EG&G ORTEC 535 Service manual

n

Model

535

Quad

Fast

Amplifier

Operating

and

Service

Manual

Model

535

Quad

Fast

Amplifier

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

05"

on

rear

panel

Printed

in

U.S.A.

ORTEC

Part

Number

678820

3348

0.5C

1186

standard

Warranty

for

EG&G

ORTEC

Nuclear

Eiectronic

Instruments

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

two

years

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

oruseof

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

or

service

furnished

or

any

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

In

this

agreement

or

pur

chase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obliga

tion

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEC

nuclear

electronic

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warrany

repair

and

as

a

source

of

statistical

information

for

design

improvements.

Repair

Service

If

It

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing,

by

telephone

[(615)

482-4411]

or

by

telex

(55-7450)

of

the

nature

of

the

fault

of

the

instrument

being

re

turned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

In

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

(In

the

case

where

the

Instrument

did

not

function

upon

pur

chase,

EG&G

ORTEC

will

pay

shipment

costs

both

ways.)

The

address

labei

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

Damage

in

Transit

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

Ill

CONTENTS

Page

WARRANTY

ij

PHOTOGRAPH

iv

1.

DESCRIPTION

1

2.

SPECIFICATIONS

'

. .

1

2.1.

Performance

1

2.2.

Controls

1

2.3.

Electrical

and

Mechanical

1

3.

INSTALLATION

2

3.1.

Connection

to

Detector

2

3.2.

Connection

of

Output

2

3.3.

Cascading

2

4.

OPERATING

INSTRUCTIONS

;

2

5.

CIRCUIT

DESCRIPTION

2

6.

MAINTENANCE

AND

CALIBRATION

3

6.1.

Preventive

Maintenance

3

6.2.

Corrective

Maintenance

3

6.3.

Calibration

3

6.4.

Factory

Repair

3

Schematic

635120

I

m

P!

EG&G

ORTEC

MODEL

535

QUAD

FAST

AMPLIFIER

1.

DESCRIPTION

The

EG&G

ORTEC

535

Quad

Fast

Amplifiercontainsfour

independent

direct-coupled

amplifiers

packaged

in

a

single-width

NIM

module.

Each

section

has

variable

voltage

gain,

5-10,

and

can

drive

±5

V

into

a

50fi

load.

The

excellent

dc

and

gain

stabilities

allow

cascading

sections

to

achieve

a

total

voltage

gain

of

10,000.

The

535

features

high

bandwidth

and

wide

dynamic

range,

<3

ns

rise

and

fall

times

to

±5

V,

coupled

with

low

noise

and

fast

overload

recovery.

Input

overload

pro

tection

is

provided

for

each

channel.

Hybrid

circuit

technology

gives

the

535

higher

reliability

In

an

economical,

high-density

package.

For

operator

convenience

independent

bandwidth

(BDW),

output

dc

offset

(DC),

and

fine

gain

(GAIN)

adjustments

are

In

cluded.

The

535

Quad

Fast

Amplifier

is

ideally

suited

to

precede

discriminators,

linear

gates,

fast

current

integrators,

or

any

instrument

requiring

fast

linear

input

signals.

The

low

noise

characteristics

of

the

535

make

it

particularly

useful

in

photon

counting

and

fast-timing

applications.

2.

SPECIFICATIONS

2.1.

PERFORMANCE

NOMINAL

VOLTAGE

GAIN

5-10;

noninverting.

RISE

TIME

<3

ns

to

±5

V

into

50

O;

bandwidth

>120

MHz.

NOISE

<25

//V

referred

to

the

input

measured

with

an

HP3400A

true

rms

voltmeter.

Wideband

noise

(200

MHz)

<30

A(V

referred

to

the

input.

INTEGRAL

NONLINEARITY

Typically

<±1%foroutput

to

±5

V.

PULSE

OVERLOAD

RECOVERY

Typically

<5

ns

for

a

X10

overload.

GAIN

INSTABILITY

Typically

<±0.05%/°

C.

DC

INSTABILITY

Typically

<±150

uVfC

referred

to

the

output.

INPUT

IMPEDANCE

50

O,

dc-coupled.

OUTPUT

IMPEDANCE

<1

Q,

dc-coupled.

OUTPUT

LINEAR

RANGE

±5

V

Into

50

O.

OPERATING

TEMPERATURE

RANGE

0

to

50°

C.

CROSSTALK

<0.02%

between

output

of

one

channel

and

input

of

another

channel.

2.2.

CONTROLS

BDW

20-turn

potentiometer

adjusts

the

output

band

width

and

overshoot.

Front

panel

mounted.

DC

20-turn

potentiometer

adjusts

the

output

dc

offset.

Front

panel

mounted.

GAIN

20-turn

potentiometer

adjusts

the

voltage

gain

from

typically

5

to

10.

Front

panel

mounted.

2.3.

ELECTRICAL

AND

MECHANICAL

POWER

REQUIRED

+24

V,

83

mA;-24

V,

83

mA;+12

V,

167

mA;

-12

V,

167

mA.

WEIGHT

Net

0.32

kg

(12

oz).

Shipping

1.25

kg

(2

lb

12

oz).

DIMENSIONS

3.81

x

6.1

x

8.89

cm

(1.5

x

2.4

x

3.5

in.).

3.

INSTALLATION

3.1.

CONNECTION

TO

DETECTOR

Connect

the

output

from

the

detector

or

preamplifier

to

the

Input

BNC

on

the

535

with

50

O

coaxial

cable.

This

cable

should

be

as

short

as

practical

to

minimize

the

physical

distance

through

which

the

detector

output-

current

pulse

has

to

pass.

The

amount

of

noise

that

will

be

added

to

the

signal

increases

with

cable

length.

An

input

signal

to

the

535

can

be

of

either

polarity

(e.g.,

it

can

originate

from

the

anode

or

any

dynode

in

a

photo-

multiplier

tube

circuit).

AC-coupiing

must

be

used

to

pre

vent

any

high

voltage

from

the

detector

being

applied

directly

to

the

535

input.

An

input-protection

circuit

is

included

which

allows

excellent

(typically

<5

ns)

over

load

recovery.

The

output

signal

from

the

535

will

have

the

same

polarity

as

the

input

and

will

be

amplified

by

a

factor

of

5-10.

The

linear

output

range

is

±5

V

into

a

50

n

load.

the

535

through

50

O

cable

terminated

by

a

50

Q

load.

If

the

driving

instrujnent

does

not

have

an

input

imped

ance

of

50

n,

an

external

terminating

resistor

should

be

added

to

prevent

pulse

reflections.

3.3.

CASCADING

When

an

amplification

greater

than

a

factor

of

10

is

de

sired,

the

input

signal

can

be

cascaded

through

additional

sections

of

the

535.

Each

section

provides

the

nominal

maximum

gain

of

10.

Cascading

the

signal

through

all

four

sections

will

provide

an

amplification

factor

of

about

10,000.

When

cascading

sections

of

the

535,

care

must

be

taken

to

ensure

proper

adjustment

of

the

DC

offset

controls

to

ensure

operation

within

the

linear

range

of

±5

V.

3.2.

CONNECTION

OF

OUTPUT

The

output

impedance

of

the

535

is

nominally

1

O.

Any

counter,

amplifier,

or

timing

instrument

can

be

driven

by

4.

OPERATING

INSTRUCTIONS

Three

operator

controls

(DC,

Gain,

and

BDW)

are

pro

vided

on

the

535.

The

DC

adjustment

permits

the

setting

of

the

dc-output

offset

to

zero

volts.

[The

input

offset

voltage

is

adjusted

by

an

internal

potentiometer

mounted

on

a

printed

wiring

board

(PWB).]

The

Gain

potentiom

eter

adjusts

voltage

gain

continuously

from

5

to

10.

The

BDW

(bandwidth)

sets

the

rise

time

or

overshoot

appro

priate

for

the

experiment.

The

tilt

is

adjusted

by

an

internal

potentiometer

mounted

on

the

PWB.

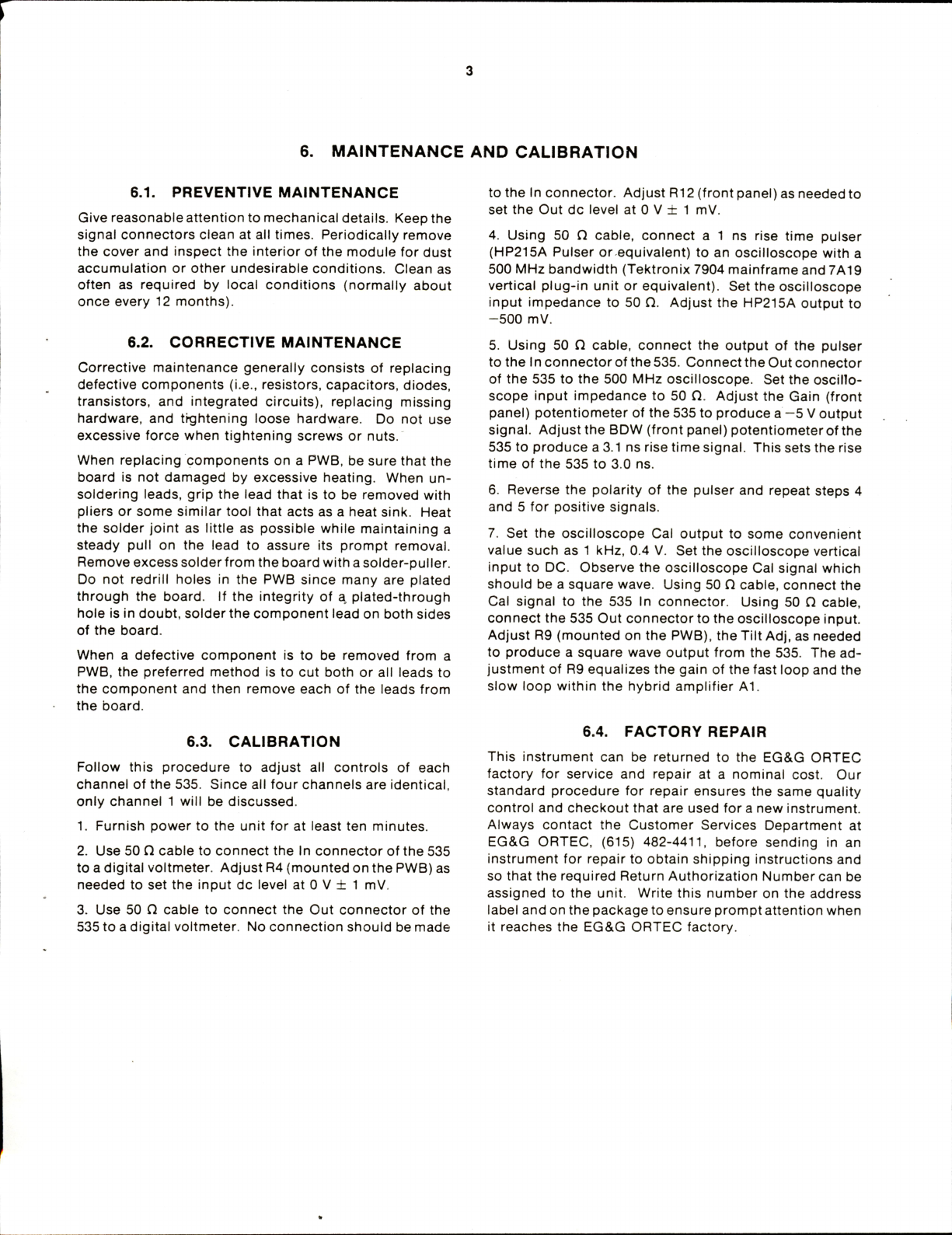

5.

CIRCUIT

DESCRIPTION

The

circuit

of

the

535

Quad

Fast

Amplifier

is

shown

in

schematic

635120

at

the

back

of

this

manual.

Refer

to

this

schematic

for

the

following

circuit

description.

