V

offset,

maximum

input

±5

V

total.

OUTPUT

AMPLITUDE

RANGE

0

to

±5

V

linear

onto

a

50n

cable

and

load.

RISETIME

<10

ns

with

filter

Out,

or

-2.2

r,

for

other

Integrate

settings.

NOISE

For

maximum

gain,

rms

noise

referred

to

the

input

is

^10

mV

with

n

=

rd

=

200

ns,

or<50

mV

with

filter

Out;

measurements

made

with

an

HP

3400A

true

rms

meter.

NONLINEARITY

<±0.05%

at

midband

frequency

over

±5

V

range.

TEMPERATURE

INSTABILITY

DC

Level

<±25

mV/°0

referred

to

the

output.

Gain

<0.06%/°

0.

OPERATING

TEMPERATURE

RANGE

0

to

50°

C

(273

to

323

K).

2.2.

CONTROLS

COARSE

GAIN

Front

panel

6-posltion

switch

to

select

XI,

X2,

X4,

X6,

XI0,

or

X20

gain

factor.

FINE

GAIN

Front

panel

single-turn

potentiometer,

con

tinuously

adjustable

from

X2

to

XI

2.5.

POLE

ZERO

ADJUST

Front

panel

screwdriver

adjust

ment

to

cancel the

pole

associated

with

the

input

signal

such

as

that

derived

from

the

preamplifier

clipping

net

work.

DIFFERENTIATE

Front

panel

6-posltlon

switch

selects

a

differentiation

time

constant

to

control

the

decay

time

of

the

pulse;

settings

select

Out

(equivalent

to

150

ms),

20,

50,

100,

200,

or

500

ns.

INTEGRATE

Front

panel

6-posltlon

switch

selects

an

integration

time

constant

to

control

the

risetlme

of

the

pulse;

settings

select

20,

50,

100,

200,

or

500

ns

or

Out

(equivalent

to

10

ns).

Note;

With

DIff

and

Int

switches

both

at

Out,

passband

is

typically

1

kHz

to

35

MHz.

INVERT/NONINVERT

Front

panel

toggle

switch

selects

inversion

or

noninversipn

of

the

input

signal

polarity

for

the

polarity

of

the

output

signal.

2.3.

INPUT

INPUT

Front

panel

BNC

connector

accepts

input

pulses

of

either

polarity;

amplitude

0

to

±1

V,

protected

to

±6

V

dc

and

to

±100

V

at

10%

duty

cycle

integrated

over

1

second;

impedance

10011

dc

coupled.

Accepts

a

±5

V

dc

offset;

maximum

input

(signal

plus

offset)

limited

to

±5

V.

2.4.

OUTPUTS

OUTPUT

Front

panel

BNC

connector

furnishes

the

shaped

and

amplified

signal

through

Z.,u.

<in,

dc

cou

pled.

Amplitude

0

to

±5

V;

risetime

and

decay

time

con

trolled

by

Integrate

and

Differentiate

filter

settings.

PREAMP

POWER

Rear

panel

standard

ORTEG

power

connector,

Amphenol

type

17-10090.

2.5.

ELECTRICAL

AND

MECHANICAL

POWER

REQUIRED

+24

V,

56

mA;

-24

V,

37

mA;

+12

V,

102

mA;

-12

V,

121

mA.

DIMENSIONS

NIM-standard

single-width

module

(1.35

by

8.714

in.)

per

TID-28093

(Rev).

3.

INSTALLATION

3.1.

GENERAL

The

474

operates

on

power

that

must

be

furnished

from

a

nuclear-standard

bin

and

power

supply

such

as

the

ORTEG

401/402

Series.

The

bin

and

power

supply

is

de

signed

for

relay

rack

mounting.

If

the

equipment

is

to

be

rack

mounted,

be

sure

that

there

is

adequate

ventilation

to

prevent

any

localized

heating

of

the

components

that

are

used

in

the

474.

The

temperature

of

the

equipment

mounted

in

racks

can

easily

exceed

the

maximum

limit

of

50°

G

(323

K)

unless

precautions

are

taken.

3.2.

