EG&G ORTEC 118A User manual

100

MIDLAND

ROAD.

OAK

RIDGE,

TENNESSEE,

37830

AREA

CODE

(615)

483-8451

TWX

810-572-1078

INSTRUCTION

MANUAL

118A

PREAMPLIFIER

•

I

ii

^

^

Li"k

is

^

i

y

il

tL'

is

^

QUEEN'S

UNIVERSITY

EBsCS

COMPANY

®

INSTRUCTION

MANUAL

118A

PREAMPLIFIER

Serial

No.

Purchaser

Date

Issued

r

;

INCORPORATED

P.

0.

BOX

C

OAK

RIDGE,

TENNESSEE

37830

Telephone

(615)

483-8451

TWX

810-572-1078

ORTEC

IncorporatecJ

1966

Printed

In

UaS«A«

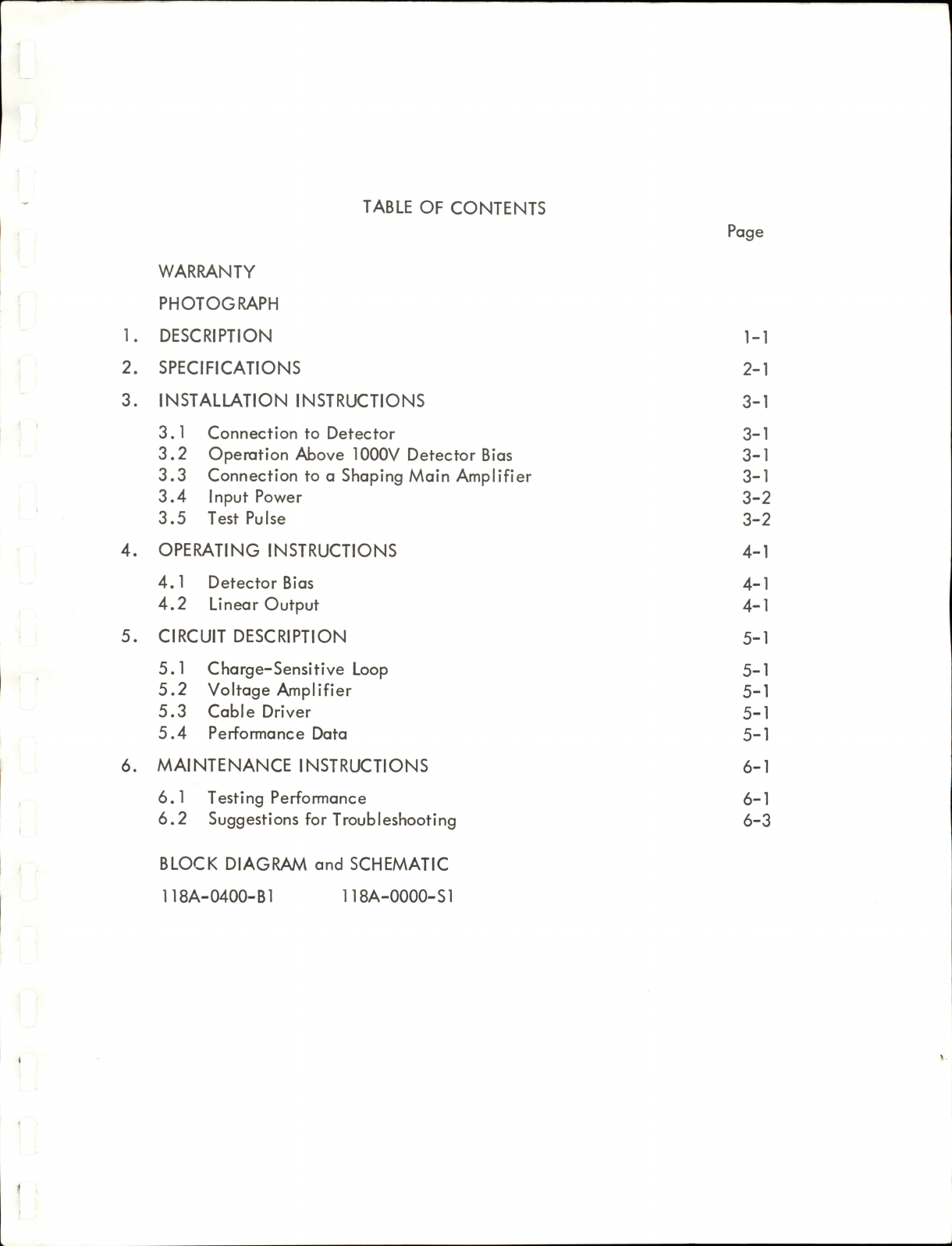

TABLE

OF

CONTENTS

Page

WARRANTY

PHOTOGRAPH

1.

DESCRIPTION

1-1

2.

SPECIFICATIONS

2-1

3.

INSTALLATION

INSTRUCTIONS

3-1

3.1

Connection

to

Detector

3-1

3.2

Operation

Above

lOOOV

Detector

Bias

3-1

3.3

Connection

to

a

Shaping

Main

Amplifier

3-1

3.4

Input

Power

3-2

3.5

Test

Pulse

3-2

4.

OPERATING

INSTRUCTIONS

4-1

4.1

Detector

Bias

4-1

4.2

Linear

Output

4-1

5.

CIRCUIT

DESCRIPTION

5-1

5.1

Charge-Sensitive

Loop

5-1

5.2

Voltage

Amplifier

5-1

5.3

Cable

Driver

5-1

5.4

Performance

Data

5-1

6.

MAINTENANCE

INSTRUCTIONS

6-1

6.1

Testing

Performance

6-1

6.2

Suggestions

for

Troubleshooting

6-3

BLOCK

DIAGRAM

and

SCHEMATIC

118A-0400-B1 118A-0000-S1

STANDARD

WARRANTY

FOR

ORTEC

ELECTRONIC

INSTRUMENTS

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

con

cealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

v^aybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

damage

claims

and

in

providing

replacement

equipment

when

necessary.

WARRANTY

ORTEC

warrants

its

electronic

products

to

be

free

from

defects

in

workmanship

and

materials,

other

than

vacuum

tubes

and

semiconductors,

for

a

period

of

twelve

months

from

date

of

ship

ment,

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replacement,

at

ORTEC

option,

will

be

made

without

charge

at

the

ORTEC

factory.

Shipping

expense

will

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors,

as

made

by

their

manufacturers,

will

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

liability

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibility

for

modification

of

previously

manufactured

units.

Since

installation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

an^

risks

or

liabilities

associated

with

the

methods

of

installation,

or

installation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

ORTEC

instruments

not

in

warranty

may

be

returned

to

the

factory

for

repairs

or

checkout

at

modest

expense

to

the

customer.

Standard

procedure

requires

that

returned

instruments

pass

the

same

quality

control

tests

as

those

used

for

new

production

instruments.

Please

contact

the

factory

for

instructions

before

shipping

equipment.

■■y^L

"■

DET.

INPUT

mM.

m

PULSE

POWER

WARRANTY

VOID

The

warranty

is

voided

unless

the

following

precautions

are

taken:

DO

NOT

connect

a

detector,

coble,

capacitor,

or

other

copocitive

device

or

low

impedance

to

the

DET.

INPUT

connector,

shown

in

the

Front

View

on

page

ii

of

this

manual,

unless

the

detector

bias

circuitry

is

COMPLETELY

DISCHARGED.

(Refer

to

explanation

below.)

The

input

transistor

wil

I

be

destroyed

if

the

DET.

INPUT

connector

is

shorted,

i.e.,

by

connecting

a

detector,

cable,

capacitor,

or

other

capacitive

device

such

as

a

voltmeter

probe,

etc.,

while

the

detector

bios

components

are

charged.

A

short

circuit,

short-term

or

continuous,

will

cause

the

applied

bias

voltage

(stored

on

C3)

to

be

coupled

via

C3

directly

to

the

input

transistor,

causing

catastrophic

breakdown.

If

this

happens,

the

only

recourse

is

to

replace

Q1

and

perhaps

Q2

also,

depending

on

the

failure

mode

of

Q1

.

To

discharge

the

detector

bias

circuitry

requires

that

either

a

low

impedance

(short

cir

cuit

preferable)

be

connected

across

the

DET.

BIAS

connector,

shown

in

the

Rear

View

on

page

ii,

for

at

least

one

minute,

or

the

bias

supply

voltage

be

reduced

to

zero

for

a

time

adequate

to

discharge

the

input

coupling

capacitor.

A

shorting

cap

is

provided

at

the

DET.

BIAS

connector

for

the

purpose

of

discharging

the

bias

circuitry

and

keeping

it

discharged

when

preamp

is

not

in

use.

If

a

variable

bias

supply

is

used,

merely

turning

down

the

voltage

control

to

zero

and

leaving

it

for

at

least

one

minute

will

suffice,

since

the

bias

circuitry

can

discharge

itself

through

the

output

impedance

of

the

bios

supply.

Sometimes

it

is

necessary

to

simply

disconnect

the

bias

supply,

such

as

when

using

batteries

for

bios.

This

situation

leaves

no

discharge

path,

so

a

path

must

be

provided

by

placing

a

short

circuit

or

low

impedance

across

the

DET.

BIAS

connector

on

the

rear

panel

of

the

unit.

(Use

shorting

cop

provided.)

DO

NOT

SHORT

the

DET.

INPUT

connector

on

the

front

panel.

This

problem

has

been

studied

extensively,

and

any

attempt

to

protect

the

input

tran

sistor

by

limiting

the

voltage

swing

by

the

use

of

diodes,

zeners,

etc.,

degrades

the

resolution

to

approximately

5.5

keV

(Si)

and

degrades

the

slope

to

approximately

0.15

keV/pF.

1-1

ORTEC

118A

PREAMPLIFIER

1.

DESCRIPTION

(See

Block

Diagram,

118-0400-B)

The

ORTEC

118A

Preamplifier

is

intended

for

use

with

cooled,

low-leakage

semi

conductor

detectors

having

relatively

low

(0

to

100

pF)

capacity.

In

order

to

achieve

the

high

performance

specified,

the

detector

bios

resistor

is

necessarily

large

(2000

megohms),

and

therefore

the

voltage

drop

across

this

resistor

can

be

significant

with

detectors

having

high

leakage.

The

118A

is

an

all-transistor

preamplifier

using

a

field-effect

transistor

in

the

input

stage.

The

preamplifier

contains

a

charge-sensitive

stage

having

an

open

loop

gain

greater

than

20,000

followed

by

a

voltage

amplifier

with

switch-selectable

gains

of

0.5

and

5.

The

voltage

amplifier

is

followed

by

a

cable

driver

capable

of

driving

a

93-ohm

cable

(series

terminated

at

the

preamplifier

end)

to

±7V.

When

the

preamp

is

operated

at

high

counting

rotes,

there

is

a

possibility

that

the

input

pulses

will

pile

up

and

cause

the

preamplifier

to

saturate.

In

order

to

opti

mize

the

preamplifier

counting

rote

capabilities,

a

SO-psec

clip

(RC

differentiation)

has

been

inserted

between

the

charge-sensitive

stage

and

the

voltage

amplifier.

With

the

addition

of

this

clip,

both

the

charge-sensitive

stage

and

the

voltage

ampli

fier

saturate

at approximately

the

same

level.

The

counting

rate

capabilities

of

the

118A

for

various

energies

are

shown

in

the

following

table:

Input

Energy

Count

Rate

With

«1%

(silicon

equivalent)

counting

losses

(cts/sec)

100

KeV

«2

X

10^

1

MeV

«2

X

10^

10

MeV

ft

.2

X

104

2-1

2.

SPECIFICATIONS

Basis

of

Warranty:

<.03

keV/pF

fwhm

Ge

slope,

si

.5

keV

fwhm

Ge

at

0

pF

input

capacity.

Typical

performance

is

shown

below:

TYPICAL

PERFORMANCE

Noise

with

2p

sec

RC

Main

Amp

Ext

Cap.

(pF)

Resolution

keV

(Ge)

Resolution

keV

(Si)

Eq.

Noise

Chg.

rms

electrons

Relative

Amplitude

Rise

Time

(nsec)

0

1.19

1.48

175

1.00

48

5

1.26

1.57

185

1.00

52

10

1.40

1.74

205

1.00

56

15

1.53

1.90

224

1.00

65

25

1.80

2.24

264

1.00

72

50

2.50

3.11

367

1.00

103

100

4.0

4.98

587

.995

168

200

6.9

8.6

1015

.985

280

500

15.0

18.6

2200

.950

580

1000

27.5

34.2

4040

.900

1000

Output

pulse

shape

Rise

time

as

in

table

above;

exponential

fal

l

with

50-psec

time

constant

Integral

nonlinearity

sO.1%

for

0-5V

with

internal

series

termination

Temperature

coefficient

±0.01%

per

°C

Detector

bias

isolation

1000V

dc

with

Microdot

connector

in

place;

2000V

dc

without

Microdot

connector

1

I

2-2

I

Input

open

loop

gain

>20,000

Power

required

+24V

dc

at

18

mA,

-24V

dc

at

18

mA;

supplied

from

ORTEC

main

amplifier

or

from

on

ORTEC

115

Preamplifier

Power

Supply

Cable

required

10-foot

compatible

cable

supplied

with

preamplifier,

type

108-C2

Power

connector

Ampheno!

17-20090

Saturated

output

amplitude

7V

at

end

of

several

hundred

feet

of

unterminated

93-ohm

cable

Output

source

impedance

Adjustable

from

50

to

150

ohms

Charge

gain

300

mV/MeV

in

XI0

gain

position

(silicon),

365

mV/MeV

(germanium);

30

mV/MeV

in

XI

gain

position

(silicon),

36.5

mV/MeV

(germanium)

Detector,

output,

and

test

pulse

connectors

BNC

Detector

bias

connector

MHV,

Gremar

6317

Size

1.8

X

4

X

6

inches

(4.5

x

10.2

x

15.3

cm)

Weight

Net,

1.5

pounds

(0.7

kg);

gross,4.0

pounds

(1.8

kg)

S

3.

AI

V

CM-C

r

0-

O

kf

C

V«

,

•1/

c

A

^7

,

%

^

.0

3-1

3.

INSTALLATION

INSTRUCTIONS

3.1

Connection

to

Detector

A

direct

connection

with

shielded

coaxial

cable

should

be

made

between

the

detector

and

the

Microdot

connector

labeled

DET.

INPUT

on

the

front

panel.

DO

NOT

CONNECT

THE

DETECTOR

TO

THE

INPUT

CONNECTOR

UNTIL

THE

DETECTOR

BIAS

VOLTAGE

HAS

BEEN

REDUCED

TO

ZERO.

FAILURE

TO

DO

THIS

WILL

CAUSE

CATASTROPHIC

DAMAGE

TO

THE

INPUT

FIELD

EFFECT

TRANSISTOR.

The

performance

of

the

118A

Preamplifier,

like

that

of

all

other

such

low-

noise

nuclear

amplifiers,

is

degraded

as

the

capacity

at

the

input

of

the

amplifier

increases;

for

this

reason,

it

is

important

that

the

length

of

coaxial

cable

used

between

the

amplifier

and

the

detector

be

kept

at

the

minimum

necessary.

Also,

it

is

preferable

to

use

93-

or

100-ohm

impedance

cable

rather

than

75-

or

50-ohm

cable,

since

the

capacity

per

foot

is

less

for

the

higher-

impedance

cable,

Microdot

cables

and

fittings

of

the

series

stocked

and

supplied

by

ORTEC

are

suitable.

The

cable

is

100-ohm

impedance,

13

pF

per

foot.

An

adapter,

ORTEC

No,

C-16,

may

be

used

on

the

input

Microdot

connector

to

permit

use

of

the

BNC

cables,

(See

pages

6-6

and

6-7,)

Once

the

input

cable

installation

has

been

made,

the

electronic

noise

perform

ance

of

the

preamp

can

be

predicted

by

calculating

the

cable

capacity

from

the

above

information,

adding

the

capacity

expected

from

the

detector,

and

referring

to

the

table

of

typical

performance

versus

input

capacity

(Section

2).

3.2

Operating

Above

1000V

Detector

Bias

If

it

is

desired

to

operate

the

detector

at

more

than

1000

volts,

the

Microdot

detector

input

connector

must

be

removed,

since

it

wil

l

not

take

more

than

1000

volts.

The

components

in

the

bias

circuitry

are

rated

for

up

to

2000

volts,

and

the

unit

may

be

operated

at

up

to

2000

volts

if

some

arrangement

is

made

to

get

the

detector

connection

inside

the

preamp

with

good

shielding.

This

is

some

times

done

by

removing

the

input

connector,

mounting

the

preamp

rigidly

against

the

outside

of

the

vacuum

wall,

and

letting

the

vacuum

feedthrough

protrude

directly

into

the

inside

of

the

preamp,

where

connection

is

made

with

the

wire

that

was

connected

to

the

input

connector.

3.3

Connection

to

a

Shaping

Main

Amplifier

The

preamp

can

be

used

to

drive

long

93-ohm

line

to

a

shaping

main

amplifier,

and

is

designed

to

be

directly

compatible

with

the

ORTEC

transistor

main

ampli

fiers.

It

can

be

used

with

any

shaping

main

amplifier

if

a

power

supply

is

used

to

power

the

preamp

,

3-2

3.4

Input

Power

Power

for

the

preamp

is

supplied

through

the

Amphenol

connector

(17-20090)

on

the

rear

of

the

chassis.

Power

may

be

supplied

by

a

single

45-volt

battery

with

a

tap

at

22.5

volts

(the

tap

is

used

as

ground,

providing

+22.5V

and

-

22.5V;

current

drain

is

18

mA),

or

any

well-filtered

±24V

pov/er

supply

such

as

the

ORTEC

115

Preamplifier

Power

Supply.

If

the

preamp

is

used

with

ORTEC

transistor

main

amplifiers,

power

for

the

preamplifier

will

automatically

be

supplied

to

the

preamplifier

from

the

tru

in

amplifier

via

the

interconnecting

cable

supplied

with

the

preamplifier.

