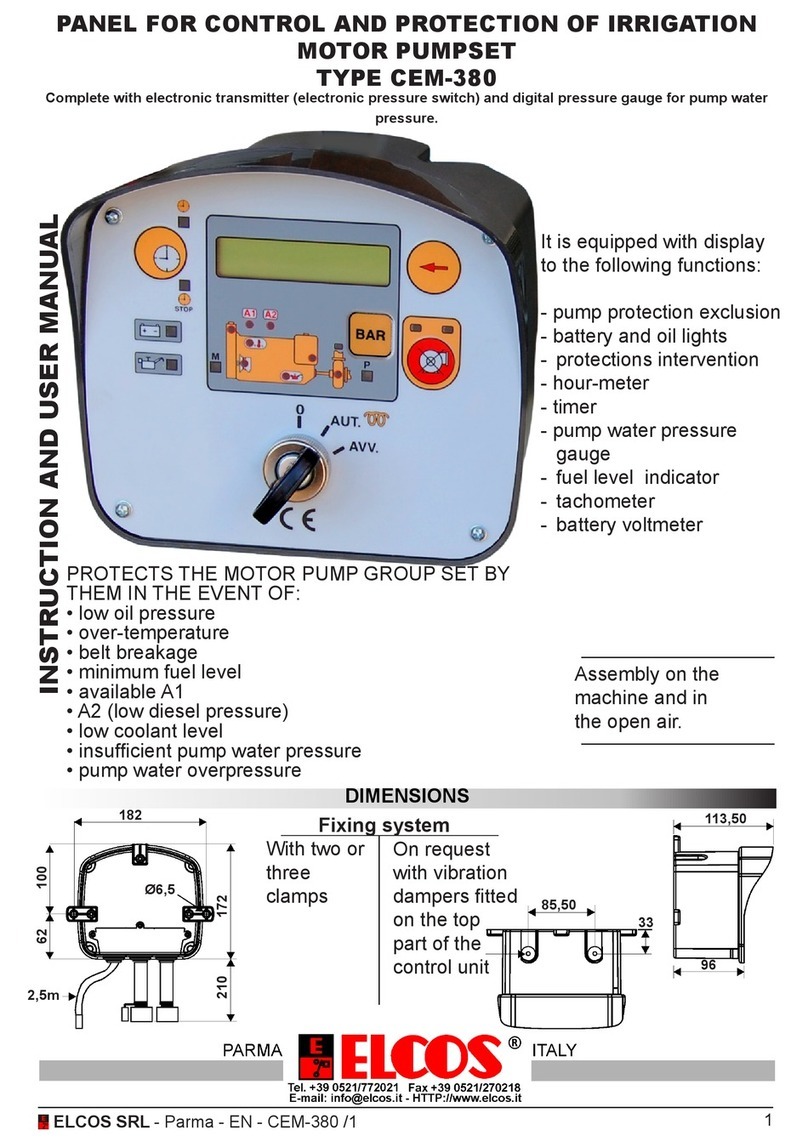

ELCOS QPE-C User manual

ENG

INSTALLATION, USE and MAINTENANCE Manual

QPE-C Elcos Polyvalent Panel

Command and control solutions

QPE-C-O-SC / QPE-C-O-CC / QPE-C-V

www.elcos.net

E-All. 47 proc.04 rev.03 del 10-01-2013

MANUAL CONTENTS:

•INSTALLATION

•USE

•MAINTENANCE

INDEX

USER MANUAL .................................................................................................. 5

1.1 INTRODUCTION ........................................................................................... 5

1.2 AIM .............................................................................................................. 5

1.3 OPERATING BASICS.................................................................................. 5

1.3.1 HOW THE QPE-C-V PANEL WORKS WITH THE GENSET ................................................5

1.3.2 QPE-C-VADJUSTABLE OPERATING MODES.....................................................................7

1.3.3 HOW THE QPE-C-O PANEL WORKS WITH THE GENSET................................................8

1.3.4 QPE-C-OCC OPERATING MODE.........................................................................................9

1.3.5 QPE-C-OSC OPERATING MODE.........................................................................................9

1.4 EXAMINATION OF “MC4 ON QPE-C PANEL” MODULE ............................. 11

1.5 FUNTIONAL DESCRIPTION OF PANEL COMPONENTS ............................ 11

1.5.1 DESCRIPTION OF KEYED SELECTOR FUNCTION .........................................................11

1.5.2 DESCRIPTION OF SINGLE BUTTONS AND WARNING LIGHT FUNCTIONS .................12

1.5.3 DESCRIPTION OF DIFFERENT MEASUREMENTS AND REPORTING PAGES .............14

1.6 COMMANDS AND FUNCTIONING IN THE THREE MODES ........................ 21

1.6.1 SETUP OF OPERATING MODES.......................................................................................21

1.6.2 MODE 1 MANUAL...............................................................................................................21

1.6.3 MODE 2 AUTOMATIC ........................................................................................................22

1.6.4 MODE 3 MOD – BUS...........................................................................................................22

1. SETUP LANGUAGE ................................................................................... 23

1.8 OTHER FUNCTIONS ................................................................................. 23

1.8.1 EMERGENCY STOP ............................................................................................................23

1.8.2 LOCKED GENSET................................................................................................................24

1.8.3 REMOTE TESTING - EJP.....................................................................................................24

