Eightpins H01 User manual

1

EIGHTPINS

EIGHTPINS

Installation Guide and Manual

Eightpins H01

Integrated dropper seatpost

READ CAREFULLY BEFORE USE!

KEEP THIS MANUAL FOR FUTURE REFERENCE

V1_1 en 18.06.2020

H01

Lupaan GmbH

Kristein 2

A-4470 Enns

www.eightpins.at

2

EIGHTPINS

Inhalt

3 General

3 Warranty Policy

3 Service

5 Safety instructions

5 Assembly and service

5 Modications

5 Use and area of application

6 Ergonomic aspects:

6 Before the assembly

7 Part list

8 Compatibilities

10 Installation

10 Frame/Seattube

10 Cable housing / bowden insallation

11 Installing the bowden end cap

11 Installing the seatpost

13 Adjustment of the saddle angle

14 Alignthesaddleandxtheseatpost

14 Install the outer sleeve screw

15 Assembly of the remote lever

19 Manual

19 Using the seatpost

19 Seat post alignment

19 Height adjustment top position

19 Saddle tilt adjustment

19 Before every trip

21 Operation

21 Adjusting the saddle height

22 Service

22 Removal of the seat post for service purposes

23 Remove outer sleeve and the bushing tube:

23 Oil lubrication of the seatpost tube

24 Reinstall the seatpost

26 Service of the outer sleeve

27 Cleaning the bushing tube

28 Clean & lubricate guide grooves

29 Seatpost tube replacement

32 Exchangeofthehydraulicgasspring

32 Required tools

32 Removal of the hydraulic gas spring

3

EIGHTPINS

General

Thank you for equipping your bike with an Eightpins variable seatpost, a highstandardized, highly technical product for mountain bikes. There is a

variety of points to take into consideration assembling and using the seatpost. As a result of the integration of the seatpost, it is designed entirely dif-

ferent in comparison to other variable seatposts. The adjustment of the seat height as well as the adjustment of the travel of the seatpost is realized

with one single tube. The mechanics for this is directly connected with the frame via the Postpin axle that absorbs all axial forces. The lateral forces

are absorbed by the bushing tubes and thus by the frame. It is therefore crucial to mind the maximal extension as well as the minimum insert length.

Attention! If assembled or used in a wrong way, you may hurt yourself as well as damage the frame or the seatpost.

Make sure all adjustment elements are in place at all times and that the tension of the cable is adjusted correctly. In case you do not have the skills

to assemble the seatpost, please refer to your local bike dealer or the service center in your country.

Attention! Read the following assembly information and manual carefully and stepby-step and mount the Eightpins

seatpost only according to the instructions.

Warranty Policy

Weoeratwo-yearswarrantyforyourseatpostbeginningatthedateofpurchase.Thewarrantyexclusivelyincludestherepairorexchangeofthe

components damaged. In order to claim a warranty case, the receipt is obligatory. Common wear, usual services and wrong assemblies are not

covered by the warranty. If the seatpost has been altered in any way, the warranty automatically expires. The rider is responsible for any damages

caused by any alteration of the seatpost.

Service

As to the service, a major advantage of the Eightpins variable seatpost is that the seatpost can be dismounted easily and that the anti-friction

bushing can be cleaned and/or exchanged quickly. In case you notice a higher friction in the system, it can be greased via a grease port in the outer

sleeve. With the right tools and a basic technical understanding, you may service the seatpost yourself including cleaning, exchanging or greasing

the bushings and exchanging the cable. If the hydraulic gas spring of the seat post gives way or fails, it must be replaced.

4

EIGHTPINS

The following service activities have to be done regularly.

Before every

ride

Every 50 opera-

ting hours

Every 100 opera-

ting hours

Every 200 operating

hours

If necessary

Remove dried dirt with

water and mild soap x

Cleaning the wiper x

Cleaning the bushing tube x

Exchange the bushing tube x

Exchange the wiper x

Exchange the Felt ring x

Relloilinoutersleeve x

Replace the hydraulic gas

spring x

lubricate longitudinal

guidance x

The various work steps can be found in the Service chapter.

For services of all kinds, please refer to your local bike workshop or to Lupaan GmbH:

Lupaan GmbH „EIGHTPINS“

Kristein 2

4470 Enns

www.eightpins.at

5

EIGHTPINS

Attention! Do not service the mechanics or the gas pressure spring yourself as the system is under high pressure

and as one may risk severe injuries.