Since

ail

four

channels

of

the

535

are

identical,

only

channel

1

will

be

discussed.

Diodes

D1

and

D2

form

a

bridge

current

limiter

which

is

voltage-clamped

by

01

and

Q2

to

limit

the

input

swing

to

'K.

W.

Renner,

M.

O.

Bedwell,

and

J.

F.

Pierce,

"A

Wideband

Direct

Coupled

Amplifier

Utilizing

a

Fast/Slow

Loop

Concept,"

IEEE

Trans.

Nucl.

Sci.,

NS-28(1),

584.

^K.

W.

Renner,

4

Direct

Coupled

Wideband

Hybridized

Amplifier

with

a

Fast/Slow

Loop,

M.A.

Thesis,

University

of

Tennessee,

Knoxville,

December

1980.

the

hybrid

fast

amplifier,

A1.

This

input

protection

cir

cuitry

ensures

that

no

harsh

overload

signals

will

reach

A1,

thus

offering

excellent

overload

recovery

time.

Voltage

gain

is

varied

by

adjusting

resistor

R2.

The

input

offset

voltage

is

adjusted

by

resistor

R4

which

controls

the

current

in

the

current

limiting

bridge.

The

fast

amplifier

hybrid

uses

a

fast/slow

loop

tech

nique.''^

The

input

signal

enters

the

slow

loop

on

pin

14

of

A1

and

is

ac-coupled

through

C2

and

C3

to

the

fast

loop

input

on

pin

1

of

A1.

The

slow-loop

gain

is

adjusted

by

resistor

R9.

The

adjustment

is

factory-set

so

that

the

fast

signal

gain

equals

the

do

gain.

The

fast

amplifier

band

width

is

controlled

by

resistorRIB.

The

slow

loop

controls

the

dc-output

offset

which

is

adjusted

by

R12.

6.

MAINTENANCE

AND

CALIBRATION

6.1.

PREVENTIVE

MAINTENANCE

Give

reasonable

attention

to

mechanical

details.

Keep

the

signal

connectors

clean

at

all

times.

Periodically

remove

the

cover

and

inspect

the

interior

of

the

module

for

dust

accumulation

or

other

undesirable

conditions.

Glean

as

often

as

required

by

local

conditions

(normally

about

once

every

12

months).

6.2.

CORRECTIVE

MAINTENANCE

Corrective

maintenance

generally

consists

of

replacing

defective

components

(i.e.,

resistors,

capacitors,

diodes,

transistors,

and

integrated

circuits),

replacing

missing

hardware,

and

tightening

loose

hardware.

Do

not

use

excessive

force

when

tightening

screws

or

nuts.

When

replacing

components

on

a

PWB,

be

sure

that

the

board

is

not

damaged

by

excessive

heating.

When

un

soldering

leads,

grip

the

lead

that

is

to

be

removed

with

pliers

or

some

similar

tool

that

acts

as

a

heat

sink.

Heat

the

solder

joint

as

little

as

possible

while

maintaining

a

steady

pull

on

the

lead

to

assure

its

prompt

removal.

Remove

excess

solder

from

the

board

with

a

solder-puller.

Do

not

redrill

holes

in

the

PWB

since

many

are

plated

through

the

board.

If

the

integrity

of

a.

plated-through

hole

is

in

doubt,

solder

the

component

lead

on

both

sides

of

the

board.

When

a

defective

component

is

to

be

removed

from

a

PWB,

the

preferred

method

is

to

cut

both

or

all

leads

to

the

component

and

then

remove

each

of

the

leads

from

the

board.

6.3.

CALIBRATION

Follow

this

procedure

to

adjust

all

controls

of

each

channel

of

the

535.

Since

all

four

channels

are

identical,

only

channel

1

will

be

discussed.

1.

Furnish

power

to

the

unit

for

at

least

ten

minutes.

2.

Use

50

O

cable

to

connect

the

In

connector

of

the

535

to

a

digital

voltmeter.

Adjust

R4

(mounted

on

the

PWB)

as

needed

to

set

the

input

dc

level

at

0

V

±

1

mV.

3.

Use

50

Q

cable

to

connect

the

Out

connector

of

the

535

to

a

digital

voltmeter.

No

connection

should

be

made

to

the

In

connector.

Adjust

R12

(front

panel)

as

needed

to

set

the

Out

dc

level

at

0

V

±

1

mV.

4.

Using

50

O

cable,

connect

a

1

ns

rise

time

pulser

(HP215A

Pulser

or.equivalent)

to

an

oscilloscope

with

a

500

MHz

bandwidth

(Tektronix

7904

mainframe

and

7A19

vertical

plug-in

unit

or

equivalent).

Set

the

oscilloscope

input

impedance

to

50

Cl.

Adjust

the

HP215A

output

to

-500

mV.

5.

Using

50

O

cable,

connect

the

output

of

the

pulser

to

the

In

connector

of

the

535.

Oonnect

the

Out

connector

of

the

535

to

the

500

MHz

oscilloscope.

Set

the

oscillo

scope

input

impedance

to

50

Q.

Adjust

the

Gain

(front

panel)

potentiometer

of

the

535

to

produce

a

-5

V

output

signal.

Adjust

the

BDW

(front

panel)

potentiometer

of

the

535

to

produce

a

3.1

ns

rise

time

signal.

This

sets

the

rise

time

of

the

535

to

3.0

ns.

6.

Reverse

the

polarity

of

the

pulser

and

repeat

steps

4

and

5

for

positive

signals.

7.

Set

the

oscilloscope

Oal

output

to

some

convenient

value

such

as

1

kHz,

0.4

V.

Set

the

oscilloscope

vertical

input

to

DO.

Observe

the

oscilloscope

Oal

signal

which

should

be

a

square

wave.

Using

50

O

cable,

connect

the

Oal

signal

to

the

535

In

connector.

Using

50

Q

cable,

connect

the

535

Out

connector

to

the

oscilloscope

input.

Adjust

R9

(mounted

on

the

PWB),

the

Tilt

Adj,

as

needed

to

produce

a

square

wave

output

from

the

535.

The

ad

justment

of

R9

equalizes

the

gain

of

the

fast

loop

and

the

slow

loop

within

the

hybrid

amplifier

A1.

6.4.

FACTORY

REPAIR

This

instrument

can

be

returned

to

the

EG&G

ORTEO

factory

for

service

and

repair

at

a

nominal

cost.

Our

standard

procedure

for

repair

ensures

the

same

quality

control

and

checkout

that

are

used

for

a

new

instrument.

Always

contact

the

Oustomer

Services

Department

at

EG&G

ORTEO,

(615)

482-4411,

before

sending

in

an

instrument

for

repair

to

obtain

shipping

instructions

and

so

that

the

required

Return

Authorization

Number

can

be

assigned

to

the

unit.

Write

this

number

on

the

address

label

and

on

the

package

to

ensure

prompt

attention

when

it

reaches

the

EG&G

ORTEO

factory.

BIN/MODULE

CONNECTOR

PIN

ASSIGNMENTS

FOR

AEC

STANDARD

NUCLEAR

INSTRUMENT

MODULES

PER

TID-20893

(Rev

4)

(adopted

by

DOE)

Pin

Function

Pin

Function

1

+3

volts

23

Reserved

2

-3

volts

24

Reserved

3

Spare

Bus

25

Reserved

4

Reserved

Bus

26

Spare

5

Coaxial

27

Spare

6

Coaxial

•28

+24

volts

7

Coaxial

•29

-24

volts

8

200

volts

dc

30

Spare

Bus

9

Spare

31

Spare

•10

+6

volts

32

Spare

•11

-6

volts

•33

117

volts

ac

(Hot)

12

Reserved

Bus

•34

Power

Return

Ground

13

Spare

••35

Reset

(Sealer)

14

Spare

••36

Gate

15

Reserved

"37

Reset

(Auxiliary)

•16

,+12

volts

38

Coaxial

•17

-12

volts

39

Coaxial

18

Spare

Bus

40

Coaxial

19

Reserved

Bus

•41

117

volts

ac

(Neut.)

