Electric Eel Z5-AF User manual

1

MODEL Z5-AF

Drain Cleaning Machine

Operator’s Manual

FOR YOUR SAFETY

Before you operate or

maintenance this equipment,

READ this manual carefully

and completely!

!! DANGER !!

ELECTRIC EEL MANUFACTURING CO., INC.

501 West Leffel Lane, Springfield, Ohio 45501-9885

Call Toll Free (800) 833-1212 (937) 323-4644 FAX: (937) 323-3767

www.electriceel.com Proudly Made in The USA Since 1939 I-21

Purchase Date: _______________

Serial Number: _______________

2

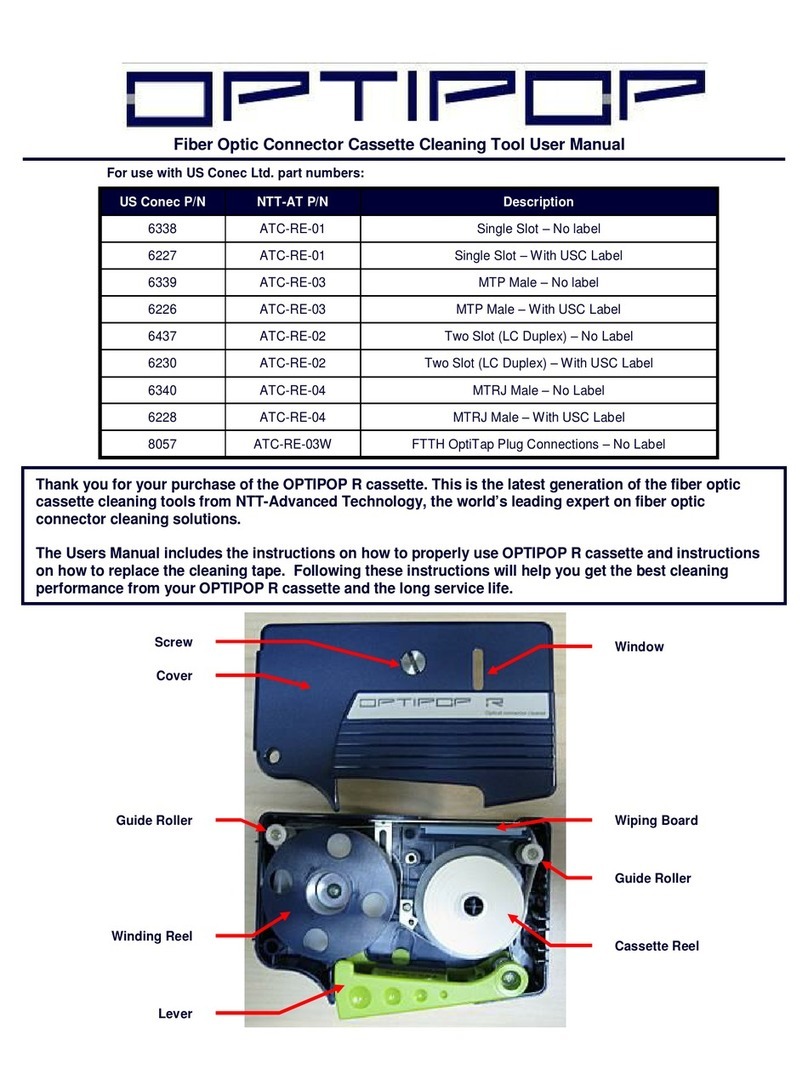

Description,

Specifications, and

Equipment

DESCRIPTION

The Electric Eel Model Z5-AF Drain

Cleaning machine is the newest of

Electric Eel’s complete line of quality

sewer and drain cleaning equipment.

This cage/drum machine is specifically

designed for 1 ¼” to 3” lines through

100 feet.

STANDARD FEATURES

1. Automatic cable feeder that

advances and retrieves cable

with the push of a lever.

2. Cable guide attached to feeder

to ensure operator does not

handle rotating cable.

3. Power cord is wrapped around

conveniently placed brackets

for safe, problem-free

transport.

4. Additional rear bar shields

motor and allows for flexible

two-position operation.

5. Easy-to-use foot-operated

switch allows the use of both

hands when working with

cable guide and feeder.

6. Ground Fault Circuit

Interrupter (GFCI) safety

feature comes standard with

20 foot power cord.

7. Heavy duty, durable tubular

frame provides stability and

balance while in operation.

8. Cast aluminum nose cone

bracket with bearing

supported guide tube.

9. Cable available in ½” certified

music wire with genuine

galvanized aircraft wire inner

core for longer life.

10. Unique inner cage/drum

design helps to prevent cable

buckling.

11. Built-in cage/drum-shaft slip

clutch minimizes cable and

tool breakage and provides

overload protection.