3.5

Test

Pulse

A

voltage

test

pulse

can

be

inserted

at

the

TEST

PULSE

connector

on

the

rear

of

the

preamp

without

the

use

of

an

external

charge

terminator,

since

the

preamp

has

a

built-in

charge

terminator.

The

shape

of

this

voltage

pulse

must

have

a

fast

rise

(less

than

10~8

seconds)

followed

by

a

slow

exponential

decay

back

to

the

baseline

(2

to

4

x

10"4

seconds).

The

input

amplitude

can

be

set

to

any

desired

level

with

the

knowledge

that

92

mV

amplitude

at

the

TEST

PULSE

connector

is

equal

to

approximately

1

MeV

energy

loss

in

a

silicon

detector.

Also,

the

test

pulse

can

be

inserted

into

the

DET.

INPUT

connector

simultaneously

with

an

operating

detector

by

using

an

external

charge

terminator,

provided

the

charge

terminator

will

withstand

the

detector

bias

voltage

(s200

volts

with

standard

ORTEC

charge

terminator).

NOTE:

In

most

experimental

situations

the

optimum

signal-to-noise

ratio

occurs

with

the

preamp

gain

switch

in

the

XI0

position.

When

this

switch

is

in

the

XI

position,

the

signal-to-noise

ratio

at

the

preamplifier

output

is

the

same

as

that

of

the

XI0

position,

but

the

signal

level

is

only

l/lO.

At

this

low

signal

level,

main

amplifier

noise

contribution

becomes

more

significant.

The

signal-to-noise

ratio

at

the

output

of

the

main

amplifier

can

be

degraded

by

the

amount

of

the

main

amp

noise

contribution

and

resolution

sometimes

suffers.

4-1

OPERATING

INSTRUCTIONS

4.1

Detector

Bias

Detector

bias

is

applied

to

the

preamplifier

through

the

high-voltage

MHV

connector

(UG-931/U).

The

detector

bios

components

are

rated

at

2000V

and

connectors

are

rated

at

1000

volts.

Inside

the

preomp,

the

detector

bias

is

applied

to

the

DET.

INPUT

connector

through

a

decoupling

network

con

sisting

of

R1

(10-megohm),

R2

(2000-megohm),

and

C1

(0.0022pF)

so that

the

total

resistance

in

series

with

the

detector

bias

is

2010

megohms.

This

resistance

must

be

taken

into

account

when

considering

the

bias

voltage

actu

ally

applied

to

a

leaky

detector.

The

voltage

dropped

in

this

network

will

be

2010

volts

for

each

microampere

of

detector

leakage

current.

It

will

be

necessary

to

increase

the

bias

supply

output

voltage

to

compensate

for

this

drop.

EXAMPLE:

It

is

desired

to

operate

a

detector

at

100

volts

bias.

Detector

leakage

at

100

volts

=

0.05

microampere.

The

drop

in

the

bias

network

=(0.05

x

10"®)=

(2000

x

10®)

=

100.5

volts

Voltage

required

at

bias

supply

=

100

+

100.5

=

200.5

volts.

4.2

Linear

Output

The

output

of

the

preomp

is

a

"step"

of

voltage

of

300

mV/MeV

with

the

gain

switch

in

the

X10

position,

or

30

mV/MeV

in

the

XI

position

(silicon

detector

equivalents).

The

dynamic

range

of

the

output

is

7

volts,

either

polarity,

when

the

output

is

"sending-end"

terminated.

"Receiving-end"

termination

will

result

in

a

3.5-volt

dynamic

range,

but

this

may

be

preferable

to

sending-end

termination.

The

integral

nonlinearity

in

the

preomp

is

specified

at

not

greater

than

0.1%

over

the

0

to

10

MeV

range.

5-

1

5.

CIRCUIT

DESCRIPTION

(See

Schematic

Diagram

118-0000-A-S)

5.1

Charge-Sensitive

Loop

The

charge-sensitive

loop

consists

of

five

transistors

acting

as

an

operatiorKil

amplifier

with

capacitive

feedback.

Transistors

Q1

and

Q2

operate

in

cascode

and

drive

Q3,

Q4,

and

Q5

in

a

low

impedance

driver

configuration

for

low

output

impedance

and

fast

rise

time.

The

rise

time

of

the

charge-sensitive

loop

output

increases

as

the

external

input

(detector)

capacitance

is

increased.

5.2

Voltage

Amplifier

The

voltage

amplifier

is

designed

for

fast

rise

time

(20

nanoseconds

in

the

XI

gain

position)

so

as

to

faithfully

reproduce

the

pulse

from

the

charge-sensitive

loop.

In

the

XIO

gain

position

the

voltage

amplifier

has

a

rise

time

of

approx

imately

40

nanoseconds

even

at

low

capacitance

values.

In

the

XIO

gain

position

the

preamplifier

overall

rise

time

does

not

change

until

the

charge-

sensitive

loop

rise

time

approaches

40

nanoseconds,

as

external

capacitance

is

increased.

5.2.1

Pole-Zero

Cancellation

Network

The

decay

time

constant

of

the

output

signal

from

the

preamplifier

is

deteimined

by

C12

and

the

parallel

combination

of

R17, R18,

and

R36.

It

is

accurately

set

at

50

microseconds.

R36

C12

is

a

1

millisecond

time

constant

in

the

proper

configuration

to

provide

a

"zero"

type

frequency

response

which

cancels

out

the

1

mil

lisecond

"pole"

generated

by

the

charge

sensitive

loop

feedback

time

constant.

The

purpose

of

this

"Pole-

Zero

Cancellation"

is

to

obtain

a

pulse

response

which

has

a

step

rise

with

a

single

50

microsecond

decay

time

constant

back

to

the

baseline

without

appreciable

undershoot.

This

will

allow

accurate

pole-zero

cancel

lation

in

the

shaping

amplifier.

5.3

Cable

Driver

The

cable

driver

consists

of

Q8,

Q9,

QIO,

and

Q11

operating

in

a

complementary

Darlington

connection.

