4

and emptying the supervision project using the “RESET”

button available. In this case, compared to what was pre-

viously seen to restore the IP address, the procedure to

follow is the following:

• open the front panel of the server Konnect4 using a

small slotted screwdriver, and exerting a slight leverage

eect in one of the side slots

• locate the RESET button on the back of the vertical

card

• press the RESET button for at least 10 seconds un-

til the SERVICE LED on the front of the device starts

ashing, then release the button.

• within the next 5 seconds, press and hold the button for

at least 10 seconds

• when the LED is solidly lit, release the button and wait

for it to go out.

• when the LED goes o, remove and restore the power

supply

• wait about one minute and log in to the server with the

factory IP address (192.168.0.110).

!

!

Disposal

File name Device

Release Update

STEKBR1TP_EN.pdf A1.0 06/2020

Warning! To avoid losing all the congurations made for the au-

tomation project during a factory reset operation, it is recommen-

ded to make periodic backups of the supervision project.

36

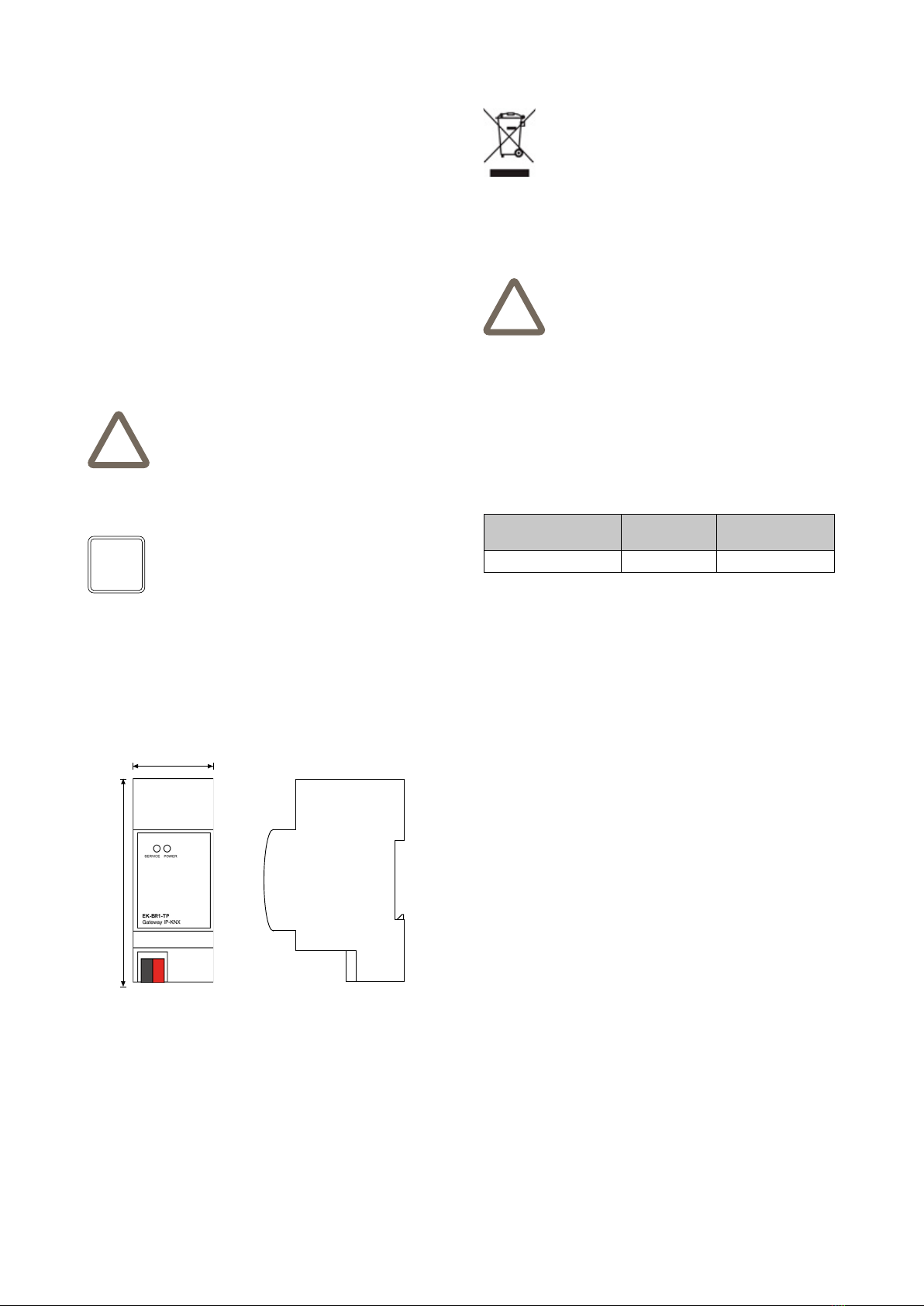

90,5

Note! The conguration and commissioning activities of the Kon-

nect4 server device require specialized skills on the KNX net-

work and knowledge of the specic automation project carried

out with ETS. To acquire these skills, it is essential to participate

in the courses organized at KNX certied training centers. For

further information: www.knx.it

Dimensions [mm]

i

The products described in this technical sheet at the end

of its useful life are classied as waste from electronic

equipment according to the European Directive 2012/19

/ EU (RAEE recast), implemented in Italy with Legislative

Decree no. 49 of 14 March 2014, and cannot be transfer-

red to unsorted municipal solid waste.

Warning! Incorrect disposal of the product can cause serious

damage to the environment and human health. For correct di-

sposal, inquire about the collection and treatment methods pro-

vided by the local authorities.

Document

This technical sheet refers to the A1.0 release of ekinex®

devices cod. EK-BR1-TP and is available for download

on the website www.ekinex.com in PDF (Portable Data

Format) format.

Warnings

• Installation, electrical connection, conguration and

commissioning of the device may only be carried out

by qualied personnel in accordance with the applica-

ble technical regulations and the laws in force in the

respective countries

• The device may not be used in safety applications. Ho-

wever, the device may be used for auxiliary signalling

functions

• Opening the housing of the device results in the imme-

diate interruption of the warranty period

• In the event of tampering, compliance with the essential

requirements of the applicable directives for which the

device has been certied is no longer guaranteed

• Defective ekinex® KNX devices must be returned to the

manufacturer at the following address: Ekinex S.p.A.,

Via Novara 37 - I-28010 Vaprio d’Agogna NO

Other useful informations

• This technical data sheet is addressed to installers, sy-

stem integrators and designers

• For more information on the product, you can con-

tact ekinex® technical support at the e-mail ad-

www.ekinex.com

• Each ekinex® device has a unique serial number on

the label. The serial number can be used by installers

and system integrators for documentation purposes

and must be added to any communication addressed

to ekinex® technical support in case of equipment mal-

function

• ekinex® is a registered trademark of Ekinex S.p.A.

• KNX® ed ETS® sono marchi registrati da KNX Asso-

ciation cvba, Bruxelles

© Ekinex S.p.A. 2021. The company reserves the right to make

changes to this technical documentation without notice.

Approvals

The products complie with the Low Voltage Directive

(2014/35 / EU) and the Electromagnetic Compatibility Di-

rective (2014/30 / EU). Tests carried out in accordance

with EN 50491-5-1: 2010, EN 50491-5-2: 2010.

Maintenance

The devices are maintenance-free. To clean them, use

a dry cloth. The use of solvents or other aggressive sub-

stances is absolutely to be avoided.