EG&G ORTEC 414A Service manual

A.

A-

I

.

^

Model

414A

Fast

Coincidence

Operating

and

Service

Manual

J

Model

414A

Fast

Coincidence

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

19"

on

rear

panel

Printed

in

U.S.A.

2880

0.5C

0580

STANDARD

WARRANTY

FOR

EG&G

ORTEC

INSTRUMENTS

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

one

year

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

oruseof

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

purchase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obligation

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

EG&G

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

f^eturn

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing

or

by

telephone

[(615)

482-4411],

of

the

nature

of

the

fault

of

the

instrument

being

returned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel Service

to

the

nearest

EG&G

ORTEC

repair

center.

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

vvarranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

Ill

CONTENTS

Page

WARRANTY

PHOTOGRAPH

1.

DESCRIPTION

,

2.

SPECIFICATIONS

I

2.1.

Performance

2.2.

Controls

'

*

'

2.3.

Inputs

!

''

'

2

2.4.

Outputs

•

•

..

.

^

2.5.

Electrical

and

Mechanical

[[

'

2

3.

INSTALLATION

2

3.1.

General

Installation

Considerations

2

3.2.

Connection

to

Power

^

3.3.

Logic

Inputs

to

the

Fast

Coincidence

.

2

4.

OPERATING

INSTRUCTIONS

3

4.1.

Front

Panel

Controls

,

,

3

4.2.

Testing

and

Observation

of

Waveforms

3

4.3.

Connector

Data

''''

3

4.4.

Typical

Operating

Considerations

3

5.

CIRCUIT

DESCRIPTION

4

6.

MAINTENANCE

5

6.1.

Testing

Performance.

.:

5

6.2.

Alignment

of

Resolving

Time

Trimmer

Capacitors

5

6.3.

Suggestions

for

Troubleshooting

.

!!

!

!

.'

6

6.4.

Tabulated

Test

Point

Voltages

on

Etched

Board

7

Replaceable

Parts

List

Block

Diagram

and

Schematics

414A-0101-B1

414A-0164-S1

ILLUSTRATIONS

Fig.

4.1.

Illustration

of

Actual

Overlapping

of

Input

Pulses

I

and

II,

but

Not

During

the

Leading-Edge

Resolving

Time;

Trace

III

Illustrates

No

Output

Pulse

3

Fig.

4.2.

Illustration

of

Input

Pulses

I

and

II

Overlapping

During

the

Leading-Edge

Resolving

Time

and

Producing

Output

Pulse

III

3

Fig.

6.1.

414A

Test

and

Calibrate

Circuit

5

*

'»

i

\

.

1

on>o^!

U

?

-

»»

'i

\

A1

ORTEC

414A

FAST

COINCIDENCE

1.

DESCRIPTION

The

414A

Fast

Coincidence

allows

fast

coincidence

determination

between

any

two

or

three

input

signals.

A

dc-coupled

anticoincidence

input

is

provided

to

inhibit

the

coincidence

output.

The

coincidence

output

can

be

inhibited

by

a

dc

voltage

or

a

pulse

that

overlaps

the

period

of

coincidence

of

the

coincident

pulses.

The

resolving

time

of

the

anticoincidence

circuit

is

set

by

the

width

of

the

input

pulse.

The

resolving

time

(2t)

of

the

Fast

Coincidence

unit

may

be

varied

over

a

10-

to

110-nsec

range

by

a

10-turn

control

for

accurate

resettability

of

the

resolving

time.

All

four

inputs

are

controlled

by

In/Out

toggle

switches.

Input

signal

requirements

are

compatible

with

NIM

slow

positive

logic

output

signals

of

a

variety

of

ORTEC

timing

equipment.

The

output

pulse

is

suitable

as

an

input

to

the

418A

Universal

Coincidence

module

and

other

modules

of

the

ORTEC

400

Series

requiring

a

logic

input

pulse.

The

module

obtains

the

necessary

operating

power

from

an

ORTEC

401/402

Series

Bin

and

Power

Supply.

The

output

signal

and

all

signal

inputs

use

front

panel

BNC

connectors.

The

instrument

is

designed

to

meet

the

recommended

interchangeability

standards

outlined

in

USAEC

Report

TID-20893

(Rev).

An

ORTEC

401/402

Bin

and

Power

Supply

provides

all

necessary

power

through

the

rear

module

connector.

All

signal

levels

and

impedances

are

compatible

with

other

modules

in

the

ORTEC

400

Series.

The

414A

is

basically

a

threefold

AND

circuit,

with

each

input

to

the

AND

circuit

regenerated,

or

reshaped,

to

a

standardized

waveform

in

passing

from

the

input

connector

to

the

actual

AND

circuit.

The

general

connotation

of

the

word

"fast"

tends

to

be

in

terms

of

elapsed

time

or

speed,

but

in

this

instrument

the

term

"fast"

is

actually

intended

to

indicate

the

general

nature

of

the

coincidence

circuit;

i.e.,

the

input

pulses

are

reshaped

and

the

actual

coincidence

determination

is

made

on

the

leading

edge,

or

leading

portion,

of

the

input

pulses.

The

three

coincidence

inputs

to

the

414A-

feed

into

identical

but

separate

shaper

circuits.

The

shaper

circuit

contains

a

voltage

limiter

to

allow

a

wide

dynamic

range

of

input

pulse

amplitudes.

The

output

of

the

limiter

feeds

into

a

regeneration

circuit,

where

a

standard

pulse

is

generated

for

each

input

pulse

regardless

of

the

actual

waveform

of

the

input

signal.

This

standard

pulse

is

then

fed

into

the

resolving

time

network,

where

it

is

reshaped

to

satisfy

the

2r

resolving

time

selected

via

the

front

panel

Resolving

Time

control.

The

outputs

of

the

three

resolving

time

networks

are

fed

in

parallel

to

an

"overlap"

coincidence

network,

i.e.,

an

AND

network.

When

portions

of

the

reshaped

input

pulses

overlap

each

other,

the

AND

circuit

recognizes

a

coincidence

event

within

the

resolving

time

set

on

the

front

panel

Resolving

Time

control

and

produces

an

output.

The

coincidence

recognition

output

from

the

AND

circuit

may

be

inhibited

by

a

signal

from

the

anticoincidence

input.

This

inhibit

signal

may

be

a

pulse

or

a

dc

voltage

since

the

anticoincidence

circuit

is

dc-coupled.

The

inhibit

period

is

determined

by

the

width

of

the

input

pulse.

If

the

output

from

the

AND

circuit

is

not

blocked

by

the

anticoincidence

circuit,

it

is

regenerated

into

a

standard

output

signal

from

the

414A,

indicating

that

a

coincidence

event

has

been

detected.

The

coincidence

inputs

are

controlled

by

front

panel

toggle

switches,

which

permit

selection

of

one-,

two-,

or

threefold

coincidence.

A

switch

is

also

provided

for

the

anticoincidence

input.

These

switches

allow

each

input

to

be

disabled

without

the

associated

coaxial

cable

having

to

be

removed.

2.

SPECIFICATIONS

2.1.

PERFORMANCE

2.2.

CONTROLS

Pulse

Pair

Resolution

<100

nsec

on

any

single

input;

for

coincidence

events,

<1

psec

on

the

coincidence

output.

Resolving

Time

(2r)

Continuously

variable

from

10

to

110

nsec

for

coincidence

signals;

set

by

the

width

of

the

input

pulse

for

the

anticoincidence

signal.

Temperature

Instability

2t

changes

<0.2%/°C,

0

to

50°C.

