EG&G ORTEC 113 Service manual

n

Subsidiary

of

EG&G,

inc.

Model

113

Scintillation

Preamplifier

Operating

and

Service

Mimual

Model

113

Scintillation

Preamplifier

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

36"

on

rear

panel

Printed

in

U.S.A.

ORTEC

Part

No.

717560

2882

1.0C

0189

standard

Warranty

for

EG&G

ORTEC

Nuclear

Electronic

Instruments

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanshipor

materials

within

two

years

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of.

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

or

use

of

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

tothe

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

pur

chase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obliga

tion

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEC

nuclear

electronic

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warrany

repair

and

as

a

source

of

statistical

information

for

design

improvements.

Repair

Service

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

CustomerServices

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing,

by

telephone

[(615)

482-4411

]

or

by

telex

(55-7450)

of

the

nature

of

the

fault

of

the

instrument

being

re

turned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC'standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

uised

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

(In

the

case

where

the

instrument

did

not

function

upon

pur

chase,

EG&G

ORTEC

will

pay

shipment

costs

both

ways.)

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

Damage

in

Transit

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

IV

'

*

V

*

'

•

"

•

.'

'-

^"*1

'••r,.

'

^

;

.

..

.

•

-'v"*

V

..'

'

*

f

mm

ORITEC*"

i..

'

«•

"'

,

'

7fVt

-,

,

ito

5oa,

:

•

1000

0

/4o

^

=

•

MODELTia^

:,

A

J'^INPUT

i

,

•-■i.

■■

■»

''

"'w/'>'"'•

^

fsft

•'

*

f..

■••

1

^

.

'

>

*

*

:,

.{'~T.TT^T-~=.'"-';j

,

-.c

{>V

V-

•'-*'

■"

.

■

••I'-T.m

'

-,

-

f,

-

-

-V'

-

z-

f

'

!

:

"

-

i'-i

<'^t^:'-'

'•

iJ.

.;

'

.

TO

WER

'

.OUTPUT

.

'

'

^

f

t

U

•V'

c

i

•

;

'

.■

'

.-...

.t...j,,.<v.

<pftj,.,>./,....j

.

. . .

.,

...

■

'"i

:'■

I

vT'

*.

'.

':£■/

/

/

•

»

ORTEC

113

SCINTILLATION

PREAMPLIFIER

1.

DESCRIPTION

The

ORTEC

113

Scintil

lation

Preamplifier

is

an

al

l-

transistor

preamplifier

designed

for

use

with

photomultiplier

tubes.

It

is

a

noninverting

preamplifier

with

no

provisions

for

pulse

shaping

except

the

variation

of

fall

time.

The

113

is

intended

to

operate

into

a

shaping-type

amplifier

such

as

the

ORTEC

410.

A

diode

network

prevents

destruction

of

the

input

transistor

if

a

sudden

positive

or

negative

high

voltage

is

applied

to

the

input.

2.

SPECIFICATIONS

PERFORMANCE

RISE

TIME

<60

nsec.

PREAMPLIFIER

FALL

TIME

Fall

time

constant

is

designed

for

50

;usec,

assuming

a

signal

source

impedance

of

1

Mn.

INTEGRAL

NONLINEARITY

<0.02%.

TEMPERATURE

COEFFICIENT

±0.01%/°C,

10to50°C.

COUNTING

RATE

The

gain

shift

of

a

250-mV

reference

pulse

is

<0.25%

with

the

application

of

an

additional

count

rate

of

65,000

counts/sec

of

200-mV

random

pulses.

CONTROL

INPUT

CAP

pF

Switch

selects

desired

input

capacity:

0,

100,200,

500,

or

1000

pF.

INPUT

BNC

connector;

isolated

for

1000

V;

positive

or

negative

polarity,

1

M^2

impedance

shunted

by

45

pF

plus

the

capacity

selected

by

switch

81

(0,

100,

200,

500,

or

1000

pF).

OUTPUT

BNC

connector;

output

impedance

adjustable

from

40

to

14012.

Output

saturation

level

±10

V

into

open

circuit;

±5.1

V

into

10012

load.

