Electra DNG DC Series User manual

Other Electra Air Conditioner manuals

Electra

Electra IOD 7 User manual

Electra

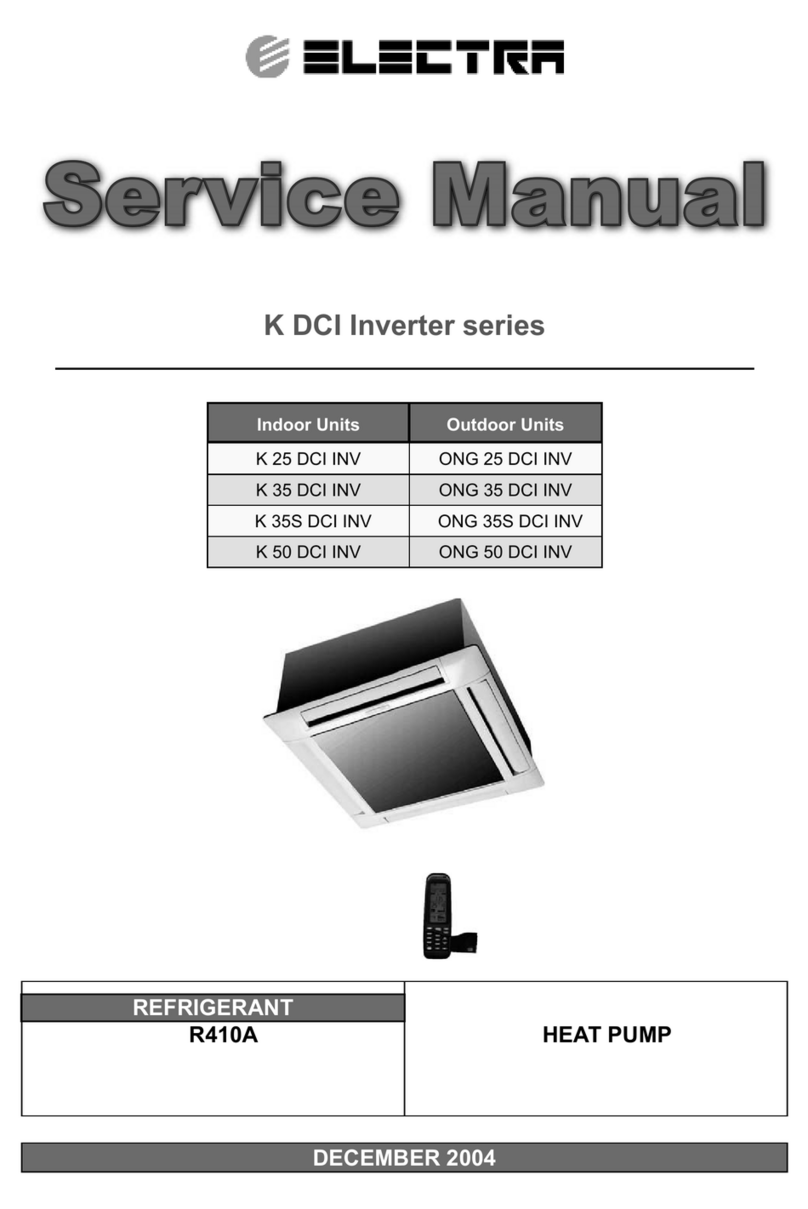

Electra K 25 DCI INV User manual

Electra

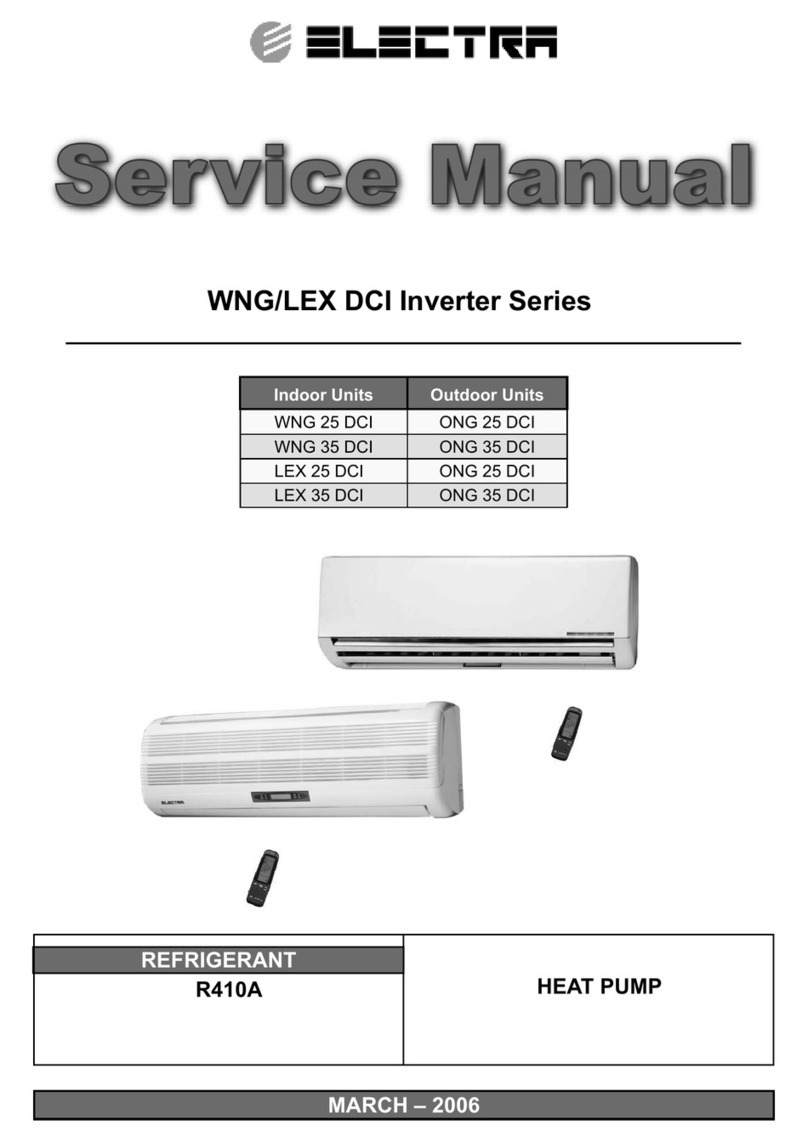

Electra WNG 25 DCI Series User manual

Electra

Electra DCI Light Commercial Series User manual

Electra

Electra KN-27SH Repair manual

Electra

Electra LEX 25 DCI User manual

Electra

Electra COMPACT 7 Operating manual

Electra

Electra WMT 090914 RC Manual

Electra

Electra WNG 25 DCI Series User manual

Electra

Electra Delta 17 DF User manual

Electra

Electra DELTA 25 User manual

Electra

Electra Multi Split DUO 50 DCI User manual

Electra

Electra DELTA 18ST User manual

Electra

Electra EMD 27 User manual

Electra

Electra ELSI-JKD009-N11 User manual

Electra

Electra Trio Delta 5.2 User manual

Electra

Electra ELSI-JYD009-H11 User manual

Electra

Electra ELSI-JGF009-N11 User manual

Electra

Electra WNG 25 DCI INV User manual

Electra

Electra WNG 7 User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions