Contents

1.The Introduction..............................................................................................................1

2.Proper usage......................................................................................................................2

Modification ................................................................................................................................2

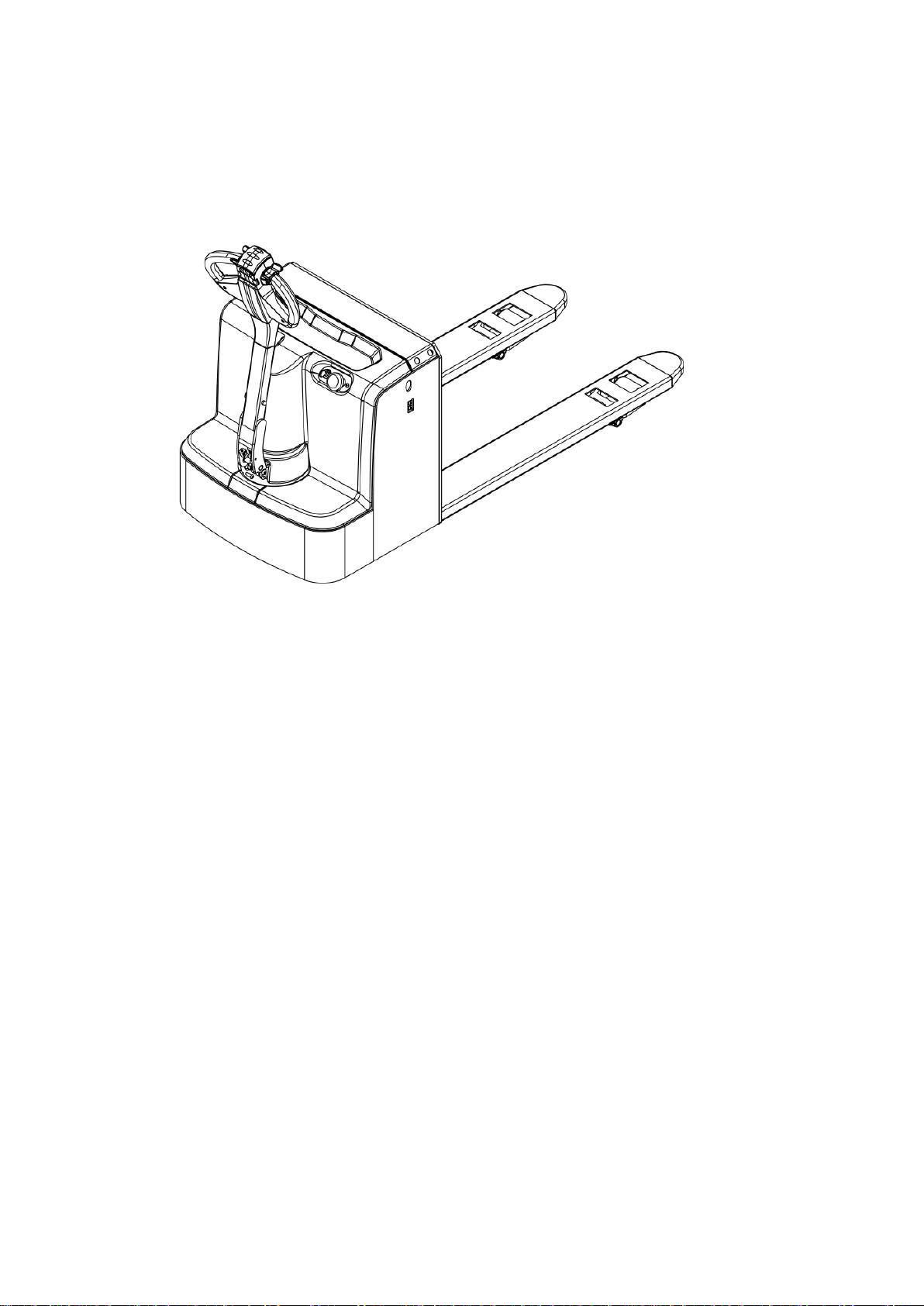

3.Introduction of the product .........................................................................................3

3.1 Model Overview .................................................................................................................3

4.Operating principle.........................................................................................................5

5.Operating principle.........................................................................................................6

5.1Running system...................................................................................................................6

5.2 Steering system ..................................................................................................................6

5.3 Braking system...................................................................................................................6

5.4 Operating System ..............................................................................................................8

5.5 Electric System ...................................................................................................................8

5.6 Hydraulic principle...........................................................................................................8

6.Electrical Schematic Diagram......................................................................................9

7.Hydraulic Schematic Diagram..................................................................................10

8.Operating Instruction.................................................................................................. 11

8.1 Start, run and parking:.................................................................................................. 11

8.2The usage of emergency safety switch.................................................................... 11

8.3 The usage of horn button. ........................................................................................... 11

8.4 Battery capacity indicator........................................................................................... 11

8.5 Handling stacking operation...................................................................................... 12

9.Maintenance ...................................................................................................................13

9.1Safety procedures for repair and maintenance................................................... 13

9.2 Daily Maintenance.......................................................................................................... 14

9.3 Professional Maintenance Manual........................................................................... 14

9.4Maintenance, Recharging and Replacement of the accumulator ................. 16

10.Safety Precautions .....................................................................................................19

10.1 general rules .................................................................................................................. 19

10.2 Transportation and storage..................................................................................... 19

10.3 Check before Using...................................................................................................... 20

10.4 Safe Operation............................................................................................................... 20

11.Repair Manual .............................................................................................................23

11.1 Malfunction analysis................................................................................................... 23

11.2 preparation work before repair............................................................................. 24

11.3 check the oil content of hydraulic oil................................................................... 24

11.4 preparation work before use after maintenance............................................ 24

12. After-sales service..................................................................................................... 24