CONNECTION

TO

POWER

The

474

contains

no

internal

power

supply

and

must

obtain

the

necessary

dc

operating

power

from

the

bin

and

power

supply

in

which

it

is

installed

for

operation.

Always

turn

off

power

for

the

power

supply

before

inserting

or

removing

any

modules.

ORTEG

modules

are

designed

so

that

a

full

complement

of

modules

installed

in

the

bin

will

not

overload

the

NIM-standard

power

supply.

Since,

however,

this

may

not

be

true

when

the

bin

contains

mod

ules

other

than

those

of

ORTEG

design,

the

dc

power

levels

should

be

checked

after

all

of

the

modules

have

been

installed.

The

ORTEG

401/402

Series

Bins

and

Power

Supplies

have

convenient

test

points

on

the

power

supply

control

panel

to

permit

monitoring

these

dc

levels.

3.3.

INPUT/OUTPUT

CONNECTIONS

The

input

impedance

of

the

474

is

about

10011

and

pro

vides

a

suitable

termination

for

cable

with

a

characteristic

impedance

of

9311.

If

the

cable

that

is

used

for

the

input

signals

has

a

characteristic

impedance

of

50fl,

use

a

BNG

Tee

at

the

474

Input

to

accommodate

the

cable

and

a

10011

terminator;

the

terminator

and

the

input

impedance,

which

are

in

parallel,

will

then

match

the

5011

cable

im

pedance.

The

low

output

impedance

of

the

474

requires

that

the

output

cable

be

terminated

by

the

characteristic

imped

ance

of

the

cable

at

its

remote

end.

This

can

be

accom

plished

at

the

input

of

a

high-input

impedance

instrument

or

by

using

an

instrument

with

an

input

impedance

equal

to

the

impedance

of

the

cable.

Both

driving

end

and

re

ceiving

end

coaxial

line

termination

is

recommended

for

long

cables,

although

this

reduces

the

driving

amplitude

by

50%.

4.

OPERATING

INSTRUCTIONS

Either

of

two

functions,

or

both,

may

be

furnished

by

the

ORTEG

474

Timing

Filter

Amplifier,

depending

on

the

details

of

the

circuit

in

which

it

is

installed.

It

may

be

used

to

linearly

amplify

a

small

amplitude

range

into

one

that

is

better

suited

to

the

requirements

of

a

subsequent

instru

ment

in

the

system;

the

gain

can

be

set

at

any

level

from

X2

through

X250

for

this

purpose.

The

shaping

time

con

stants

that

select

integration

and

differentiation

circuits

in

the

474

can

be

set

to

normalize

a

pulse

rise

and

decay

time

to

optimize

timing

measurements.

In

addition

to

these

basic

functions,

the

474

can

also

be

used

to

invert

the

pulse

polarity

if

desired

and

to

correct

for

the

pole-

zero

effect

that

is

prov'ded

from

the

preamplifier

in

the

system.

There

are

no

typical

control

settings

that

can

be

sug

gested

for

operation,

since

each

application

of

the

474

will

require

a

different

combination

of

functions.

After

the

system

has

been

installed,

use

an

oscilloscope

to

observe

the

waveforms

at

the

input

and

output

of

the

474

and

adjust

its

controls

to

optimize

its

operation,

con

sidering

the

functions

that

are

required

of

it.

Generally

speaking,

the

Integrate

time

constant

can

be

selected

so

that

the

risetime

of

the

output

pulses

is

nor

malized

at

a

rate

that

is

slower

than

the

risetimes

of

the

input

pulses.

This

function

is

of

greatest

value

when

the

pulses

originate

in

a

large

detector

so

that

they

generate

a

wide

variety

of

risetimes

and

are

difficult

to

observe

for

timing

measurements.

The

Differentiate

time

constant

is

also

selectable

and

determines

the

total

interval

before

the

pulse

returns

to

the

baseline

and

allows

a

new

pulse

to

be

observed.

The

combination

of

integration

and

differ

entiation

time

constants

also

contributes

to

the

amount

of

electronic

noise

that

is

seen

in

the

system,

so

the

resulting

waveforms

should

be

considered

from

each

of

these

points

of

view

and

adjusted

for

optimum

results.