Linear

output

±7 V

into

open

circuit;

±3.5

V

into

10012

load.

TEST

PULSE

BNC

connector;

accepts

a

pulse

generator

output

with

fast

rise

and

slow

decay

to

check

operation

of

the

electronics;

input

impedance

10012.

ELECTRICAL

AND

MECHANICAL

POWER

REQUIRED

+24

V

dc,

17

mA;

-24

V

dc,

17

mA;

suppl

ied

from

any

ORTEC

transistor

main

amplifier

or

an

ORTEC

Preamplifier

Power

Supply

through

10-ft

captive

cable.

WEIGHT

(Shipping)

2.3

lb

(1.05

kg).

WEIGHT

(Net)

1.5

lb

(0.68

kg).

DIMENSIONS

1

.75

X

4

X

6

in.

(4.5

x

10.2

x

15.3

cm).

RELATED

EQUIPMENT

The

113

can

be

operated

with

any

ORTEC

Shaping

Main

Amplifier.

Test

input

pulses

can

be

furnished

from

any

ORTEC

Pulse

Generator.

3.

INSTALLATION

INSTRUCTIONS

3.1.

CONNECTION

TO

PHOTOMULTIPLIER

TUBE

Connect

the

output

of

the

photomultipl

ier

to

the

input

of

the

113

with

a

coaxial

cable.

This

cable

should

bg

kept

as

short

as

practicable.

The

photomultipl

ier

output

can

be

taken

from

the

anode,

cathode,

or

any

dynode

and

wil

l

general

ly

be

ac-coupled.

The

input

connector

of

the

113

is

isolated

for

1000

V

dc;

however,

it

can

be

modified

for

3000-V

dc

isolation

by

being

replaced

with

a

type

SHV

connector.

3.2.

CONNECTION

TO

A

SHAPING

MAIN

AMPLIFIER

The

113

can

be

used

to

drive

long

lengths

of

9312

cable

to

a

shaping

ampl

ifier

and

is

designed

to

be

directly

compatible

with

ORTEC

transistor

main

ampl

ifiers.

The

output

impedance

of

the

113

is

93S2;

therefore

if

the

93f2

cable

is

used,

it

is

not

necessary

to

terminate

it

at

the

receiving

end.

If

unterminated

cable

is

used

on

the

output,

with

impedance

other

than

93f2,

resistor

R24

should

be

adjusted

for

an

output

impedance

equal

to

the

value

of

the

cable

imped

ance

to

prevent

pulse

reflections.

3.3.

INPUT

POWER

Power

for

the

113

is

suppl

ied

through

an

Amphenol

connector

(17-20090)

on

the

rear

of

the

chassis.

Power

may

be

supplied

by

a

single

45-V

battery

with

a

tap

at

22.5

V

(use

the

tap

as

ground,

providing

-1-22.5

V

and

-22.5

V;

current

drain

is

17

mA)or

by

any

well-filtered

±24-V

power

supply

such

as

the

ORTEC

114

Preamplifier

Power

Supply.

If

the

113

is

used

with

ORTEC

transistor

main

amplifiers,

power

for

the

preamplifier

can

be

supplied

from

the

main

ampl

ifier

through

the

interconnecting

cable

supplied

with

the

113.

3.4.

TEST

PULSE

A

voltage

pulse

can

be

inserted

at

the

Test

Pulse

connector

on

the

rear

of

the

113.

The

113

has

a

built-in

charge

terminator

that

converts

the

input

voltage

to

an

input

charge

to

simulate

a

charge

pulse

from

the

photomultipl

ier

tube.

The

shape

of

the

voltage

test

pulse

should

have

a

fast

rise

time

(less

than

10"®

sec)

followed

by

a

slow

ex

ponential

decay

back

to

the

basel

ine

(2

to

4

x

10""*

sec).

A

1-V

input

signal

at

the

Test

Pulse

connector

produces

a

pulse

of

approximately

135

mV

when

an

input

capacity

of

1

GO

pF

is

selected

by

SI.

4.