Resolving

Time,

10-110

nsec

Front

panel

10-turn

poten

tiometer

for

controlling

resolving

time

for

inputs

A,

B,

and

C

over

a

range

of

10

to

110

nsec.

In/Out

Toggle

switches

for

using

any

input

combination

desired

and

for

disabling

input

signals

to

the

coincidence

and

anticoincidence

circuits

without

input

coaxial

cables

having

to

be

removed.

2.3.

INPUTS

Coinc

Front

panel

BNC

connectors

provide

3

ac-coupled

coincidence

inputs

(A,B,C)

of

positive

polarity;

2-V

threshold,

20-nsec

minimum

width

required;

absolute

maximum

input

50

V;

impedance

>300Qfi.

Anticoinc

Front

panel

BNC

connector

provides

one

dc-coupled

anticoincidence

input

(D)

for

inhibiting

coincidence

output;

+2-V

threshold,

20-nsec

minimum

width

required;

absolute

max

input

50

V;

impedance

>3000n.

2.4.

OUTPUTS

Outputs

Two

seperate

buffered

coincidence

output

signals

through

BNC

connectors

on

front

panel

provide

positive

pulses

500

nsec

wide

with

5-V

minimum

amplitude;

ac-coupled

with

<10^2

impedance;

monitored

through

oscilloscope

test

points

on

front

panel.

2.5.

ELECTRICAL

AND

MECHANICAL

Power

Required

+24

V,

30

mA;

-24

V,

30

mA;

+

12

V,

120

mA;-12

V,

85

mA.

Weight

(Shipping)

4.4

lb

(2.0

kg).

Weight

(Net)

2.4

lb

(1.09

kg).

Dimensions

NIM-standard

double-width

module

(2.70

by

8.714

in.)

per

TID-20893

(Rev).

3.

INSTALLATION

3.1.

GENERAL

INSTALLATION

CONSIDERATIONS

The

414A

contains

no

internal

power

supply

but

is

used

in

conjunction

with

a

401/402

Series

Bin

and

Power

Supply,

which

is

intended

for

rack

mounting.

Therefore,

if

vacuum

tube

equipment

is

operated

in

the

same

rack,

there

must

be

sufficient

cooling

air

circulating

to

prevent

any

localized

heating

of

the

all-transistor

circuitry

used

throughout

the

414A.

The

temperature

of

equipment

mounted

in

racks

can

easily

exceed

the

recommended

maximum

unless

precautions

are

taken;

the

414A

should

not

be

subjected

to

temperatures

in

excess

of

120°F

(50°C).

must

be

given

to

ensure

that

reflections

in

the

driving

transmission

cable

do

not

occur.

There

are

three

general

methods

of

termination

that

are

used.

The

simplest

of

these

is

shunt

termination

at

the

receiving

end

of

the

cable.

A

second

method

is

series

termination

at

the

sending

end.

The

third

is

a

combination

of

series

and

shunt

termination,

where

the

cable

impedance

is

matched

both

in

series

at

the

sending

end

and

in

shunt

at

the

receiving

end.

The

most

effective

method

is

the

combination,

but

termination

by

this

method

reduces

the

amount

of

signal

strength

at

the

receiving

end

to

50%

of

that

which

is

available

in

the

sending

instrument.

3.2.

CONNECTION

TO

POWER

Turn

off

the

Bin

power

supply

when

inserting

or

removing

modules.

The

ORTEC

400

Series

is

designed

so

that

it

is

not

possible

to

overload

the

Bin

power

supply

with

a

full

complement

of

modules

in

the

Bin.

Since,

however,

this

may

not

be

true

when

the

Bin

contains

modules

other

than

those

of

ORTEC

design,

the

Power

Supply

voltages

should

be

checked

after

the

modules

are

inserted.

The

401/402

has

test

points

on

the

Power

Supply

control

panel

to

monitor

the

dc

voltages.

3.3.

LOGIC

INPUTS

TO

THE

FAST

COINCIDENCE

The

input

pulses

to

the

Fast

Coincidence

unit

may

come

from

any

source

of

logic

pulses.

The

input

impedance

of

the

Fast

Coincidence

is

greater

than

3000f2,

and

some

care

To

use

shunt

termination

at

the

receiving

end

of

the

cable,

connect

the

1J2

output

of

the

sending

device

through

93f2

cable

to

the

input

of

the

receiving

instrument.

Then

use

a

BNC

tee

connector

to

accept

both

the

interconnecting

cable

and

a

100S2

resistive

terminator

at

the

input

connector

of

the

receiving

instrument.

Since

the

input

impedance

of

the

receiving

instrument

is

normally

1000J2

or

more,

the

effective

instrument

input

impedance

with

the

100J2

terminator

will

be

of

the

order

of

93f2,

and

this

correctly

matches

the

cable

impedance.

For

series

termination,

use

the

93f2

output

of

the

sending

instrument

for

the

cable

connection.

Use

Q3SI

cable

to

interconnect

this

into

the

input

of

the

receiving

instrument.

The

1000J2

(or

more)

normal

input

impedance

at

the

input

connector

represents

an

essentially

open

circuit,

and

the

series

impedance

in

the

sending

instrument

now

provides

the

proper

termination

for

the

cable.

For

the

combination

of

series

and

shunt

termination,

use

the

93n

output

in

the

sending

instrument

for

the

cable

connection

and

use

9312

cable.

At

the

input

for

the

receiving

instrument,

use

a

BNC

tee

to

accept

both

the

interconnecting

cable

and

a

100J2

resistive

terminator.

Note

that

the

signal

span

at

the

receiving

end

of

this

type

of

receiving

circuit

will

always

be

reduced

to

50%

of

the

signal

span

furnished

by

the

sending

instrument.

For

your

convenience,

ORTEC

stocks

the

proper

terminators

and

BNC

tees,

or

you

can

obtain

them

from

a

variety

of

commercial

sources.

4.

OPERATING

INSTRUCTIONS

4.1.

FRONT

PANEL

CONTROLS

In/Out

Toggle

switches

which

allow

the

input

signals

to

the

coincidence

and

anticoincidence

circuits

to

be

disabled

without

the

input

coaxial

cables

having

to

be

removed.

The

circuit

may

be

effectively

changed

to

either

a

onefold,

twofold,

or

threefold

coincidence

circuit,

as

desired,

by

operating

these

switches.

Resolving

Time

10-turn

potentiometer

which

determines

the

2t

resolving

time

of

the

coincidence

circuit;

resolving

time

is

variable

from

10

to

110

nsec.

4.2.

TESTING

AND

OBSERVATION

OF

WAVEFORMS

Refer

to

Sections

6.1

and

6.2

for

information

on

testing

performance

and

observing

waveforms.

4.3.

CONNECTOR

DATA

Inputs

A,

B,

and

C

The

coincidence

Inputs

A,

B,

and

C

are

BNC

connectors

providing

ac-coupled

coincidence

inputs.

Input

impedance

is

greater

than

3000J2.

A

positive

2-V

pulse

with

20-nsec

minimum

width

is

required.

To

minimize

reflections

when

driving

from

a

low

impedance

source

into

these

connectors,

a

terminator

equal

to

the

characteristic

impedance

of

the

driving

cable

should

be

shunted

from

this

connector

to

ground.

Input

D

The

anticoincidence

Input

D

is

a

BNC

connector

providing

a

dc-coupled

anticoincidence

input.

Input

impedance

is

greater

than

3000J2.

A

positive

2-V

pulse

with

20-nsec

minimum

width

is

required;

longer

pulse

durations,

to

dc,

are

acceptable

and

determine

the

anticoincidence

control

period.

To

minimize

reflections

when

driving

from

a

low

impedance

source

into

this

connector,

a

terminator

equal

to

the

characteristic

impedance

of

the

driving

cable

should

be

shunted

from

this

connector

to

ground.

Outputs

Two

separate,

buffered

coincidence

output

signals

are

provided

on

BNC

connectors.

These

signals

are

greater

than

5

V

in

amplitude

and

are

500

nsec

wide.

The

outputs

are

ac-coupled

with

less

than

10S2

output

impedance.

Coincidence

Output

Test

Points

(TP1

and

TP2)

These

oscilloscope

test

points

are

for

monitoring

signals

on

each

coincidence

Output

BNC

connector,

to

which

they

are

connected

by

a

470S2

series

resistor.

Power

Connector

The

Nuclear-standard

module

power

connector

is

an

AMP

202515-5.

4.4.

TYPICAL

OPERATING

CONSIDERATIONS

The

Fast

Coincidence

circuit

measures

coincidence-from

the

leading

edge,

or

leading

portion,

of

the

input

waveform.

The

input

signals

are

reshaped

to

a

standard

pulse

width

from

the

leading

edge.

Figures

4.1

and

4.2

illustrate

that

the

input

pulses

can

actually

overlap

in

time

but

not

satisfy

the

coincidence

requirements

as

dictated

by

the

front

panel

Resolving

Time

control.

1

1 1

rr

ny

\

t

i

l

l

-

•

*1-

T

TT^i

II

"

III

-

Fig.

4.1.

Illustration

of

Actual

Overlapping

of

Input

Pulses

I

and

II,

but

Not

During

the

Leading-Edge

Resolving

Time;

Trace

III

Illustrates

No

Output

Pulse.

1

It

1

III

Fig.

4.2.

Illustration

of

Input

Pulses

I

and

II

Overlapping

During

the

Leading-Edge

Resolving

Time

and

Producing

Output

Pulse

III.