1.8.4 MASTER START..................................................................................................................24

1.8.5 MAINTENANCE REQUEST..................................................................................................24

1.8.6 TELEPROCESSING .............................................................................................................24

1.8.7 SCHEDULED START-UPS...................................................................................................24

1.8.8 PROGRAMMABLE RELAY GENSET CONDITIONS...........................................................25

1.8.9 DIFFERENTIAL OR EARTH FAILURE PROTECTION......................................................25

1.8.10 ELECTRONIC OVERLOAD (51) AND SHORT-CIRCUITS (50) PROTECTION................25

1.8.11 REVERSE POWER PROTECTION (32) ............................................................................26

1.8.12 ALARMS HISTORY.............................................................................................................26

1.8.13 FUEL PUMP COMMAND....................................................................................................27

1.8.14 PROGRAMMING THE CARD THROUGH USB PORT......................................................27

1.8.15 PASSWORD LOCKED & UNLOCKING PROCEDURE .....................................................27

1.8.16 LED TEST ...........................................................................................................................27

1.8.17 AUTOMATIC BATTERY CHARGER FUNCTION................................................................27

1.8.18 FUEL THEFT FUNCTION....................................................................................................28

1.8.19 DUMMY LOAD FUNCTION .................................................................................................28

1.8.20 LOAD SHEDDING FUNCTION............................................................................................28

1.8.21 DOUBLE STARTER FUNCTION.........................................................................................28

1.8.22 FUEL MONITORING FUNCTION........................................................................................28

1.8.23 BATTERY CHARGED TEST FUNCTION............................................................................29

1.8.24 LOW R.P.M. OPERATING FUNCTION...............................................................................29

1.8.25 SERVICE PHONE NUMBER SIGNALLING ........................................................................29

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 3 of 102

1.8.26 VARIABLE SPEED FUNCTION........................................................................................... 29

1.9 INTERPRETATION OF ALARMS AND CONTROLS ..................................... 30

1.9.1 WHAT TO DO IN CASE OF GENSET FAILURE ................................................................. 30

1.9.2 ALARMS AND STATES SUMMARY..................................................................................... 34

1.9.3 ELECTRICAL MAINTENANCE............................................................................................. 35

1.9.4 MCCB RESET....................................................................................................................... 35

1.9.5 MECHANICAL MAINTENANCE ........................................................................................... 35

1.9.6 PERIODIC CHECKS............................................................................................................. 35

2.0 INSTALLATION MANUAL .......................................................................... 36

2.1 CONSTRUCTIVE DESCRIPTION OF QPE-C PANEL ................................... 36

2.1.1 EXTERNAL COMPOSITION QPE-C-V PANEL ................................................................... 36

2.1.2 QPE-C-OCC PANEL COMPOSITION (WITH SWITCHING ON BOARD) ........................... 37

2.1.3. QPE-C-SC PANEL COMPOSITION (WITHOUT SWITCHING)........................................... 38

2.2 CONSTRUCTIVE DESCRIPTION OF MC4 CARD ........................................ 40

2.2.2 CONSTRUCTIVE CHARACTERISTICS MC4 CARD.......................................................... 40

2.2.3 TECHNICAL CHARACTERISTICS SUMMARY................................................................... 41

2.3 ELECTRICAL CONNECTIONS BETWEEN MC4 MOTHERBOARD AND THE

GENERATING SET .......................................................................................... 42

2.3.1 J1 CONNECTOR POWER SUPPLY SYSTEMS C.C AND COMMAND RELAY.................. 42

2.3.2 J2 CONNECTOR CAN-BUS ENGINE CONNECTION......................................................... 43

2.3.3 J3 CONNECTOR ENGINE PROTECTION DIGITAL INPUTS............................................. 43

2.3.4 J4 CONNECTOR ANALOGICAL INPUTS TO MEASURE ENGINE PARAMETERS.......... 45

2.3.5 J5 CONNECTOR TOROID CONNECTION DIFFERENTIAL PROTECTION...................... 48

2.3.6 J7 CONNECTOR MCCB OPENING COIL ........................................................................... 50

2.3.7 J8 CONNECTOR LINE GENERATOR INPUT...................................................................... 50

2.3.8 J9 CONNECTOR FUEL PUMP SUPPLY............................................................................. 51

2.3.9 J10 CONNECTOR FLOATING OVERFLOW ....................................................................... 51

2.4 ELECTRIC WIRING MC4 MOTHERBOARD WITH EXTERNAL USERS ....... 52

2.4.1 J11 CONNECTOR DATA TRASMISSION IN MOD-BUS...................................................... 52

2.4.2 J12 CONNECTOR REMOTE CONTROLS .......................................................................... 52

2.4.3 J13 CONNECTOR REMOTE SIGNALS............................................................................... 52

2.4.4 J14 CONNECTOR PROGRAMMABLE REPORTING RELAY............................................. 53

2.4.5 J15 CONNECTOR MANAGEMENT OF MAINS-GENSET REMOTE SWITCHING ............ 53

2.4.6 J16 CONNECTOR BATTERY CHARGER CONNECTION.................................................. 55

2.4.5 J17 CONNECTOR MAINS PRESENCE SENSOR CONNECTION..................................... 56

2.5 SETUP ...................................................................................................... 5

2.5.1 SETUP MODE ACTIVATION................................................................................................ 57