Safety instructions

Assembly and service

The assembly and the service of the Eightpins variable seatpost requires a special understanding of technical matters. Do not overestimate your

own skills but refer to a professional bicycle shop or to an authorized Eightpins service partner at all times. This is the only way a correct service can

be guaranteed.

Modications

The Eightpins variable seatpost is not to be altered in any way. Do not dismount it, sand it down or paint it. Always use a torque wrench where

necessary. Read the manual carefully and follow it step-by-step.

Attention: A seatpost that has not been mounted correctly does not work correctly.This may lead to crashes and

injuries. Besides, the frame can be damaged.

Use and area of application

The intended use of the system is installation in a designated bicycle frame with an postpin mounting interface. The seat post is used to adjust the

heightoftheseatpositionofthesaddleintherangeoftheadjustmentpathspeciedbytheproduct.Therangeofapplicationincludestouringbikes,

trekkingbikesandmountainbikes.Bicycleframesthatdonothavethisfeatureshouldnotbemodied.TheEightpinsvariableseatpostmustonly

beassembledandcombinedwiththeoriginalEightpinsremotelever.Dierentleverageratioscancauseirreparabledamages.

Modicationstothesystemorinstallationinunapprovedbicycleframesisnotpermitted.

The system is not suitable for children under the age of 12. There is a risk of crushing!

Keep the seat post away from children and keep it out of the reach of children.

The use is only intended for private purposes. The product is not approved for competitions.

6

EIGHTPINS

The product may only be used by a person who has no physical restrictions and is familiar with the operating instructions.

The use of the product is only permitted by a person sitting on the bike.

Ergonomic aspects:

TheergonomicspointwasconsideredtakingDINENISO12100:2011intoaccount.SincethetelescopicseatpostoeredbyEightpinsisonlypart

of the bicycle, ergonomic considerations cannot be considered.

Furthermore, it is not a work tool, but a leisure and sports device.

For further questions, please contact your dealer, supplier or manufacturer of your bike.

Specialinformationonhandlinglubricantsandthedangerfromnitrogenwithwhichthegasspringislled,

are also available in the operating instructions.

These can be found at the end of these operating instructions.

Before the assembly

The post-pin mounting interface in the frame contains an adjustment screw on the right side of the frame for vertical alignment of the seatpost.

This screw is already set at the factory and glued with a detachable screw glue.

If the adjusting screw is not included in the frame or adjusted correctly, contact the frame supplier.