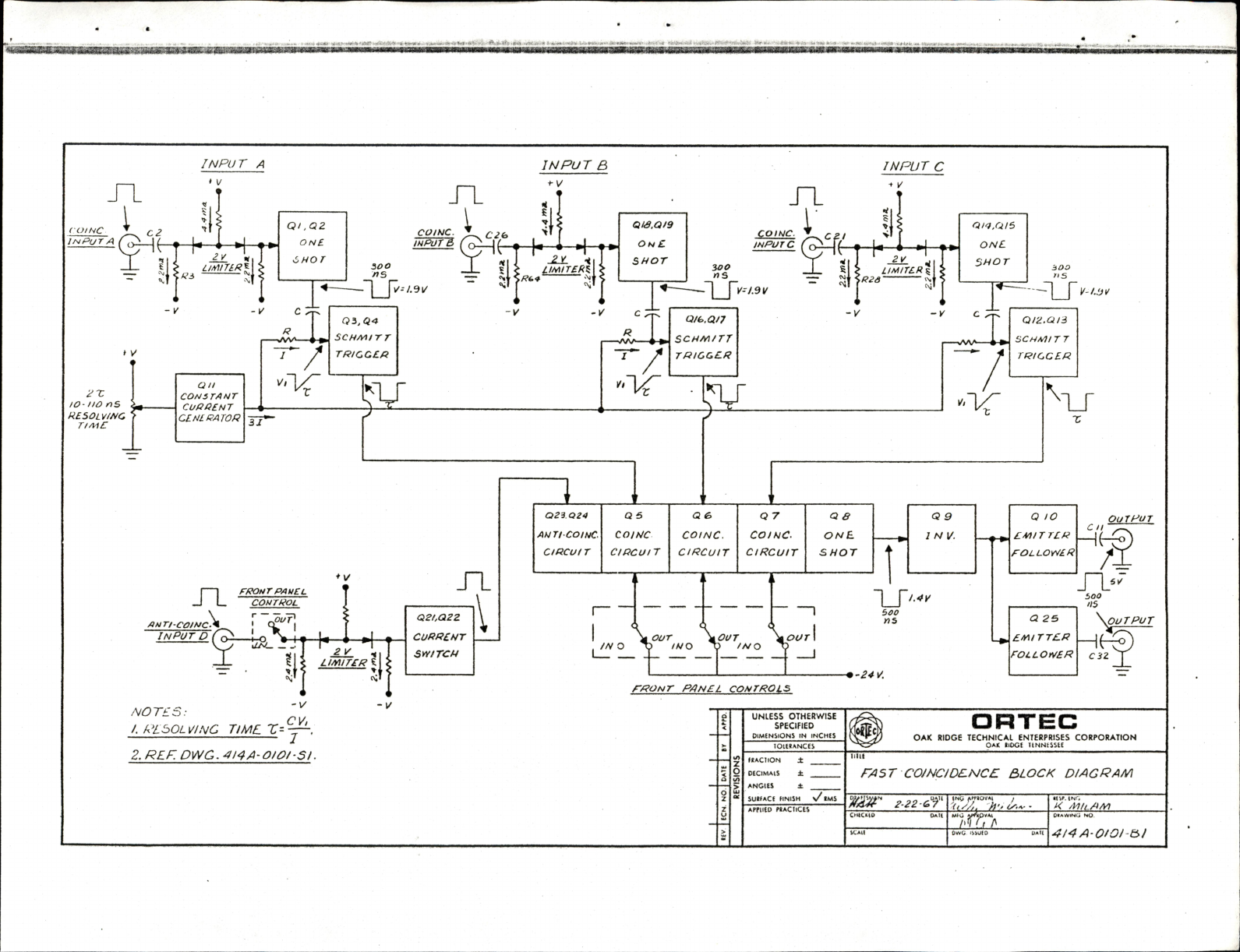

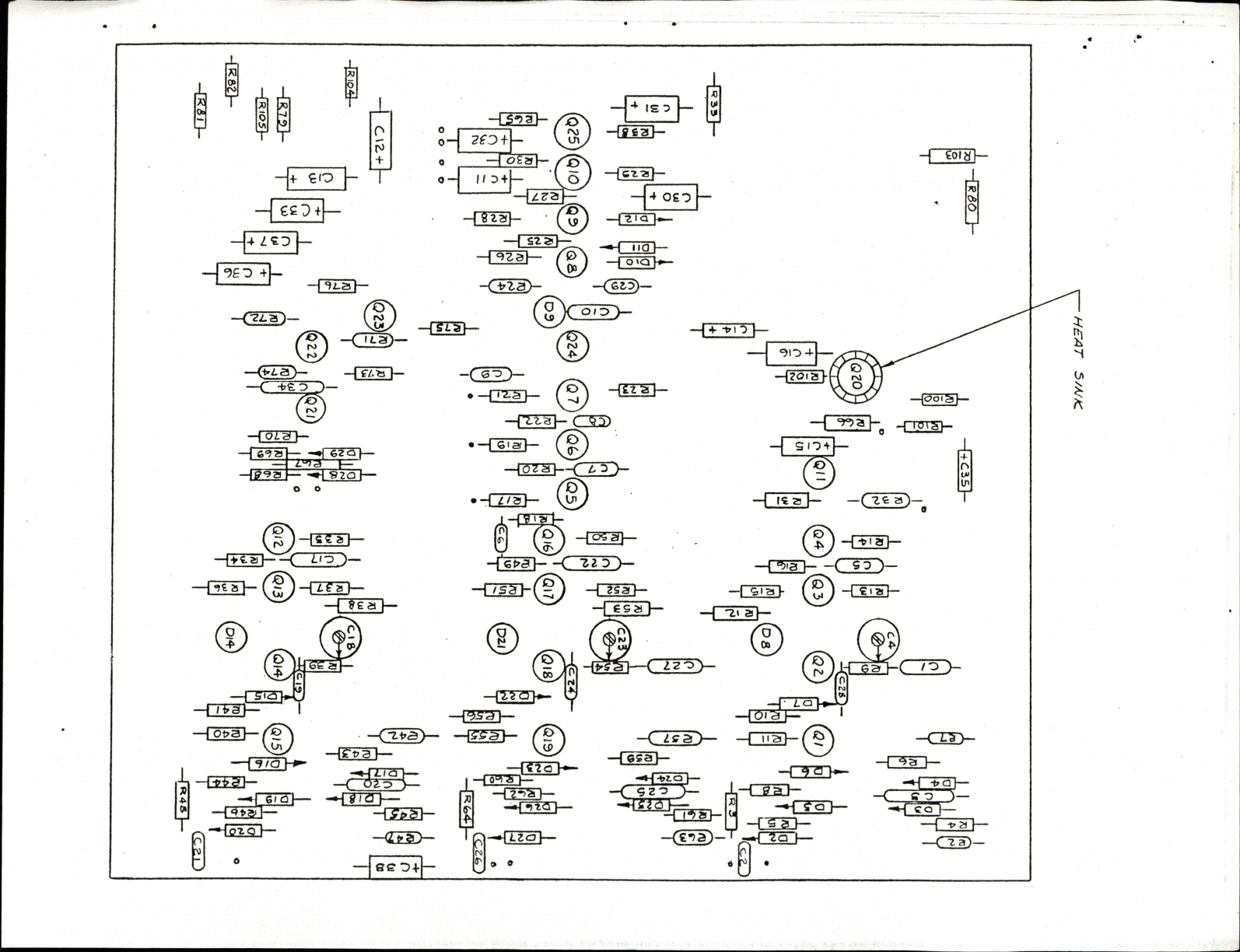

5.

CIRCUIT

DESCRIPTION

(Etched

Board

220

-

164)

The

fast

coincidence

circuit

consists

of

three

identical

coincidence

input

stages

and

an

anticoincidence

input

stage,

all

feeding

in

parallel

to

a

coincidence

stage

or

AND

gate

(see

Drawings

414A-0164-S1

and

414A-0101-B1).

The

coincidence

stage

is

composed

of

transistors

Q5,

Q6,

Q7,

and

Q24,

which

constitute

one

side

of

a

one-shot

trigger

circuit,

and

Q8,

which

constitutes

the

other

side.

The

output

of

this

trigger

circuit

is

fed

to

Q9,

where

it

is

inverted

and

sent

to

QlO

and

Q25,

the

output

emitter-followers.

The

coincidence

input

signals

are

all

regenerated

in

the

regeneration

and

pulse

forming

stages;

for

example,

coincidence

Input

A

signal

is

regenerated

by

the

one-shot

trigger

circuit

Q1

and

02

and

is

again

reshaped

and

fed

out

by

the

ac-coupled

Schmitt

trigger

circuit

03

and

04

to

05,

The

input

signal

is

fed

into

regeneration

circuit

01

and

02

through

a

2-V

limiter

consisting

of

resistors

R2,

R3,

R5,

and

R8.

The

limiting

action

is-accomplished

by

switching

the

constant

current

that

normally

flows

through

D2

and

R3

through

limiter

load

resistor

R5

by

the

application

of

a

positive

input

signal

on

Input

A.

The

2t

resolving

time

is

set

by

the

On

duration

of

the

ac-coupled

Schmitt

trigger

circuit

03

and

04.

The

signal

input

to

03

is

a

negative-going

pulse

with

a

precisely

controlled

amplitude

from

the

collector

of

01.

The

negative-going

pulse

is

coupled

through

C4

to

the

base

of

03

and

turns

off

03.

03

remains

off

for

a

duration

t.

The

constant-current

generator

Oil

and

series

resistor

R12

control

the

duration,

t,

by

discharging

capacitor

C4

back

from

its

negative

value

toward

ground.

When

the

voltage

at

03

exceeds

ground

potential,

03

again

is

switched

on

and

04

is

turned

off.

The

duration

that

04

remains

on

constitutes

one-half

the

resolving

time,

i.e.,

t.

The

output

of

04

is

a

negative-going

pulse

which

turns

off

05

in

the

coincidence

circuit

and

combination

one-shot

multivibrator.

The

anticoincidence

input

has

a

similar

voltage

limiter,

a

current

switch

(021

and

022),

and

a

voltage

clamp

which

turns

024

on

or

off.

The

anticoincidence

circuit

is

dc-coupled

from

the

input

to

024;

therefore

024

may

be

turned

on

by

a

pulse

or

a

dc

voltage.

The

combination

of

05, 06,

07,

and

024

constitutes

one

side

of

a

one-shot

trigger

circuit,

with

08

constituting

the

other

side.

024,

the

anticoincidence

input,

is

normally

biased

off,

while

05, 06,

and

07,

the

coincidence

inputs,

are

normally

biased

on.

In

the

event

that

05,

06,

and

07

are

all

turned

off

simultaneously

and

024

is

not

turned

on

by

an

anticoincidence

input,

the

one-shot

multivibrator

circuit

is

triggered,

and

08

conducts

the

normal

current

flowing

through

R26.

A

negative-going

pulse

is

formed

at

the

collector

of

08

and

is

inverted

by

09.

The

output

signal

of

invertor

09

is

fed

through

emitter-followers

.010

and

024,

and

thence

to

the

output

BNC

connectors.

The

constant-current

generator

Oil

generates

a

current

which

is

equal

to

31.

This

current

is

then

split

into

three

equal

parts,

with

one

part

going

to

each

of

the

three

input

pulse-forming

circuits,

i.e.,

03-04,

017-016,

and

012-013.

Either

A,

B,

or

C

front

panel

control

switch

(SI,

S2,

or

S3)

can

disable

one

coincidence

input

of

the

combination

threefold

coincidence

and

one-shot

multivibrator

circuit

composed

of

05,

,06,

07,

024,

and

08

(see

Drawing

414A-0101-S1).

When

one

of

these

switches

is

moved

to

Out,

the

transistor

corresponding

to

that

switch

is

reverse-biased,

resulting

in

a

twofold

coincidence

circuit.

The

actual

coincidence

recognition

is

performed

by

transistors

05,

06,

and

08,

while

024

acts

to

inhibit

the

coincidence

output

when

a

signal

is

applied

to

the

anticoincidence

input.

The

anticoincidence

input

can

be

disabled

by

placing

switch

D

(S4)

to

the

Out

position.

This

interrupts

the

signal

to

the

anticoincidence

circuit.

With

front

panel

control

switches

A,

B,

and

C

all

placed

to

In,

a

current

of

approximately

3

mA

flows

through

R26

and

then

is

passed

through

transistors

05,

06,

and

07

in

parallel

and

thence

through

R23.

Moving

switch

A,

B,

or

C

to

Out

back-biases

the

particular

transistor

associated

with

that

switch,

thus

making

the

series

path

consist

of

R26,

the

two

remaining

transistors,

and

R23.

With

the

application

of

simultaneous

negative

input

pulses

to

05,

06,

and

07

and

in

the

absence

of

an

anticoincidence

pulse

to

turn

on

024,

the

current

flow

through

R23

ceases

and

a

positive

pulse

is

coupled

through

CIO

into

the

base

of

08.