When

the

shaping

time

constants

impose

considerable

changes

in

the

input

waveform,

the

nominal

gain,

which

is

the

product

of

the

Coarse

and

Fine

control

settings,

may

be

degraded

somewhat.

This

is

not

normally

a

pro

blem,

since

the

gain

is

constant

even

though

it

may

be

less

than

the

nominal

settings

indicate.

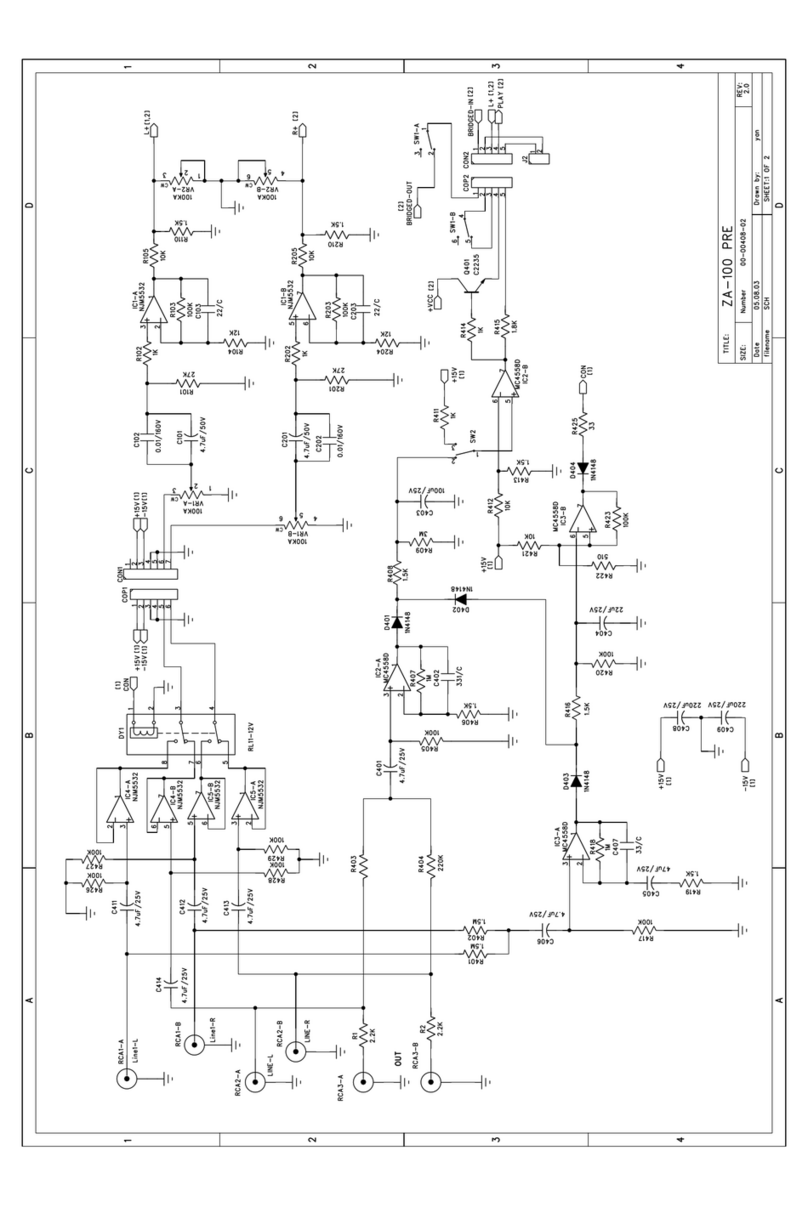

5.

CIRCUIT

DESCRIPTION

The

circuit

of

the

ORTEC

474

Timing

Filter

Amplifier

is

shown

in

schematic

474-0201-S1,

included

at

the

back

of

this

manual.

The

front

panel

toggle

switch,

SI,

selects

a

resistance

network

for

Invert

or

a

circuit

through

Q.1

and

Q2

for

Non-

invert

for

pulses

of

either

polarity,

and

the

pulses

are

then

furnished

into

the

differentiation

network

at

82.

If

82

is

set

at

Out,

the

input

pulse

is

coupled

through

R34

to

the

input

of

A1.