7

EIGHTPINS

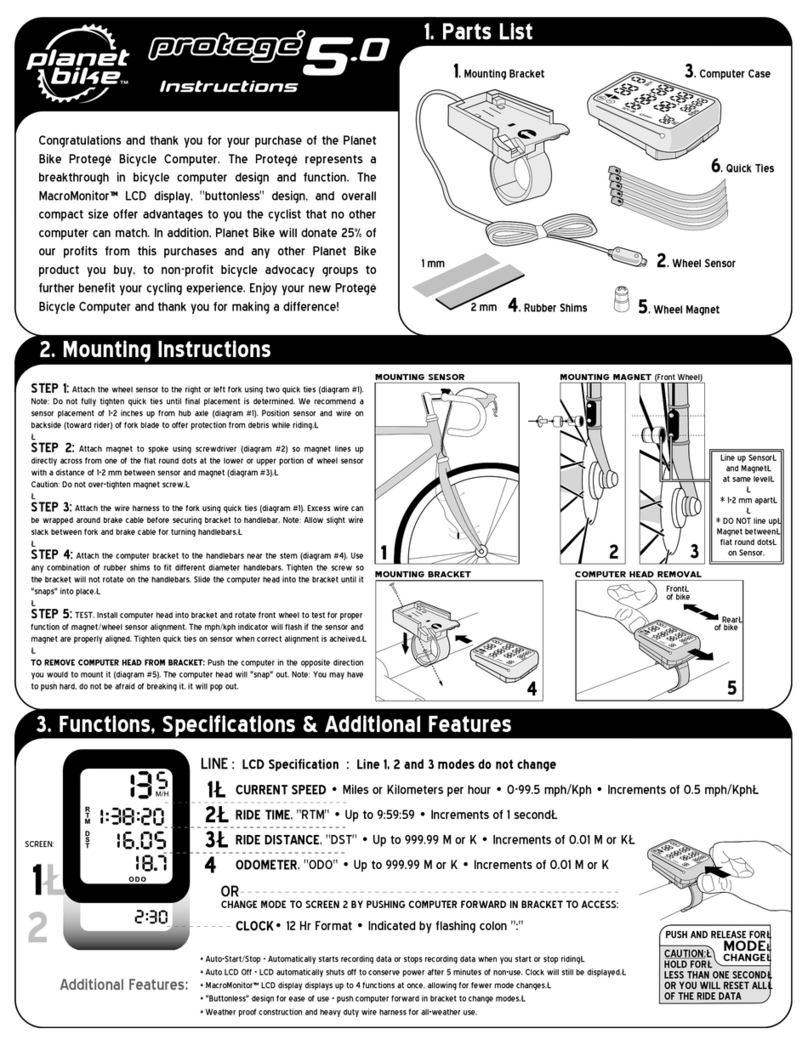

Part list

1 H01 Seatpost tube

2 H01 Cartridge unit

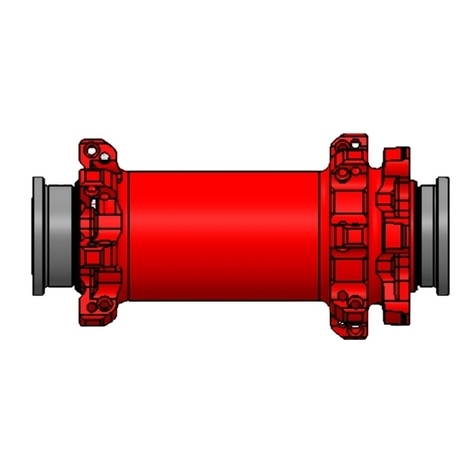

3 Hydraulic gas spring

4 Postpin mounting interface

5 Postpin axle M7

6 Cable housing

7 Flexchain outer sleeve

8 Cable

9 Special bowden endcap

10 Height adjust lever

11 Seatclamp screw front 40mm

12 Seatclamp screw back 35mm

13 Seatclamp bottom

14 Inline adjuster

15Aluminiumexoutersleeve

16 Clamping nut

17 Remote lever nn-bar

18 Longitudinal guidance

19 Cable housing holder

20 Actuation lever

21 Bushing tube

22 Outer sleeve

1

2

3

4

5

79

6

8

10

11

12

12

13

14

15

16

17

19

20

18

21

22

8

EIGHTPINS

Compatibilities

TheintegratedEightpinsvariableseatpostisexclusivelydesignedforframeswithaPostpininterface.Onecannotretrotthisinterfacetoabicycle

frame. Refer to your local bike shop in case you are in doubt.

Currently released frames:

Liteville (6X- Size sheme) Ghost (6X- Size sheme) Rowild (4X- Size sheme) Bulls (4X- Size sheme)

-H-3 MK3 -LectorSupert -750er Baureihe -Sonic Evo EN Alu

-301 MK15 -Sonic Evo Carbon

-4-One Gravel MK1

-301CE MK1

Attention: Eightpins decisively advices its customers not to modify a frame in any way, as this

can weaken the frame, cause crashes and lead to severe injuries including death.