This

circuit

gives

extremely

good

linearity

and

an

output

impedance

of

a

few

ohms.

However,

51

ohms

is

inserted

in

series

with

each

cir

cuit,

so

that

the

minimum

output

impedance

(R35

at

0

ohms)

is

51

ohms.

The

maximum

output

impedance

is

150

ohms

(R31

at

ICQ

ohms),

so

that

cables

in

the

ra

nge

of

50

to

150

ohms

can

be

series

(sending-end)

terminated.

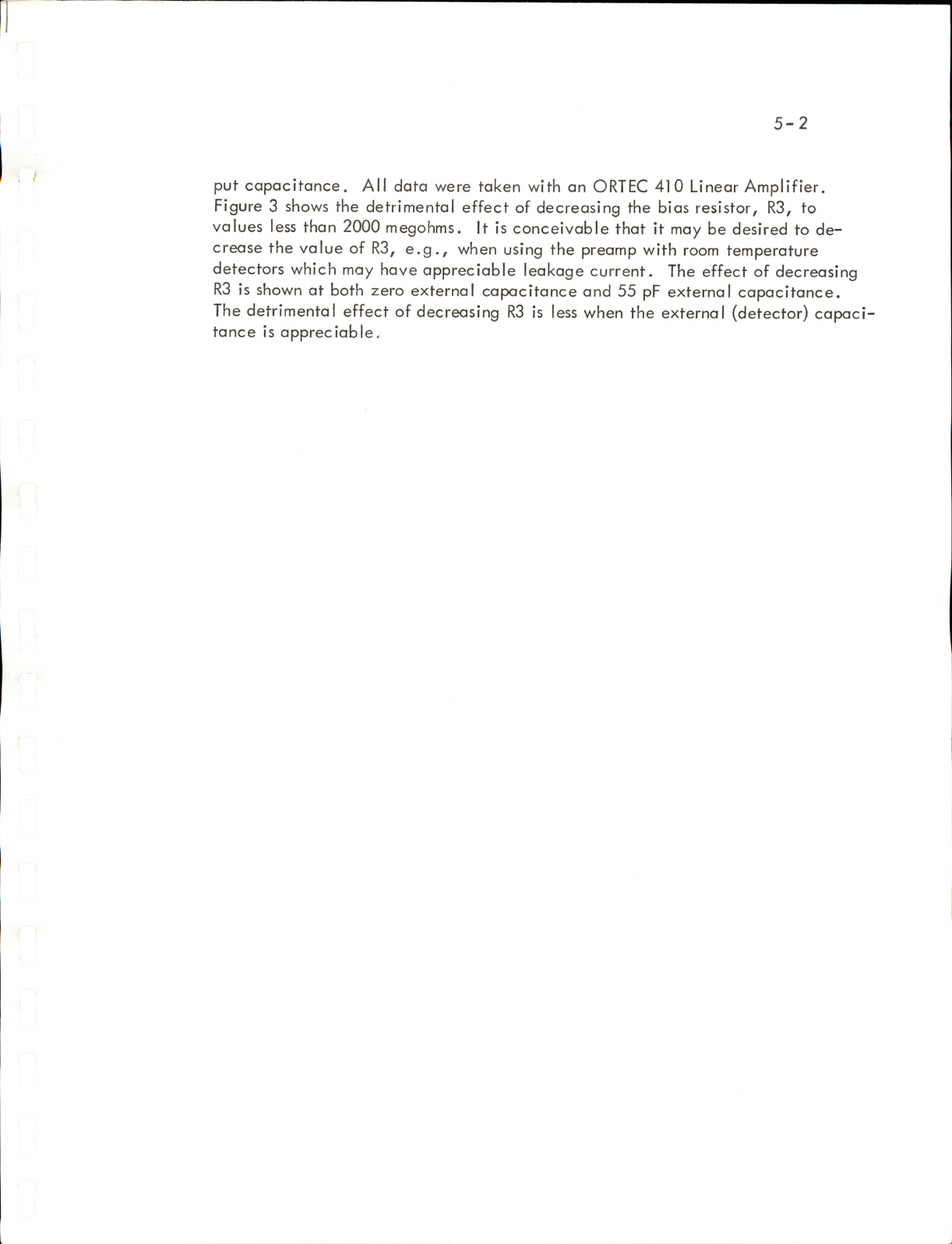

5.4

Performance

