DK50 2V/50

DK50 2x2V/110

06/2020 -1- NP-DK50 2V 50, 2x2V 110-13_06-2020-MD A

CONTENTS

IMPORTANT INFORMATION ................................................................................................................. 2

CONFORMITY WITH THE REQUIREMENTS OF EUROPEAN UNION DIRECTIVES ............ 2

INTENDED USE ......................................................................................................................... 2

CONTRAINDICATIONS AND SIDE-EFFECTS ......................................................................... 2

WARNINGS AND SYMBOLS ..................................................................................................... 2

WARNINGS ................................................................................................................................ 3

STORAGE AND TRANSPORT .................................................................................................. 5

TECHNICAL DATA ..................................................................................................................... 6

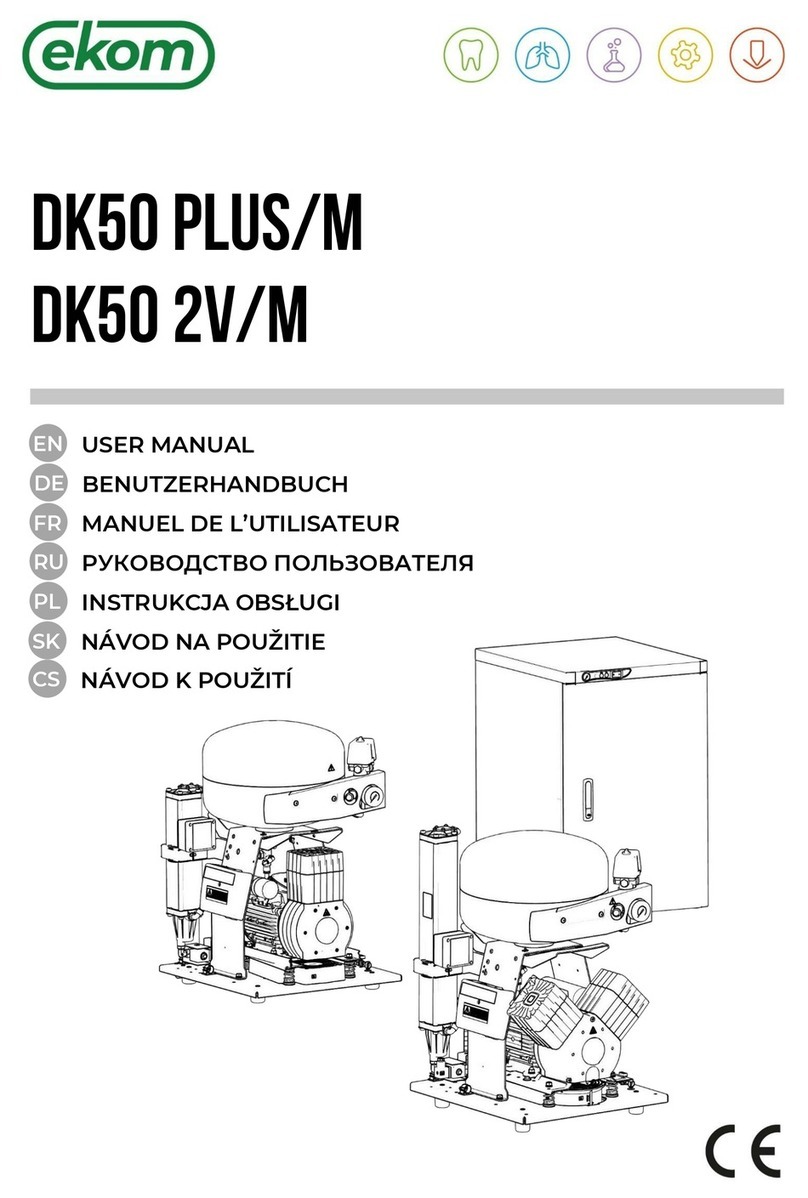

PRODUCT DESCRIPTION ...................................................................................................... 14

PRODUCT FUNCTIONALITY .................................................................................................. 16

PNEUMATIC DIAGRAM ........................................................................................................... 22

INSTALLATION .................................................................................................................................... 25

CONDITIONS FOR USE .......................................................................................................... 25

PLACEMENT OF THE COMPRESSOR .................................................................................. 26

PNEUMATIC CONNECTIONS ................................................................................................ 30

ELECTRICAL CONNECTIONS ................................................................................................ 31

CONNECTION DIAGRAM ....................................................................................................... 32

OPERATION ......................................................................................................................................... 37

COMMISSIONING .................................................................................................................... 37

SWITCHING THE COMPRESSOR ON ................................................................................... 38

COMPRESSOR SHUT-DOWN ................................................................................................ 38

MAINTENANCE .................................................................................................................................... 39

DEVICE MAINTENANCE ......................................................................................................... 39

TROUBLESHOOTING .......................................................................................................................... 47

REPAIR SERVICE .................................................................................................................... 48

STORAGE ................................................................................................................................ 48

DISPOSAL OF THE DEVICE ................................................................................................... 48

ANNEX ................................................................................................................................................ 194

INSTALLATION RECORD ..................................................................................................... 194