12. Impact-resistant plastic belt-

guard for additional operator

safety.

13. Rugged 1/3 H.P. motor

delivers optimum cleaning

power.

14. Wheel brake to stabilize unit

while in operation.

15. 10” wheels for better

maneuverability.

16. Handle folds down for easy

transport and storage.

SPECIFICATIONS

Cage/Drum Capacity: Up to 100

ft. of 1/2” certified music wire with

genuine galvanized aircraft wire

inner core cable.

3

Line Capacity: 1 ¼” to 3” lines up

to 100 Ft.

Weight: Machine only –61 lbs.

Frame: 1” diameter tubing

framework

Clutch: Dual disc cage/drum shaft

slip clutch

Motor: 1/3 H.P.

STANDARD EQUIPMENT

Electric Eel Model Z5-AF comes

complete with:

•Z5-AF unit with auto cable feeder

•75 Ft. of ½” certified music wire

with genuine galvanized aircraft

wire inner core cable

•5 Cleaning tools including:

DN-10 general purpose tool

DN-11 drill for hard

stoppages

DN-12 finishing tool

DN-14 drill for 2” –3” lines

DN-16 clean up tool for 3”

lines

SAFETY

INSTRUCTIONS

The following safety rules for operating

Electric Eel Sewer and Drain Cleaning

equipment MUST be read carefully

before operating this machine.

DANGER

TO PREVENT SERIOUS BODILY

INJURY:

GENERAL SAFETY

1. ALWAYS wear HEAVY leather

gloves and safety glasses when

operating equipment.

2. Place machine cable guide at

pipe opening. NEVER have

exposed cable.

3. DO NOT wear loose clothing or

jewelry while operating this

machine.

4. Use foot switch to operate

machine while keeping good

footing and balance at all times.

DO NOT OVERREACH.

DANGER

To prevent serious injuries including:

•Shock, electrocution or burns due

to improper grounding.

•Serious injuries to body, limbs or

hands and feet due to cables that

twist, kink and break.

•Eye injuries caused by loose cable,

thrown debris or splashed water.

READ SAFTEY INFORMATION

THOROUGHLY!

4

5. Machine, foot switch and cable

should be operated by one

person only. Additional

personnel in the working area

should observe all safety

instructions.

6. ALWAYS keep all guards in

place during operation.

7. ALWAYS wear rubber-soled

non-slip shoes.

8. ALWAYS avoid direct contact of

skin, facial area and especially

eyes with drain water. Chemical

compounds used in drains can

result in serious burns and other

injuries.

9. Replace fittings, cables and any

rotating parts as soon as they

become visibly worn. Replace

any cables which become

fractured, bent, kinked, or any

other damage occurs.

10. NEVER attempt to service

equipment beyond the

recommendations of the operat-

ing instructions. All other

servicing should be referred to

qualified service personnel.

11. To maintain safe operation, use

only identical replacement parts

and cables from Electric Eel.

12. ALWAYS keep clear of rotating

cages/drums, shafts, pulleys,

belts, or other rotating parts.

DANGER

TO PREVENT SERIOUS BODILY

INJURY AND TO AVOID DANGER

FROM ELECTRICAL SHOCK:

1. ALWAYS use a Ground Fault

Circuit Interrupter (GFCI) with a

properly grounded outlet for all

electrical cords, connections, and

parts as installed by factory and

DO NOT make any alterations.

2. NEVER use machine in damp or

wet conditions.

3. NEVER expose machine to rain.

4. THE USER SHOULD NEVER

ATTEMPT TO SERVICE THE

ELECTRICAL COMPONENTS.

For safety reasons, all electrical

replacement components should

be installed by a qualified

electrician.

5. ALWAYS disconnect the power

cord from the electrical source

before making any adjustments

or changes to power units.

6. If an extension cord is used, the

power source MUST be equipped

with a Ground Fault Circuit

Interrupter (GFCI) and properly

grounded.

7. Only use 14/3 or larger three-

wire extension cords with three-

prong grounding plugs and

three-pole receptacles.

5

8. When using extension cord

outdoors, only use those

intended for outdoor use.

(Indicated on cord by suffix

“W-A” after cord type.)

THE GROUND FAULT CIRCUIT

INTERRUPTER

(GFCI)

This machine is equipped with a

Ground Fault Circuit Interrupter (GFCI)

which is designed to prevent a serious

electrical shock. This device should be

tested on the job site before putting

the machine into operation as follows:

1. To ensure protection against

electric shock, test the device

before each use. When test

button is pushed in, the indicator

light should go off. Reactivate

the device by pushing the reset

button in. If the indicator light

goes on, the device is ready for

use. DO NOT use the device if

the indicator light does not go on

when reset or if the indicator

light remains on, when the test

button is pushed in.