2.5.2 CLOCK MENU ...................................................................................................................... 57

2.5.2 DIFFERENTIAL MENU......................................................................................................... 58

2.5.4 TIMES MENU........................................................................................................................ 59

2.5.5 THRESHOLDS MENU.......................................................................................................... 59

2.5.6 SETTINGS MENU................................................................................................................. 61

2.5.7 CALIBRATION MENU........................................................................................................... 64

2.5.8 MODEM MENU..................................................................................................................... 65

2.5.9 CAN-BUS MENU .................................................................................................................. 66

2.5.10 MOD-BUS MENU................................................................................................................ 67

2.5.11 USB MENU......................................................................................................................... 67

2.5.12 CARD MENU ....................................................................................................................... 68

2.5.13 SPECIAL FUNCTIONS MENU ........................................................................................... 70

2.6 TECHNICAL NOTES OF MC4 CARD .......................................................... 3

2.6.1 ENGINE RUNNING DETECTION.......................................................................................... 73

2.6.2 OPERATING WHEN THE MICROPRECESSOR IS BLOCKED........................................... 73

2.6.3 PASSWORD LOCK AND RELEASE..................................................................................... 73

2.6.4 PASSWORD RELEASE......................................................................................................... 74

2.6.2 FIRMWARE SOFTWARE DISPLAY...................................................................................... 74

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 4 of 102

2. ACCESSORIES COMBINABLE WITH QPE-C PANEL .................................. 6

2.7.1 MODEM FOR REMOTE MANAGEMENT OF GENERATING SET.......................................76

2.7.2 REMOTE DISPLAY...............................................................................................................78

2.7.3 AUX16 AUXILIARY 16-RELAY MODULE..............................................................................81

2.7.4 RADIO CHANNEL.................................................................................................................85

2.7.5 REMOTE MANAGEMENT SOFTWARE MC4 MONITORING .............................................85

2.7.6 MOD-BUS PROTOCOL........................................................................................................86

2.8 ELECTRIC CONNECTION DIAGRAM QPE-C ............................................. 90

2.8.1 ENGINE CONNECTOR QPE-C-V AND QPE-C-O...............................................................90

2.8.2 ALTERNATOR CONNECTOR FOR QPE-C-V.....................................................................90

2.8.3 FUEL TOPPING SYSTEM CONNECTOR QPE-C-V AND QPE-C-O...................................91

2.8.4 WIRING DIAGRAM FOR QPE-C-V.......................................................................................92

2.9 INSTALLATION ........................................................................................ 95

2.9.1 PROTECTION DEGREE........................................................................................................95

2.9.2 GROUND CONNECTIONS (PE)............................................................................................95

2.9.3 POWER CONNECTIONS......................................................................................................95

2.9.4 BATTERY CONNECTION.....................................................................................................96

2.9.5 SUMMARY OF CONTROL PROBES MOUNTED ON THE ENGINE ..................................96

2.9.8 DIELECTRIC STRENGTH TEST...........................................................................................97

2.10 SERVICE PROCEDURES ........................................................................ 98

2.10.1 FIRST START-UP PROCEDURE........................................................................................98

2.10.2 PROCEDURE FOR REPLACING THE BATTERY..............................................................98

2.10.3 PROCEDURE FOR REPLACING MC4 CARD....................................................................98

3.0 MAINTENANCE MANUAL ......................................................................... 99

3.1 ROUTINE MAINTENANCE.......................................................................................................99

3.2 ELECTRICAL AND MECHANICAL MAINTENANCE................................................................99

3.3 TEST AND ALARMS SIMULATION..........................................................................................99

3.3 ENGINE PROTECTIONS..........................................................................................................99

3.4 GENERATOR PROTECTION...................................................................................................99

3.5 51 OVERLOAD PROTECTION................................................................................................99

3.6 TROUBLESHOOTING ............................................................................................................100

WARRANTY ................................................................................................... 101

This document is the exclusive property of Elcos S.r.l. and it reserves all rights in this document and in the information

contained therein.

Elcos S.r.l. reserves the right to update and modify this document at any time and without any advance notice.

Reproduction, use or disclosure to third parties without express authority is strictly forbidden.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 5 of 102

The data presented herein could undergo modifications for technical improvements without any notice.

USER MANUAL

1.1 INTRODUCTION

Congratulations for choosing QPE-C panel (with MC4 electronic logic) for managing your genset.

Later on, you will appreciate the great flexibility of use and high performance allowed by the high technology

of the electronic module MC4.

This is a microprocessor based electronic module that manages all types of gensets, both traditional ones

and with CAN-BUS commands. It is set to communicate over MOD-BUS with various devices such as main-

genset transfer switching cabinets with switching, pc, remote touch-screen panels, alarm repeating modules

etc.

Through a GSM module (integrated on-demand) you can manage and totally control your genset from miles

away.

MC4 is equipped with fully digital instrumentation that allows you to monitor all the parameters of the engine,

generator, and related accessories.

The USER MANUAL aims to provide a clear and simple guide in order to consent a quick, complete and

safe use of the genset.