20

Spare

•42

High

Quality

Ground

21

Spare

G

Ground

Guide

Pin

22

Reserved

Pins

marked

(*)

are

installed

and

wired

in

EG&G

ORTEC's

4001A. 40018.

4001C.

401A.

and

4018

Modular

System

8ins.

Pins

marked

(*)

and

(")

are

installed

in

EG&G

ORTEC-HEP

M250/N

and

M350/N

NIM8INS.

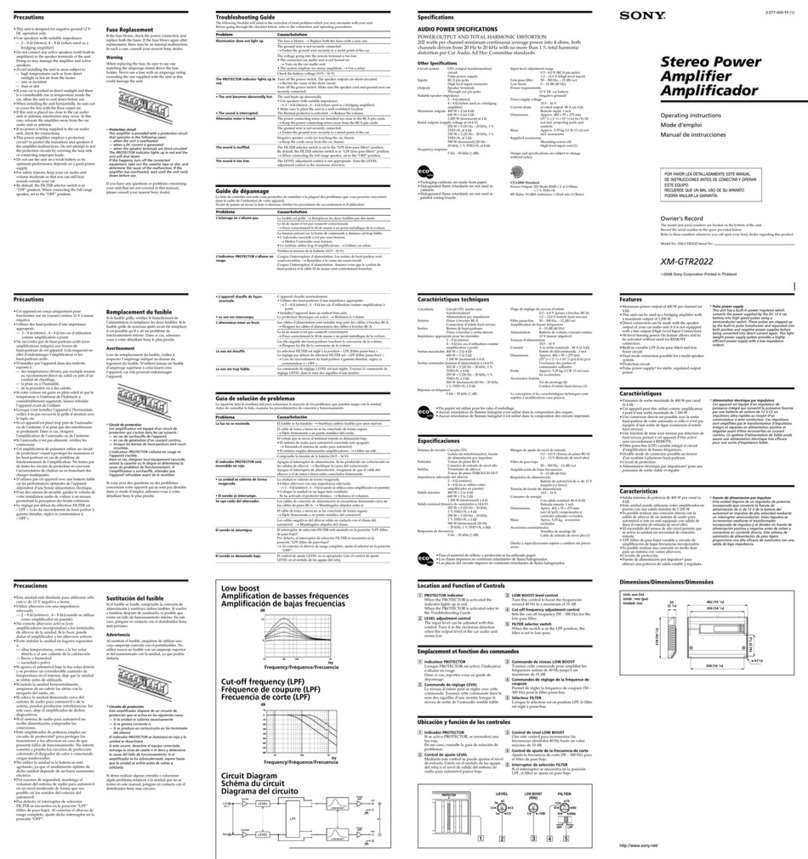

MODEL

535

ORTEC

QUAD

FAST

AMP

ASSY

63840C

P/N

6202605

rw)

—j

Ri7

R26[-

H

R21

h

rrra

(ci

C

C37)

—I

R57

I—

H

R51

-

H

R45t-

H

RA6h-

CC2^

(C3

rgrr>

R77t-

("^)

(c^fcts^

—i

r7i

[-

R79F

R62

—

R6d

—

—

o:

—

R63

-

fC5i

—I

R61

I—

R72

CE53

rcT^

ro

CD

CD

c

CC

535-1

:iMM

7X1//

r|.'

■

-

J

3

05

OJ

J

00

I

o

o

■n

3

o

m

o

»

m

r

n

o

cn

3

C4

■0

cn

o

:

=

-

I

{

S

•

2

'

ES

?!

E"

Pi

C]

s

ttw

Table of contents

Other EG&G Amplifier manuals

EG&G

EG&G ORTEC 474 Service manual

EG&G

EG&G ORTEC 485 User manual

EG&G

EG&G 128A Service manual

EG&G

EG&G ORTEC 113 Service manual

EG&G

EG&G ORTEC 427 User manual

EG&G

EG&G 113 Service manual

EG&G

EG&G ORTEC 118A User manual

EG&G

EG&G ORTEC 452 User manual

EG&G

EG&G ORTEC 444 User manual

EG&G

EG&G ORTEC 414A Service manual