2. This device does not guard

against electric shock resulting

from defects or faults in any

wiring supplying power to this

device, or from contact with both

circuit conductors.

DANGER

TO PREVENT SERIOUS BODILY

INJURY AND TO AVOID DANGER

FROM ROTATING CABLES AND

EQUIPMENT:

1. USE CAUTION AT ALL TIMES.

Cable can twist or kink and

cause serious injury. Fingers or

other body parts can be caught

in rotating parts.

2. NEVER handle the rotating

cable.

3. NEVER handle any cable

under tension. Relieve all

tension build up before

attempting to handle cable.

4. NEVER operate machine without

cable guide in place.

5. Use feeder to advance or retract

cable with motor switch in

FORWARD position for ALL

cleaning operations.

6. DO NOT continue to operate

machine when cleaning tool

becomes stuck in obstruction.

Excess torque on a cable

could cause it to fracture.

(Refer to operating instructions

to free cleaning tool.)

7. NEVER force a tool and cable

into a pipeline blockage. This

may overload the cable or tool

and cause it to fracture.

8. ALWAYS wear HEAVY leather

gloves and safety glasses when

operating machine.

9. Use correct tool for the job or

application. Check the tool

listing for the correct tool and

line size.

6

10. To maintain safe and efficient

operation, thoroughly clean all

cables with water after use.

Acids in the drain and sewer

lines attack and deteriorate the

metal of the cables and tools.

Deterioration will cause

weakness in cable and tools and

result in fracture or breakage.

11. Replace all cables and tools that

become deteriorated, worn,

kinked, bent, or any other

damage that occurs.

MACHINE SET-UP

DANGER

TO PREVENT SERIOUS BODILY

INJURY:

THIS MACHINE IS EQUIPPED

WITH A CAGE/DRUM/DISC

CLUTCH. THE MAXIMUM TORQUE

OF THE CLUTCH SETTING MUST

NEVER EXCEED 35 INCH/LBS.

NEVER USE ANY CABLE IN THIS

MACHINE OTHER THAN ELECTRIC

EEL GALVANIZED AIRCRAFT WIRE

REINFORCED MUSIC WIRE CABLE

IN 1/2" DIAMETER.

DISCONNECT POWER CORD

BEFORE ANY SET UP OR

MAINTENANCE IS ATTEMPTED.

This machine comes completely

assembled except for cable.

CAGE/DRUM REMOVAL

1. Disconnect power cord before

any set up or maintenance is

attempted.

2. Remove auto cable feeder from

mount by removing two (2)

5/16” bolts on the underside of

the mount.

3. Remove pulley guard by

unscrewing the thumb screw/

knob on the top of the pulley

guard.

4. Push down on motor to

compress spring. This will allow

the belt to be removed.

5. Pull spring loaded pin on rear of

cable axle.

6. Slide cage/drum unit with clutch

assembly forward.

7. Use reverse procedure for

reinstalling cable assembly.

8. Reinstall pulley guard.

9. Reinstall feeder on mount.

CABLE INSTALLATION

1. Disconnect power cord before

any set up or maintenance is

attempted.

2. Completely uncoil cable to be

installed. This will help avoid

unnecessary kinking.

3. Insert approximately 12” of

cable through the feeder and the

guide tube into the cage/drum.

The cable should coil in the

7

cage/drum in the same direction

as the decal indicates on the

rear of the cage/drum.

4. Attach cable anchor (DN-6) to

end of cable.

5. Grasp cable inside the

cage/drum near the end and

position cable anchor on end so

that the ¼-20 screw can be

inserted through the hole in the

rear of the cage/drum into the

cable anchor.

6. Insert remaining cable into the

cage/drum.

AUTO FEEDER ALIGNMENT

•Disconnect power cord before

any set up or maintenance is

attempted.

•Machine is shipped with auto

cable feeder aligned with

opening in nose cone of

cage/drum.

•If feeder mounting post height

or alignment is altered, loosen

the set screw which attaches the

feeder to the mounting post.

Insert a 5/8” diameter rod

through the feeder and align

with the nose cone opening.

Retighten set screw and locking

nut. Remove the rod from the

feeder. Feed cable back through

the feeder.

MAINTENANCE

•Disconnect power cord before

any set up or maintenance is

attempted.

•Maintenance on the Model Z5-AF

machine should be minimal for

the life expectancy of the

machine.

•The cage/drum/clutch should be

exercised daily.

Exercise as follows:

1. Wearing HEAVY leather gloves,

hold pulley firmly with one hand

and grasp cage/drum with the

other hand.

2. Rotate cage/drum back and forth

several times ensuring that the

cage/drum clutch assembly slips

(the cage/drum clutch assembly

moves while pulley remains

fixed).