08

conducts

for

a

time

constant

determined

by

CIO

and

R24,

thereby

back-biasing

the

parallel

combination

of

05,

06,

and

07.

Notice

that

in

the

quiescent

state

08

is

back-biased

by

the

voltage

drop

across

diode

D9,

since

09

is

forward-biased

with

a

current

of

1

mA.

6.

MAINTENANCE

I

ai.

TESTING

PERFORMANCE

The

following

paragraphs

are

Intended

as

aids

in

the

installation

and

checkout

of

the

414A.

These

instructions

present

information

on

front

panel

controls,

waveforms,

at

test

points,

and

output

connectors.

The

following,

or

equivalent,

test

equipment

is

needed:

ORTEC

419

Precision

Pulse

Generator

Tektronix

Model

580

Oscilloscope

100S2

BNC

terminators

Vacuum

tube

voltmeter

ORTEC

410

Linear

Amplifier

Two

ORTEC

420A

Timing

Single

Channel

Analyzers

Schematic

and

block

diagram

for

414A

Preliminary

procedures

consist

of

the

following:

1.

Visually

check

module

for

possible

damage

due

to

shipment.

2.

Connect

ac

power

to

ORTEC

401

/402.

3.

Plug

module

into

Bin

and

check

for

proper

mechanical

alignment.

4.

Switch

on

ac

power

and

check

the

dc

Power

Supply

voltages

at

the

test

points

on

the

402

control

panel.

Testing

the

performance

of

the

414A

involves

the

following:

1.

Feed

the

output

of

the

420A

into

coincidence

Input

A.

Terminate

with

lOOfi

the

RG-62/U

connecting

cable

feeding

Input

A.

2.

Set

the

In/Out

control

toggle

switches

as

follows:

A,

In;

B,

C,

and

D,

Out.

3.

Set

the

Resolving

Time

control

to

100.

4.

Observe

the

Fast

Coincidence

output

pulse;

it

should

be

a

positive

pulse,

6.5

±

0.6

V

and

0.5

±

0.1

/isec

wide.

Loading

the

414A

Output

with

100J2

should

reduce

the

output

to

not

less

than

5

V

and

the

width

to

not

less

than

0.5psec.

5.

Putting

In/Out

switch

B

or

C

to

the

In

position

should

inhibit

the

pulse

on

the

414A

Output.

Check

that

both

B

and

C

inhibit.

Connect

the

input

into

Input

8

and

check

that

both

A

and

C

inhibit.

Connect

the

input

into

Input

C

and

check

that

both

A

and

B

inhibit.

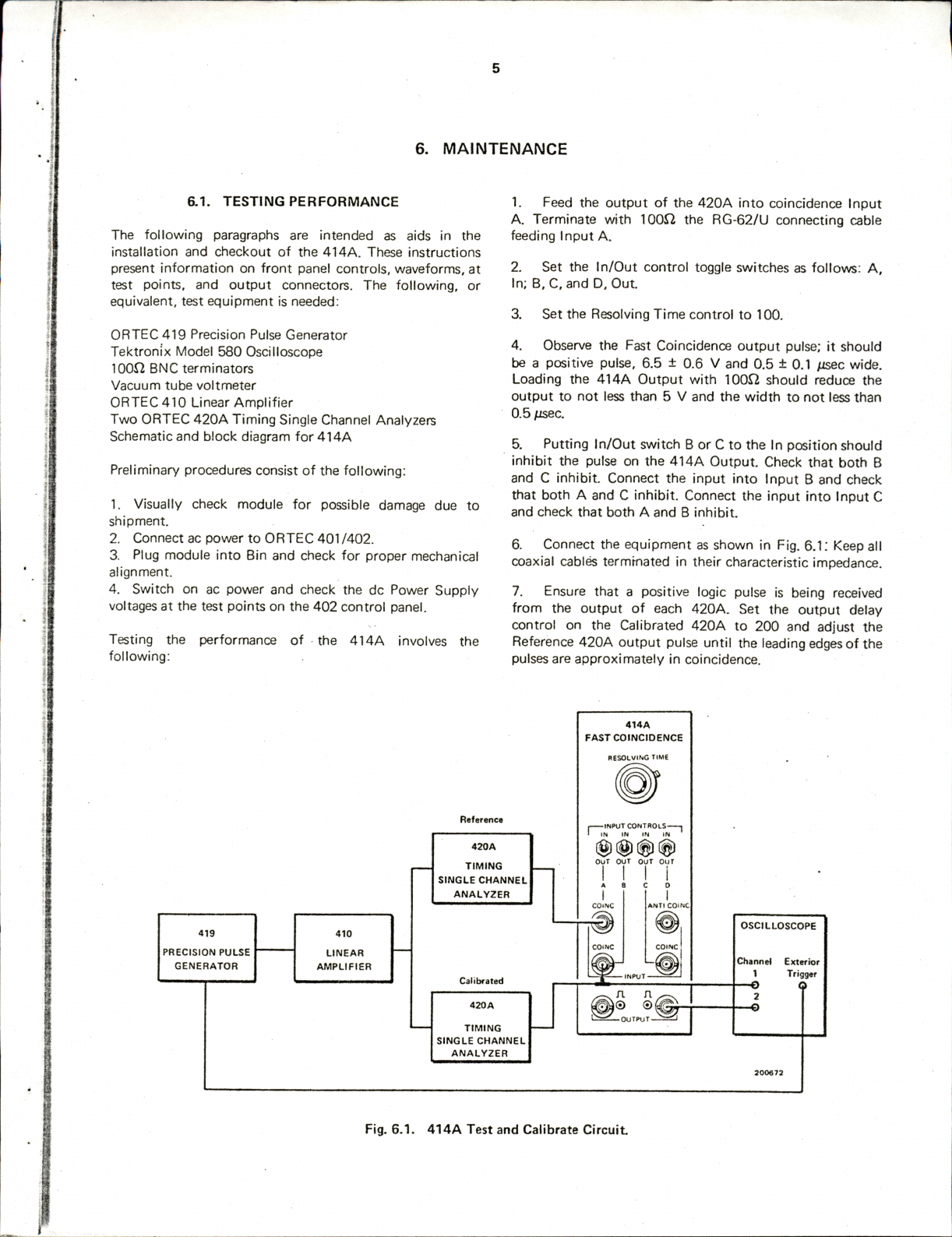

6.

Connect

the

equipment

as

shown

in

Fig.

6.1;

Keep

all

coaxial

cables

terminated

in

their

characteristic

impedance.

7.

Ensure

that

a

positive

logic

pulse

is

being

received

from

the

output

of

each

420A.

Set

the

output

delay

control

on

the

Calibrated

420A

to

200

and

adjust

the

Reference

420A

output

pulse

until

the

leading

edges

of

the

pulses

are

approximately

in

coincidence.