Data

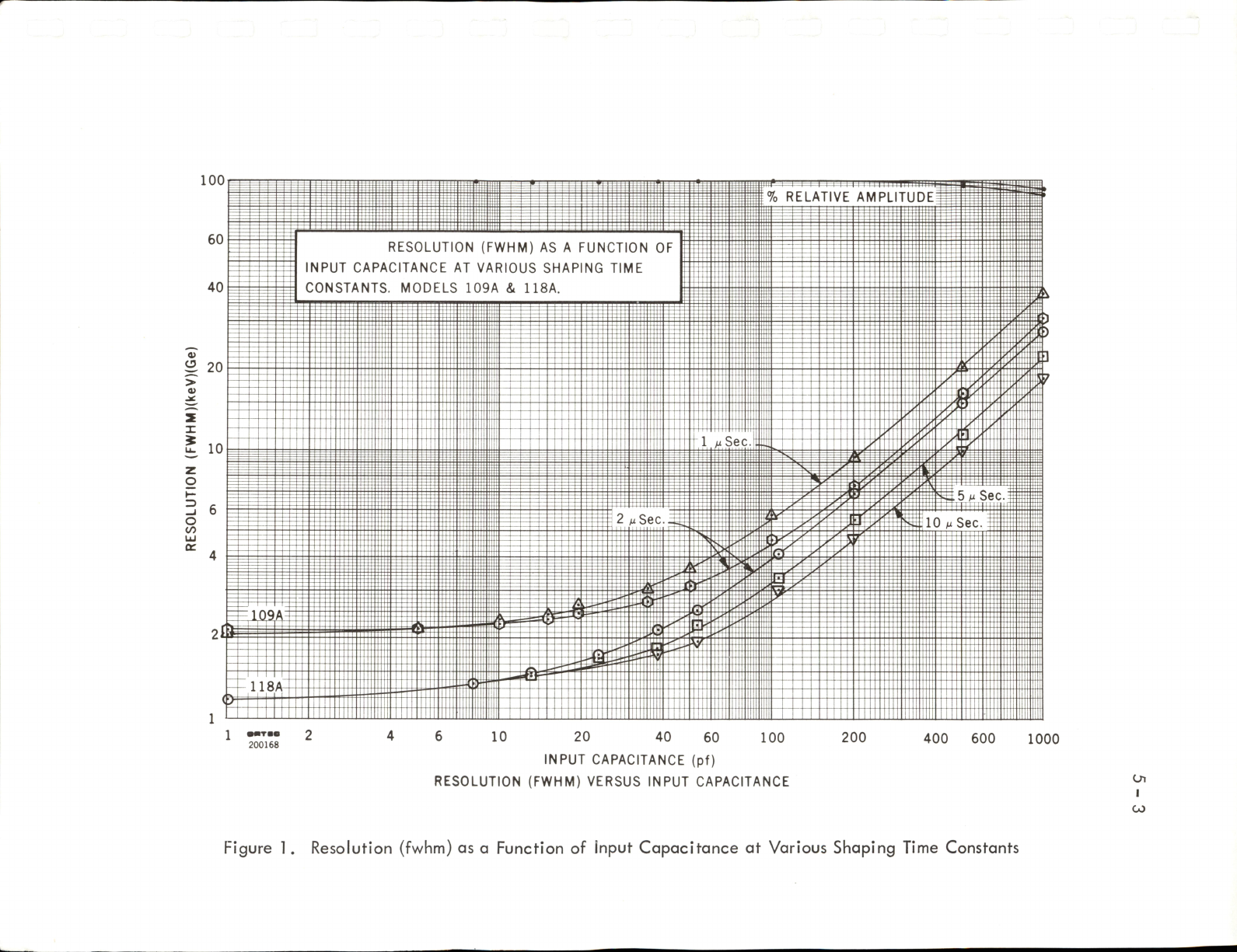

Figure

1

shows

typical

performance

characteristics

of

the

preamp

on

relative

amplitude

and

resolution

(fwhm)

as

a

function

of

external

capacitance

on

the

input

of

the

preamp

for

1

psec,

2psec,

5Hsec,

and

lOpsec

single

RC

integration

and

differentiation

time

constants.

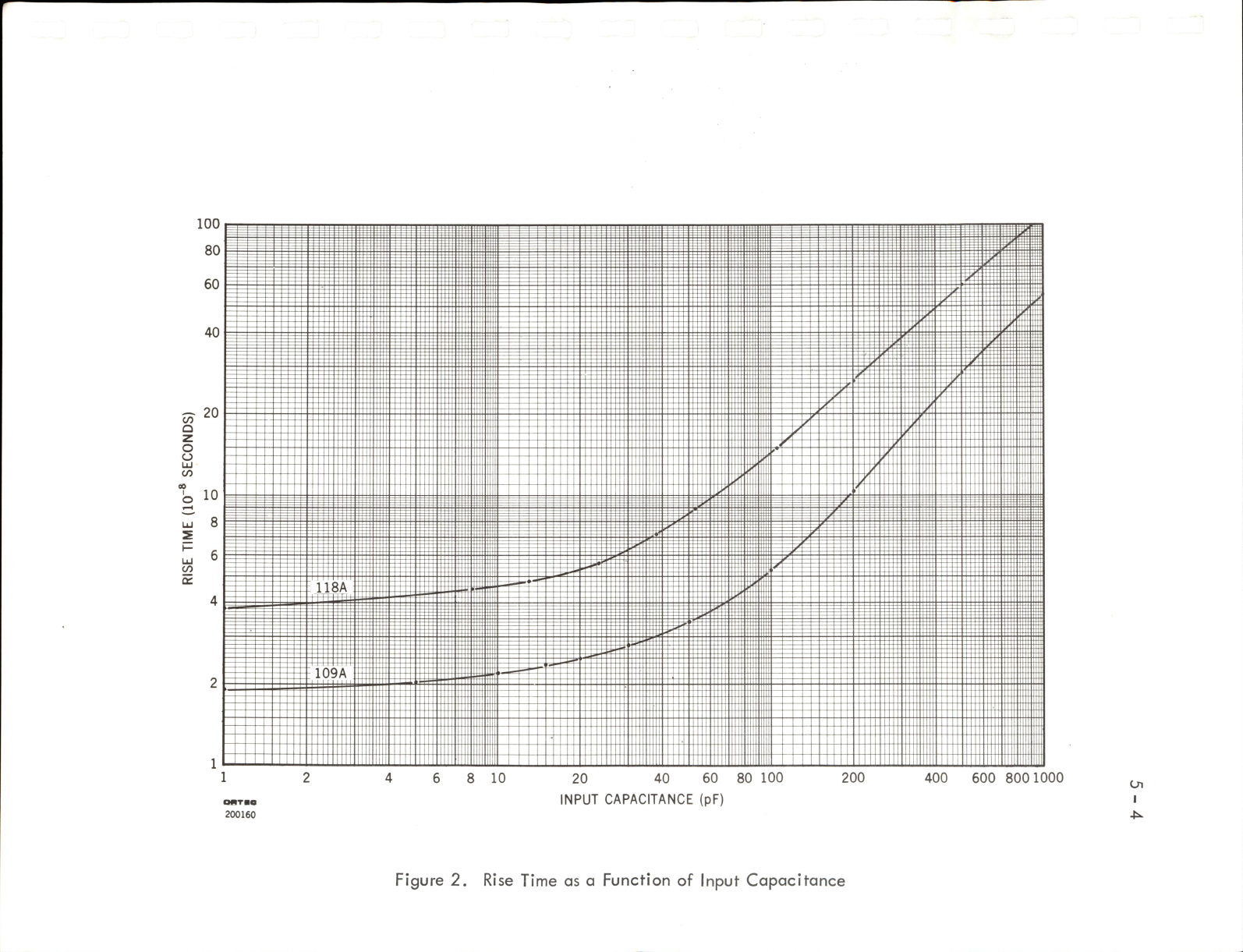

Figure

2

shows

rise

time

as

a

function

of

in-

5-2

put

capacitance.