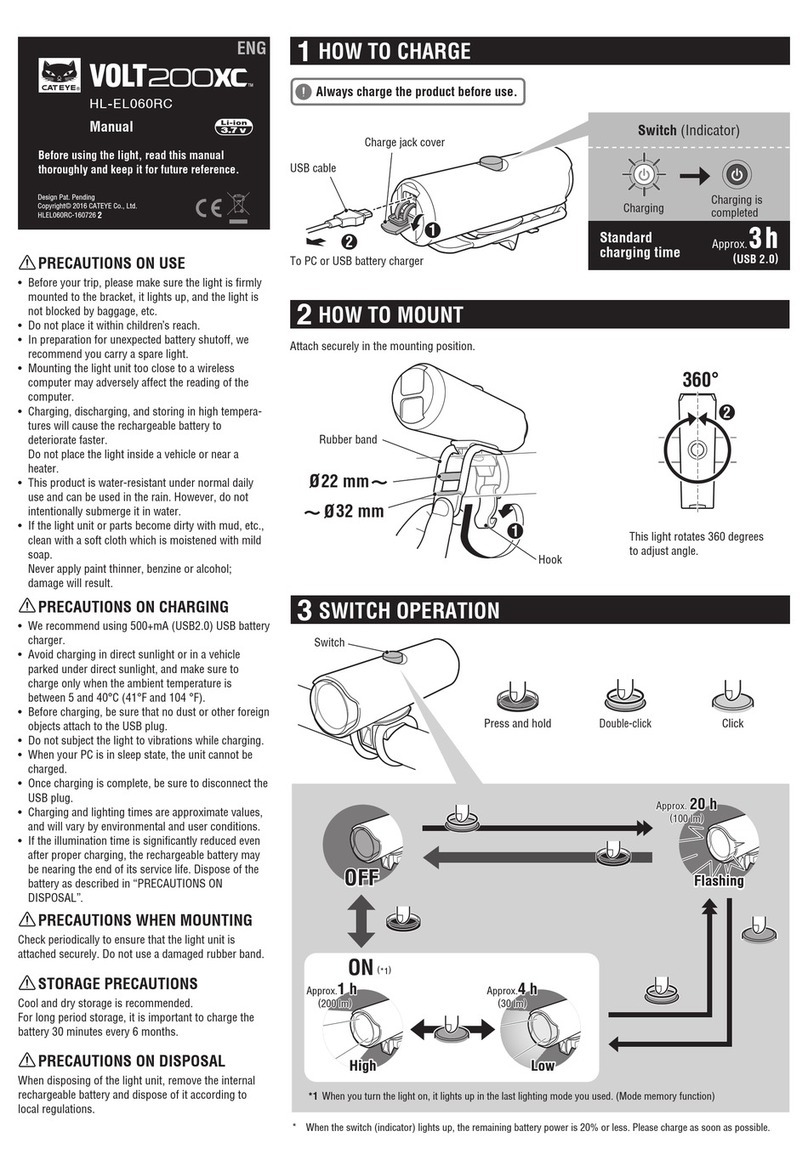

Eightpin‘sseatpostsaredividedintotwodierentsizeschemes.Thereisasizeschemewith4sizes:S,M,LandXLanda

size scheme with 6 sizes: XS, S, M, L, XL, XXL. The size to use depends entirely on the frame size.

UseonlyEightpinscartridgesofthecorrectsizefortheappropriateframesize.(Example:6X-Lcartridgetsintoaframe

with 6-fold size scheme with the size L)

The bushing tube length is selected so that it corresponds to the minimum insertion depth of the seattube in the frame. All

bending forces are transferred to the frame via the bushing tube. When assembling or exchanging the bushing tube, the

correct length must be used. The respective length can be found in the table under the column bushing tube.

It is also important to pay attention to the compatibility of the seatpost tube lengths. The table contains all possible combi-

nations. The corresponding adjustment ranges can also be found in the table. The values refer to the distance between the

bottom bracket and the upper edge of the saddle. Included is a saddle with a height of 4cm.

ATTENTION! Only the intended and compatible seat post sizes, strokes and bushing tube

lengths specied by the bike manufacturer may be used.

HP

LP

9

EIGHTPINS

10

EIGHTPINS

Installation

Frame/Seattube

Cable housing / bowden insallation

Install the cable housing in the frame before installing the seat post. Please follow the instructions of the frame manufacturer. The cable housing is

to be inserted into the seat tube until about 2 cm of it reach out of it. The second end of the housing – at the top of the frame – is to be cut depen-

ding on the frame size. The cable housing is pushed further out of the frame during assembly of the seat post by the length X. Observe the following

table when cutting the cable housing and shorten it to the desired length.

Theframemusthavea5mmholeatthetopoftheseattubetomountandxtheoutersleeve.Ifthisholedoesnot

exist,refertothemanualoftheframesuppliertondouthowtodrillthisholeintheseattubeoftheframe.

ca. 20mm

Länge X

length X

Länge X

length X

11

EIGHTPINS

Installing the bowden end cap

Installing the seatpost

AspecialendcapisrequiredtoxtheoutercovertothewidemountinginterfaceoftheH01seatpost.Thespecial

end cap is only required in bicycles without e-drive (left image). Bicycles with electric drive have little space between

themotorandseatpostfortheexitofthecable.Aspecialexchainoutercableisusedhere(rightpicture).Thisis

installed between the outer shell and the special end cap.

Hook the cable head into the

actuation lever of the seat post

Insert the cable into the outer shell and push it almost

completely through the cable housing

Before installing the seat post, check whether the small tube and the washers for tole-

rance compensation of the seat post are installed.