The

pole-zero

adjustment,

R30,

does

not

pro

vide

any

effect

for

the

Out

setting

of

82.

If

82

is

set

at

any

of

its

other

five

positions,

the

input

pulse

is

coupled

through

a

capacitor

that

is

in

parallel

with

a

portion

of

the

signal,

furnished

through

the

pole-zero

circuit,

and

pro

vided

to

the

input

of

A1.

Amplifier

A1

is

an

ORTEC

Hybrid

circuit,

type

HBA0106,

that

includes

Coarse

Gain

control

83.

The

amplified

out

put

at

pin

5

of

At

is

furnished

to

the

integration

network

at

the

input

to

A2,

which

is

another

type

HBA0106

ORTEC

Hybrid

circuit.

Amplifier

A2

has

a

gain

that

is

adjusted

by

Fine

Gain

con

trol

R64.

The

output

of

A2

is

furnished

to

the

base

of

09,

which

is

the

input

of

the

output

voltage

amplifier.

The

out

put

voltage

amplifier,

consisting

of

transistors

09

through

Q20

and

associated

resistors

and

capacitors,

has

a

volt

age

gain

of

approximately

5.

A

complementary

Darlington

output

stage

is

used

to

provide

good

bipoiar

drive

capa

bility.

Potentiometer

R100

is

a

factory-adjusted

balance

control

for

the

two

halves

of

the

complementary

Darling

ton

output

stage.

Integrated

circuit

101

senses

the

output

at

CN2

and

acts

in

the

dc

feedback

loop

to

force

the

output

to

zero.

IC1

is

connected

as

an

integrator,

with

a

time

constant

of

ap

proximately

150

IJ.S

(corresponding

to

about

1

kHz).

The

NIM

power

connector

includes

circuits

that

accept

±12

V

and

±24

V.

These

input

power

levels

are

filtered

and

are

used

internally

in

the

circuits

of

the

474.

The

four

leveis

are

also

furnished

through

the

rear

panel

Preampli

fier

Power

connector,

CN4,

and

can

be

used

as

the

power

source

for

an

associated

ORTEC

preamplifier.

6.

MAINTENANCE

6.1.

CORRECTIVE

MAINTENANCE

The

ORTEC

474

should

require

no

regular

maintenance

other

than

replacement

of

components

that

have

failed

due

to

age.

Always

ensure

that

the

replacement

compo

nents

are

equivalent

to

the

original

parts,

designated

in

schematic

474-0201-81.

No

internal

trimming

or

adjust

ment

is

necessary

for

the

474.

To

aid

in

the

identification

of

a

malfunctioning

compo

nent,

typical

dc

voltages

are

listed

in

Table

6.1.

Note

that

these

are

typical

values,

and

may

vary

from

one

unit

to

another

without

indicating

a

fault.

6.2.

FACTORY

SERVICE

This

instrument

can

be

returned

to

the

ORTEC

factory

for

service

and

repair

at

a

nominal

cost.

The

ORTEC

standard

procedure

for

repair

ensures

the

same

quaiity

control

and

checkout

that

are

used

for

a

new

instrument.

Always

contact

Customer

8ervices

at

ORTEC,

(615)

482-

4411,

before

sending

in

an

instrument

for

repair

to

obtain

shipping

instructions

and

so

that

the

required

Return

Authorization

Number

can

be

assigned

to

the

unit.

This

number

should

be

written

on

the

address

label

and

on

the

package

to

ensure

prompt

attention

when

it

reaches

the

factory.

n

Table

6.1.

Typical

dc

Voltages

NONINV

mode;

Diff

and

Int

switches

set

to

"Out";

Fine

Gain

2;

Coarse

Gain

=

1.