1.2 AIM

This manual provides all the necessary information regarding the use of the genset with QPE-C panel, both

in vertical QPE-C-V and in horizontal version QPE-C-O:

1. Knowing the operating basics of the panel;

2. Interpreting the indications of the electronic panel;

3. Setting the electronic card in the different service requirements;

4. Making the minimum necessary checks to ensure the smooth functioning of the genset.

Any technical or adjustment elements are not discussed because they are managed by the manufacturer

during creation of the machine.

1.3 OPERATING BASICS

The types of QPE-C panels differ in type of construction, based on the powers of use and the presence or

absence of the integrated switching between Mains-Gen Set:

- QPE-C-V vertical arrangement for Gen Sets from 110kVA to 2.500kVA,

- QPE-C-OSC horizontal arrangement without switching for Gen Sets from 7kVA to 100kVA,

- QPE-C-OCC horizontal arrangement with switching on board for Gen Sets from 7kVA to 100kVA.

1.3.1 HOW THE QPE-C-V PANEL WORKS WITH THE GENSET

The QPE-C panel can be matched with all the generators with power range from 10 to 2500 KVA, with

operating voltages from 220 to 460 volts, 50 or 60Hz, with traditional engines or with Can-bus control ones.

In Fig. 1 is shown the standard components of the plant that is made of:

a generating set GE, control panel QPE-C-V, a machine switch INT. (which varies according to the power of

the genset).

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 6 of 102

The QPE-C panel monitors and detects all the parameters of both the engine and the generator. It has a

three-position key that sets the type of plant’s operating mode.

With key on position 0 the panel is switched off, the genset is off.

With key on Manual the start-up is decided by the user by pressing the start button.

With key on Automatic, depending on the operating mode, the start-up could be through external contact,

lack of electricity from the relative mains, command in MOD-BUS, from the communication network via sms,

etc..

During the functioning all the electrical and mechanical parameters of the genset are displayed and all the

protections are enabled, including overload, short-circuit and earth fault if set.

If an anomaly happens the INT switch opens through the opening coil and it disconnects the load, then after

the cooling phase the engine stops.

In combination with an ATS (Automatic Transfer Switch) with or without mains sensor, it becomes a

complete system for the mains failure, (as per Figure 2). The QPE-C panel is even able to autonomously

manage the switching mains-genset.

Fig.2

RETE

Public mains

QPE

-

C

Command and control panel

CR

Mains counter

GE

Generating set

CARICO

Preferential load

CG

Genset counter

Fig. 1

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 7 of 102

(generator + engine)

1.3.2 QPE-C-VADJUSTABLE OPERATING MODES

The QPE-C panel, in order to cover all needs, can be set in three distinct operating modes:

1 Manual mode “MOD 1” (start-up command from external potential free contact)

2 Automatic mode “MOD 2” (start-up command from internal mains sensor)

3 Mod-bus mode “MOD 3” (start-up command from remote mod-bus)

The setting of these three modes is done by inserting three micro-switches (dip 1-2-3) on the

motherboard, see page 30.

MANUAL MODE (MODE 1)

In Manual mode, the panel can be used in two ways, depending on the position of the board key.

With key on Manual, the genset start-up occurs exclusively by pressing the "start" button by the user.

With key on Automatic, the start-up occurs through an external command (potential free contact) that if

Active, it launches the automatic process of start-up and the possible management of inserting load.

So, the consent of start-up can be given by external devices such as floats, pressure switches,

thermostats, relay voltmeters etc.

AUTOMATIC MODE (MODE 2)

With key on Manual, the genset start-up occurs exclusively by pressing the "start" button by the user.

With key on Automatic, the panel is able to operate as an emergency system to the mains. It fully

manages both the start-up of the genset and the complete management of mains-genset switching in the

separated ATS.

Suppose that we are in the situation represented in Figure 2, where the mains is within normal values:

the CR counter is closed and the use is powered by the mains.

The QPE-C monitors the mains and in case of any anomaly or the lowering or lack of a phase or

because of asymmetry of the phases themselves, it acts as follows:

1. It commands the opening of CR mains counter;

2. It enables the start-up of the genset and once it has reached the right functioning level, it commands the

closing of the CG counter, powering the use through the GE generator;

N.B.: During the functioning, the engine and generator are monitored to determine if any abnormalities

occur. If this is the case, these abnormalities would cause the immediate arrest of the genset with

consequent storage and visualization onto the display, showing the cause of the alarm (e.g. low oil

pressure, overload, etc.).

3. When the mains come back to normal values, after a set delay the QPE-C opens the CG genset

counter and after one second, closes the CR counter. In this way it re-powers the use with the mains.

4. The genset keeps running for at least one minute to burn off the excessive heat and at the end of cooling

time, it stops automatically.

If the user has his own ATS with an independent management of switching, then he can only use the

mains sensor of QPE-C panel to handle only the start-up when the mains fail.

MOD-BUS MODE (MODE 3)

In Manual mode, the panel can be used in two ways, depending on the position of the board key.

With key on Manual, the genset start-up occurs exclusively by pressing the "start" button by the user.

With key on Automatic, the start input can be sent through a Mod-Bus message, which is sent by a

management control unit or by an external PLC.

The start-up input may be given from external devices such as PLCs, remote management systems,

etc..