12

EIGHTPINS

Hang the special end cap in the cable housing holder of the seat post mounting inter-

face.

Attention! When installing in an aluminum frame with non-anodized

inner walls, lubricate the bushing tube with grease beforehand.

When installing in a carbon frame, never treat parts with rubbing

paste

Now carefully insert the seat post into the frame until the bushing tube slides into the

seat tube. Carefully press the outer sleeve onto the seat tube by hand until you feel the

outer sleeve stop.

Push the seat post down until the post pin mounting

interface of the seat post reaches the Pospin interface of

the frame. You can see this from the outside when you

look into the hole in the postpin interface of the frame. If

necessary, turn the seat post a little and slide it so that the

postpin axle can be inserted. Screw in the Postpin axle with

a 5mm Allen key and tighten it loosely

Push the outer sleeve and the bushing tube down for easier assembly. The cable must

remain tensioned throughout the insertion of the seat post into the seat tube of the fra-

me. It is best to hold the cable together with the cable housing at its end. Pull the cable

and the cable housing slightly during insertion so that it can slide through the frame.

13

EIGHTPINS

Adjustment of the saddle angle

Before the Postpin axle is

tightened, the saddle must

be installed to align the seat

post.

Loosen both seat clamp

screws and unhook the

front seat clamp screw to

the front. Lift the upper

saddle clamp and position it

above the two saddle rails.

Let the saddle frame rails

rest on the lower saddle

clamp plate and hang the

front saddle clamp screw

back in. Loosely tighten

both seat clamp screws.

When tightening the saddle

clamp screws, press the

saddle clamp nuts down

withyourngersothatthey

completely disappear into

the upper saddle clamp

plate.

Attention!The nuts

which are installed

in the top seatclamp

have two small at

areas which have to

be aligned in the long

hole parallel to the

riding direction.

Attention! The screws on the seat post head must not be tightened more than the specied torque of 8Nm. It could

break. This increases the risk of injury.

Loosen the rear fastening screw on the seat post head

with a 5mm Allen key. Adjust the saddle inclination by tur-

ning the front seat clamp screw. After aligning the saddle

inclination with the help of the front and rear saddle

clamping screw, the rear screw must be tightened with a

torque tool with a maximum torque of 8Nm.

14

EIGHTPINS

Alignthesaddleandxtheseatpost

Attention! The Postpin axis must be tightened to 8Nm after assembly.

Install the outer sleeve screw

Rotate the outer sleeve so that the mounting hole of the

outer sleeve coincides with the mounting hole on the fra-

me. Screw the M5 mounting screw of the outer sleeve into

the outer sleeve using a 3mm Allen key.

Attention! The screw must be able to be screwed into the outer sleeve easily and without resistance. If this is not the

case, the hole in the frame may not coincide with the mounting hole in the outer sleeve. The frame can be squashed

or damaged

After mounting the saddle, the saddle must be rotated in the direction of riding. It is

best to orient it with the saddle tip on the top tube. Then tighten the Postpin axis with a

torque wrench with 8Nm.

15

EIGHTPINS

Assembly of the remote lever

The cable system of the Eightpins seatpost consists of a common

cablehousingwithaSteelcoreandashort,moreexiblecable

housing with an Aluminum core directly at the remote lever. The

cable system right at the remote lever consists of a 10 cm Aluminum

cablehousing,aspeciccabletensionadjusetrandaspecicend

cap for the remote lever featuring a reduced outer diameter. The

specicendcapisinstalledattheoneendofthecablehousing,the

cable tension adjuster at the other end. The cable tension adjuster

is installed so that the side with the 4 mm label is connected with the

Aluminum cable housing. The second end is attached to the steel

cable housing that reaches out of the frame.

Note: Initially, put the cable tension adjuster into the minimum cable length position.

Install the remote lever between the grip and the brake lever and tighten its screw with 2.5 Nm.

Note: The lever can be used with 2-speed drivetrain gear levers and without. Make sure the Eight-

pins remote lever does not interfere with the gear lever. Further turn it upwards, in order to avoid this.

Beforethecableisattachedtotheremote,pullitrmlyuntilthedroppermechanicsisfullyopen.Thisprocessis

importanttoconrmthatallcomponentsofthecablesystemsittightly.

