2ENDURA AZ20, AZ25, AZ30 | PUMPED REFERENCE AIR UNIT | INF09/027-EN REV. F

1 Health & Safety

the following points must be noted:

• The relevant sections of these instructions must be read

carefully before proceeding.

•

observed.

• Installation, operation, maintenance and servicing must

only be carried out by suitably trained personnel and in

accordance with the information given.

•

possibility of an accident occurring when operating in

conditions of high pressure and / or temperature.

Safety advice concerning the use of the equipment described in

this manual or any relevant Material Safety Data Sheets (where

applicable) may be obtained from the Company address on the

Document symbols

Symbols that appear in this document are explained below:

DANGER

The signal word ‘DANGER’ indicates an imminent danger.

Failure to observe this information will result in death or

severe injury.

WARNING

The signal word ‘WARNING’ indicates an imminent danger.

Failure to observe this information may result in death or

severe injury.

CAUTION

The signal word ‘CAUTION’ indicates an imminent danger.

Failure to observe this information may result in minor or

moderate injury.

NOTICE

The signal word ‘NOTICE’ indicates potential material

damage.

Note

‘Note’ indicates useful or important information about the

product.

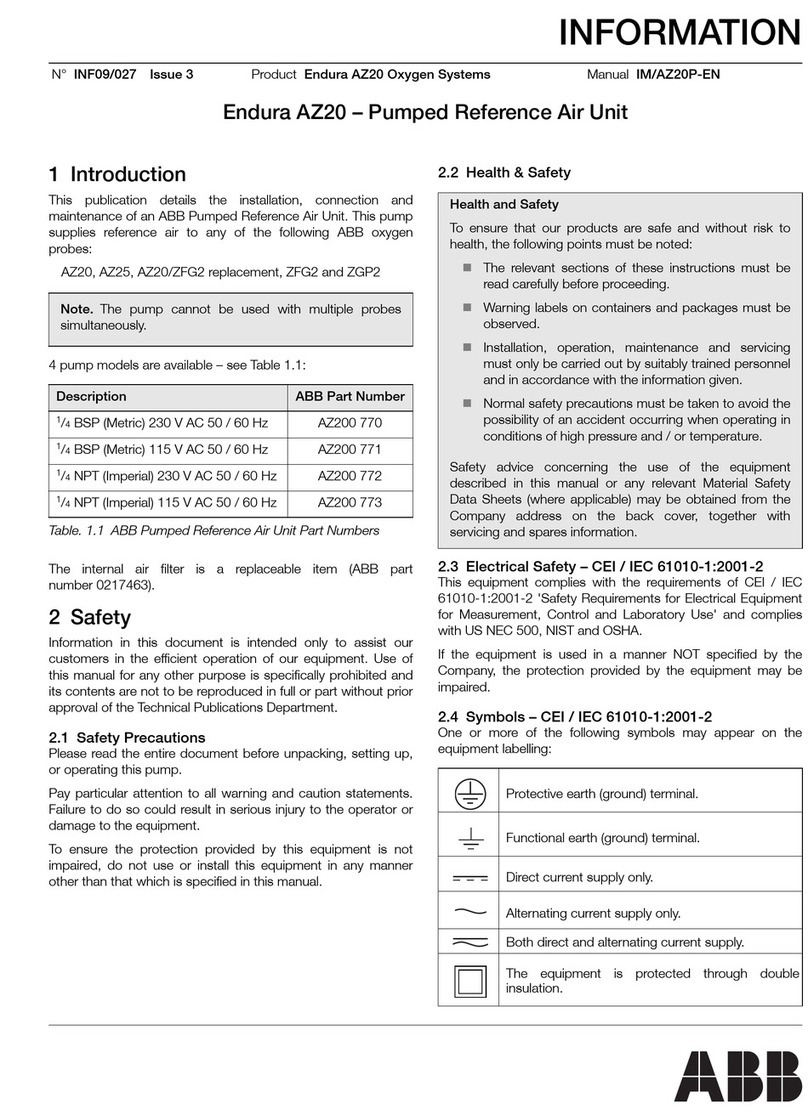

Product symbols

Symbols that may appear on this product are shown below:

Protective earth (ground) terminal.

Functional earth (ground) terminal.

This symbol, when noted on a product, indicates a

injury and/or death. The user should reference this

instruction manual for operation and/or safety

information.

This symbol, when noted on a product enclosure or

electrocution exists and indicates that only

should open the enclosure or remove the barrier.

Recycle separately from general waste under the

WEEE directive.

Safety precautions

WARNING

The installation of the pump should be performed

on electrical installations, in accordance with relevant local

regulations.

Information in this document is intended only to assist our

customers in the efficient operation of our equipment. Use of

this manual for any other purpose is specifically prohibited and

its contents are not to be reproduced in full or part without

prior approval of the Technical Publications Department.

or operating this pump.

Pay particular attention to all warning and caution statements.

Failure to do so could result in serious injury to the operator or

damage to the equipment.

To ensure the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner

other than that which is specified in this manual.