OPERATING

INSTRUCTIONS

The

shape

of

the

output

pulse

from

the

photomultiplier

tube

is

dependent

on

the

form

-of

the

l

ight

pulse,

the

transit-time

spread

in

the

photomultiplier,

and

the

anode

resistance

and

capacitance.

Since

the

form

of

the

light

pulse

and

the

transit

time

of

the

tube

cannot

be

altered,

our

concern

is

with

the

anode

and

associated

circuitry.

The

signal

at

the

anode

appears

as

a

current

pulse

or

a

quantity

of

charge,

and

the

voltage

produced

by

this

quantity

of

charge

is

given

by

where

C

=

Cj

-t

Cjn

(see

Fig.

4.1).

(Cj

and

C2

are

coupl

ing

capacitors

that

are

large

in

value

compared

to

C,

and

therefore

accumulate

a

negligible

amount

of

voltage

from

the

charge

transferred.)

The

voltage

developed

across

Cy

+

Cjn

wil

l

decay

with

a

time

constant

of

ry=

R^C,

where

Rr

=

Rin

(

+

Rj)

Rin

+

Ri

+

Rs

and

R5

=

high-voltage

supply

output

resistance.

From

the

above

equations

it

can

be

seen

that

the

pulse

ampl

itude

can

be

varied

by

varying

Cjn,

which

can

be

ANODE

I

DYNODE

1

^Bin

Fig.

4.1.

Functional

Diagram

of

the

113

Preamplifier.

varied

by

steps

with

switch

SI

on

the

front

panel.

The

input

capacity

of

the

113

is

approximately

45

pF

plus

the

capacity

selected

by

SI.

Rjn

was

selected

to

produce

a

fall

time

constant

of

50

insec,

assuming

a

driving

source

im

pedance

of

1

X

10®

f2.

If

a

pole-zero-cancelled

amplifier

is

used

following

the

113,

it

wil

l

be

necessary

to

adjust

the

pole-zero

trim

on

the

ampl

ifier

each

time

a

different

input

capacitance

is

selected

for

the

113.

5.

CIRCUIT

DESCRIPTION

Switch

81

permits

adjustment

of

the

input

capacity

of

the

113

for

reasons

discussed

in

the

preceding

section.

Diodes

D1

and

D2

protect

Q1

by

preventing

the

excursions

of

the

base

of

Q1

from

exceeding

±12

V

when

a

positive

or

negative

high

voltage

is

abruptly

appl

ied

to

the

input

connector.

Q1

and

Q3

make

up

an

emitter

white

fol

lower

with

a

gain

of

(R9

+

R4)/R4.

Q2

has

been

added

to

increase

the

current

gain

for

negative

pulses.

C8

bootstraps

R2

to

produce

a

high

input

resistance.

Resistors

R20

through

R23

set

a

fall

time

constant

of

50

jusec

for

the

output

pulse,

assuming

a

driving

source

impedance

of

1

x

10®

J2.

The

output

impedance

of

the

amplifier

section

is

approximately

2J2;

therefore

the

output

impedance

at

connector

CN3

is

equal

to

R16

plus

R24

for

all

practical

purposes.

R24

should

be

adjusted

so

that

R24

plus

R16

is

equal

to

the

characteristic

impedance

of

the

cable

connected

to

the

output

CN3,

unless

the

cable

is

terminated

at

the

receiving

end.

6.

MAINTENANCE

INSTRUCTIONS

6.1.

TESTING

PERFORMANCE

Insert

a

voltage

pulse

in

the

Input

connector

and

monitor

the

output

with

an

oscilloscope.

The

output

pulse

should

be

equal

to

the

input

pulse

when

the

output

is

not

loaded

and

equal

to

one-half

the

input

pulse

when

it

is

loaded

with

93J2

and

R16

plus

R24

is

equal

to

93^2.

Perform

this

test

with

both

positive

and

negative

input

pulses.

Insert

a

voltage

pulse

into

the

Test

Pulse

input

connector

and

monitor

the

output

pulse

with

an

oscilloscope.