All

data

were

taken

with

an

ORTEC

410

Linear

Amplifier.

Figure

3

shows

the

detrimental

effect

of

decreasing

the

bias

resistor,

R3,

to

values

less

than

2000

megohms.

It

is

conceivable

that

it

may

be

desired

to

de

crease

the

value

of

R3,

e.g.,

when

using

the

preamp

with

room

temperature

detectors

which

may

have

appreciable

leakage

current.

The

effect

of

decreasing

R3

is

shown

at

both

zero

external

capacitance

and

55

pF

external

capacitance.

The

detrimental

effect

of

decreasing

R3

is

less

when

the

external

(detector)

capaci

tance

is

appreciable.

100

i±H44=t

RELATIVE

AMPLITUDE

RESOLUTION

(FWHM)

AS

A

FUNCTION

OF

INPUT

CAPACITANCE

AT

VARIOUS

SHAPING

TIME

CONSTANTS.

MODELS

109A

&

118A.

H

10

5

M

Sec

2

uSec

10

m

Sec.

118A

•■m

2

200168

20 40

60

100

INPUT

CAPACITANCE

(pf)

RESOLUTION

(FWHM)

VERSUS

INPUT

CAPACITANCE

200

400

600

1000

Oi

I

CO

Figure

1.

Resolution

(fwhm)

as

a

Function

of

Input

Capacitance

at

Various

Shaping

Time

Constants

8

10

Qtirn

200160

20

40

60

80

100

200

INPUT

CAPACITANCE

(pF)

400

600

800

1000

Oi

Figure

2.

Rise

Time

as

a

Function

of

Input

Capacitance

700

<

s

ce

ui

(S

>

«

o

I/)

Ui

fl

C

600„

400

O

200200

50

100

200

500

1000

2000

BIAS

RESISTOR

VALUE

(MEGOHMS)

5000

Oi

Figure

3.

Resolution

(fwhm)

os

a

Function

of

Bias

Resistor

6-

1

6.

MAINTENANCE

INSTRUCTIONS

6.1

Testing

Performance

As

ordinarily

used

in

a

counting

or

spectroscopy

system,

the

preamp

is

one

part

of

a

series

system

involving

the

source

of

particles

to

be

analyzed,

the

detector,

the

preamp,

the

main

amplifier,

and

the

pulse

height

analyzer.

In

situations

where

proper

results

are

not

being

obtained

and

tests

for

proper

performance

of

the

preamp

and

the

other

components

are

indicated,

it

is

important

to

realize

that

rapid

and

logical

testing

is

possible

only

when

the

individual

components

are

separated

from

the

series

system.

In

proving

the

performance

of

the

preamp,

this

consists

of

removing

it

from

the

system

and

dealing

with

it

alone,

by

providing

a

known

electrical

input

signal

and

testing

for

proper

output

signal

with

an

oscilloscope.

6.1.1

Use

a

voltage

pulse

in

the

TEST

PULSE

jack,

as

outlined

in

Section

3.5,

or

use

a

pulser

with

a

charge

terminator

at

the

DET.

INPUT

jack.

The

polarity

of

the

test

pulse

signal

should

be

in

agreement

with

the

expected

signal

input

polarity

from

a

detector.

6.1.2

If

a

suitable

input

signal

has

been

obtained

for

the

preamp

as

outlined

in

the

preceding

section,

the

performance

of

the

instrument

may

be

checked

by

observing

the

pulse

waveform

at

the

OUTPUT

jack.

If

an

input

signal

of

920

mV,

corresponding

to

about

10

MeV,

has

been

obtained

as

described

above,

one

can

expect

an

output

pulse

amplitude

of

about

3.0

volts

with

the

gain

switch

in

the

XIO

position,

and

0.3

volt

with

the

gain

switch

in

the

XI

position.

6.1.3

The

noise

contribution

of

the

preamplifier

may

be

verified

by

two

basic

methods.

In

either

case,

the

normal

capacity

of

the

detector

and

associated

cables

should

be

replaced

by

a

capacitor

of

equal

value

connected

to

the

DET.

INPUT

jack.

This

is

necessary

because

the

noise

contribution

of

the

preamplifier

is

dependent

upon

input

capacity,

as

can

be

seen

from

the

noise

specifications

given

in

Section

2.

The

only

meaningful

statement

of

the

noise

level

of

the

preamplifier

is

one

that

relates

to

the

spread

caused

by

the

noise

in

actual

spectra.

This

can

be

measured

and

expressed

in

terms

of

the

ful

l

width

at

half

maxi

mum

of

a

monoenergetic

signal

after

passing

through

the

preamplifier

and

main

amplifier

system.

The

noise

performance

referenced

in

Section

2

is

stated

in

these

terms,

and

verification

methods

wil

l

be

described.

If

desired,

the

preamplifier

can

be

tested

with

no

external

capacity

on

the

DET.

INPUT

jack,

inwhich

case

the

noise

width

should

be

approxi

mately

that

shown

for

zero

external

capacity.

In

any

case,

the

input

jack

and

capacitors,

when

used,

should

be

completely

shielded

electri

cal

ly.

A

wrapping

of

aluminum

foil

around

the

input

jack

will

suffice

for

testing

at

zero

capacity,

taking

care

not

to

short

the

center

conductor

to

ground.

6-2

The

preamplifier

must

be

tested

in

conjunction

with

an

associated

main

amplifier

that

provides

the

required

pulse

shaping.

The

typical

noise

per

formance

given

in

Section

2

is

based

on

main

amplifier

pulse

shaping

consisting

of

equal

RC

differentiation

and

integration

of

2-microsecond

time

constant.

For

comparison

to

these

tabulated

values,

it

is

preferable

to

test

the

preamplifier

under

identical

pulse

shaping

conditions.

It

is

also

important

to

ensure

that

the

noise

level

of

the

input

stage

of

the

associated

main

amplifier

does

not

contribute

materially

to

the

total

noise.

This

is

usually

no

problem

provided

input

attenuators,

if

any,

on

the

main

amplifier

are

set

for

minimum

attenuation.

