Ultrasonic cleaning equipment pg. 2

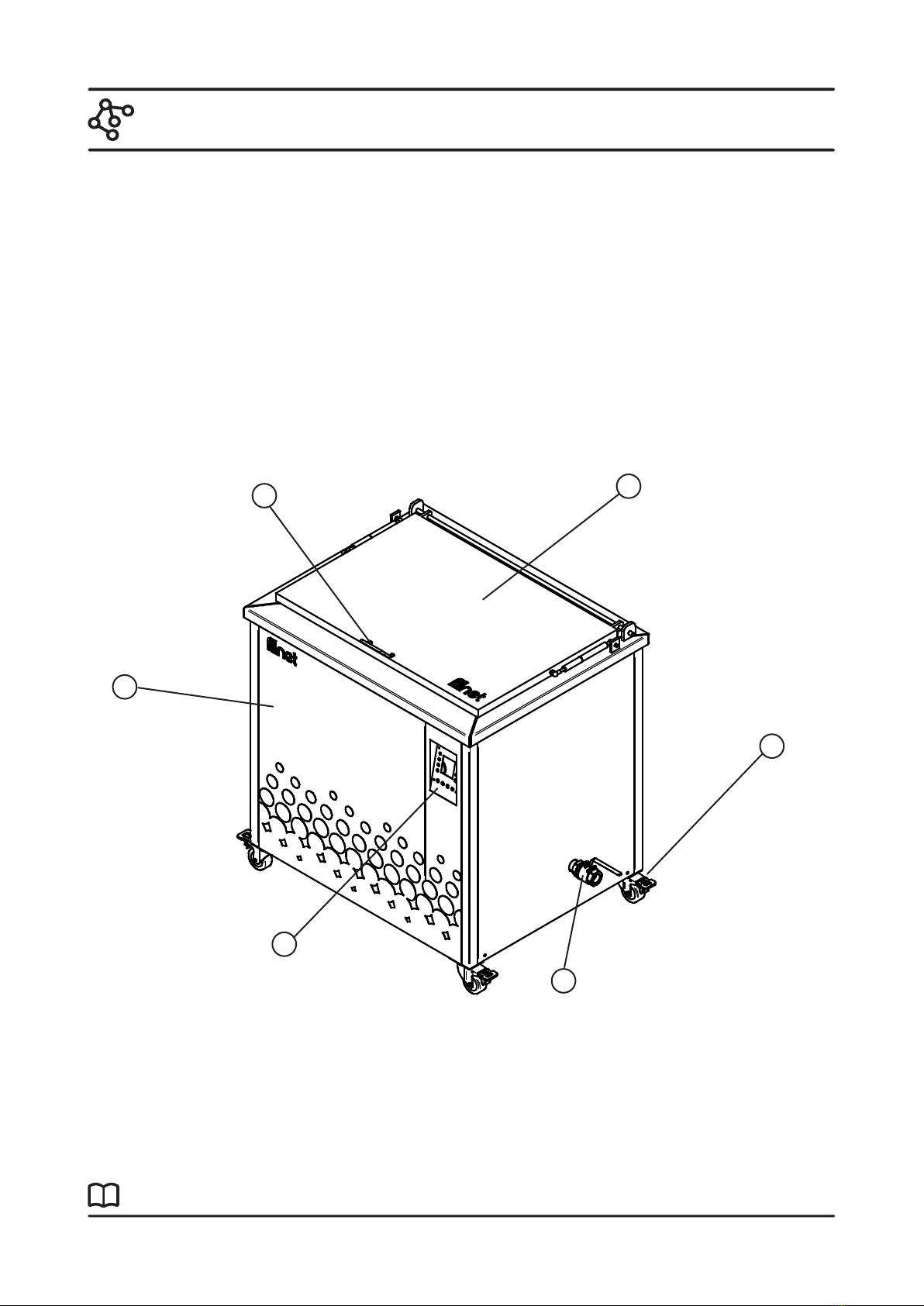

Filnet B300 ultrasonic

introduction

Dear customer:

Many thanks for having placed your trust in a quality product

from TEINNOVA.

This product has been developed with modern manufacturing

procedures and a range of measures to guarantee quality.

We endeavour to do everything possible so that you are satisfied with this

product and can work with it without any problems.

If you have any questions about this product

please contact your distributor or contact our company directly.

Before starting the machine, carefully read the

usage instructions for your equipment.

Consider this manual as part of the machine and always have it to

hand for future queries.

Nuestros servicios de formación han sido diseñados para

apoyar a nuestros clientes en la consecución de sus objetivos y juntos

desarrollamos programas de formación que encajen con su

estrategia.

Ofrecemos la opción de dotar a las empresas de una formación

específica para el uso de nuestros equipos y de capacitar a sus

operarios para que realicen el mejor servicio y contribuir así al

éxito de sus clientes finales. Aspectos como saber elaborar un buen

presupuesto de forma objetiva, dar respuesta a problemas concretos que

puedan surgir, u ofrecer un servicio más profesional y eficiente.

Thanks to manufacturing the cleaning equipment ourselves we can control

the quality and the performance of each machine we manufacture at all

times.

This has allowed us to have very low repair rates which have

always been resolved by our own Technical Assistance Service in very

short time frames. The service is managed by the same human

team as the factory.

We have every type of replacement available for your equipment as well

as related accessories.

This instruction manual is protected by copyright. We reserve all rights, especially

the right to produce, translate and create using electronic systems.

Training services

Technical service

941445056