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 8 of 102

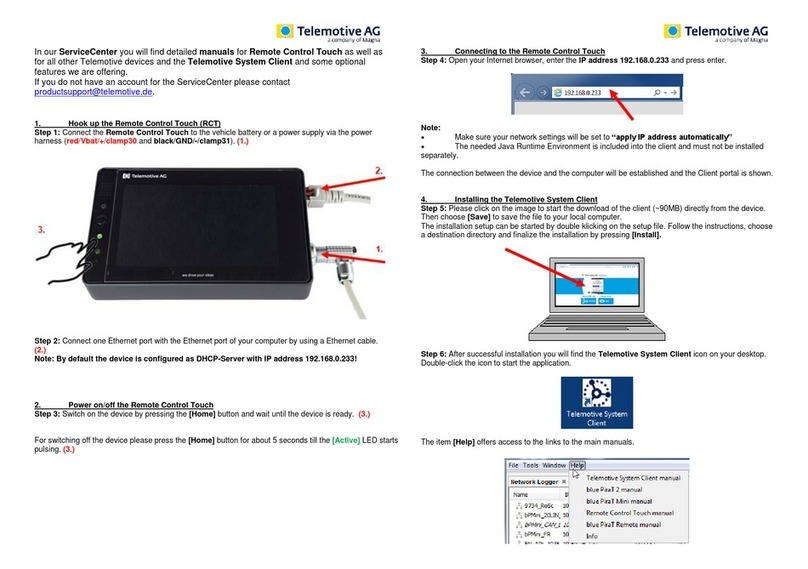

1.3.3 HOW THE QPE-C-O PANEL WORKS WITH THE GENSET

The QPE-C-O panel can be matched with all the generators with power range from 4 to 100 kVA, with

operating voltages from 220 to 460 volts, 50 or 60Hz, with single or three-phase system.

The following two executions are available:

1. QPE-C-OCC (fig 1) panel with internal mains-genset switching by mechanically and electrically

interlocked contactors.

2. QPE-C-OSC (fig. 2) panel without mains-genset switching and equipped with a 63A switch

complete with opening coil for units up to 40 kVA, and a 160A switch for units up to 100 kVA.

Fig.2

The QPE-C-O panel monitors and detects all the parameters of both the engine and the generator. It has

a three-position key that sets the type of plant’s operating mode.

With key on position 0 the panel is switched off, the genset is off.

With key on Manual the start-up is decided by the user by pressing the start button.

With key on Automatic, depending on the operating mode, the start-up could be through external

contact, lack of electricity from the relative mains, command in MOD-BUS, from the communication

network via sms, etc..

During the functioning all the electrical and mechanical parameters of the genset are displayed and all

the protections are enabled, including overload, short-circuit and earth fault if set

If an anomaly happens the switch (QPE-C-OSC) opens or the genset contactor (QPE-C-OCC) and it

disconnects the load, then after the cooling phase the engine stops.

Fig. 1

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 9 of 102

1.3.4 QPE-C-OCC OPERATING MODE

The QPE-C-OCC panel, (with switching) is complete with a 4P mains-genset switching system realized

through mechanically and electrically interlocked contactors.

The installation is very easy and it exclusively needs the main power line connection with the load inside

the genset.

MANUAL MODE.

With key on manual, the genset start-up is only made by pressing the "start" button by the operator. If the

public mains is present, then the load remains supplied from the mains. In case of power failure, the

generating set provides power to feed the load instantly.

AUTOMATIC MODE.

With key on Automatic, the panel is able to operate as an emergency system to the mains. It fully

manages both the start-up of the genset and the complete management of mains-genset switching.

Suppose that we are in the situation represented in Figure 1, where the mains is within normal values:

the CR counter inside the panel is closed and the user is powered by the mains.

The QPE-C-OCC monitors the mains and in case of any anomaly or the lowering or lack of a phase or

because of asymmetry of the phases themselves, it acts as follows:

1. It commands the opening of CR mains counter;

2. It enables the start-up of the genset and once it has reached the right functioning level, it commands

the closing of the CG counter, powering the user through the GE generator;

N.B.: During the functioning, the engine and generator are monitored to determine if any abnormalities

occur. If this is the case, these abnormalities would cause the immediate arrest of the genset with

consequent storage and visualization onto the display, showing the cause of the alarm (e.g. low oil

pressure, overload, etc.).

3. When the MAINS come back to normal values, after a set delay the QPE-C-OCC opens the CG

genset counter and after one second, closes the CR counter. In this way it re-powers the use with

the mains.

4. The genset keeps running for at least one minute to burn off the excessive heat and at the end of

cooling time, it stops automatically.

The switching contained in the QPE-C-OCC panel is capable of switching line currents up to max 60A for

panels with power up to 40 kVA and 160A for panels up to 100 kVA.

1.3.5 QPE-C-OSC OPERATING MODE

The QPE-C-OSC panel, in order to cover all needs, can be set in three distinct operating modes:

1 Manual mode “MOD 1” (start-up command from external potential free contact)

2 Automatic mode “MOD 2” (start-up command from internal mains sensor)

3 Mod-bus mode “MOD 3” (start-up command from remote mod-bus)

The setting of these three modes is done by inserting three micro-switches (dip 1-2-3) on the

motherboard, see paragraph 1.6.1.

MANUAL MODE (MODE 1).

In Manual mode, the panel can be used in two ways, depending on the position of the board key.

With key on Manual, the genset start-up occurs exclusively by pressing the “start” button by the operator.