If

a

multichannel

pulse

height

analyzer

is

used

following

the

main

ampli

fier,

testing

of

the

noise

performance

can

be

accomplished

merely

by

using

a

calibrated

test

pulse

generator

with

charge

terminator,

as

outlined

in

Section

6.1.1

.

With

only

the

charge

terminator

connected

to

the

DET.

INPUT

jack,

the

spread

of

the

pulser

peak

thus

analyzed

will

be

due

only

to

the

electronic

noise

contribution

of

the

preamplifier

and

main

amplifier.

The

analyzer

can

be

calibrated

in

terms

of

keV

per

channel

by

observing

two

different

pulser

peaks

of

known

energy,

and

the

fwhm

of

a

peak

can

be

taken

directly

from

the

analyzer

readout.

It

is

also

possible

to

determine

the

noise

performance

of

the

preamplifier

by

the

use

of

a

wide-bandwidth

rms

ac

voltmeter

such

as

the

Hewlett-

Packard

400D,

reading

the

main

amplifier

output

noise

level

and

correlating

with

the

expected

pulse

amplitude

per

keV

of

input

signal

under

the

same

conditions.

Again,

a

calibrated

test

pulse

generator

is

required

for

an

accurate

measurement.

In

this

method,

the

preamplifier

and

main

amplifier

are

set

up

as

they

would

be

used

normal

ly,

but

with

a

dummy

capacitor

(or

no

capacity)

on

the

DET.

INPUT

jack,

and

with

the

ac

voltmeter

connected

to

the

amplifier

output.

The

noise

voltage

indicated

by

the

meter,

designated

Erms,

'S

read

and

noted.

Then,

a

test

pulse

of

known

energy,

Ejp

(in

keV),

is

applied

to

the

input

jack,

and

the

amplitude

of

the

resulting

output

pulse,

Eq^j.

is

measured

in

volts

with

an

oscilloscope.

The

noise

spread

can

then

be

calculated

from

the

formula

fwhm

(keV,

Si

det.)

=

2.66

(Epms)

(Ein)

^out

where

Epms

's

output

noise

in

volts

on

the

400D

meter,

E|n

is

the

input

signal

in

keV

particle

energy,

Eout

output

signal

in

volts

corresponding

to

the

above

input.

The

factor

2.66

is

the

product

of

two

relations:

correction

from

rms

to

fwhm

(2.35),

and

correction

of

the

4000

meter

from

sine-wave

to

white

noise

(1.13).

6-3

The

noise

performance

of

the

preamplifier,

as

measured

by

the

above

methods,

should

not

differ

significantly

from

that

given

in

the

specifi

cations

in

Section

2.

6.1.4

When

testing

the

preamplifier

and

detector,

if

the

noise

performance

of

the

preamplifier

has

been

verified

as

outlined

in

the

preceding

section,

or

is

otherwise

not

suspect,

a

detector

may

be

tested

to

some

extent

by

duplicating

the

noise

performance

tests

with

the

detector

connected

in

place,

and

with

normal

operating

bias

applied.

The

resulting

combined

noise

measurement,

made

either

with

an

analyzer

or

by

the

voltmeter

method,

indicates

the

sum

in

quadrature

of

the

separate

noise

sources

of

the

amplifier

and

the

detector.

In

other

words,

the

total

noise

is

given

by

(N^ot)^

=

(Njet)^

(Namp)®

•

Each

quantity

is

expressed

in

keV

fwhm.

The

quantity

Njet

'S

known

as

the

"noise

width"

of

the

detector,

and

is

included

as

one

of

the

specified

parameters

of

each

ORTEC

semiconductor

detector.

By

use

of

the

above

equation,

with

a

knowledge

of

the

noise

of

the

preamplifier,

the

noise

width

of

the

detector

can

be

determined.

The

significance

of

this

noise

width

in

evaluating

the

detector

is

subject

to

interpretation,

but

general

ly

the

actual

resolution

of

the

detector

for

protons

or

electrons

will

be

approxi

mately

the

same

as

the

noise

width;

the

resolution

of

the

detector

for

alpha

particles

will

be

poorer

than

the

noise

width.

The

most

useful

application

of

determining

the

noise

width

of

a

detector

is

in

the

occasional

monitoring

of

this

quantity

to

verify

that

the

detector

characteristics

have

not

undergone

any

significant

change

during

use.

6.2

Suggestions

for

Troubleshooting

In

situations

where

the

preamp

is

suspected

of

malfunction,

it

is

important

to

isolate

the

preamp

and

test

it

alone,

not

in

a

system

involving

other

units

such

a

sourceof

particles

to

be

analyzed,

the

detector,

the

preamp,

a

main

amplifier

and

subsequent

sealers

and/or

analyzers.

Such

logical

isolation

and

individual

testing

of

components

will

be

the

most

productive

approach.

6.2.1

Charge-Sensitive

Loop

The

function

of

the

preamp

is

simple

and

lends

itself

to

relatively

easy

scrutiny.

The

charge-sensitive

loop

performs

a

charge-to-voltage

conversion

on

the

input

signal.

It

has

an

output

signal

that

manifests

itself

as

a

fast

rise

(~40

nanoseconds

at

0

pF

external

capacitance)

step

of

voltage

whose

height

is

determined

by

the

input

charge,

followed

by

a

400-microsecond

decay

back

to

the

baseline.

This

signal

can

be

observed

at

the

emitter

of

Q4

while

impressing

a

signal,

as

described

in

Section

3.5.

The

amplitude

of

this

signal

should

be

90

mV

per

MeV

equivalent

input

signal

.

Table of contents

Other EG&G Amplifier manuals

EG&G

EG&G ORTEC 485 User manual

EG&G

EG&G ORTEC 414A Service manual

EG&G

EG&G 113 Service manual

EG&G

EG&G ORTEC 452 User manual

EG&G

EG&G ORTEC 113 Service manual

EG&G

EG&G ORTEC 474 Service manual

EG&G

EG&G ORTEC 444 User manual

EG&G

EG&G ORTEC 427 User manual

EG&G

EG&G ORTEC 575A Service manual

EG&G

EG&G 128A Service manual