Q1B

-2.7

mV

018E

-29

mV

Q1E

-0.6

V

019B

8.65

V

QIC

12.0

V

0190

11.70

V

Q2B

45

mV

O20B

-8.65

V

020

5.90

V

O20O

-11.70

V

03E

5.35

V

101(2)

-2.6

mV

Q4B

-6.76

V

101(3)

-2.2

mV

Q4E

-7.40

V

101(4)

-12

V

Q5B

-7.40

V

101(6)

-70

mV

Q6E

-7.30

V

101(7)

12

V

07B

14.50

V

A1(1)

100

mV

Q7E

13.95

V

A1(2)

120

mV

Q8E

14.55

V

A1(3)

-0.50

V

Q9B

90

mV

A1(4)

17

mV

Q9E

0.73

V

A1(5)

0

mV

090

-9.25

V

A1(6)

-11.5

V

O10B

7.60

V

A1(7)

-5.8

V

O10E

8.25

V

A1(8)

0

V

011B

8.20

V

A1(9)

0.65

V

0110

12.0

V

A1(lb)

11.7V

012E

8.20

V

A2(1)

-17

mV

0120

1.27

V

A2(2)

-1.0

mV

013E

1.21

V

A2(3)

-0.6

V

0130

-1.25

V

A2(4)

40

mV

014E

-9.85

V

A2(5)

-56

mV

0140

-1.31

V

A2(6)

-11.5

V

015E

0.66

V

A2(7)

-5.8

V

0150

8.0

V

A2(8)

0

V

016E

25

mV

A2(9)

0.77

V

017E

-0.68

V

A2(10)

11.7

V

0170

-8.0

V

7.

APPLICATION

NOTES

7.1.

GENERAL

The

most

important

function

that

is

served

by

the

474

Timing

Filter

Amplifier

is

pulse

shaping.

This

is

especially

important

when

using

the

output

from

a

large

volume

de

tector,

with

a

wide

range

of

charge-collection

times

for

its

output

pulses,

and

attempting

to

obtain

timing

infor

mation

from

these

nonuniform

pulses.

By

adjusting

the

pulse

risetime

with

the

474

to

an

interval

that

is

longer

than

any

of

the

input

risetimes,

the

474

output

pulses

will

have

the

advantage

of

uniformity.

The

pulse

decay

time

constant

is

also

selectable

so

that

the

operator

can

com

promise

between

pulse-pair

resolution

time

and

system

noise;

as

shorter

time

constants

are

used,

pulse-pair

resolution

time

is

shortened

at

the

expense

of

an

increase

in

noise.

Other

functions

that

are

also

included

in

the

474

are

linear

amplification

of

small

pulses

of

either

polarity,

polarity

control,

and

adjustable

pole-zero

cancellation.

These

additional

features

provide

useful

functions

in

most

of

the

circuits

where

pulse

shaping

is

necessary.

Each

application

for

the

474

will

require

a

different

com

bination

of

the

data

enhancement

parameters

that

are

available.

Use

each

as

required

in

the

specific

application.

7.2.