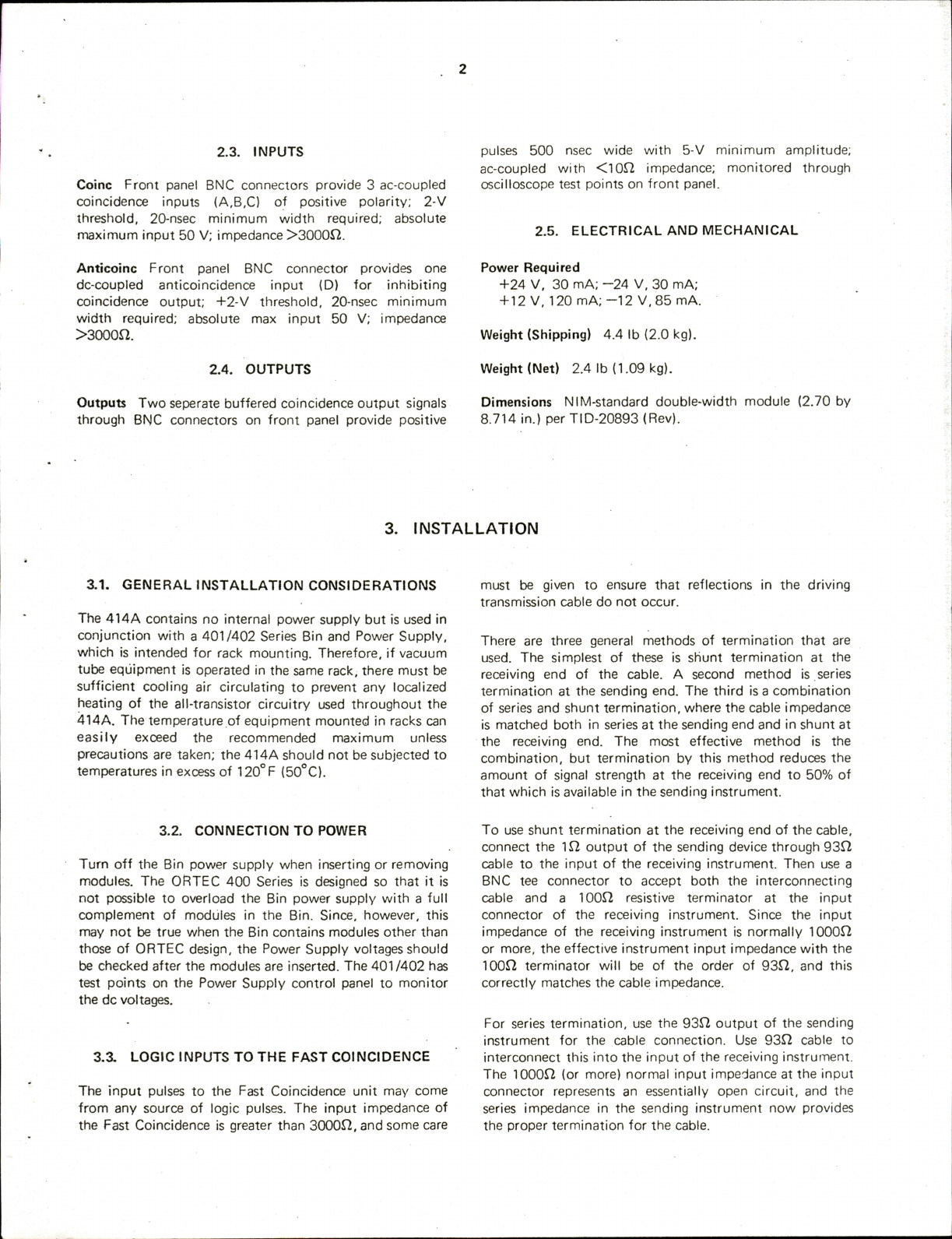

414A

FAST

COINCIDENCE

RESOLVING

TIME

Refer

enc«

Out

out

outout

Calibrated

300673

PRECISION

PULSE

GENERATOR

419

LINEAR

AMPLIFIER

410

TIMING

SINGLE

CHANNEL

ANALYZER

420A

TIMING

SINGLE

CHANNEL

ANALYZER

420A

Channel

Exterior

1

Trigger

OSCILLOSCOPE

Fig.

6.1.

414A

Test

and

Calibrate

Circuit.

8.

Set

the

In/Out

Control

switches

as

follows:

A

and

B,

In;

C

and

D,

Out.

9.

Set

the

Resolving

Time

control

to

1

TOO.

10..

With

the

equipment

connected

as

shown

in

Fig.

6.1,

two

pulses

(the

Calibrated

420A

output

and

the

414A

output)

should

be

visible

on

the

oscilloscope.

Set

the

horizontal

time

base

to

20

nsec/cm.

It

may

be

necessary

to

use

the

Delayed

Sweep

function

on

the

oscilloscope

in

order

to

observe

both

pulses

at

this

horizontal

sweep

speed.

11.

Decrease

the

output

delay

control

on

the

Calibrated

420A

until

the

414A

output

pulse

disappears.

12.

Increase

the

output

delay

control

on

the

Calibrated

420A,

and

the

414A

output

pulse

should

reappear

and

disappear

again

as

the

delay

is

increased.

Measure

the

change

in

delay

of

the

Calibrated

420A

pulse

from

the

time

that

the

414A

output

pulse

reappears

until

it

disappears

again.

This

time

can

be

accurately

measured

looking

at

the

oscilloscope.

The

time

measured

represents

the

2t

resolving

time

of

the

414A

with

the

Resolving

Time

control

set

at

1100

and

should

be

110-150

nsec.

13.

Connect

the

Calibrated

420A

output

to

Input

C

on

the

414A.

14.

Set

the

In/Out

control

switches

as

follows:

A

and

C,

In;

B

and

D,

Out.

15.

Repeat

steps

.9

through

12.

16.

Connect

the

Reference

420A

output

to

Input

B

on

the

414A.

17.

Set

the

In/Out

control

switches

as

follows:

A

and

D,

Out;

B

and

C,

In.

18.

Repeat

steps

9

through

12.

19.

Repeat

steps

9

through

16

with

the

following

exceptions:

a.

In

step

9

set

the

Resolving

Time

control

to

100.

b.

In

step

10

set

the

oscilloscope

horizontal

time

base

to

10

nsec/cm.

c.

In

step

12

the

2t

resolving

time

should

be

less

than

10

nsec

with

the

Resolving

Time

control

set

at

100.

20.

Set

the

output

delay

control

on

the

Calibrated

420A

so

that

its

output

occurs

approximately

100

nsec

prior

to

the

Reference

420A

output.

21.

Connect

the

Reference

420A

output

to

the

414A

Input

A.

22.

Connect

the

Calibrated

420A

output

to

the

414A

Input

D.

23.

Set

the

Resolving

Time

control

to

1100.

24.

Set

the

In/Out

control

switches

as

follows:

A,

In;

B,

C,

and

D,

Out.

25.

A

pulse

should

be

present

at

the

output

of

the

414A.

Place

In/Out

control

switch

D

to

the

In

position,

and

the

414A

output

pulse

should

disappear.

6.2.

ALIGNMENT

OF

RESOLVING

TIME

TRIMMER

CAPACITORS

If

the

resolving

time

readings

(Section

6.1)

were

not

satisfactory,

the

trimmer

capacitors

in

each

resolving

network

may

be

adjusted

to

optimize

the

resolving

time

in

each

channel:

1.

,

Connect

and

adjust

the

equipment

as

stated

in

Section

6.1,

steps

6

and

7.

2.

Set

the

In/Out

control

switches

as

follows:

A,

In;

B,

C,

and

D,

Out.

3.

Set

the

Resolving

Time

control

to

100.

4.

Observe

the

414A

output

with

an

oscilloscope.

5.

Using

an

insulated

screwdriver,

adjust

capacitor

C4

until

the

output

pulse

disappears.

Continue

to

rotate

C4

adjustment

until

the

output

reappears.

Stop

the

adjustment

of

C4

as

soon

as

an

output

pulse

appears

for

each

input

pulse.

6.

Set

the

In/Out

control

switches

as

follows:

A,

C,

and

D,

Out;

B,

In.

7.

Adjust

C23

as

explained

in

step

5.

8.

Connect

Reference

420A

to

Input

C.

9.