With key on Automatic, the start-up occurs through an external command (potential free contact) that if

Active, it launches the automatic process of start-up and the possible management of inserting load.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 10 of 102

So, the consent of start-up can be given by external devices such as floats, pressure switches,

thermostats, relay voltmeters etc.

AUTOMATIC MODE (MODE 2).

With key on Manual, the genset start-up occurs exclusively by pressing the “start” button by the operator.

With key on Automatic, the panel is able to operate as an emergency system to the mains. It fully

manages both the start-up of the genset and the complete management of mains-genset switching in the

separated ATS.

Suppose that we are in the situation represented in Figure 2, where the mains is within normal values:

the CR counter is closed and the use is powered by the mains.

The QPE-C monitors the mains and in case of any anomaly or the lowering or lack of a phase or

because of asymmetry of the phases themselves, it acts as follows:

1. It commands the opening of CR mains counter;

2. It enables the start-up of the genset and once it has reached the right functioning level, it commands

the closing of the CG counter, powering the use through the GE generator;

N.B.: During the functioning, the engine and generator are monitored to determine if any abnormalities

occur. If this is the case, these abnormalities would cause the immediate arrest of the genset with

consequent storage and visualization onto the display, showing the cause of the alarm (e.g. low oil

pressure, overload, etc.).

3. When the mains come back to normal values, after a set delay the QPE-C-OSC opens the CG

genset counter and after one second, closes the CR counter. In this way it re-powers the use with

the mains.

4. The genset keeps running for at least one minute to burn off the excessive heat and at the end of

cooling time, it stops automatically.

If the user has his own ATS with an independent management of switching, then he can only use the

mains sensor of QPE-C-OSC panel to handle only the start-up when the mains fail.

MOD-BUS MODE (MODE 3).

In manual mode the panel can be used in two ways, depending on the position of the key on board.

With key positioned to manual, the genset start-up is only made by pressing the "start" button by the

operator.

With key positioned to automatic, the start-up is made through an external command, sent on the MOD-

BUS line that, if active, starts the automatic start-up process and possible management of inserting load.

So, the start input can be sent from external devices, such as teleprocessing systems, PLCs, etc..

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 11 of 102

1.4 EXAMINATION OF “MC4 ON QPE-C PANEL”

MODULE

Functional description of panel controls.

1.5 FUNTIONAL DESCRIPTION OF PANEL COMPONENTS

1.5.1 DESCRIPTION OF KEYED SELECTOR FUNCTION

1. The keyed selector selects the operating mode. With key on AUT position,

the genset starts automatically. According to the functional mode that is

set, the command can be made via external potential free contact, via the

mains failure, via a Mod-Bus signal, or through an sms etc.

With key on automatic, the green led corresponding to the writing

remains turned on with fixed light.

1. COMMAND KEY

Automatic functioning. (AUT)

Manual functioning. (MAN)

4.

RESET / ENTER buttons to restore

functions or unlock alarm. In Setup mode,

it confirms the set data (T4).

5.

CK MUTE alarm

Fuel pump manual command

Engine pre-heater or glow-plug (T1 - T2 - T3)

2.

Buttons for manual command of

running or arrest. (T7 - T8)

3.

Graphic display for visualizing all the

measurements, alarms and commands.

6

. Button for activating the

automatic weekly test and

instantaneous test (T9).

7.

Buttons to change the display view or

to modify parameters in Setup. (T5 - T6)

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 12 of 102

2. With the keyed selector on ZERO, the genset is totally disabled, power consumptions on the power

battery are excluded. If the key is turned to ZERO position while the genset is running, the panel will

not switch off immediately, but it will first start the process of shutdown and when the engine cooling

process is finished, the panel will shut down entirely. The timing of the shutdown procedure is

displayed through an animated hourglass on the graphic display.

3. When the key is on MAN, the START and STOP buttons are enabled. Therefore, it is up to the user

to decide the start-up of the genset.

1.5.2 DESCRIPTION OF SINGLE BUTTONS AND WARNING LIGHT FUNCTIONS

1. SIREN MUTE BUTTON (T1)

When it is pressed, this button silences the alarm buzzer, the corresponding

red LED indicates the presence of a failure. The reset of the alarm occurs by

pressing the reset button indicated here below. In Setup mode, pressing the

button allows you to leave the various Setup menu.

2. FUEL PUMP ACTIVATION BUTTON (T2)

If it is pressed with key on Manual, it activates the pump for refuelling the daily

tank from an external tank, if it is pressed again, it switches it off. The pump

stops automatically when it reaches the maximum level. The corresponding

green LED lights up every time the pump starts running.

With key on Automatic, the button is disabled because the activation of the fuel

pump takes place automatically according to the level of the tank.

In setup mode, the pressure of the button needs to increase the values of the parameters visualized on

the display.

3 GLOWPLUGS OR ENGINE PRE-HEATER ACTIVATION BUTTON (T3)

The warning light corresponding with this button has two distinct functions,

depending on the type of setting. If the “glow-plugs” function is enabled in the

card, the light will turn on before the start-up, indicating the insertion of glow-

plugs for pre-scheduled time.

If the “engine pre-heater” function is enabled on the card, the light turns on

every time the resistance that keeps the engine water at the correct

temperature is activated. The button is active only in manual mode and only in "glow-plugs" mode. If

pressed, it allows the reintegration of glow-plugs.