CONSTANT-FRACTION

TIMING

WITH

GERMANIUM

DETECTORS

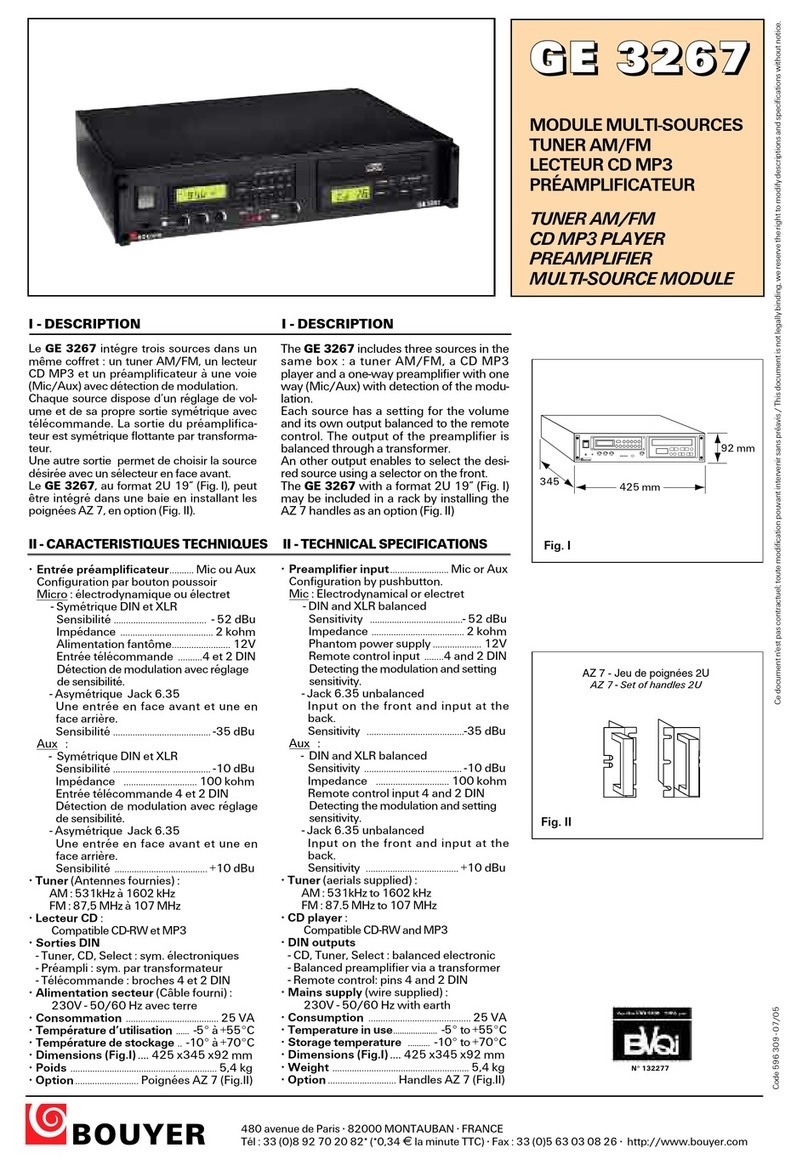

Figure

7.1

is

a

block

diagram

of

a

gamma-gamma

coin

cidence

sy.stem

that

can

be

used

for

timing

with

germa

nium

detectors.

In

this

system

the

TPHC

start

channel

456

HIGHVOLTAGE

POWERSUPPLY

1-bv

1-

in.

KL236

459

DETECTOR

BIAS

SUPPLY

265

PM

BASE

RCA

8575

PM

TUBE

Anode

11

SCINTIL

PREAMI

3

LATION

'LIFIER

1

r

460

OELAY-LINE

AMPLIFIER

473A

CONSTANT-

FRACTION

DISCRIMINATOR

^^Na

Source

*

425A

NANOSECOND

DELAY

GeaO

COAXIAL

DETECTOR

473A

CONSTANT-

FRACTION

DISCRIMINATOR

120-4

PREAMPLIFIER

474

TIMING

FILTER

AMPLIFIER

Start

^

f

^

Stop

TIMING

SCA

457

TIME-TO

PULSE

HEIGHT

CONVERTER

414A

FAST

COINCIDENCE

j

551

TIMING

SCA

460

OELAY'LINE

AMPLIFIER

6240B

MULTICHANNEL

ANALYZER

8169

Fig.

7.1.

Gamma-Gamma

Coincidence

System

Using

a

Piastic

Scintiilator

and

a

Large

Ge(Li)

Coaxial

Detector.

uses

a

fast

plastic

scintiilator

and

the

stop

channel

uses

a

coaxial

germanium

detector.

Excellent

timing

spectra

have

been

obtained

by

combining

the

pulse

shaping

avail

able

with

the

474

together

with

the

use

of

the

slow-rise-

time

(SRT)

reject

circuitry

in

the

constant-fraction

dis

criminator.

The

SRT

circuitry

is

most

effective

when

used

with

a

wide

dynamic

range

of

energies.

It

can

provide

dramatic

improvement

in

timing

resolution

below

the

FWHM

level

and

makes

reliable

timing

data

possible

at

even

the

FW(1/100)M

level.

The

SRT

circuitry

in

the

constant-fraction

discriminator

can

provide

improved

timing

resolution

by

rejecting

those

logic

pulses

that

result

from

leading-edge

timing

in

the

instrument.

Since

the

input

signals

that

cause

leading-

edge

walk

represent

valid

energy

information,

use

of

the

SRT

circuitry

results

in

a

loss

in

the

counting

efficiency

of

the

system.

A

system

for

measuring

the

lifetimes

of

excited

states

at

extremely

low

energies

is

similar

to

the

system

shown

in

Fig.