For

each

volt

input

an

output

voltage

of

approximately

135

mV

should

be

obtained

when

an

input

capacity

of

100

pF

is

selected

by

SI.

The

output

pulse

should

decrease

in

am

plitude

as

the

input

capacity

is

increased.

6.2.

SUGGESTIONS

FOR

TROUBLESHOOTING

Perform

the

tests

outlined

in

Section

6.1.

If

an

output

pulse

of

the

proper

magnitude

is

not

obtained,

check

all

dc

voltagesand

compare

them

with

the

values

tabulated

below.

6.3.

DC

VOLTAGES

The

voltages

listed

below

will

help

to

locate

defective

components.

All

voltages

are

measured

with

respect

to

ground.

Typical

dc

Voltages

LOCATION

DC

VOLTAGES

+24

V

Supply

-24

V

Supply

Qle

Qlb

QIC

Q2e

Q2c

Q3e

Q3b

+24

-24

-1.0

-0.5

+

13.3

+

13.8

-1.65

-13.2

-12.6

6.4.

FACTORY

REPAIR

This

instrument

can

be

returned

to

the

ORTEC

factory

for

service

and

repair

at

a

nominal

cost.

Our

standard

proce

dure

for

repair

ensures

the

same

quality

control

and

checkout

that

are

used

for

a

new

instrument.

Always

contact

Customer

Services

at

ORTEC,

(615)

482-4411,

before

sending

in

an

instrument

for

repair

to

obtain

ship

ping

instructions

and

so

that

the

required

Return

Authori

zation

Number

can

be

assigned

to

the

unit.

Write

this

num

ber

on

the

address

label

and

on

the

package

to

ensure

prompt

attention

when

it

reaches

the

ORTEC

factory.

o

#6

O

m

•

H3IEH

•

t—[

R

&

\—I

H6

C

It,

~j*

C

iS

I

I

H3

1

C

/4

^2-4

j

I—I

•

H

to

HZSL

'

H

II

u

i

Icii

C/3

•

H

H

i-tSJ23-i

r

+

>

Ci

T

r

^-SZ]-

T

C

Cfa

^

-C1H>

dSZED

HZSZID—

crs30

O

O

•

HZ

•

//3

•

H4

•H5

•—IZSD—t

b

I

I3-020I

©

Hi3

.

o

(J

LLAD

CONNECTS

TO

CNI-

l'

Vj/dJ

//3

-_54_

"3-

?i

s

FCfV

6C-3g

5

^

.

M

11

tM-V

iaJR'

CXa

53

~T^

DU

G

NO

mczco

OAK

RIOGE

TECHNICAL

ENTERPRISES

CORP.

OAK

RIOOC.

TLNN

wmrm

6

PWB

ASSY,

PREAMPLIFIER

l.C

I

C>HAWIf<('

NO

inno^n

113

0000

-s/

I

e/7

l.Skl

+

-e/a

5.

3SV

fN^009

*cfe

Q!

c».

/

iAJPUT

38*5

C/7.3

/ooo

</OMi

e/z

C,ZiC

C6

fezz

600f^\//0ki

'OCOf^K

^(s.C

SJofe

:

/.

^es/sfo^s

msriced

(

<3nT

^ctaf

f/fm

/%

,

^

^f

T-O.

dd

r^T^f^tor^

are

^^9

S%,

co/^p.

un/ess

of/>er}v/se

^pecz/^/ed*

2,

Capacitors

:

(s)

C/^

C3

^

C7

are

ct/-SC

cerar»ic.

(d)

C3

-

CC

arc

dipped

mic^.

(c)

/)//

others

^re

tanta/unt.

T-:.-13

e

->l-03

-)

l-

D8

e/-

/e/9

:/-

eta

2^

DATE

NU.

ecN

-n

s^dAf

t/3

-

a

■J

Oid

ECtJ

//3-

6

ear/

//3

-

^

SCO/

//J-

/

REVISION

dOh>

JOW

JOU^

DRAWN

I

DA<E

yo-9-4S

OAK

RIDGE

TECHNICAL

ENTERPRISES

CORP.

OAK

RIDGE.

TENN.

MODEL

//3

SC/AJ

r/L

L

3

T/Otd

PEE3MPL

/F/EP.

^CHEMFTtC

NEEP.

ENOR.

F.

Mi

tarn

£m.

DRAWING

N

113

ooOO-S!

Table of contents

Other EG&G Amplifier manuals

EG&G

EG&G ORTEC 118A User manual

EG&G

EG&G ORTEC 575A Service manual

EG&G

EG&G ORTEC 474 Service manual

EG&G

EG&G 128A Service manual

EG&G

EG&G ORTEC 452 User manual

EG&G

EG&G ORTEC 572 Service manual

EG&G

EG&G ORTEC 414A Service manual

EG&G

EG&G ORTEC 535 Service manual

EG&G

EG&G 113 Service manual

EG&G

EG&G ORTEC 444 User manual

Popular Amplifier manuals by other brands

Kramer

Kramer TP-310A user manual

SIIG

SIIG 1x4 HDMI 1.3 CAT5e Distribution Amplifier Quick installation guide

Altec Lansing

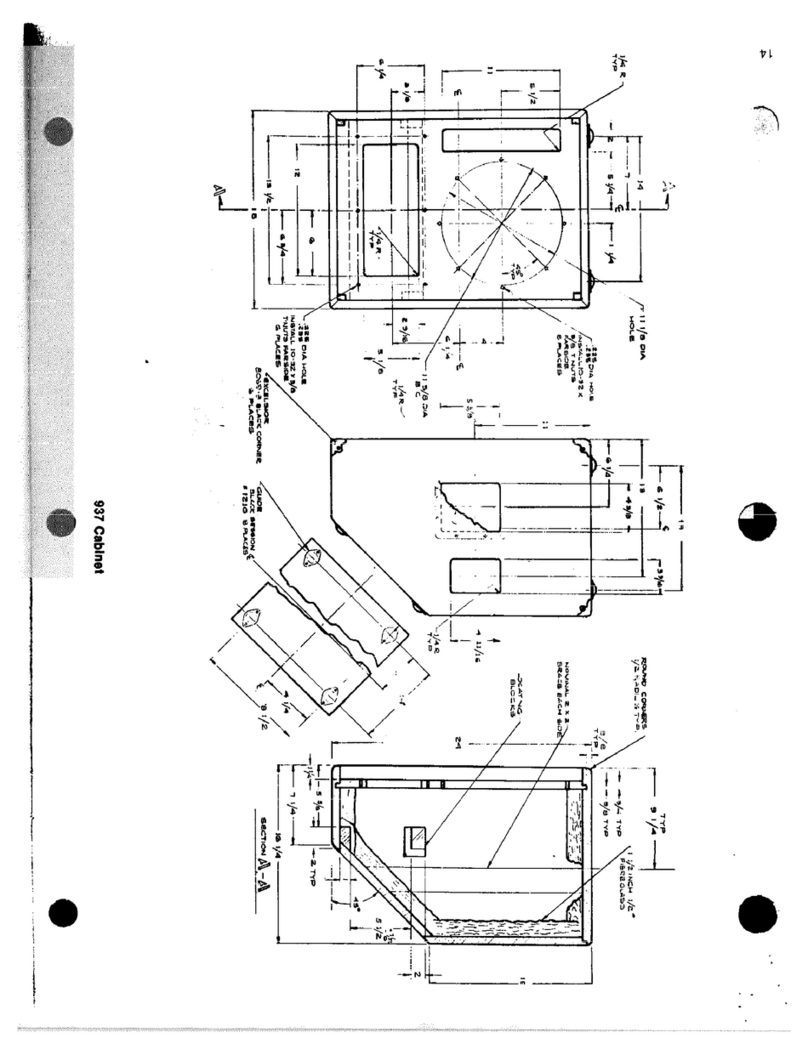

Altec Lansing 937 SPEAKER SYSTEM CABINET PLAN manual

Denon

Denon HEOS LINK quick start guide

Manley

Manley INTEGRATED AMPLIFIER owner's manual

Apex Digital

Apex Digital CloudPower Series Operation manual