In Setup mode, the pressure of the button needs to decrease the values of the parameters visualized on

the display.

4 RESET-ENTER BUTTON (T4)

If pressed during normal functioning, it erases the alarms states and restores

the functions. In setup mode, it confirms the selection or stores the data.

5 STOP BUTTON (T7)

This button is always enabled both in manual and automatic. It stops the

machine when pressed. The red LED corresponding with this button indicates

that the shutdown phase is in progress.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 13 of 102

6 START BUTTON (T8)

This button in enabled only when the change-over switch is on MAN position.

The control is manual, it is therefore necessary to hold the start button until the

start-up is completed. The green LED corresponding with this button indicates

that the start-up command is in progress. With key turned to automatic

position, if the Start Button is pressed for more than 5 seconds, it activates the

automatic battery test by running the starter motor without starting the engine.

7 GENSET TEST BUTTON (T9)

The button in active only if the key is on Automatic and it enables two

different functions:

“Instantaneous automatic test” is obtained by pressing the button for more

than 3 seconds. The genset starts, the machine runs freely for the scheduled

time and then it stops automatically. The corresponding green led flashes,

indicating that it has activated the function.

“Programmed automatic test” is activated by quickly pressing the button. This function allows the inner

timer to activate, in order to test the genset at pre-scheduled times and dates.

If this function is activated, the corresponding green LED remains turned on with fixed light.

The setup test scheduling is carried out in Setup menu described later, see page 47.

8 DISPLAY MODE BUTTONS (T5-T6)

These buttons allow you to navigate around the display pages. In setup

mode, they allow you to access the different menus.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 14 of 102

1.5.3 DESCRIPTION OF DIFFERENT MEASUREMENTS AND REPORTING PAGES

During the ignition phase, for a few seconds, the screen displays the company logo and the version of the relay card

software. Then the first page display appears:

Page 1

The first page shows the user the main functioning indications of the genset.

In detail, these are as follows:

1. Key state display, possible indications AUT. (key on automatic), MAN (key on manual), MSTR (forced

start-up with key on off, Master start function).

2. Voltage supplied by the generator, the parameter changes sequentially according to the phases

indicated by point 12.

3. Current supplied by the machine on phase X.

4. Operating frequency.

5. Engine alarm display, in case of multiple alarms they are displayed alternatively.

6. Page number

7. Generator status, possible combinations, G-ALRM (genset in alarm), G-off (genset turned off), G-on

(genset running), G-stop (genset shutting down), G-strt (genset starting up).

8. Indication of operating mode MOD1 (manual operating), MOD2 (automatic operating) MOD3 (mod-bus

operating).

9. Time Display

10.Date display

11.Display numbers of alarms occurring simultaneously.

12.Sequential display of voltage measurements.

13.This icon indicates the presence of a modem, of a GSM signal and, if flashing, the presence of sending

and receiving an SMS.

14.Presence of scheduled events of genset start-up on a pre-set timetable.

15.Animated icon to display timing in progress.

1

2

3

4

5

6

8

16

7910

151413

12

11

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 15 of 102

By pressing the down arrow underneath the display screen, you will display the following pages.

Page 2

In detail, the indications are as follows:

1. Engine cooling water temperature.

2. Level of engine lubrication oil pressure

3. Amount of fuel in the tank expressed in percentage

4. Battery voltage

5. Available space for an additional programmable

analogue measure of engine.

If one of the measures is not present, it means that it is not planned in the preparation of the machine. In

engines equipped with CAN-bus communication, the values of water temperature and oil pressure are

communicated by the engine electrical box.

Page 3

In detail, the indications are as follows:

1. Concatenated voltage phase L1-L2

2. Concatenated voltage phase L2-L3

3. Concatenated voltage phase L3-L1

In case of running in single-phase, the following page will

not be displayed.

Page 4

In detail, the indications are as follows:

1. Neutral-phase L1-N Voltage

2. Neutral-phase L2-N Voltage

3. Neutral-phase L3-N Voltage

In case of running in single-phase, only the first measure

will appear.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 16 of 102

Page 5

In detail, the measures are as follows:

1. Current supplied by the machine on phase L1

2. Current supplied by the machine on phase L2

3. Current supplied by the machine on phase L3

In case of running in single-phase, only the first measure will appear.

Page 6

In detail, it is displayed as follows:

1. Instantaneous active produced power

2. Instantaneous apparent produced power

3. Instantaneous reactive power

4. Power factor, the value is displayed only with machine

operating at load.

Page 7

In detail, it is displayed as follows:

1. Total power produced by the machine throughout its

lifetime (not resettable).

2. Partial power produced with resettable option by the

user (see page 50) This is for the calculation of

operating costs for rent.

3. Power produced after each start-up of the machine, it

automatically resets at shutdown of the panel.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 17 of 102

Page 8

In detail, it is displayed as follows:

1. Total hours of running produced by the machine.

2. Partial hours of running resettable by the user (see

page 50) for rented time.

3. Working time of the machine from last start-up

made.

4. Countdown for the remaining hours until

maintenance. Once it reaches "0" hours, the count

restarts indicating the hours of running that go past

the deadline. At the end of the maintenance hours

of the machine, a beep and a warning icon with

the "required maintenance” writing are displayed.