7.1.

In

this

configuration

the

coaxial

Ge(Li)

detector

and

preamplifier

are

replaced

with

a

Ge(Li)

low-energy

photon

spectrometer

(LEPS)

detector

and

preamplifier.

7.3.

NANOSECOND

FLUORESCENCE

SPECTROMETRY

The

ORTEC

9200

Nanosecond

Fluorescence

Spectrom

eter

is

used

in

lifetime

measurements

of

excited

molecular

states.

In

the

specific

application

where

the

molecular

structure

is

studied,

the

experimenter

seeks

to

verify

a

complex

model

of

a

particular

molecule

or

to

determine

how

a

particular

molecule

is

altered

by

its

surroundings.

This

type

of

experiment

requires

that

the

total

efficiency,

the

exact

energy,

and

the

complete

time

function

involved

in

the

de-excitation

of

an

electronic

state

be

known

so

that

the

e,xperimental

results

can

be

fit

precisely

to

a

model.

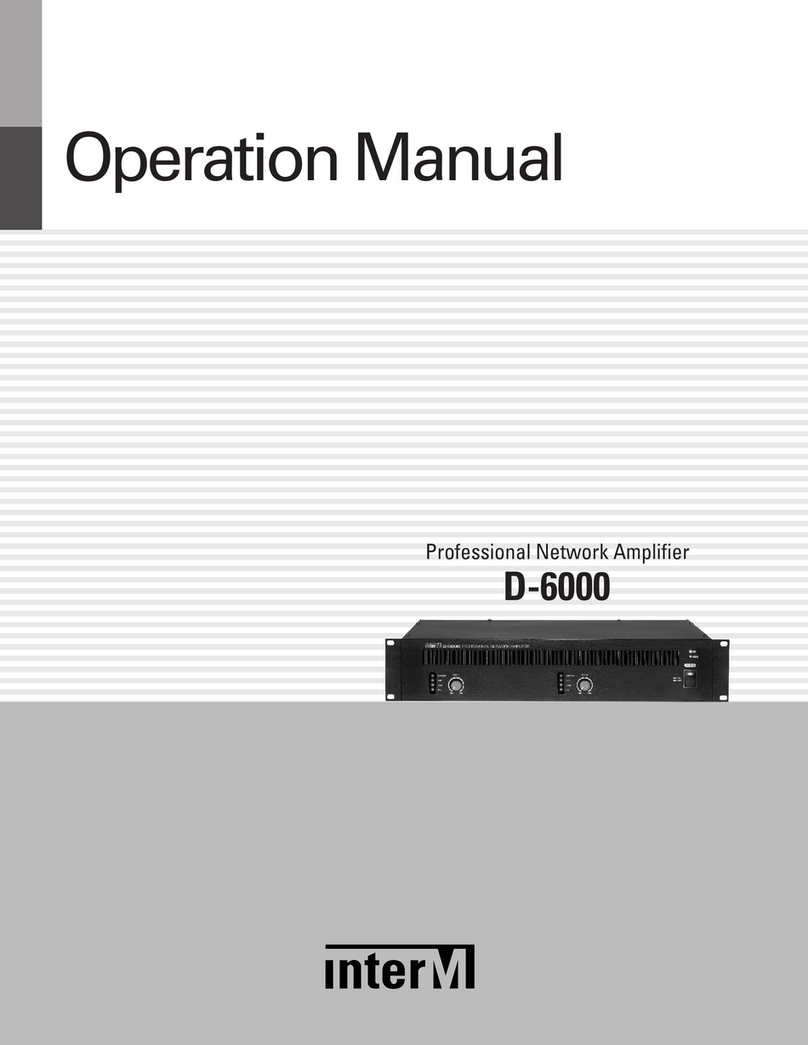

Figure

7.2

shows

the

9200

System,

and

Fig.

7.3

shows

the

detailed

lifetime

characteristics

of

a

0.1

N

solution

of

quinine

sulfate

in

sulfuric

acid

that

was

excited

with

im

pulses

of

light

at

approximately

340

nm

with

the

9200

System.

The

quantity

of

information

available

from

such

a

lifetime

measurement

is

illustrated

by

this

set

of

data.