Seilzug Aussenhülle

Seilzug

Seilzugeinsteller

Flex Aluminium-

Aussenhülle

Endkappe klein

Seilzugklemme

16

EIGHTPINS

If the cable housing can be pushed into the frame in any way during the check, it has been detached from the cable

housing counterpart at the Postpin mounting interface. Take out the seatpost and attach the outer sleeve in the coun-

ter part of the mounting interface

Pull the cable clamp of the

remote lever over the cable

and guide it all the way to

the cable housing.

Very slightly tighten its

screw with a 3mm Allen key

on both sides so it can still.

be moved. Position it about

2mm away from the cable

housing.

Check the measurement

again by pulling the cable

very lightly to ensure that

the cable has not slipped

back into the cable housing.

Otherwise adjust the cable

clamp until the distance of

2mm is correct again.

Cut the cable directly at the

cable clamp. Pull it away

from the cable housing a

little bit in order to have

the end of the cable itself

disappear within it.

17

EIGHTPINS

Attention! In order to avoid injuries, the cable needs to be pulled back into the cable clamp for hiding any type of

cable bits sticking out of it.

3mm

The distance between cab-

le clamp and cable housing

should still not exceed 3

mm.

Tighten the two screws of

the cable clamp simul-

taneously with a torque

wrench with 5 Nm.

5mm

Hold the Aluminum cable

housing with your hand.

With the other hand, pull

the cable in order to open

the dropper mechanism.

IWiththispretension,rst

hang the Aluminum cable

housing with the end cap

on the remote lever.

In the last step, the cable

clamp can be hanged on

the remote lever.

18

EIGHTPINS

Press the lever in order to

control the function of the

mechanics.

If the tension is too low, the

seatpost speed will be low.

Adjust the cable tension

with the cable tension

adjuster in order to the

maximum speed of the

droper post.

19

EIGHTPINS

Manual

Using the seatpost

In order to lower the seatpost, push the remote lever at the handlebar and push down the seatpost. In order to keep the new saddle position,

releasetheremotelever.Extendingtheseatpostagain,youneedtopushtheremoteleverandwithoutcounterforceletitnditsoriginalheight.The

Eightpins H01 seat post is locked or extended using a hydraulic gas spring. The lowering function works steplessly.

Attention: The remote lever must not be pushed if the bike hangs on the saddle.

Seat post alignment

The Eightpins H01 seat post is equipped with a tolerance compensation system. This enables a rotation of the seat post of ± 3 ° around the

longitudinal axis. If the saddle alignment is rotated around the longitudinal axis, the saddle can be aligned again by loosening the postpin axle and

tightening it again with 8Nm after alignment.

Height adjustment top position

See chapter height adjustment

Saddle tilt adjustment

See chapter saddle mounting

Before every trip

Before each ride, check the following functions on the seat post.

- Freedom of play rotation: The seat post should have only slight play in both directions of rotation. If there is more play, check whether the Postpin

thru axle is screwed tight with 8Nm.

- Clearance of seat post: The seat post tube should only have a maximum of 2-3mm play to the front and rear when tipping. If the play is greater,

check whether the minimum insertion depth has been reached and whether the slide sleeve tube is in order. (See service)

20

EIGHTPINS

- Saddle freedom from play: The saddle frame must always be tight so that the saddle is mounted without play. The rear seat post screw is to be

tightened to 8Nm.

- Smooth running lowering: The seat post must be easy to lower and must also extend easily and smoothly. If this is not guaranteed (friction too

high), the guide must be lubricated via the outer sleeve (see service). If there is no improvement in the lubrication of the seat post, there may be a

setting error in the setting ring in the frame. Broken or squeezed sliding bushes can also be other reasons, or the longitudinal guide on the housing

of the capsule has run dry.

- Remote lever: The remote lever must be easy to operate. Check the free travel of the lever and adjust the cable tensioner if necessary. (See

chapter „Installation of the control lever“) The cable must pull back completely after it has been released so that the lever is tensioned again and the

cable clamp is completely in the holder. If this is not the case, the cable or the outer casing must be replaced (see service)

Note:

After a fall with your bike, or a fall of the bike with possible damage to the seat post tube, the tube must be checked

for damage. Particular attention should be paid to: dents, cracks and chips of the paint. The connection between the

head and the pipe must also be checked.

Pay attention here also to cracks, deformations, etc. and also check the tightness of the screws of the seat clamp.

If you are unsure or have any questions, please contact your local dealer before driving on or starting up.

Table of contents

Other Eightpins Bicycle Accessories manuals