Set

the

In/Out

control

switches

as

follows:

A,

B,

and

D,

Out;

C,

In.

10.

Adjust

C18

as

explained

in

step

5.

11.

Perform

the

tests

outlined

in

Section

6.1,

steps

1

—

25,

to

check

the

instrument

performance.

6.3.

SUGGESTIONS

FOR

TROUBLESHOOTING

In

situations

where

the

414A

is

suspected

of

malfunction,

it

is

essential

to

verify

such

malfunction

in

terms

of

simple

pulse

generator

impulses

at

the

input

and

output.

The

414A

must

be

disconnected

from

its

position

in

any

system,

and

routine

diagnostic

analysis

performed

with

a

test

pulse

generator

and

oscilloscope.

It

is

imperative

that

testing

not

be

performed

with

a

source

and

detector

until

the

amplifier

and

logic

inputs

to

the

Fast

Coincidence

unit

perform

satisfactorily

with

the

test

pulse

generator.

The

testing

instructions

in

Section

6.1

of

this

manual

and

the

circuit

description

in

Section

5

should

provide

assistance

in

locating

the

region

of

trouble

and

in

repairing

the

malfunction.

The

guide

plate

and

shield

cover

can

be

completely

removed

from

the

module

to

enable

oscilloscope

and

voltmeter

observations

with

a

minimal

chance

of

accidentally

short-circuiting

portions

of

the

etched

board.

The

414A

may

be

returned

to

ORTEC

for

repair

service

at

nominal

cost.

Our

standardized

procedure

requires

that

each

repaired

instrument

receive

the

same

extensive

quality

control

tests

that

a

new

instrument

receives.

Contact

our

Customer

Service

Department,

(615)

4824411,

for

shipping

instructions

before

returning

the

instrument.

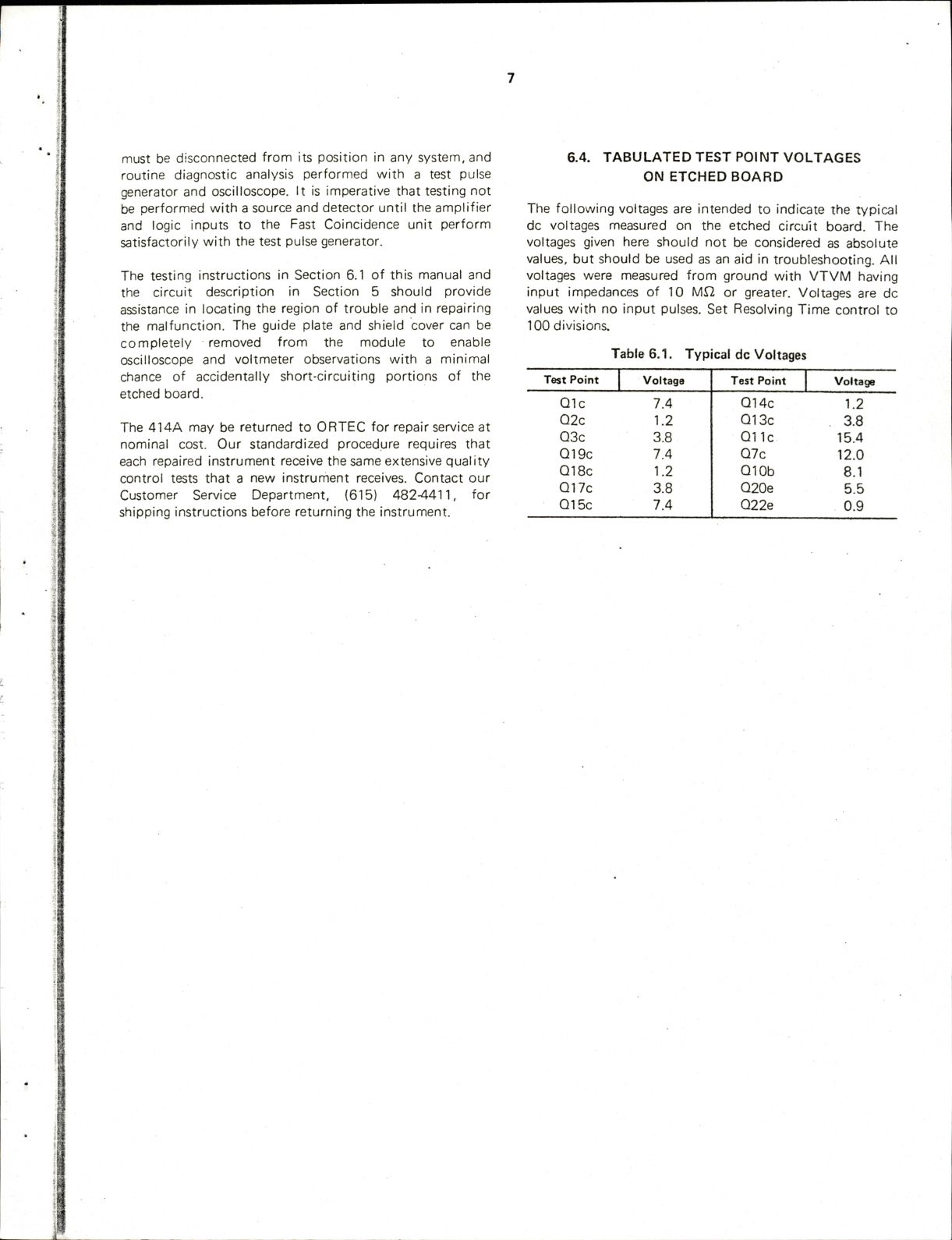

6.4.

TABULATED

TEST

POINT

VOLTAGES

ON

ETCHED

BOARD

The

following

voltages

are

intended

to

indicate

the

typical

dc

voltages

measured

on

the

etched

circuit

board.

The

voltages

given

here

should

not

be

considered

as

absolute

values,

but

should

be

used

as

an

aid

in

troubleshooting.

All

voltages

were

measured

from

ground

with

VTVM

having

input

impedances

of

10

or

greater.

Voltages

are

dc

values

with

no

input

pulses.

Set

Resolving

Time

control

to

100

divisions.

Table

6.1.