PUT

Aperture

Control

Puiser

Aperture

Control

'

9351

FLUORESCENCE

ORTEC

RCA

9201

8850

PHOTOMULTIPLIER

BASE

8.

TUBE

1

456

HIGH-VOLTAGE

POWER

SUPPLY

Stop

Channel

Linear

Channel

474

TIMING

FILTER

AMPLIFIER

SAMPLE

COMPARTMENTI

CUVETTE

ABC

C

8

-

A

9290

HIGH-VOLTAGE

POWER

SUPPLY

Start

Channel

A

-

Aperture

B

-

Filter

C

-

Polarizer

9352

Nanosecond

Light

Puiser

473A

CONSTANT-

FRACTION

DISCRIMINATOR

(Used

as

Ratio

Indicator)

DUAL

COUNTER/TIMER

Start

From

473A,

4890,

or

457

Data

Accumulation

Channel

473A

CONSTANT-

425A*

FRACTION

NAraUSECUNO

DISCRIMINATOR

DELAY

Stop

4890

PREAMPLIFIER/

AMP/SCA

457

BIASED

TIME-

TO-PULSE-

HEIGHT

CONVERTER

i

i

Ext. Strobe

DC

6240B

MULTICHANNEL

ANALYZER

"When

using

the

50-ns

time

range

of

the

457,

the425A

should

be

used

in

the

start

channel

rather

than

in

the

stop

channel.

8169a

Rg.

7.2.

Nanosecond

Decay

Time

Fluorescence

Spectrometer

System.

.

■

r

=

19.2n!

lOr

Fig.

7.3.

Lifetime

Spectrum

of

Quinine

Suifate

in

Sulfuric

Acid.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

—3

volts

24

Reserved

3

Spare

Bus

25

Reserved

4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

*28

.

+24

volts

7

Coaxial

*29

—24

volts

8

200

volts

dc

30

Spare

Bus

9

Spare

31

Spare

•10

+6

volts

32

Spare

■11

—6

volts

*33

115

volts

ac

(Hot)

12

Reserved

Bus

*34

Power

Return

Ground

13

Spare

**35

Reset

(Sealer)

14

Spare

**36

Gate

15

Reserved

**37

Reset

(Auxiliary)

+12

volts

38

Coaxial

^17

—12

volts

39

Coaxial

18

Spare

Bus

40

Coaxial

19

Reserved

Bus

*41

115

volts

ac

(Neut.)

20

Spare

*42

High

Quality

Ground

21

Spare

G

Ground

Guide

Pin

22

Reserved

Pins

marked

{*)

are

installed

and

wired

in

ORTEC

401A

and 401

B

Modular

System

Bins.

Pins

marked

(*)

and

(**)

are

installed

and

wired

in

EG&G/ORTEC—HEP

M250/N

and

M350/N

NIMBINS,

OBTEC

^7^-0201C

-TrsT]-

/-EHIl-V

-Qty-

Hri

i«h-

«

-I

R'lS

-IR120I-

-TrtoI-

-I

R65I-

-CMD-

-TR67|-

—I

R

7

9"]—

^

Q

t

-I

R95>-

I I I

h-

-LR'7

©

I

j_

-OH}-

1$

-BI53-

©

-OH}-

-OM-

-OzS-

rc*o

-O^M-

,

HrToTV-

-037}-

'

-087I-

RIOI

-OH

S

)-|hTo8}-

I

1-6

I

u/

—IR109H

-ETTo}-

-OZz}-

-OO-

-OTtl-

srs

GO

-CriI}-

ol-

Table of contents

Other EG&G Amplifier manuals

EG&G

EG&G ORTEC 575A Service manual

EG&G

EG&G ORTEC 452 User manual

EG&G

EG&G ORTEC 118A User manual

EG&G

EG&G 113 Service manual

EG&G

EG&G ORTEC 572 Service manual

EG&G

EG&G ORTEC 113 Service manual

EG&G

EG&G ORTEC 427 User manual

EG&G

EG&G ORTEC 414A Service manual

EG&G

EG&G ORTEC 485 User manual

EG&G

EG&G ORTEC 855 Service manual