5. Start-up counter. The number of successful start-ups are stored, whether performed both in

manual and automatic.

Page 9

In detail, it is displayed as follows:

1. Date, day/month/year.

2. Day of week

3. Time

The watch is equipped with a backup battery, so even

disconnecting the battery of the genset, the date will not

be lost.

Page 10

In detail, it is displayed as follows:

Current wasted during the running of genset.

Setting up of the alert threshold. If the wasted current

exceeds the set value, the device for releasing the load

intervenes.

Setting the delay of intervention of the differential

protection.

This display page will appear only if the function of

differential protection is enabled, and only with

generators that have delta-star neutral connected to the

earth. With the machine running the following writing will

appear “TEST: press RESET/ENTER for 5 seconds”, which

enables the possibility of testing the differential protection device.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 18 of 102

Page 11

Display of input/output states summary table.

This page appears only if it is enabled in the Setup menu

(see page 50).

The following instructions are very useful for

technicians to display any problems related to the

malfunctions of the connected sensors.

Into IN column the states of inputs are indicated. Into OUT

column, the states of the output relays are displayed.

The table shows the details of input states.

Input

Description

1

Dynamo Report of the operating state of battery charger dynamo

2

P.oil Report of oil pressure sensor conditions.

3

Temp. Report of high temperature water sensor

4

RisFuel Report of the fuel reserve float

5

Liv.H2O Report of the low water level float in the radiator

6

H2O-Oil Report of the presence of water in the fuel

7

Aux1 Report of auxiliary input 1 active

8

Aux2 Report of auxiliary input 2 active

9

Rete Report of referenced mains in tolerance

10

Blocco Report of external operating lock active

11

Test Report of start-up testing enabled

12

Start Report of external start enabled

13

StartM Report of external master start enabled

14

P.A.E. Report of emergency alarm button on board enabled

15

Emerg.R Report of remote emergency alarm button enabled

16

Sic.Carb Report of overflow float enabled

The table shows the details of output states.

Output

Description

1

Start Report of starter motor enabled

2

StopE.M

. Report of electromagnet stop enabled

3

E.V. Report of fuel solenoid activated

4

Candel. Report of pre-heater glow-plugs enabled

5

Rete Report of contactor mains output command’s conditions

6

Gruppo Report of contactor genset output command’s conditions

7

Pompa Report of fuel pump conditions

8

R.Prog Report of programmable relay’s activation

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 19 of 102

Page 12

This page is available only in combination with engines

equipped with CAN-BUS electrical box and depending on the

engine type, the following measures may be available:

Instantaneous fuel consumption.

Oil or fuel temperature.

Engine speed.

Coolant liquid level in percentage.

Oil level in percentage.

Intercooler air temperature.

Intercooler air pressure.

Page 13

This page displays the alarms transmitted via CAN-BUS from

the engine electrical box. In case of failure, the alarm codes

are displayed to identify the type of failure.

This system constitutes a diagnostics on the entire electrical

system of the machine, even if the engine stopped, the

efficiency of sensors and wiring is checked.

To interpret the code you should check the corresponding

engine’s manual (N.B.: each model, even if it is from the same

manufacturer has its own manual to consult).

The engine manual lists the type of alarm and the remedy to

be made to the machine.

For ex.: I own a genset with engine Volvo type TAD1242GE

and the display shows CAN 184 writing. By consulting the manual, this anomaly code corresponds to "fault

on the oil temperature sensor”, so the connections of the sensor or the sensor itself have to be checked.

Page 14

This page appears after switching on the panel only with card

set to operate in mode 2. It displays the status of the genset-

mains switching and the three mains voltages.

The ON-OFF writings on top of the mains and genset

symbols indicate the actual presence of mains or genset

voltage within the limits.

The CR and CG contacts symbols indicate the status of

contacts for the management of remote switching.

The display shows the three mains voltages. Even if in only

one phase the voltage goes out of minimum and maximum

voltage set bounds, the genset starts up automatically

anyway. With mains presence, the direction of rotation of the

mains input line is also indicated. So, on the display "correct

sequence" or "wrong sequence" will then appear.

Name file REV. File Date Rev. LANGUAGE

PAGE

QPE-C ENG version 01 13

03

01/01/2013 ENG

Page 20 of 102

Page 15

This page appears automatically only in mode 2, and only

when the genset is running. It displays the status of

switching and shows the genset voltage.

The ON-OFF writings on top of the mains and genset

symbols indicate the actual presence of mains or genset

voltage within the limits.

The CR and CG contacts symbols indicate the status of

contacts for the management of remote switching.

Page 16

This screen appears only if the fuel monitoring (on demand)

is active and provides an estimation of runtime, calculated on

the actual power consumption.

Then the residue liters of fuel in the tank is indicated together

with the estimated fuel consumed by the machine during its

life.

The data shown have to be considered only as an indication,

since many external parameters may introduce errors of

assessment (For instance precision of fuel sensor, highly

variable load applied etc.).

Important

The display is sensitive to direct rays of the sun, any prolonged exposure can damage the display, avoid

exposure by interposing a shield. The display is temperature compensated and can work from -20 to +70 °

C, higher temperatures may cause a temporary darkening of the screen and make it unreadable.

This manual suits for next models

4

Table of contents

Other ELCOS Control Panel manuals