CLUTCH ADJUSTMENT

•Disconnect power cord before

any set up or maintenance is

attempted.

•The clutch setting of 35 inch/lbs.

must NEVER be exceeded.

•The clutch setting in most cases

will not need to be adjusted for

the life of the machine.

•If the clutch needs to be reset,

the following procedure should

be used:

8

1. Obtain an inch/lbs. torque

wrench and E-20 from Electric

Eel.

2. Fit the adapter to the nose

cone of the Model Z5-AF

machine as per included

instructions with the adapter.

3. Check the setting of the

clutch with the torque

wrench.

If adjustment is needed, proceed

as follows:

1. Remove feeder as described

in cage/drum removal.

2. Remove 4 cage/drum bolts

from aluminum backing plate.

This will allow cage/drum

removal and expose clutch

mechanism.

3. Move clutch adjustment bolt

1/8th of a turn tighter or

looser as needed and recheck

setting after reassembly of

cage/drum. Repeat the

procedure as needed to

obtain 35 inch/lbs. maximum.

4. Reassemble and check all 4

bolts for tightness.

5. Reinstall feeder on mount.

OPERATING

INSTRUCTIONS

DANGER

OPERATOR MUST BE

THOROUGHLY FAMILIAR

WITH ALL SAFETY

INSTRUCTIONS BEFORE

OPERATING EQUIPMENT.

FOR AUTOMATIC CABLE

FEEDER

1. Attach a small spear-type

cleaning tool to the end of the

cable. This tool will enable you

to bore a starter hole in the

obstruction, allowing backed-up

water to drain.

2. Place machine cable guide at

pipe opening. NEVER have

exposed cable.

3. Position foot actuator for easy

operator accessibility.

4. Make sure switch is in the

FORWARD position. Run

machine in FORWARD at all

times during cleaning operation.

5. Place one HEAVY leather gloved

hand on the cable guide to

control cable as it rotates inside;

and use the other hand to work

the Feeder Control Lever.

DANGER: Operator must keep

one HEAVY leather gloved hand

on cable guide at all times

during operation.

6. In order to feed cable, the

operator must move the feeder

control lever from NEUTRAL

(the position midway between

FORWARD and REVERSE) to the

FORWARD position, while

depressing the foot actuator.

9

NOTE: The speed at which the

cable is fed initially can be

controlled by moving the feeder

control lever toward FORWARD to

increase speed and moving back

toward NEUTRAL to slow speed.

NOTE: If the feeder control lever is

initially put in FORWARD but the

cable is not advancing, then turn

the cable tension knob in a

clockwise direction until the cable

begins to advance. DO NOT over-

tighten cable tension knob as it

may damage feeder bearings.

7. Continue to automatically feed

cable until obstruction is met.

When cable begins to drag or

rotation becomes difficult, move

the lever to the NEUTRAL

position and allow tool to cut

away at the obstruction.

DANGER: NEVER force the

cable or tool into the

obstruction. Choose the proper

feeding speed in order to give a

smooth cutting action.

8. If tool becomes hung up in the

obstruction, move control lever

to the REVERSE position to back

out tool.

9. After tool as been removed from

obstruction, move control lever

back to the FORWARD position

and continue to work through

obstruction.

10. To retrieve cable from line,

move control lever to the

REVERSE position (while

continuing to operate cage/drum

in forward rotation) and cable

will back out of line and feed into

cage/drum.

NOTE: It is recommended to

use a continuous flush of water

to clean tool, cable, and sewer

line as cable is retrieved.

11. When tool is close to cleanout

opening, return Control Lever to

NEUTRAL position, release foot

actuator, and allow machine to

come to a complete stop.

DISCONNECT POWER CORD.

12. Pull remaining cable and tool

from sewer line and hand-feed

cable back into machine.

Other manuals for Z5-AF

1

Table of contents

Other Electric Eel Cleaning Equipment manuals

Electric Eel

Electric Eel CT User manual

Electric Eel

Electric Eel R User manual

Electric Eel

Electric Eel R Guide

Electric Eel

Electric Eel Z5 User manual

Electric Eel

Electric Eel E User manual

Electric Eel

Electric Eel D-5 User manual

Electric Eel

Electric Eel C User manual

Electric Eel

Electric Eel Z5 User manual

Electric Eel

Electric Eel S User manual

Popular Cleaning Equipment manuals by other brands

Bieffe

Bieffe SCARPAVAPOR NO LIMITS Use and maintenance manual

Clarus Technologies

Clarus Technologies PCS-25 Operator's manual

PRIMED

PRIMED DART 9192 Instructions for use

Vermop

Vermop Equipemove operating instructions

Kärcher

Kärcher T-Racer T 300 Plus Original instructions

HAKO

HAKO Citymaster 650 Short instructions