Typical

dc

Voltages

Test

Point

Voltage

Test

Point

Voltage

QIC

7.4

Ql4c

1.2

Q2c

1.2

013c

3.8

Q3c

3.8

011c

15.4

019c

7.4

07c

12.0

QiSc

1.2

010b

8.1

Ql7c

3.8

O20e

5.5

Ql5c

7.4

022e

0.9

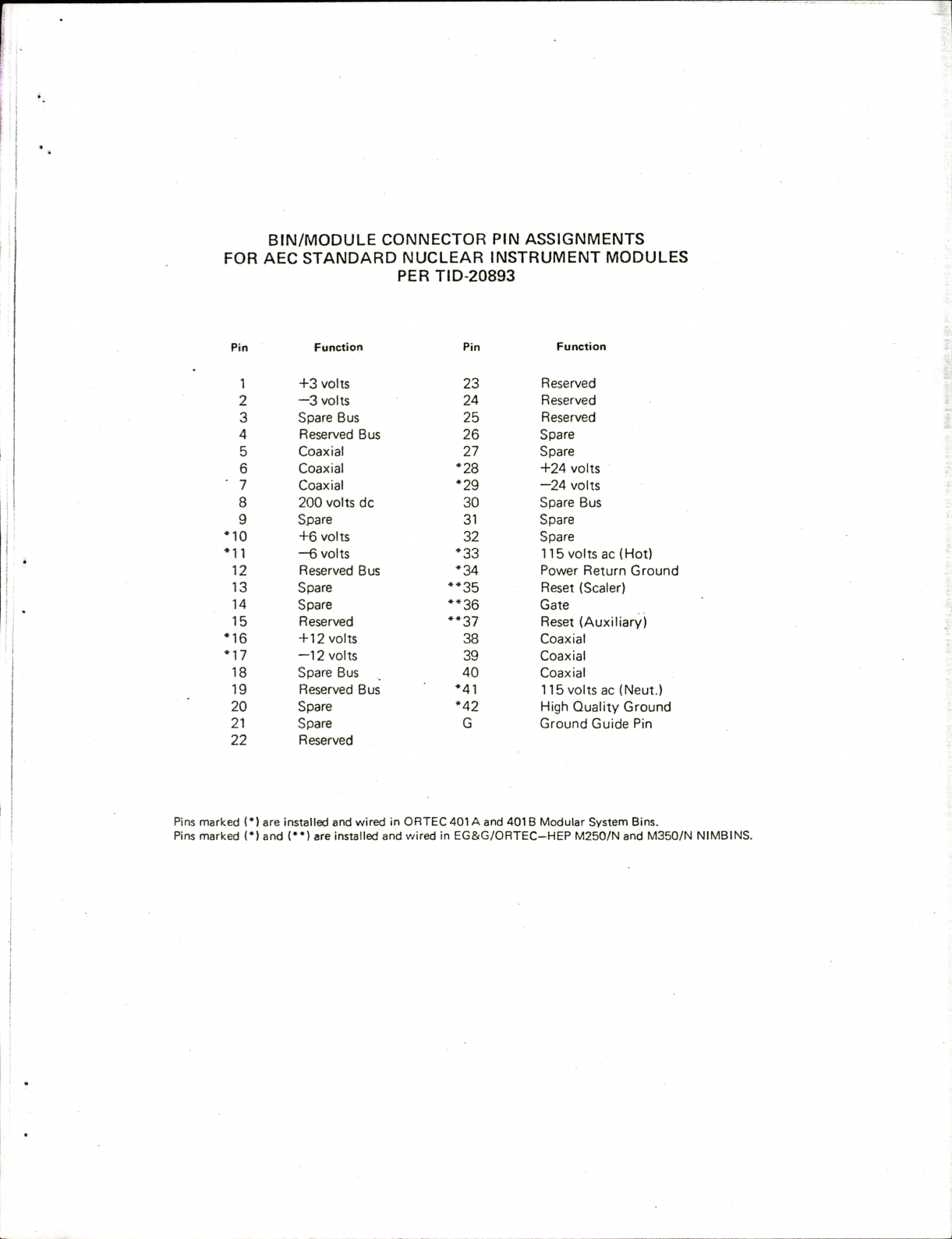

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

—3

volts

24

Reserved

3

Spare

Bus

25

Reserved

4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

*28

+24

volts

■

7

Coaxial

*29

—24

volts

8

200

volts

dc

30

Spare

Bus

9

Spare

31

Spare

*10

+6

volts

32

Spare

*11

—6

volts

*33

115

volts

ac

(Hot)

12

Reserved

Bus

*34

Power

Return

Ground

13

Spare

**35

Reset

(Sealer)

14

Spare

**36

Gate

15

Reserved

**37

Reset

(Auxiliary)

*16

+

12

volts

38

Coaxial

*17

—12

volts

39

Coaxial

18

Spare

Bus

40

Coaxial

19

Reserved

Bus

*41

115

volts

ac

(Neut.)

20

Spare

*42

High

Quality

Ground

21

Spare

G

Ground

Guide

Pin

22

Reserved

Pins

marked

(*)

are

Installed

and

wired

in

ORTEC

401A

and

401B

Modular

System

Bins.

Pins

marked

(*)

and

(**)

are

installed

and

wired

in

EG&G/ORTEC—HEP

M250/N

and

M350/N

NIMBINS.

iBIiiWtM'aiWIMCiiWI

INPU

T

INPUT

B

INPUTC

QiS.QI9

Qf^.QlS

ONL

'J

HOT

Qt

.az

(

UtNC

COlhJC

OINC.

jMPur

A

INPUT

OnL

INPUT

C

r'<\

2}L

^

iiMiriR^

6Hor

UAl/TSR

Q/e>.Q/7

Qiz.aii

schnutt

TRICCER

SCHMtTT

TRICCER

SCHM/TT

QU

constant

CURRENT

CLNIPATOR

ZX

lO-no

ns

RE50LV/NC

T/Al€

FRONT

PANEL

CONTROL

QZLQ2Z

ANTt-COtNC

2

INPUT

D

swtrcN

LimiTER

023.024

AUT/COIUC.

CIPCUIT

QS

COITIC

CIPCUl

T

a

e

COINC.

CIRCUIT

Q7

COINC.

CIRCUIT

aa

ONE

SHOT

IN

O

Q

10

£Ml

T

TCP

FOLLOTIER

Output

r\j'

500

n5

500

rl5

INO

ipur

V

^NO

a

25

EAMTTE-R

follower

\

OUTPUT

C'SZ

9-24)/.

rPONT

P/^N£L

CONTROLS

AOT£S:

C\/,

/.

A'£50L

VINC

TIML

Z-

2.

RLE

DWG.

4l4A-OIOI-5t.

-V

UNLESS

OTHERWISE

SPECIFIED

Dimensions

in

inches

E8AC1ION

i

DECiMAlS

±

ANCIES

SUIEaCE

EINISH

v^li

APriiEO

MACIlCES

ORTEC

OAK

RIDGE

TECHNICAL

ENTERPRISES

CORPORATION

OAK

liDOE

UNNtSSEE

FAST

COJNCiDBNCE

SLOCK

DIACPAM

2-22C.r

tNy

^WIOVM

!

m

lA.

OtvG

i^WiO

itir

{NO

K

MIlAM

PIAWINU

NO.

4l4A-0l0l-(il

-CZ5I1-

—Igcaf—

•H

oSah-

/'jo

H

goiat-

-

•+

oe-3

—

e£D

+

—

H

8tah-

—I

sz

^

I—

—I

—

ngj—

—I

O

<Q

—

+

-qtd—

-da)

•90+

—

-{WttJ—

-CE3J-

•

I—

r

-|£zah-

—l"Z-t.ah-

CSS)

—1

Slat—

-fgrST—rTT>-

S

h

—C~±£2_I)—

--(goTdj--

H

^aK

-[WS}-

—i

oil2<

h~

H

e=ja

-j

so-<-|—

Hy^al

<H

920I—

—{^cFdT—

—C

3

)—

^

j

—I

"fri

a

h-

lHU

—rrrsj>-

-mTu=

—(

/ga>—

—I

naH-f

$

—1

csa

I—

-<

9a

K-

-czzi—

h-

-C

9za

>-

-moT^

jj-jsor^^

-*4TTO|—

—<~0Id

'y—

-CHS—

—

xx^C^sZH™

~-S52}-~

-Q51}—

•^£5353""

"*Hozo

I—

eco4.--

Table of contents

Other EG&G Amplifier manuals

EG&G

EG&G ORTEC 444 User manual

EG&G

EG&G 128A Service manual

EG&G

EG&G ORTEC 575A Service manual

EG&G

EG&G ORTEC 118A User manual

EG&G

EG&G ORTEC 474 Service manual

EG&G

EG&G ORTEC 535 Service manual

EG&G

EG&G ORTEC 427 User manual

EG&G

EG&G 113 Service manual

EG&G

EG&G ORTEC 113 Service manual

EG&G

EG&G ORTEC 855 Service manual